A kind of compatibilizer based on sebs and preparation method thereof

A compatibilizer and solvent technology, which is applied in the field of SEBS-based compatibilizer and its preparation, can solve the problems of high odor, poor bonding performance, inability to obtain, etc., and achieves simple preparation method, adjustable graft density, chain link Long controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

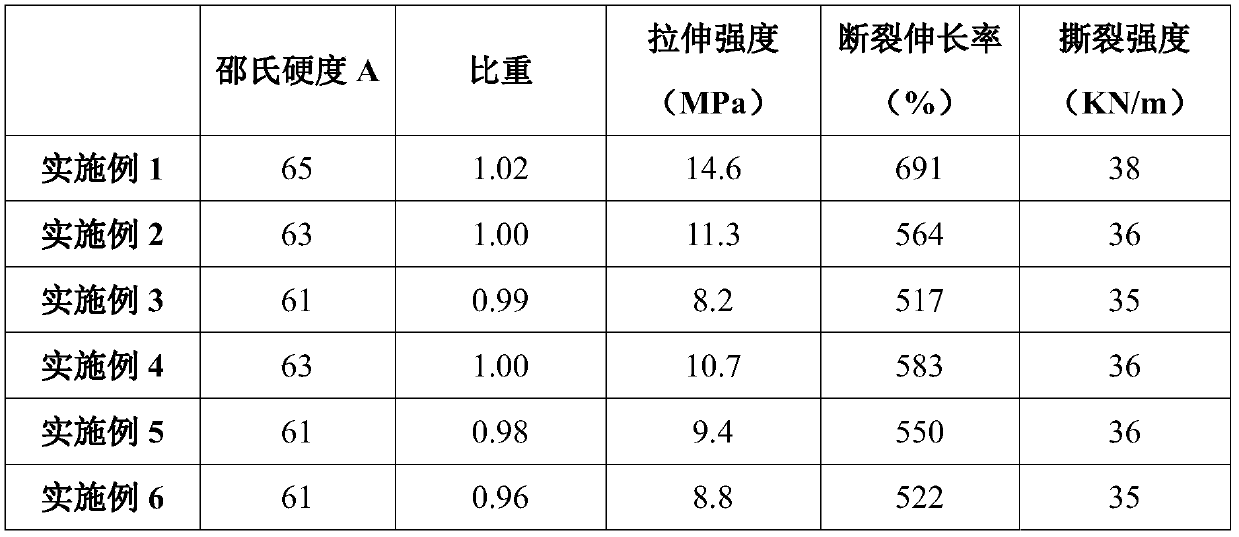

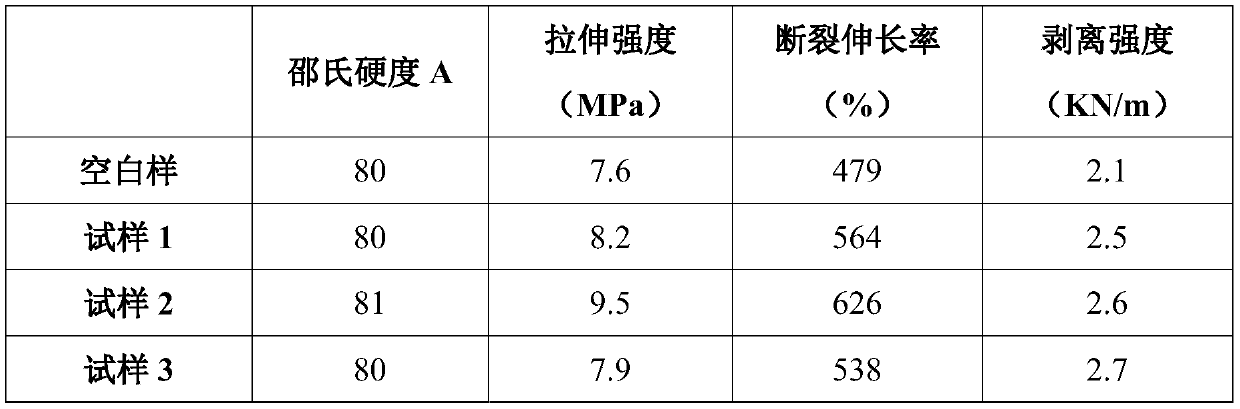

Examples

preparation example Construction

[0029] The preparation method of above-mentioned SEBS-based compatibilizer, comprises the following steps:

[0030] 1) Preparation of SEBS-g-TPU: Add SEBS, isocyanate, initiator and solvent into the reaction kettle, vacuumize and fill with protective gas, react at 80-130°C for 3-8 hours to obtain isocyanate-modified SEBS, then add terminal hydroxyl Polyurethane and catalyst react at 70-90°C for 2-6 hours to obtain SEBS-g-TPU;

[0031] 2) Preparation of SEBS-co-TPU: Add SEBS, isocyanate, initiator and solvent into the reaction kettle, vacuumize and fill with protective gas, react at 80-130°C for 3-8 hours to obtain isocyanate-modified SEBS, then add dihydroxy Compound, react at 60-100°C for 3-5 hours to obtain hydroxyl-terminated SEBS, then add polyurethane prepolymer, react at 70-90°C for 4-6 hours to obtain SEBS-co-TPU;

[0032] 3) Preparation of SEBS-g-TPU / TPU / SEBS blend: Add SEBS, isocyanate, initiator and solvent to the reaction kettle, vacuumize and fill with protective ...

Embodiment 1

[0052] A preparation method of a compatibilizer based on SEBS, comprising the following steps:

[0053] 1) Preparation of isocyanate-modified SEBS: Add 38 parts of anhydrous xylene and 2 parts of SEBS into a three-necked flask equipped with a stirrer, thermometer and dropping funnel and protected by argon, and heat to 80°C to completely dissolve SEBS , add dropwise a mixture solution of 0.1 part of TMI, 0.02 part of DCP and 2 parts of anhydrous xylene. After the dropwise addition, replace the dropping funnel with a spherical reflux condenser and react at 80°C for 5 hours to obtain isocyanate-modified SEBS;

[0054] 2) Preparation of SEBS-g-TPU: Add 3.6 parts of pre-dried linear polyether polyurethane oligomers (number average molecular weight 6000) and 0.02 parts of dibutyltin dilaurate to the isocyanate-modified SEBS of step 1) , react at 90°C for 6h, precipitate the product with methanol, and dry it to constant weight to obtain SEBS-g-TPU.

Embodiment 2

[0056] A preparation method of a compatibilizer based on SEBS, comprising the following steps:

[0057] 1) Preparation of isocyanate-modified SEBS: Add 26 parts of anhydrous toluene and 2 parts of SEBS into a three-neck flask equipped with a stirrer, a thermometer and a dropping funnel and protected by argon, and heat to 120 ° C to completely dissolve SEBS. Add dropwise a mixture solution of 0.2 parts of TAI, 0.03 parts of DBPH and 2 parts of anhydrous toluene. After the addition is completed, replace the dropping funnel with a spherical reflux condenser and react at 80°C for 8 hours to obtain isocyanate-modified SEBS;

[0058] 2) Preparation of SEBS-g-TPU: Add 2.4 parts of pre-dried hyperbranched polyurethane oligomers (number average molecular weight 2500) and 0.02 parts of stannous octoate to the isocyanate-modified SEBS in step 1), and react at 80 ° C for 3 h , the product was precipitated with methanol and dried to constant weight to obtain SEBS-g-TPU.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com