Synergistic modified methyl polysiloxane/poly-n-butyl methacrylate polylactic acid material of borax-intumescent flame retardant and preparation of synergistic modified methyl polysiloxane/poly-n-butyl methacrylate polylactic acid material

A technology of polybutyl methacrylate polylactic acid and polybutyl methacrylate is applied in the field of flame retardant, which can solve the problems of easy-to-melt drop secondary combustion, low elongation at break, low oxygen index, etc. Oxygen stability and barrier properties, good tensile strength and processability, effect of increasing surface density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

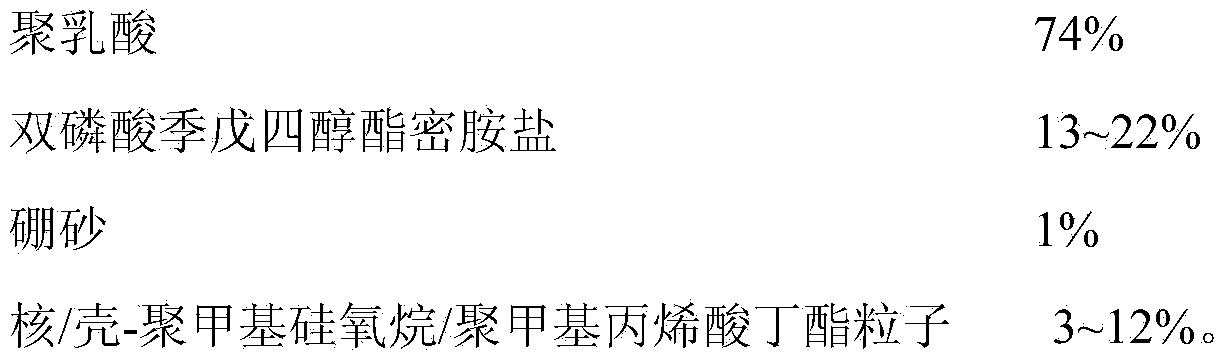

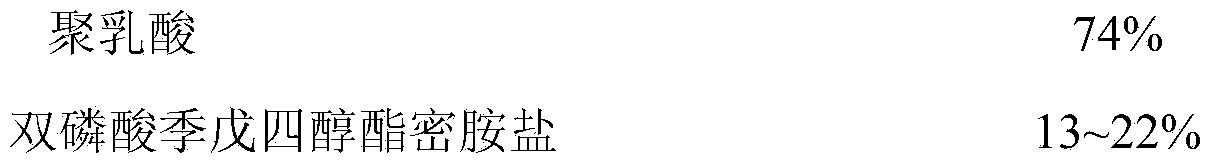

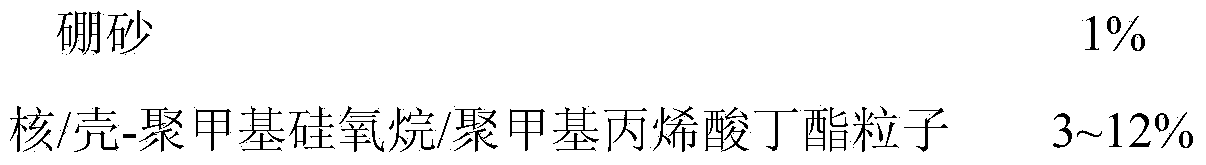

Embodiment 1

[0029] Take core / shell-polymethylsiloxane / polybutylmethacrylate 6g, borax 0.5g, pentaerythritol diphosphate melamine salt 6.5g, dry at 60°C for 8h and pass through 80-mesh sieve, polylactic acid 37g Dry at 60°C for 8 hours, physically blend the four materials, and put them into the torque rheometer. Mix for 5-8 minutes. Get the target material.

Embodiment 2

[0031] Take core / shell-polymethylsiloxane / polybutylmethacrylate 4.5g, borax 0.5g, pentaerythritol diphosphate melamine salt 8g, dry at 60°C for 8h and pass through 80 mesh sieve, polylactic acid 37g Dry at 60°C for 8 hours, physically blend the four materials, and put them into the torque rheometer. Mix for 5-8 minutes. Get the target material.

Embodiment 3

[0033] Take core / shell-polymethylsiloxane / polybutylmethacrylate 3g, borax 0.5g, pentaerythritol diphosphate melamine salt 9.5g, dry at 60°C for 8h and pass through 80-mesh sieve, polylactic acid 37g Dry at 60°C for 8 hours, physically blend the four materials, and put them into the torque rheometer. Mix for 5-8 minutes. Get the target material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com