High-performance vacuum anti-reflection film and preparation method thereof

An anti-reflection coating and high-performance technology, applied in the field of optical materials, can solve the problems of poor transmission performance and poor weather resistance of the anti-reflection coating, and achieve the effect of improving anti-pollution ability, weather resistance and high anti-pollution ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of the high-performance vacuum anti-reflection film of the present embodiment comprises the following steps:

[0028] (1) Mix tetraethyl orthosilicate, perfluorotriglyme, catalyst and organic solvent uniformly in a mass ratio of 2:5:0.5:20 and age at 20°C for 16 days to obtain Modified SiO 2 a first sol of porous particles;

[0029] (2) Dissolve the poly-n-butyl methacrylate block polymer in a mixed solution of acetone and sec-butanol by ultrasonic solubilization to prepare a filling solution with a concentration of 0.078g / mL; wherein, acetone and sec-butanol The mass ratio is 1:1; ultrasonic conditions include: ultrasonic frequency 15kHz, ultrasonic power 500W, ultrasonic time 5min;

[0030] (3) According to the fact that poly-n-butyl methacrylate accounts for 3% of the mass of tetraethyl orthosilicate, the filling solution is added to the first sol and stirred for 4 hours to obtain the second sol;

[0031] (4) The second sol was coated on the...

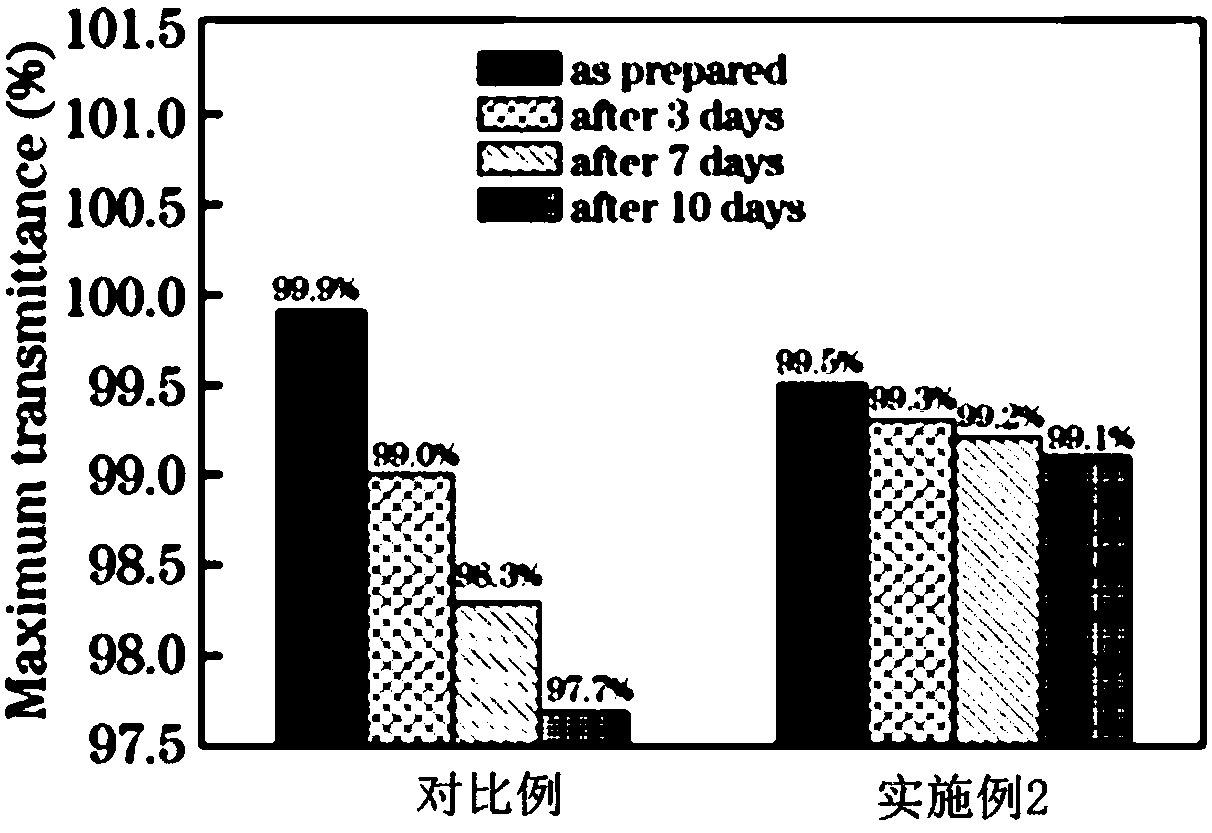

Embodiment 2

[0035] The preparation method of the high-performance vacuum anti-reflection film of the present embodiment comprises the following steps:

[0036] (1) Mix tetraethyl orthosilicate, perfluorotriglyme, catalyst and organic solvent in a mass ratio of 3.5:6:1:30 and age at 25°C for 14 days to obtain Modified SiO 2 a first sol of porous particles;

[0037] (2) Dissolve the poly-n-butyl methacrylate block polymer in a mixed solution of acetone and sec-butanol by ultrasonic solubilization to prepare a filling solution with a concentration of 0.192g / mL; wherein, acetone and sec-butanol The mass ratio is 1:1.5; ultrasonic conditions include: ultrasonic frequency 20kHz, ultrasonic power 470W, ultrasonic time 8min;

[0038] (3) According to the fact that poly-n-butyl methacrylate accounts for 4% of the mass of tetraethyl orthosilicate, the filling solution is added to the first sol and stirred for 6 hours to obtain the second sol;

[0039] (4) Coating the second sol on the cleaned su...

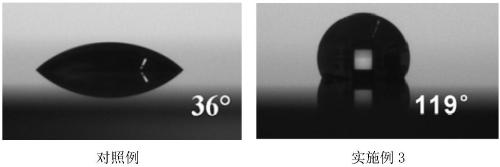

Embodiment 3

[0043] The preparation method of the high-performance vacuum anti-reflection film of the present embodiment comprises the following steps:

[0044] (1) Mix tetraethyl orthosilicate, perfluorotriglyme, catalyst and organic solvent in a mass ratio of 5:7:1.5:40 and age at 30°C for 12 days to obtain Modified SiO 2 a first sol of porous particles;

[0045] (2) Dissolve the poly-n-butyl methacrylate block polymer in a mixed solution of acetone and sec-butanol by ultrasonic solubilization to prepare a filling solution with a concentration of 0.375g / mL; wherein, acetone and sec-butanol The mass ratio is 1:2; ultrasonic conditions include: ultrasonic frequency 25kHz, ultrasonic power 450W, ultrasonic time 10min;

[0046](3) According to the fact that poly-n-butyl methacrylate accounts for 5% of the mass of tetraethyl orthosilicate, the filling solution is added to the first sol and stirred for 8 hours to obtain the second sol;

[0047] (4) The second sol was coated on the cleaned s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| optical properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com