Segmented copolymer capable of being self-assembled into micelle and preparation method thereof

A self-assembly and copolymer technology, applied in the field of amphiphilic block copolymers and their preparation, can solve the problems of less applicable monomers and harsh reaction conditions, and achieve mild reaction conditions, high product purity, and good controllability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Prepare BMA:CPAD:AIBN=60:1:0.1 toluene solution system according to the molar ratio. Quenched for 2 min to stop the reaction. Diluted with a small amount of toluene, precipitated with methanol, filtered and dried to obtain a red solid, namely polybutyl methacrylate (PBMA);

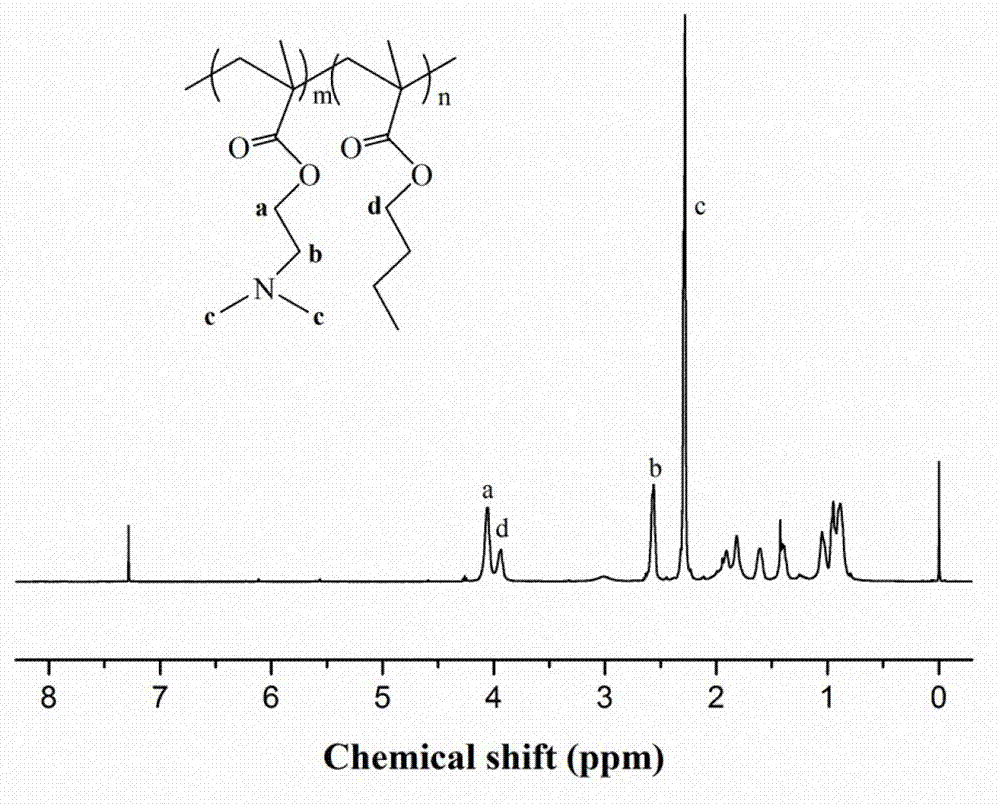

[0030] 2) According to the molar ratio DMA:PBMA:AIBN=350:1:0.1, add the metered DMA, PBMA and AIBN into the reaction solution, seal it and freeze and degas it three times, react in an oil bath at 65°C for 13h, liquid nitrogen Quenched for 2 min to stop the reaction. Diluted by adding a small amount of toluene, precipitated with methanol, filtered and dried to obtain a pink solid, namely poly(butyl methacrylate-dimethylaminoethyl methacrylate), relative 1 HNMR spectrum as figure 1 shown;

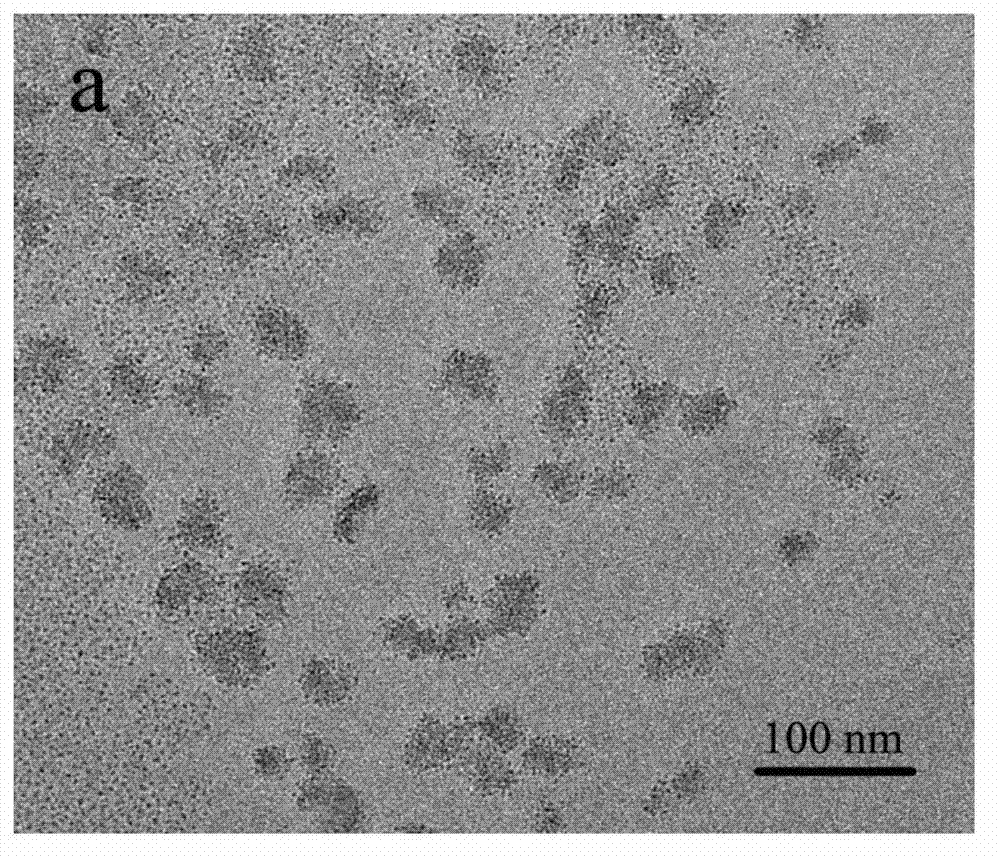

[0031] 3) Prepare the obtained poly(butyl methacrylate-dimethylaminoethyl methacrylate) solid into a 0.1 mg / mL tetrahydrofuran solution, add deionized water drop by drop, and wait for the solvent to evaporat...

Embodiment 2

[0033] Similar to Example 1, the difference lies in the BMA: CPAD: AIBN=120: 1: 0.1 toluene solution system in step 1), and the rest are the same as in Example 1 to obtain poly(butyl methacrylate-dimethylaminoethyl methacrylate) ) block copolymer, the prepared amphiphilic block copolymer forms a micellar solution in deionized water (such as Figure 2b shown).

Embodiment 3

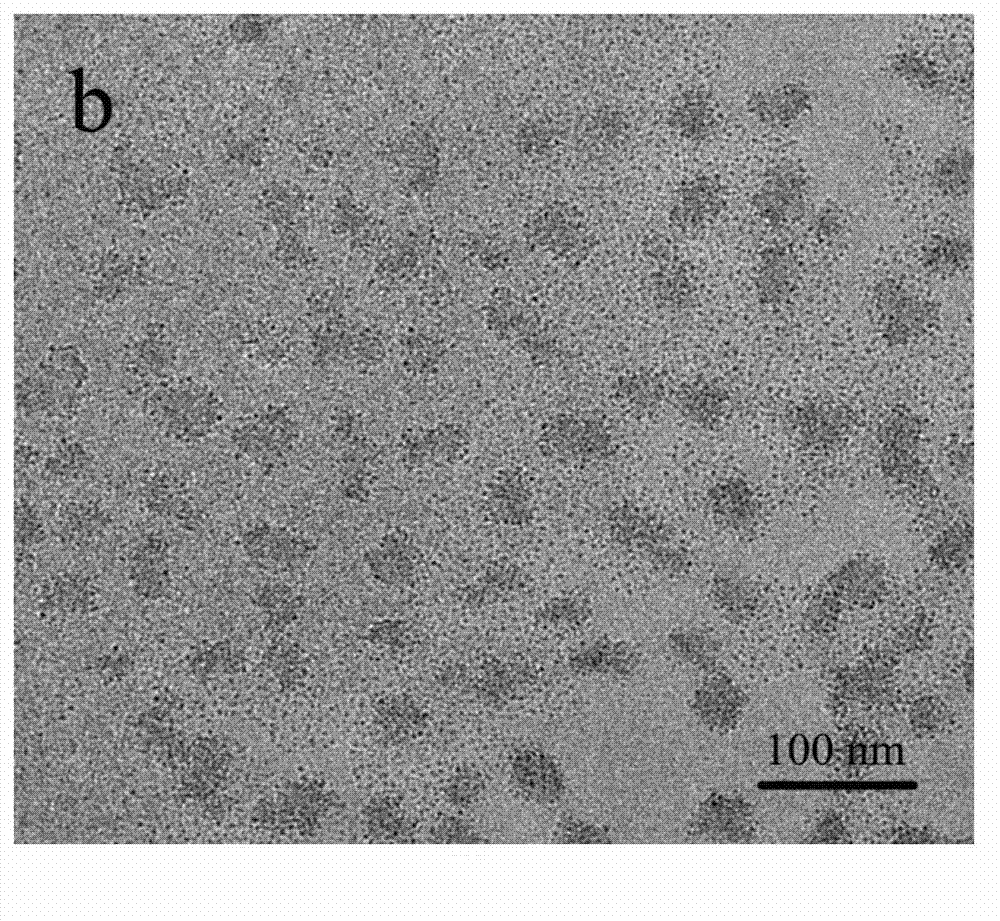

[0035] Similar to Example 1, the difference is that the reaction time described in step 2) is 6h, and the rest are the same as Example 1 to obtain a poly(butyl methacrylate-dimethylaminoethyl methacrylate) block copolymer, and the prepared The resulting amphiphilic block copolymers formed micellar solutions in deionized water (e.g. Figure 2c shown).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com