Antistatic protective film with stable viscosity

An antistatic and protective film technology, applied in the direction of adhesives, adhesive types, ester copolymer adhesives, etc., can solve the problems that PET films do not have antistatic and electromagnetic shielding properties, are difficult to use, and have unstable viscosity. , to achieve obvious antistatic effect, prevent transfer or dissolution, and reduce self-shrinkage stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] An antistatic protective film with stable viscosity, comprising a PET substrate layer, an antistatic layer arranged on the upper surface and a lower surface of the PET substrate layer, and an adhesive layer arranged on the outer surface of the antistatic layer;

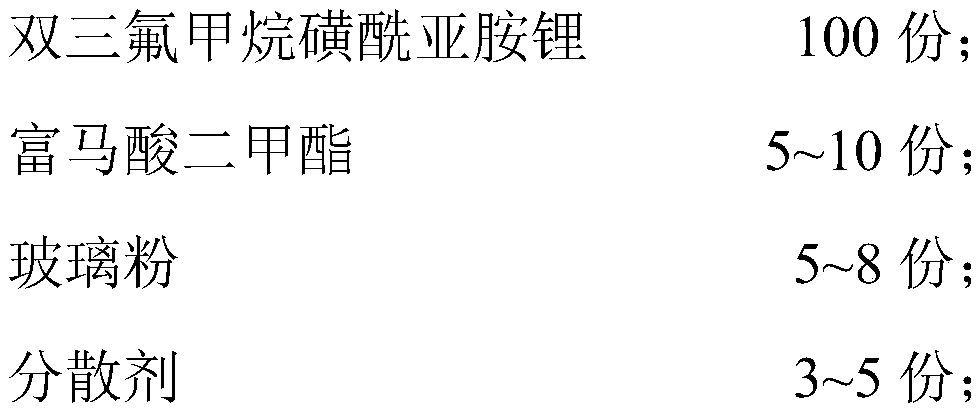

[0029] Wherein, the antistatic layer comprises the composition of the following parts by weight:

[0030]

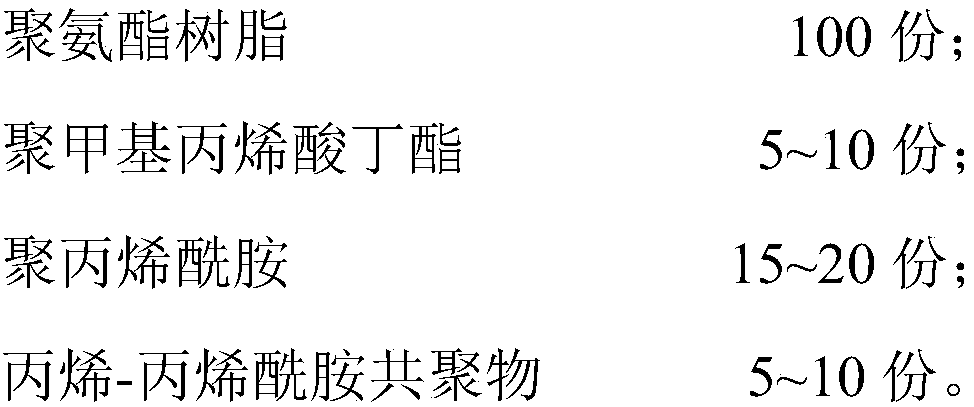

[0031] Wherein, the adhesive layer comprises the composition of the following parts by weight:

[0032]

[0033] Wherein, the number average molecular weight of the polyacrylamide is 12000-13000 g / mol. The number average molecular weight of the propylene-acrylamide copolymer is 9000-10000 g / mol. The number average molecular weight of the polyurethane resin is 16000-17000 g / mol. The number average molecular weight of polybutyl methacrylate is 17000-18000 g / mol.

Embodiment 2

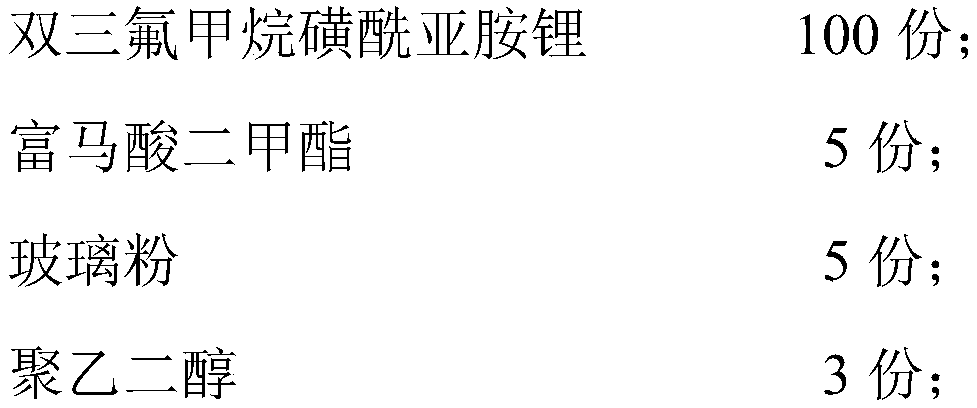

[0035] Different from Example 1, the antistatic layer comprises the following compositions by weight:

[0036]

[0037] Wherein, the adhesive layer comprises the composition of the following parts by weight:

[0038]

[0039] Others are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0041] Different from Example 1, the antistatic layer comprises the following compositions by weight:

[0042]

[0043] Wherein, the adhesive layer comprises the composition of the following parts by weight:

[0044]

[0045] Others are the same as in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com