SEBS-based compatibilizer and preparation method thereof

A technology of compatibilizer and solvent, which is applied in the field of SEBS-based compatibilizer and its preparation, can solve the problems of poor bonding performance, strong odor, and inaccessibility, and achieve adjustable graft density, simple preparation method, chain long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

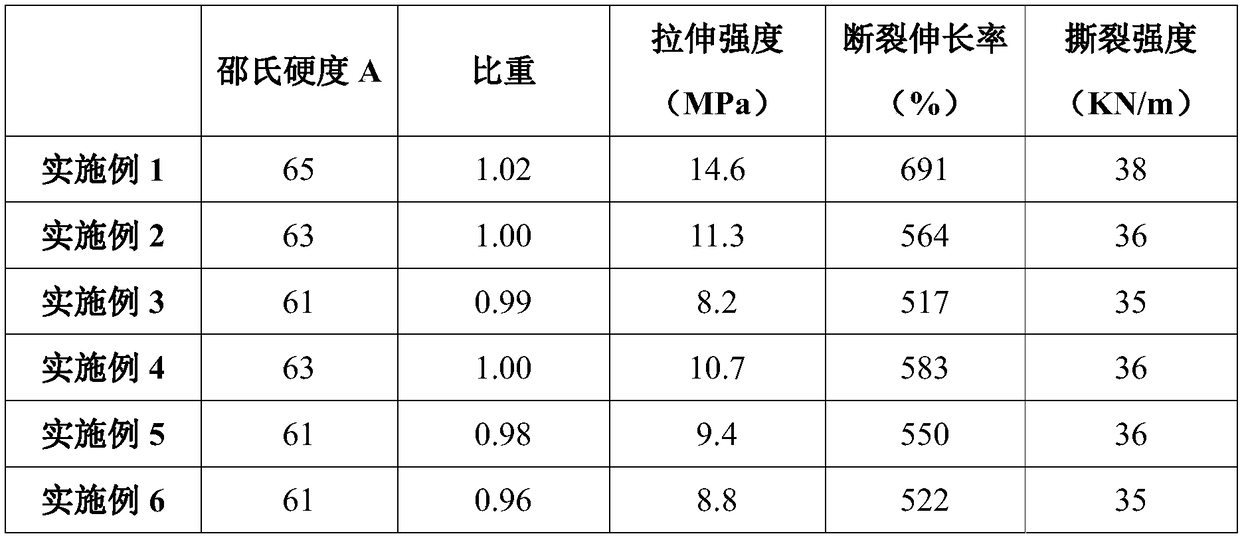

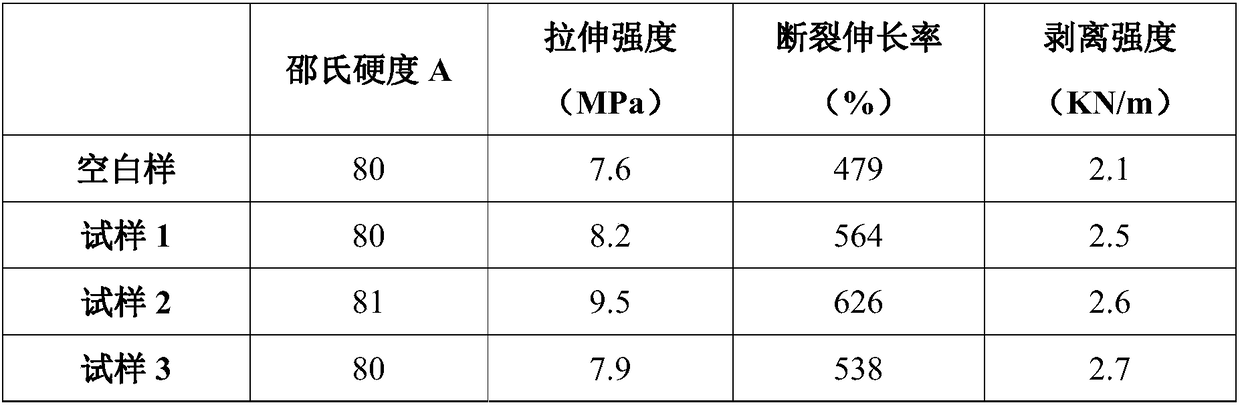

Examples

preparation example Construction

[0029] The preparation method of above-mentioned SEBS-based compatibilizer, comprises the following steps:

[0030] 1) Preparation of SEBS-g-TPU: Add SEBS, isocyanate, initiator and solvent into the reaction kettle, vacuumize and fill with protective gas, react at 80-130°C for 3-8 hours to obtain isocyanate-modified SEBS, then add terminal hydroxyl Polyurethane and catalyst react at 70-90°C for 2-6 hours to obtain SEBS-g-TPU;

[0031] 2) Preparation of SEBS-co-TPU: Add SEBS, isocyanate, initiator and solvent into the reaction kettle, vacuumize and fill with protective gas, react at 80-130°C for 3-8 hours to obtain isocyanate-modified SEBS, then add dihydroxy Compound, react at 60-100°C for 3-5 hours to obtain hydroxyl-terminated SEBS, then add polyurethane prepolymer, react at 70-90°C for 4-6 hours to obtain SEBS-co-TPU;

[0032] 3) Preparation of SEBS-g-TPU / TPU / SEBS blend: Add SEBS, isocyanate, initiator and solvent to the reaction kettle, vacuumize and fill with protective ...

Embodiment 1

[0052] A preparation method of a compatibilizer based on SEBS, comprising the following steps:

[0053] 1) Preparation of isocyanate-modified SEBS: Add 38 parts of anhydrous xylene and 2 parts of SEBS into a three-necked flask equipped with a stirrer, thermometer and dropping funnel and protected by argon, and heat to 80°C to completely dissolve SEBS , add dropwise a mixture solution of 0.1 part of TMI, 0.02 part of DCP and 2 parts of anhydrous xylene. After the dropwise addition, replace the dropping funnel with a spherical reflux condenser and react at 80°C for 5 hours to obtain isocyanate-modified SEBS;

[0054] 2) Preparation of SEBS-g-TPU: Add 3.6 parts of pre-dried linear polyether polyurethane oligomers (number average molecular weight 6000) and 0.02 parts of dibutyltin dilaurate to the isocyanate-modified SEBS of step 1) , react at 90°C for 6h, precipitate the product with methanol, and dry it to constant weight to obtain SEBS-g-TPU.

Embodiment 2

[0056] A preparation method of a compatibilizer based on SEBS, comprising the following steps:

[0057] 1) Preparation of isocyanate-modified SEBS: Add 26 parts of anhydrous toluene and 2 parts of SEBS into a three-neck flask equipped with a stirrer, a thermometer and a dropping funnel and protected by argon, and heat to 120 ° C to completely dissolve SEBS. Add dropwise a mixture solution of 0.2 parts of TAI, 0.03 parts of DBPH and 2 parts of anhydrous toluene. After the addition is completed, replace the dropping funnel with a spherical reflux condenser and react at 80°C for 8 hours to obtain isocyanate-modified SEBS;

[0058] 2) Preparation of SEBS-g-TPU: Add 2.4 parts of pre-dried hyperbranched polyurethane oligomers (number average molecular weight 2500) and 0.02 parts of stannous octoate to the isocyanate-modified SEBS in step 1), and react at 80 ° C for 3 h , the product was precipitated with methanol and dried to constant weight to obtain SEBS-g-TPU.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com