Borax-intumescent flame retardant synergistically modified polymethylsiloxane/polybutylmethacrylate polylactic acid material and its preparation

A technology of polybutyl methacrylate polylactic acid and polybutyl methacrylate, which is applied in the field of flame retardancy, can solve the problems of secondary combustion, low elongation at break, low oxygen index, etc. Oxygen stability and barrier properties, good tensile strength and processability, effect of increasing surface density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

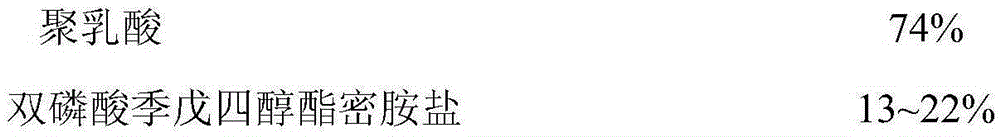

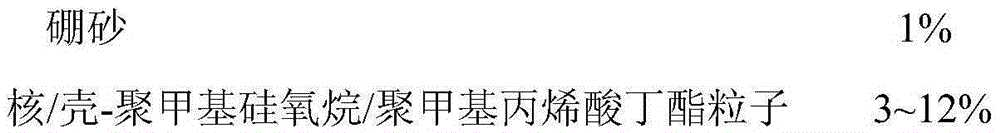

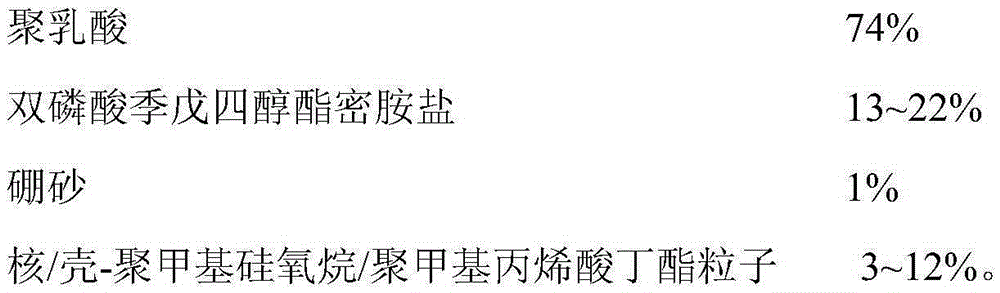

[0029] Take core / shell-polymethylsiloxane / polybutylmethacrylate 6g, borax 0.5g, pentaerythritol diphosphate melamine salt 6.5g, dry at 60°C for 8h and pass through 80-mesh sieve, polylactic acid 37g Dry at 60°C for 8 hours, physically blend the four materials, and put them into the torque rheometer. Mix for 5-8 minutes. Get the target material.

Embodiment 2

[0031] Take the core / shell-polymethylsiloxane / polybutylmethacrylate 4.5g, borax 0.5g, pentaerythritol diphosphate melamine salt 8g, dry at 60°C for 8h and pass through a 80-mesh sieve, polylactic acid 37g Dry at 60°C for 8 hours, physically blend the four materials, and put them into the torque rheometer. Mix for 5-8 minutes. Get the target material.

Embodiment 3

[0033] Take core / shell-polymethylsiloxane / polybutylmethacrylate 3g, borax 0.5g, pentaerythritol diphosphate melamine salt 9.5g, dry at 60°C for 8h and pass through 80 mesh sieve, polylactic acid 37g Dry at 60°C for 8 hours, physically blend the four materials, and put them into the torque rheometer. Mix for 5-8 minutes. Get the target material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com