Pipe thread sealant for tunnel construction

A tunnel construction and sealant technology, applied in the direction of adhesives, epoxy resin glue, polyether adhesive, etc., can solve the problems of insufficient lubricity and sealing performance, residue cleaning and treatment pollution, etc., and achieve good durability Good heat and cold resistance, wettability and lubricity, and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

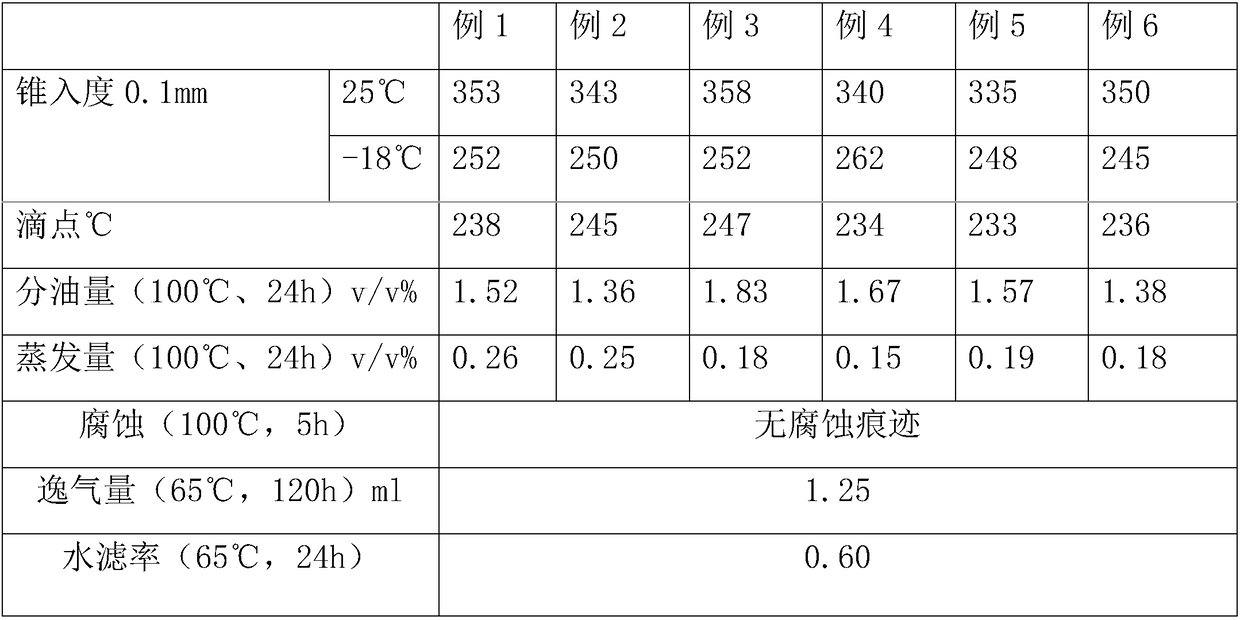

Examples

Embodiment 1

[0016] The pipe thread sealant for tunnel construction in this embodiment, the sealant raw material includes the following components by weight: 30 parts of epoxy resin, 15 parts of polytetrahydrofuran ether polyol, 5 parts of 2,4-toluene diisocyanate, 3 parts , 5 parts of 3'-dichloro-4,4' diaminodiphenylmethane, 1 part of azobisisobutyronitrile, 1 part of poly-n-butyl methacrylate, 5 parts of styrene elastomer, poly-2,6 - 2 parts of dimethyl-1,4-phenylene ether, 5 parts of polyvinyl acetate, 5 parts of ceramic particles, 1 part of silicon dioxide, 1 part of antioxidant, 1 part of tackifier; the tunnel construction pipe Thread sealants are prepared by:

[0017] a. Mix epoxy resin and polytetrahydrofuran ether polyol and heat to 95°C, continue to heat to 110°C and dehydrate under high vacuum for 2 hours, then cool down to 45°C, then add 2,4-toluene diisocyanate, Styrene elastomer, poly-2,6-dimethyl-1,4-phenylene ether and polyvinyl acetate were heated to 75°C for 2 hours;

[...

Embodiment 2

[0020] The pipe thread sealant for tunnel construction in this embodiment, the sealant raw material includes the following components by weight: 40 parts of epoxy resin, 25 parts of polytetrahydrofuran ether polyol, 15 parts of 2,4-toluene diisocyanate, 3 , 10 parts of 3'-dichloro-4,4' diaminodiphenylmethane, 5 parts of azobisisobutyronitrile, 5 parts of poly-n-butyl methacrylate, 10 parts of styrene elastomer, poly-2,6 - 6 parts of dimethyl-1,4-phenylene ether, 10 parts of polyvinyl acetate, 15 parts of ceramic particles, 5 parts of silicon dioxide, 5 parts of antioxidant, 3 parts of tackifier; the tunnel construction pipe Thread sealants are prepared by:

[0021] a. Mix epoxy resin and polytetrahydrofuran ether polyol and heat to 105°C, continue to heat to 110-120°C, dehydrate under high vacuum for 2 hours, then cool down to 55°C, and then add 2,4-toluene Continue to heat isocyanate, styrene elastomer, poly-2,6-dimethyl-1,4-phenylene ether and polyvinyl acetate to 85°C for ...

Embodiment 3

[0024] The pipe thread sealant for tunnel construction in this embodiment, the sealant raw material includes the following components by weight: 30 parts of epoxy resin, 25 parts of polytetrahydrofuran ether polyol, 5 parts of 2,4-toluene diisocyanate, 3 parts , 10 parts of 3'-dichloro-4,4' diaminodiphenylmethane, 1 part of azobisisobutyronitrile, 5 parts of poly-n-butyl methacrylate, 5 parts of styrene elastomer, poly-2,6 - 6 parts of dimethyl-1,4-phenylene ether, 5 parts of polyvinyl acetate, 15 parts of ceramic particles, 1 part of silicon dioxide, 5 parts of antioxidant, 1 part of tackifier; the tunnel construction pipe Thread sealants are prepared by:

[0025] a. Mix epoxy resin and polytetrahydrofuran ether polyol and heat to 95°C, continue to heat to 120°C and dehydrate under high vacuum for 2 hours, then cool down to 45°C, then add 2,4-toluene diisocyanate, Styrene elastomer, poly-2,6-dimethyl-1,4-phenylene ether and polyvinyl acetate were heated to 85°C for 2 hours; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com