Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

212results about How to "Smooth preparation process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing high filling polyvinyl chloride or polyolefin composite material by employing industrial solid wastes

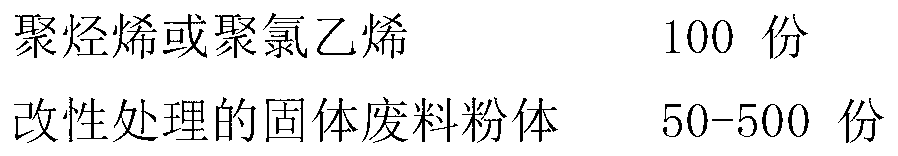

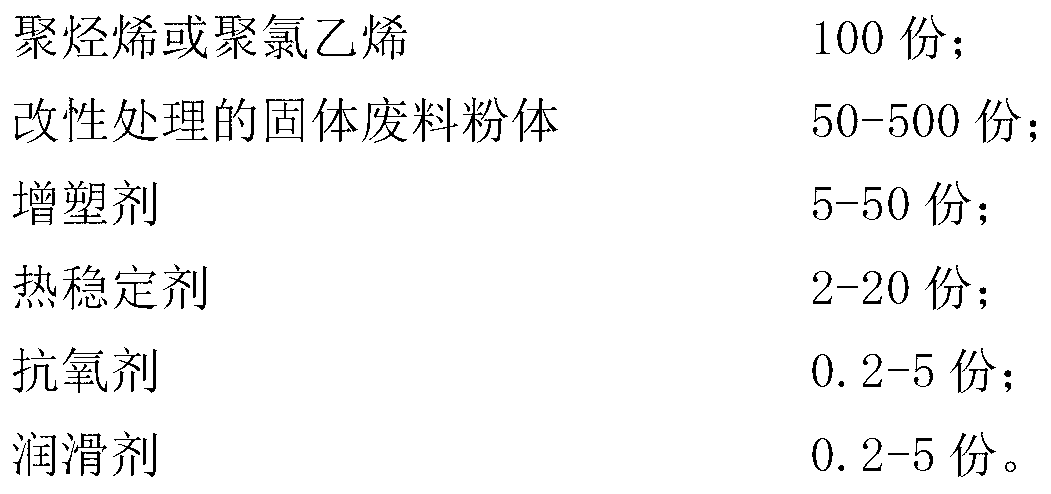

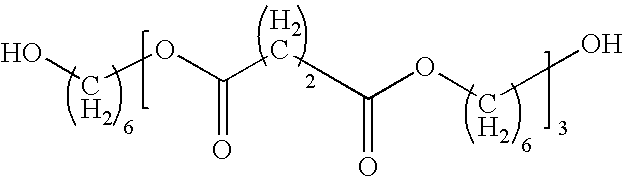

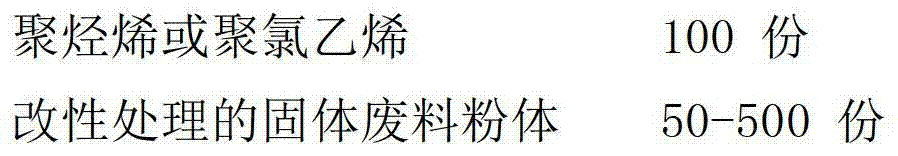

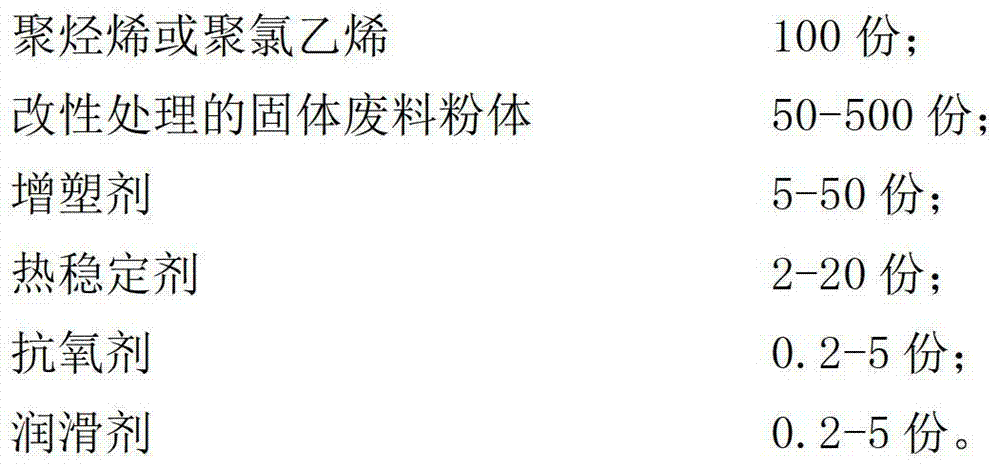

The invention discloses a method for preparing a high filling polyvinyl chloride or polyolefin composite material by employing industrial solid wastes and belongs to the field of chemical materials. According to the method, the industrial solid wastes and polyvinyl chloride or polyolefin serve as main raw materials, the industrial solid wastes are subjected to surface modification, the compatibility between the industrial solid wastes and the polyvinyl chloride or polyolefin is improved, the liquidity and processability of the composite material is improved by utilizing a compound plastifier, and the composite material is subjected to mixing and pelleting under the coaction of a proper amount of aids, so that the high filling polyvinyl chloride or polyolefin composite material is prepared. The method is simple in process, low in cost and high in additional value of products. The composite material has the characteristics of high filling amount of industrial solid wastes, enough strength and toughness, environment friendliness, stable performance and the like and can be widely applied to preparing green building materials and advanced engineering products in various fields of national economy.

Owner:TSINGHUA UNIV

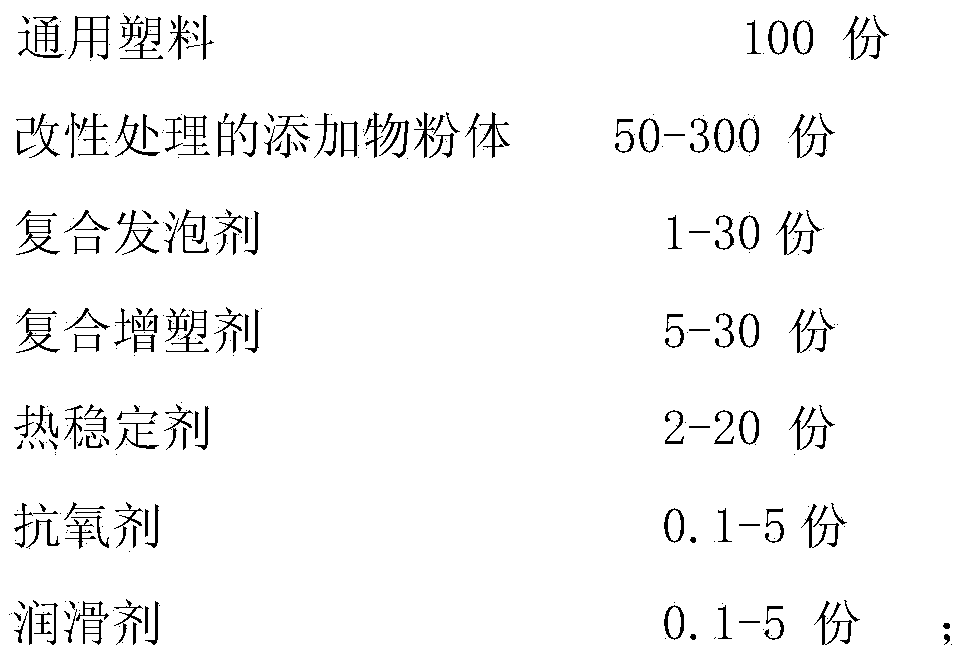

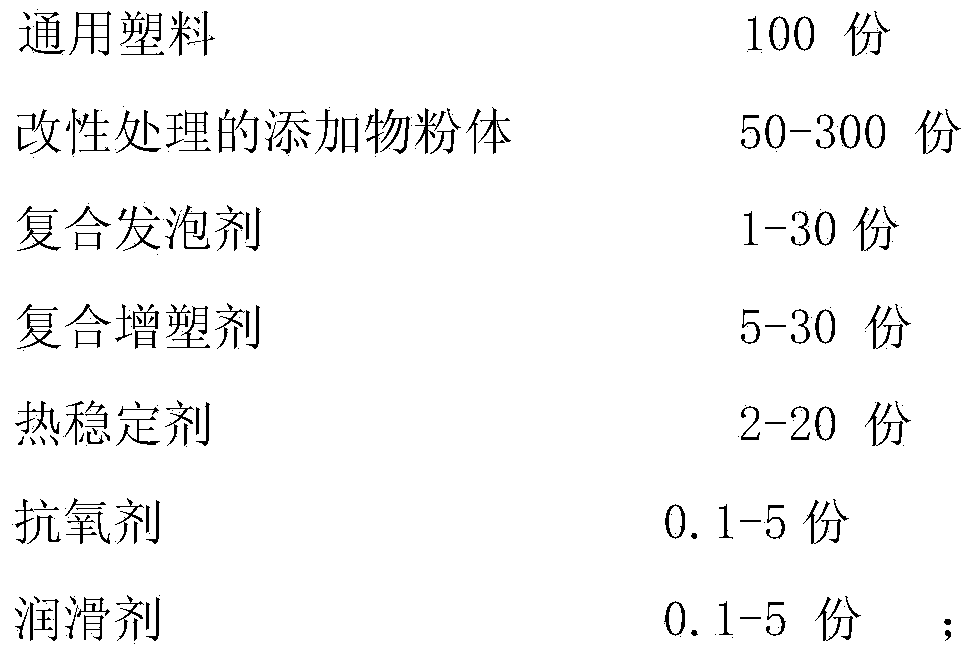

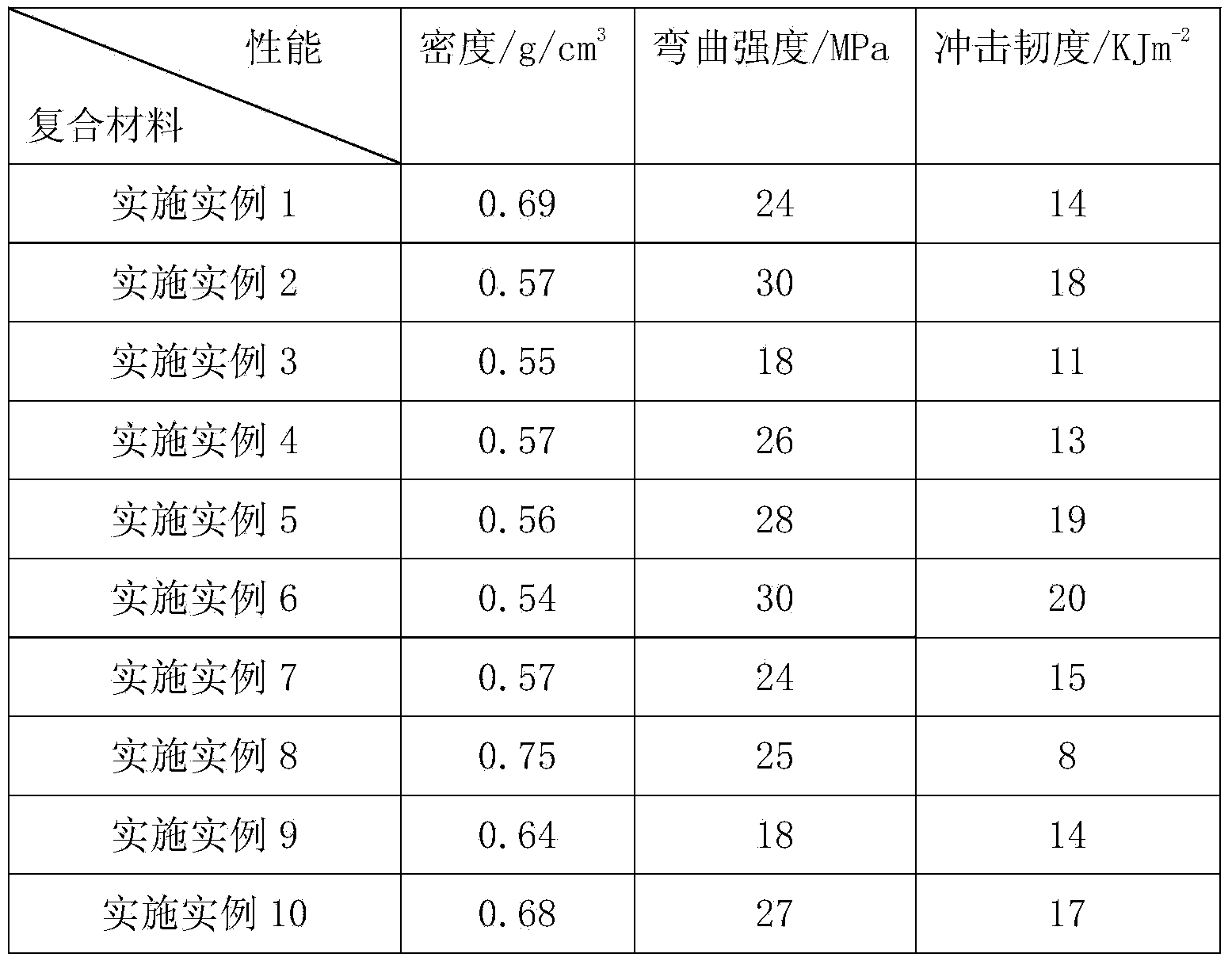

Method for preparing light general plastic composite material by adding bulk industrial solid wastes

The invention discloses a method for preparing a light general plastic composite material by adding bulk industrial solid wastes, and belongs to the field of preparation of chemical materials. The method comprise the following steps: with the bulk industrial solid wastes and general plastic as main raw materials, performing surface modification on the bulk industrial solid wastes to improve compatibility with the general plastic, improving the mobility and processing performance of the composite material by using a compound plasticizer, and under the combined action of an appropriate amount of a foaming agent and auxiliary agent, mixing, granulating and forming to prepare the light general plastic composite material added with the bulk industrial solid wastes. The method is simple and convenient in process and low in cost; the light general plastic composite material is light in weight, high in strength and high in added value; the light general plastic composite material prepared by the method has the characteristics of high filling amount of the industrial solid wastes, low density, good mechanical properties, strong impact resistance and the like, has excellent buffering and damping, sound-insulating and heat-insulating, insulating, corrosion-resistant and mold-resistant performances and the like; light environmentally friendly building materials and engineering products made of the light general plastic composite material can be widely applied to construction, chemical industry, metallurgy, transportation and other fields.

Owner:TSINGHUA UNIV

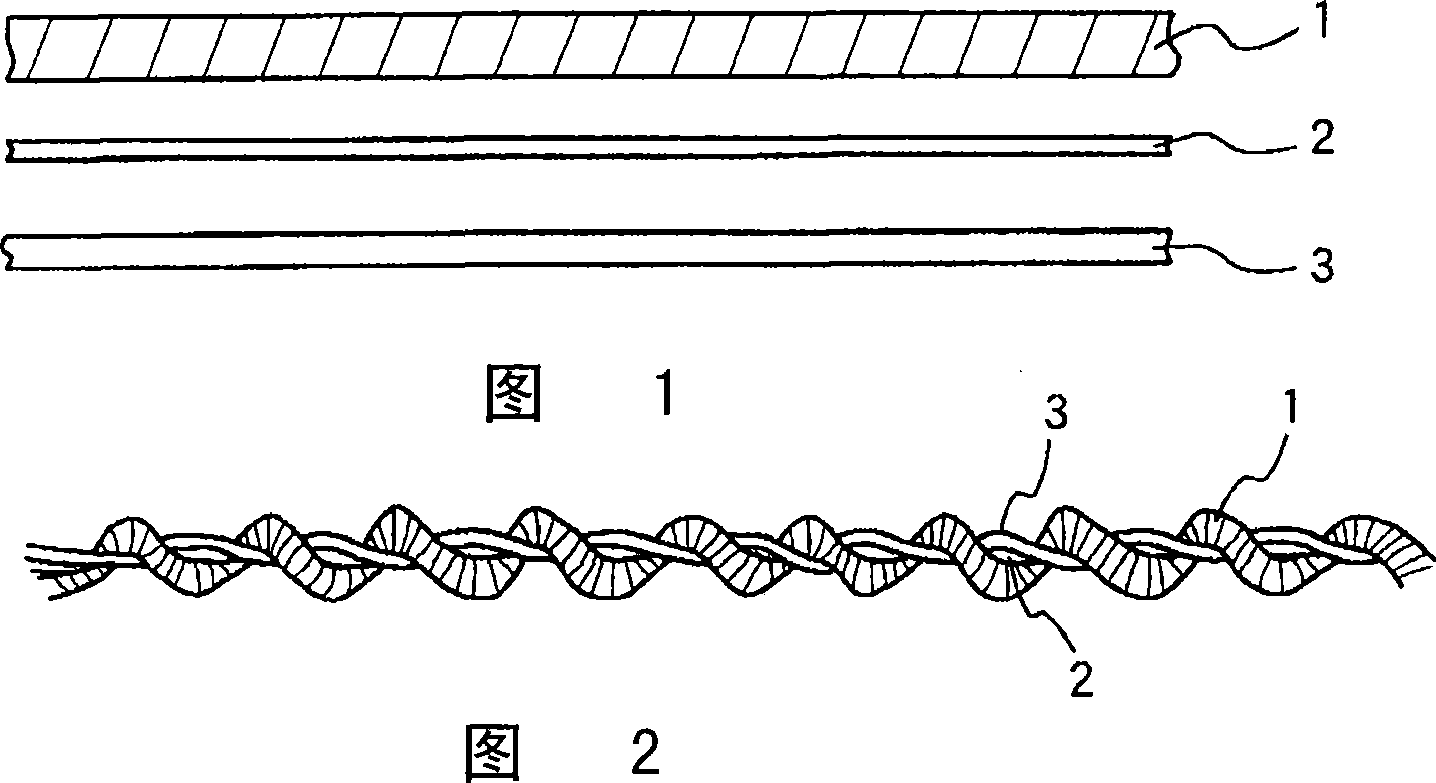

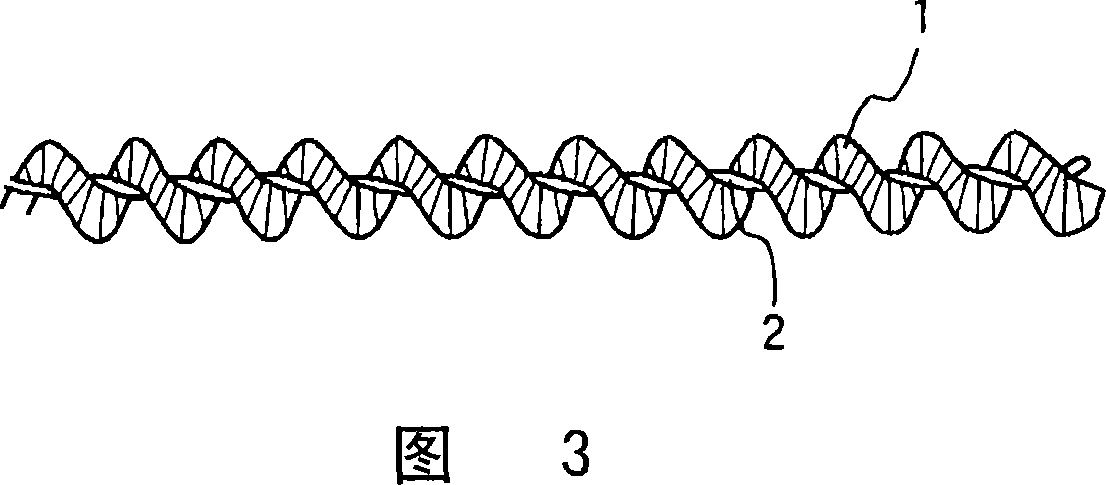

Composite twist yarn

The present invention relates to the production of woven or knitted fabrics or fabrics, which have high yarn strength, can be woven or knitted with high-speed looms or knitting machines, will not cause problems such as thread breakage, and have high stretchability sex. The present invention also prepares a composite twisted yarn, which at least twists a spun yarn and a water-soluble yarn, the twist direction of the composite twisted yarn is opposite to that of the spun yarn, and satisfies the following necessary conditions (1 ) or (2): (1) The twist number of the composite twisted yarn is 1.3-3 times that of the spun yarn, and the ratio (weight ratio) of the spun yarn to the water-soluble yarn is spun yarn / Water-soluble yarn = 20 / 80-98 / 2; (2) further twist the elastic yarn (2) stretched to 2-5 times, and the twist number of the composite twisted yarn relative to the twist number of the spun yarn is 0.3-3 times, while the ratio (weight ratio) of spun yarn (1) to the above-mentioned elastic yarn (2) is spun yarn (1) / elastic yarn (2)=50 / 50-99.9 / 0.1, spun yarn (1) and the total amount of elastic yarn (2) and the ratio (weight ratio) of water-soluble yarn (3) is: total amount of spun yarn (1) and elastic yarn (2) / water-soluble yarn (3)= 30 / 70-99 / 1.

Owner:KURARAY TRADING CO LTD +1

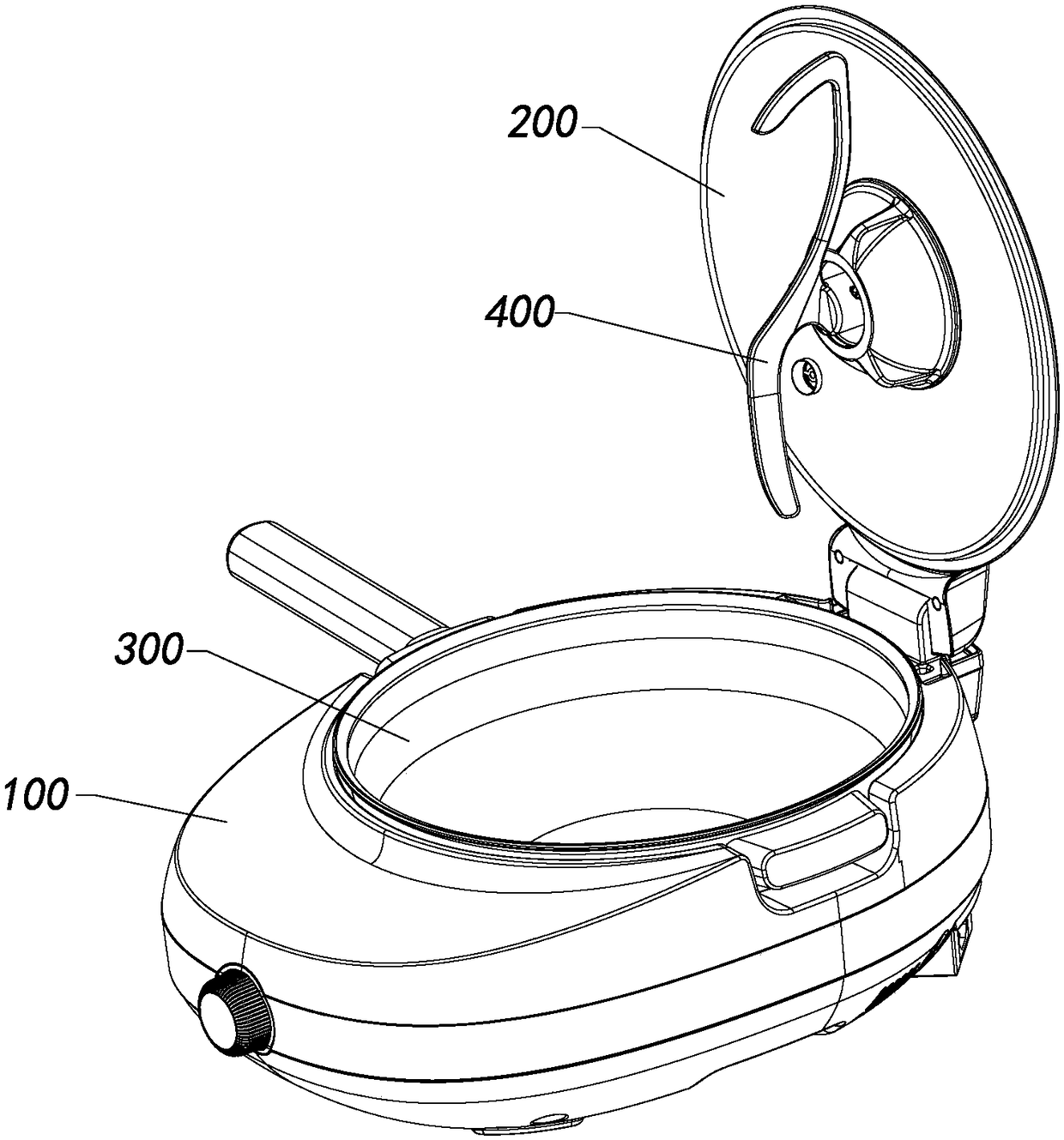

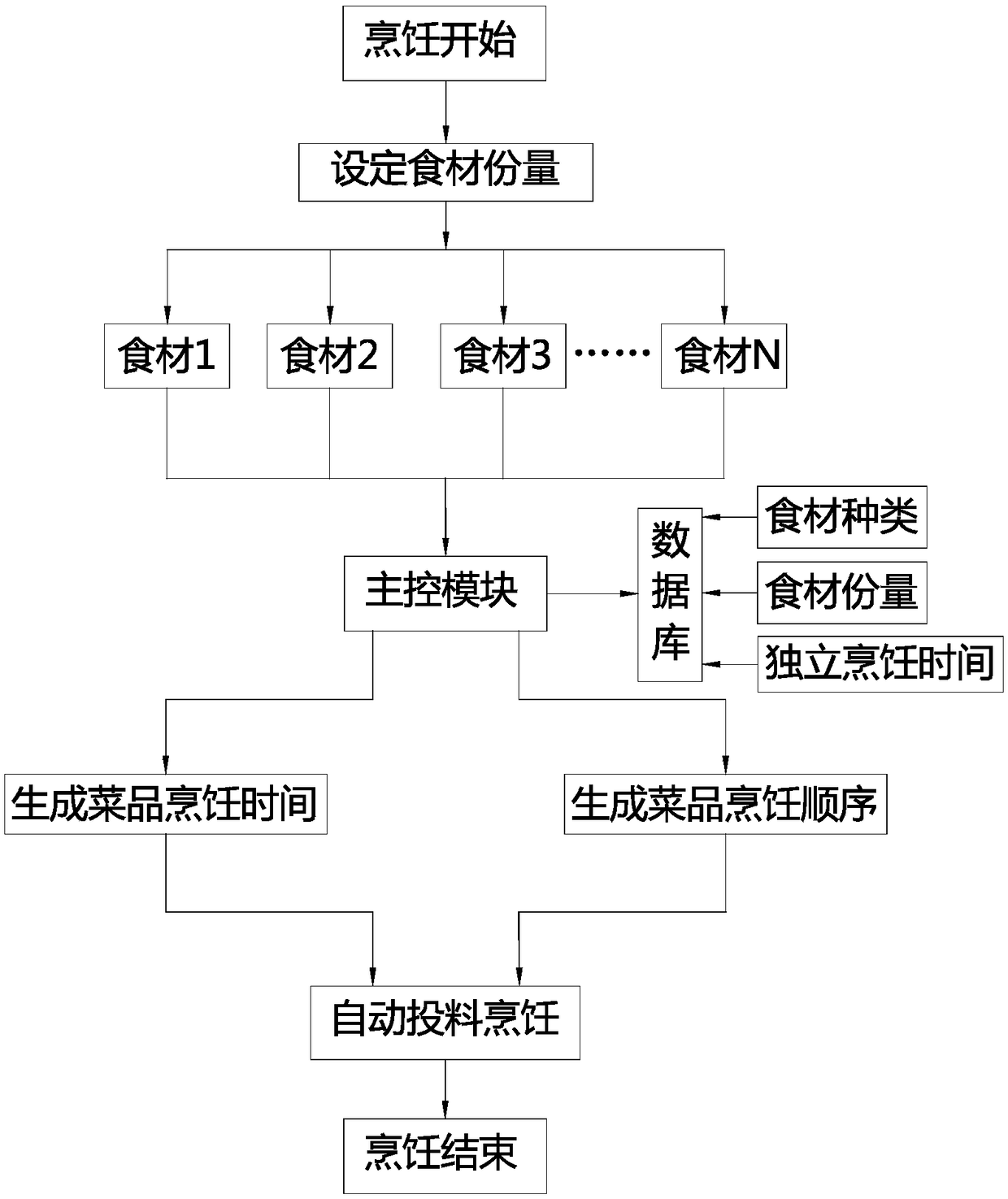

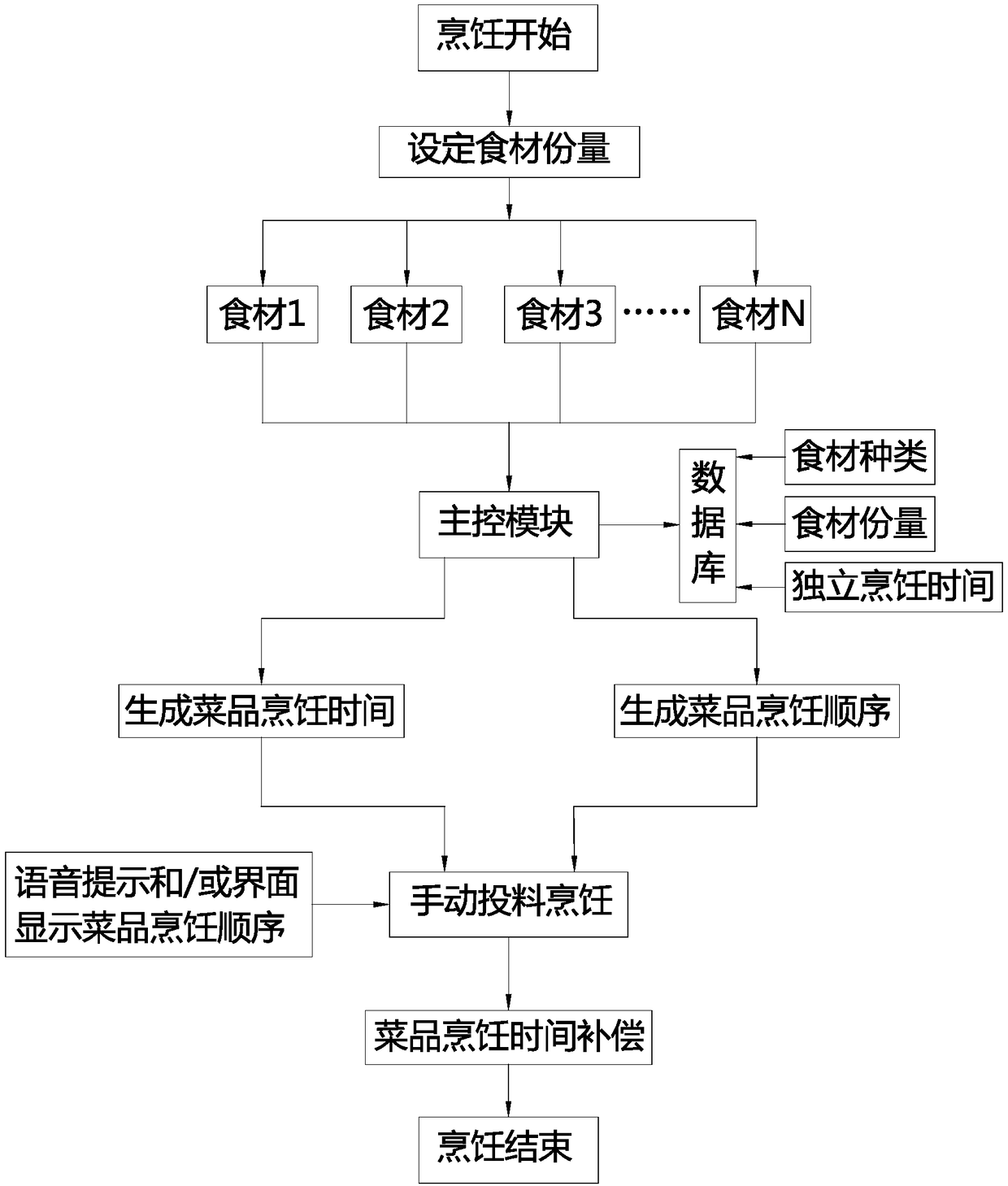

Automatic cooker and cooking method of automatic cooker

InactiveCN108552936AFor culinary needsIncrease success rateCooking vessel constructionsFood materialProcess engineering

The invention discloses an automatic cooker and a cooking method of the automatic cooker and belongs to the field of kitchen household appliances. The problems are solved that the cooked dish of an existing automatic cooker is monotonous, and adaptive adjustment cannot be made according to actual demands of users. According to the cooking method of the automatic cooker, the automatic cooker is provided with an operation interface and a main control module, and multiple cooking cookbooks are pre-stored in the main control module. The cooking method of the automatic cooker comprises the following steps that the cooking cookbooks are selected through the operation interface, and the main control module controls the operation interface to display food material information of the selected cooking cookbooks according to the selected cooking cookbooks; parameters of the food material information are set through the operation interface; the main control module generates independent cooking parameters of food materials according to the set parameters of the food material information, and accordingly the dish cooking parameters of the corresponding cooking cookbooks are determined.

Owner:JOYOUNG CO LTD

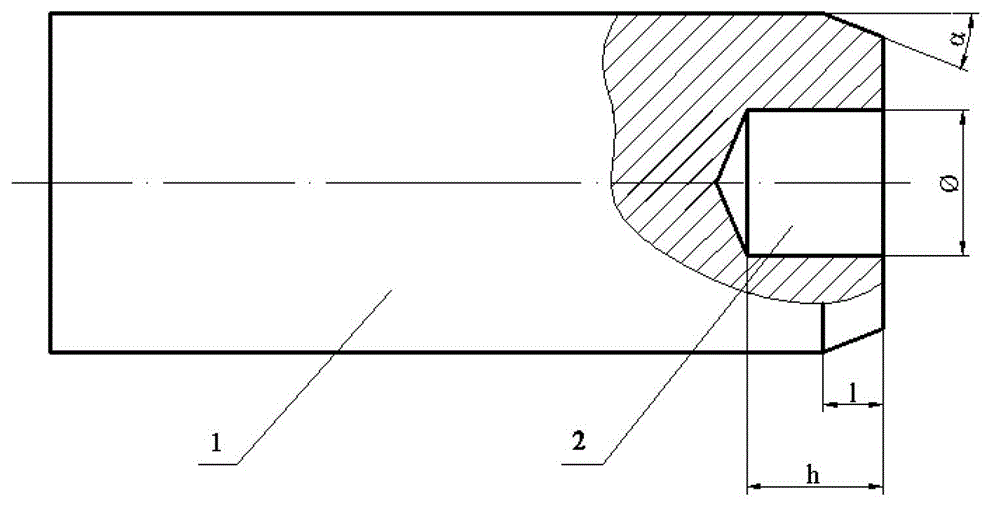

Titanium alloy pipe and manufacturing method

ActiveCN103146956AThe group ratio is reasonableHigh strengthMetal rolling arrangementsNon destructiveTitanium alloy

The invention belongs to the technical field of titanium alloy pipe pressure processing, and specifically relates to a titanium alloy pipe and a manufacturing method. The pipe is a seamless pipe, the outer diameter of the pipe is 140-300mm, and the wall thickness is 10-30mm. The manufacturing method is as follows: manufacturing a titanium alloy stick blank, machining the outer surface of the stick blank, and performing ultrasonic non-destructive testing on the stick blank; cutting the qualified stick blank in fixed length according to the weight requirement on the finished product pipe to manufacture a bar, machining at the centre of the head part of one end of the rod to obtain a guiding hole and an excircle chamfer, uniformly coating a layer of titanium alloy antioxidant protective coating on the surface of the bar, heating to 950-1100 DEG C after the bar coating is dried, and then keeping the temperature so that the temperature of the bar is uniform and consistent, rolling the bar on a cone mill. The titanium alloy pipe provided by the invention is simple in production process, short in flow, low in production cost and high in yield, the produced pipe is good in surface quality and high in wall thickness uniformity.

Owner:WUCHANG SHIPBUILDING IND

Device and method for preparing bimetallic compounding roll by electric slag remelting method

The invention relates to a device and a method for preparing a bimetallic compounding roll by an electric slag remelting method. The device comprises an upper crystallizer and a lower water-cooling crystallizer, wherein the upper crystallizer and the lower water-cooling crystallizer form a T-shaped crystallizer; the upper crystallizer is a conductive crystallizer, and is insulated and isolated from the lower water-cooling crystallizer, and the lower water-cooling crystallizer is provided with a liquid level detector; a remelting compounding transformer is connected with the upper crystallizerthrough a short electrified wire. The method comprises the following steps of after slagging is finished, disengaging a slagging power supply loop; during slag firing, when the liquid level of a slagtank in the crystallizer submerges the lower edge of a conductive graphite block, conducting a roll core preheating power supply loop, and preheating a roll core; after preheating is finished, closingthe loop, lowering a self-consumption electrode to the end part, inserting into the slag tank, conducting an electrode melting and bimetallic compounding power supply loop, and finally performing thebimetallic melting compounding. The device and the method have the advantages that by adopting a method for improving the electric slag testing device and the power supply loop, the temperature fieldat the surface of the roll core is reasonably optimized, so as to prepare the bimetallic compounding roll with better interface bonding quality.

Owner:NORTHEASTERN UNIV

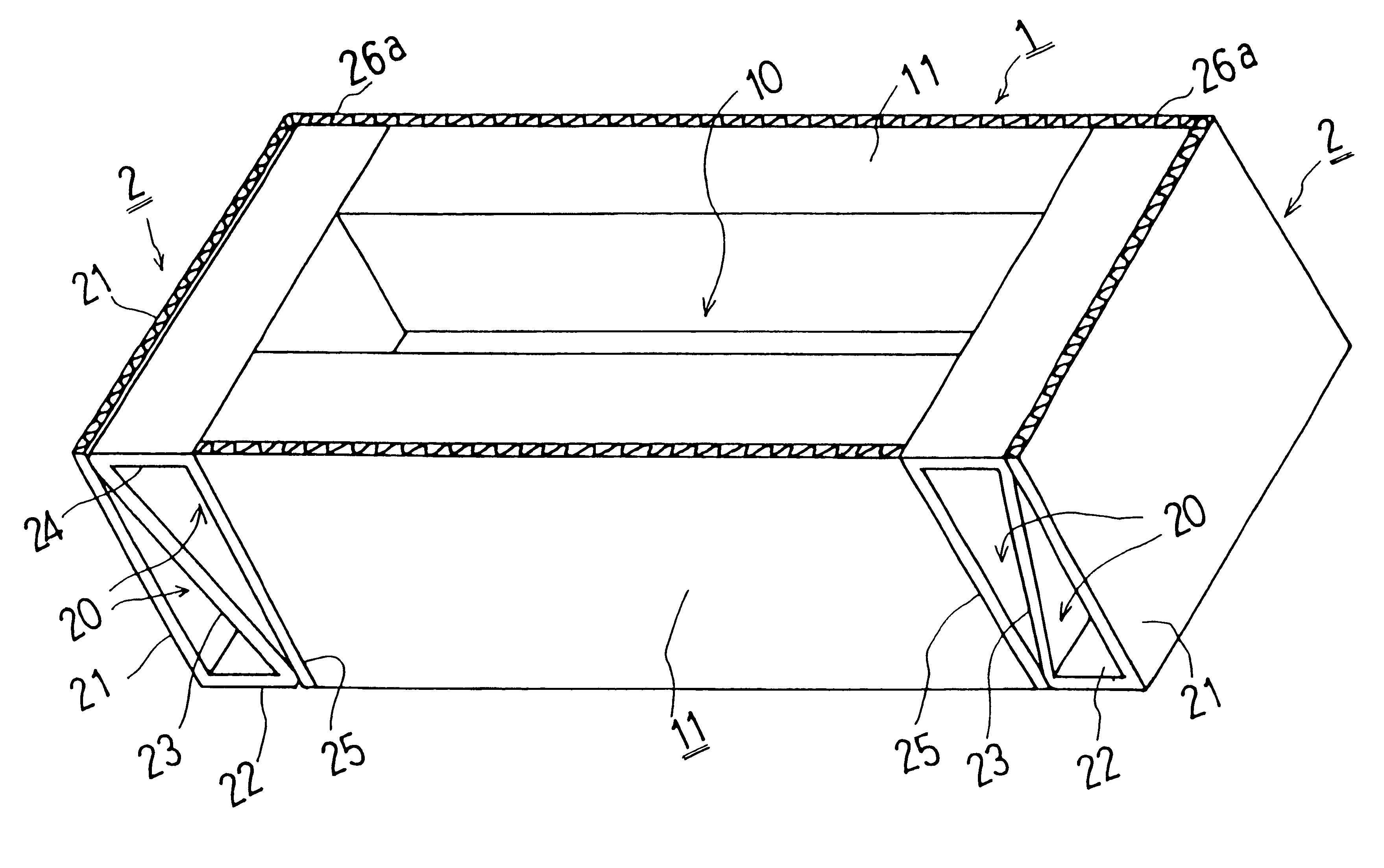

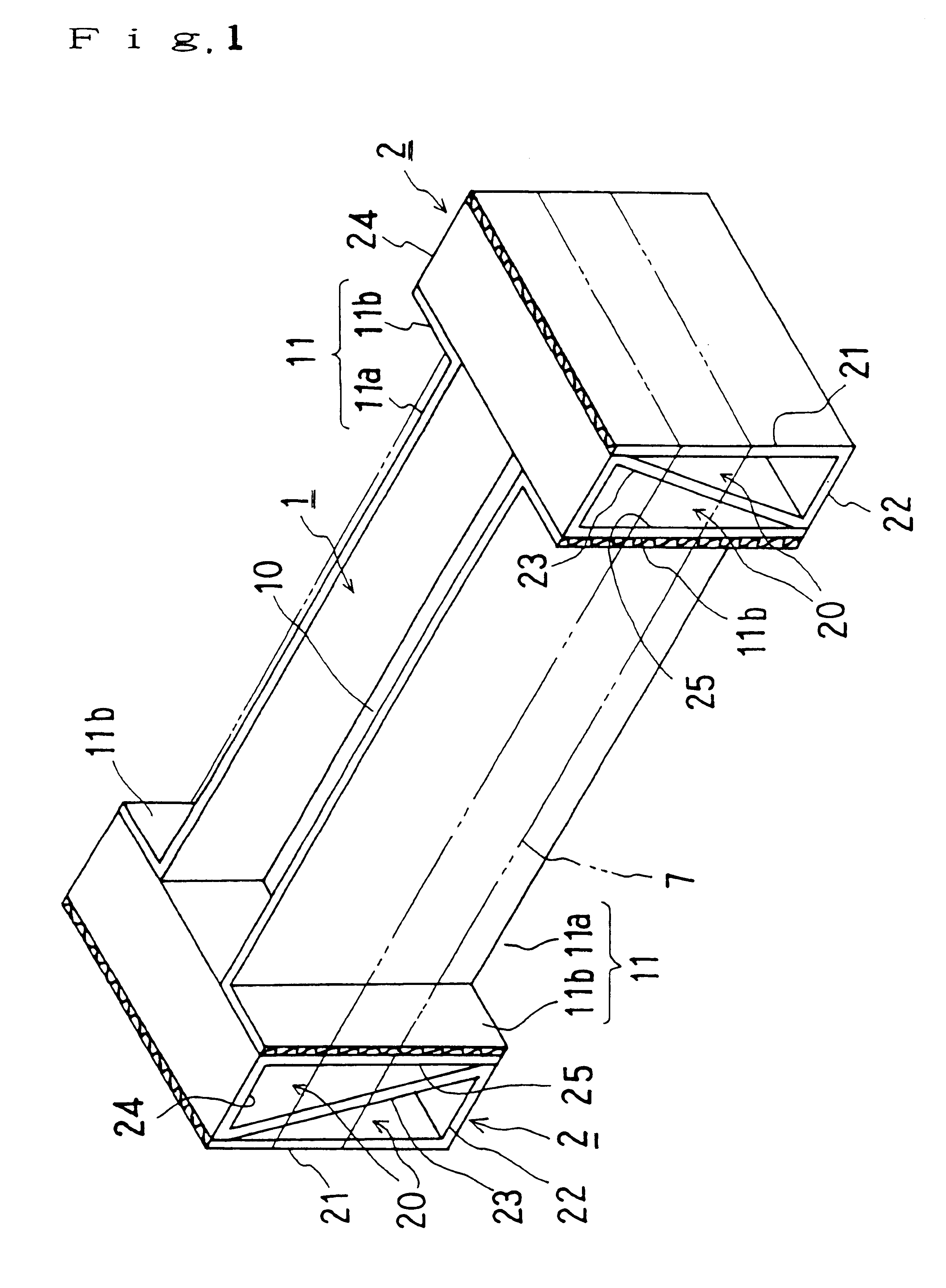

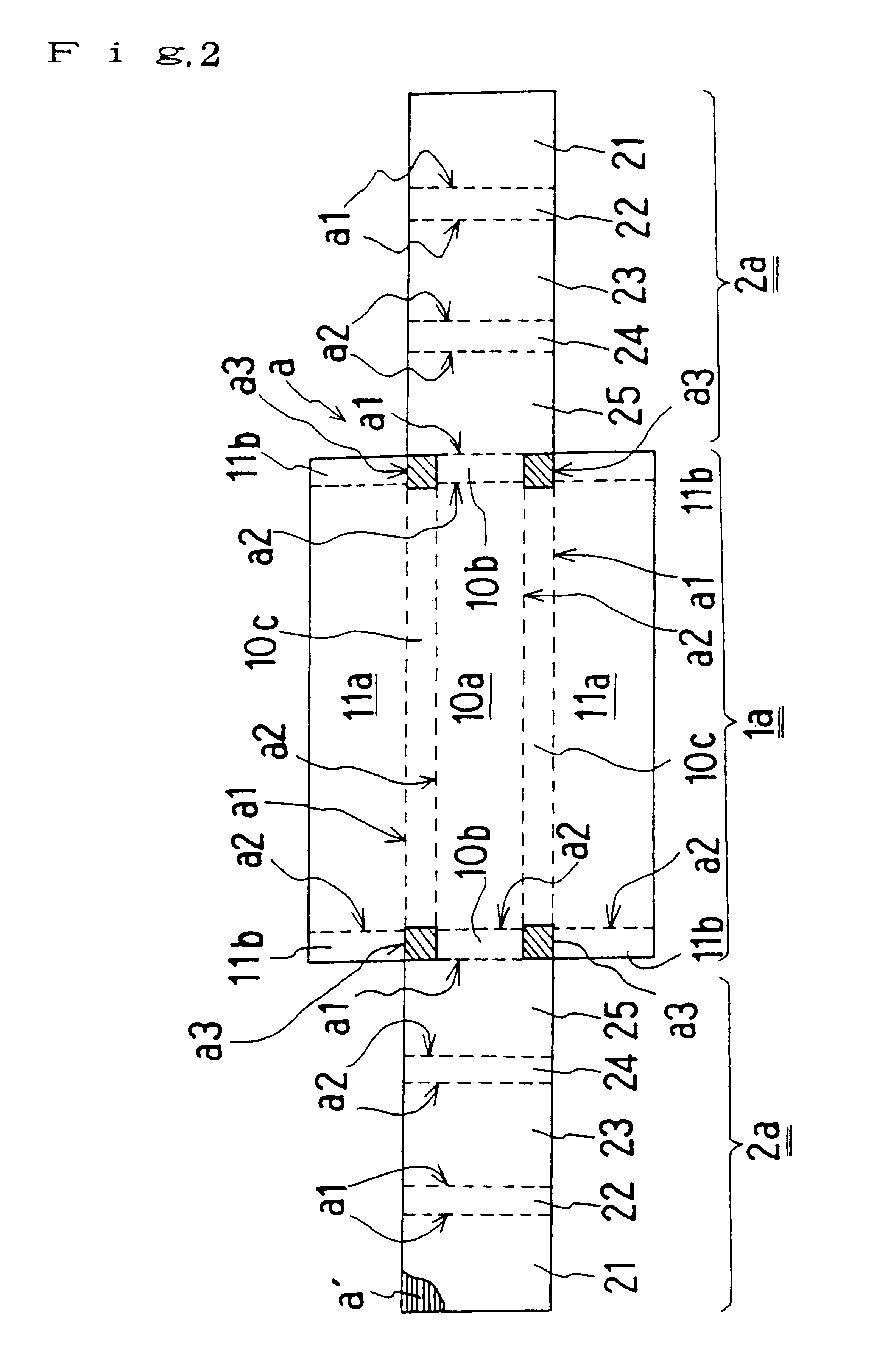

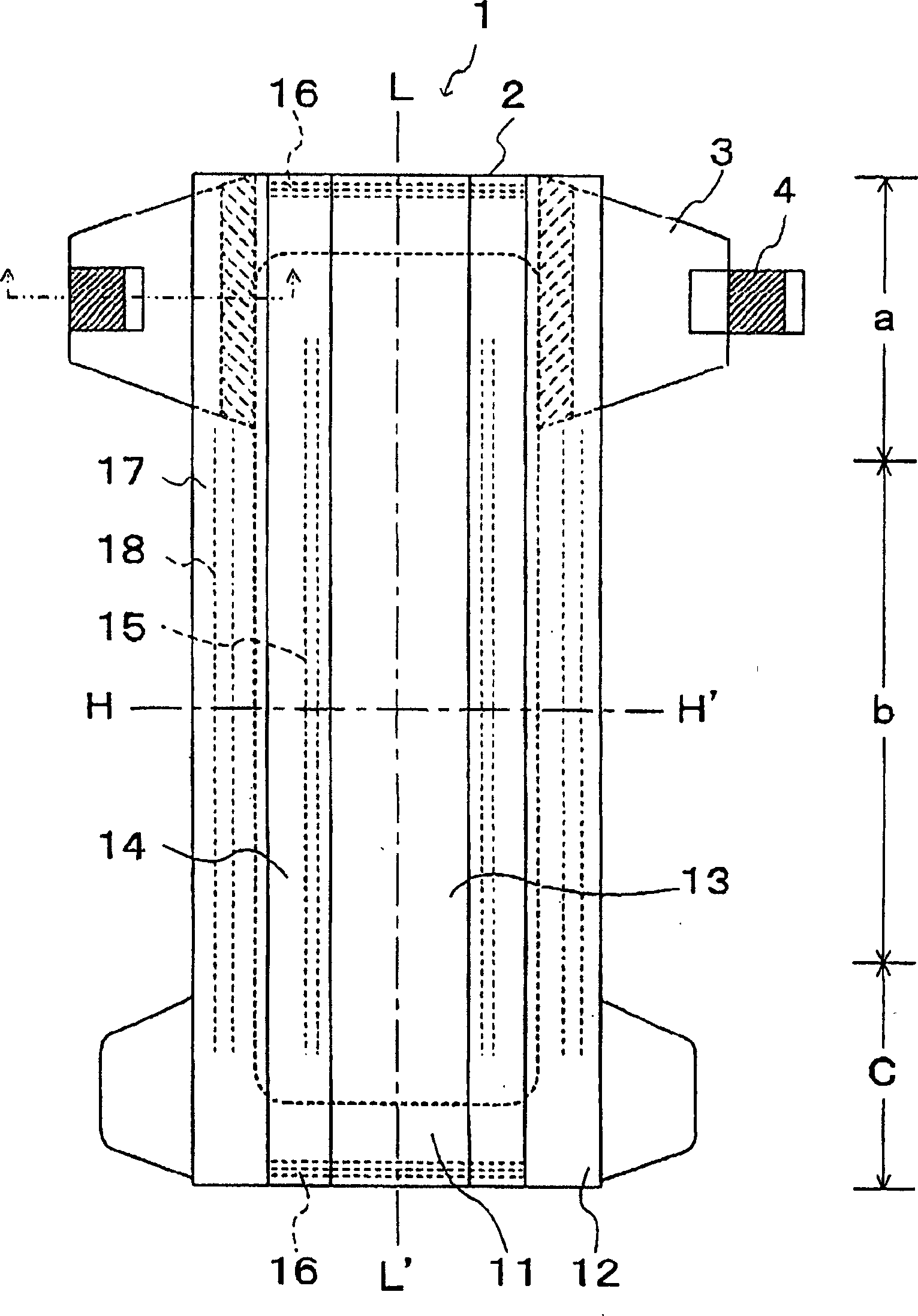

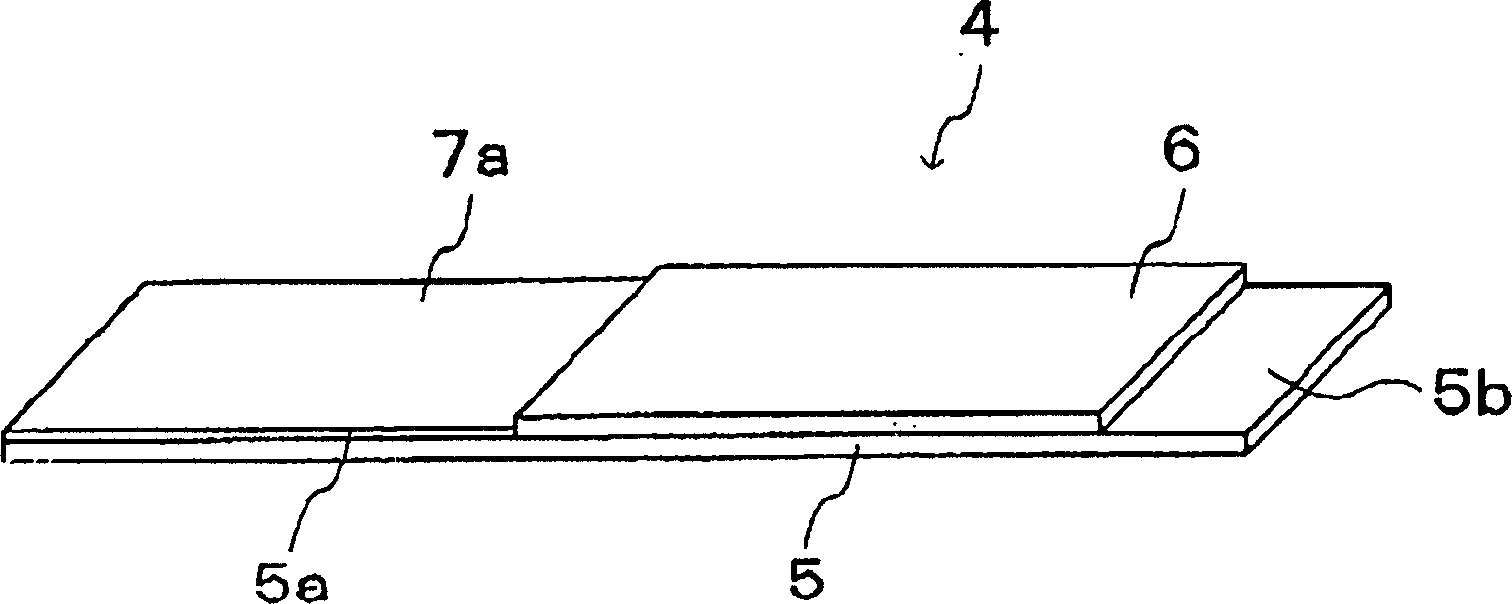

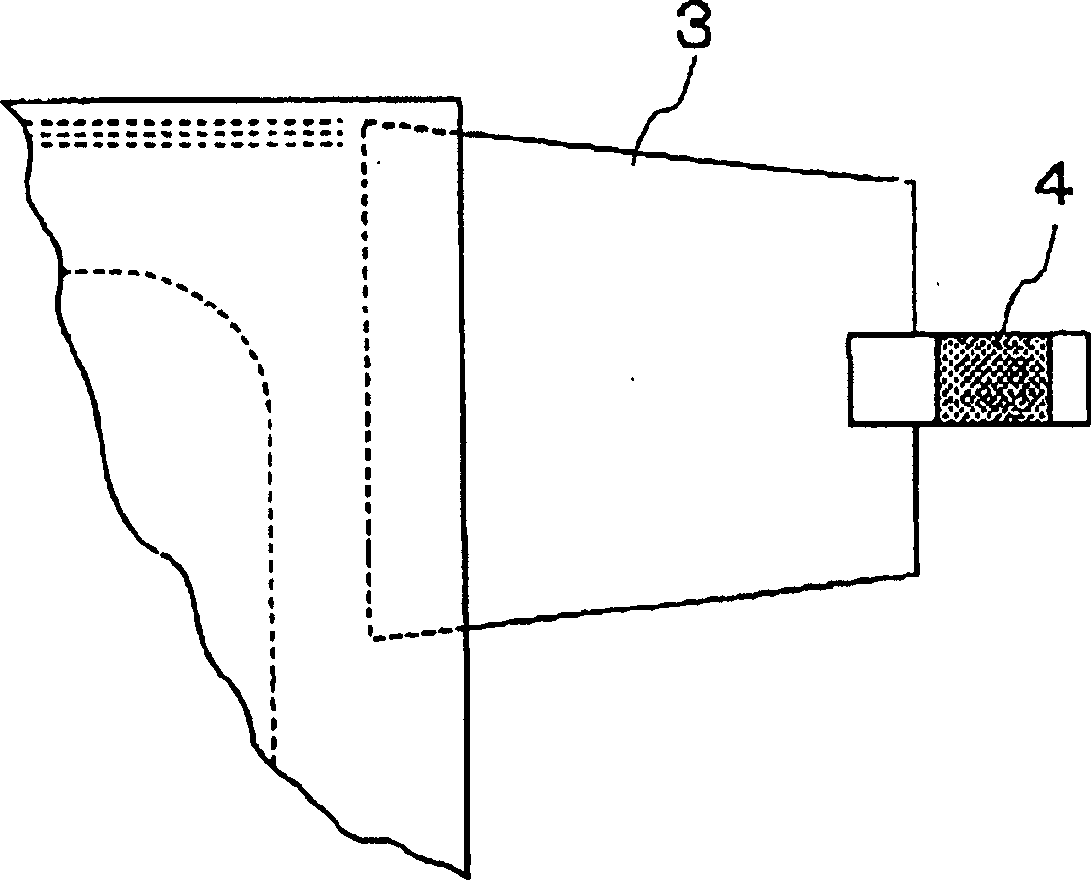

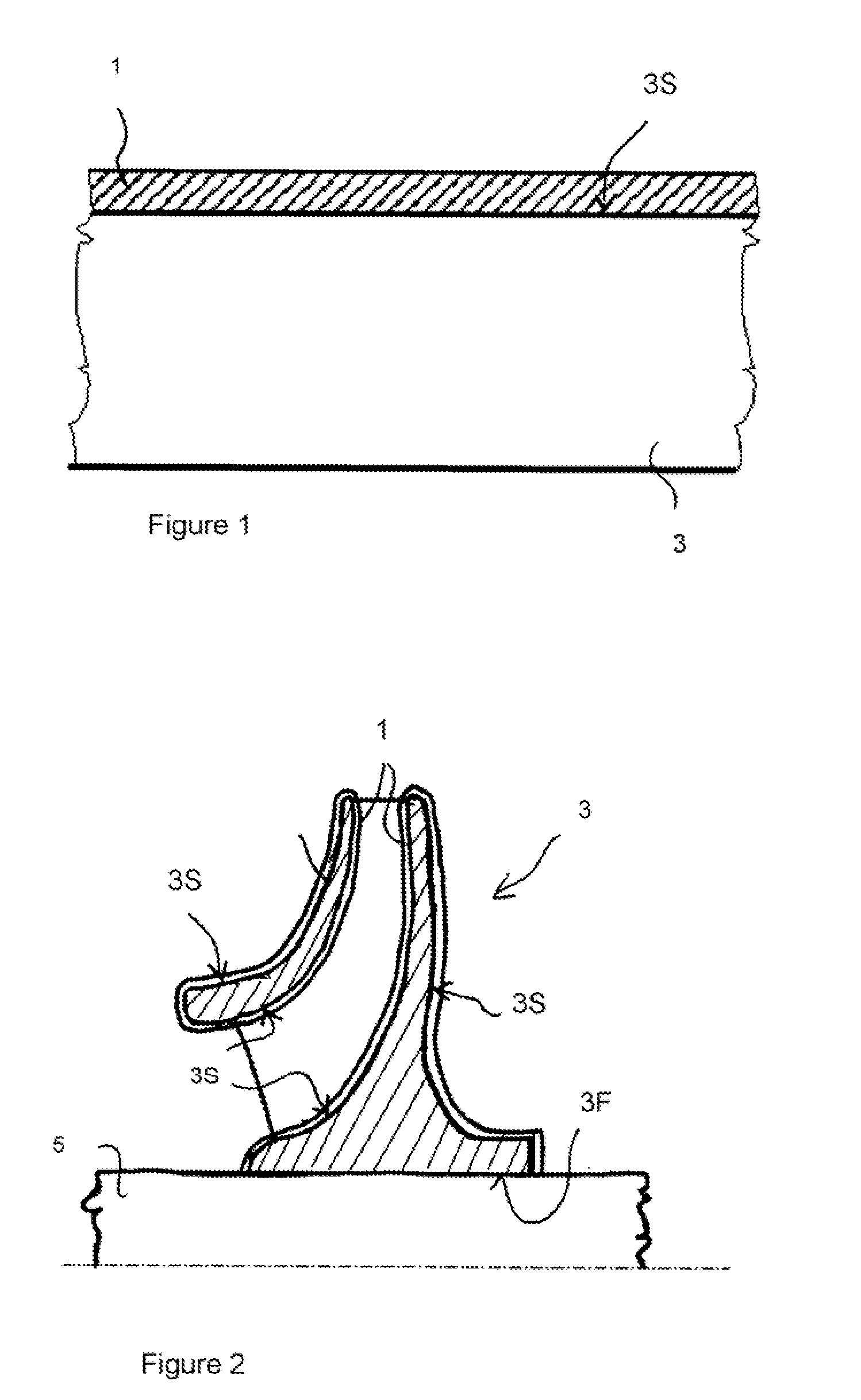

Folded cushioning material for packaging

InactiveUS6257412B1Small bulk densitySmooth preparation processOther accessoriesContainer/bottle contructionCushioningEngineering

A cushioning material for packaging is provided, which is used when an article having a rectangular cross section or a cubic shape is packaged in an outer case, such as a corrugated cardboard box. The cushioning material is suitable for packaging the article therewith in an outer case while an end portion, which has a pair of corner sections, of the article is inserted into and supported by the cushioning. The cushioning material is provided with a grooved retainer (1) and a pair of end support members (2,2) disposed so as to close the ends of both end portions of the grooved retainer (1). The grooved retainer has a raised bottom (10) and two side walls (11,11) and is adapted to receive one inserted end portion of the article having a rectangular cross section or a cubic shape. The end support members each have a plurality of hollow portions (20), which are arranged in parallel in a predetermined direction, and a rectangular cross-section orthogonal to the longitudinal direction of the hollow portions (20). The grooved retainer (1) and end support members (2,2) are formed by folding a single sheet a of a predetermined planar shape along valley-forming folding lines (a1) and ridge-forming folding lines (a2) formed on the sheet. This enables to provide a cushioning material for packaging which has a simple structure and a low bulk specific gravity, and is not likely to deform.

Owner:HITACHI ZOSEN CORP +1

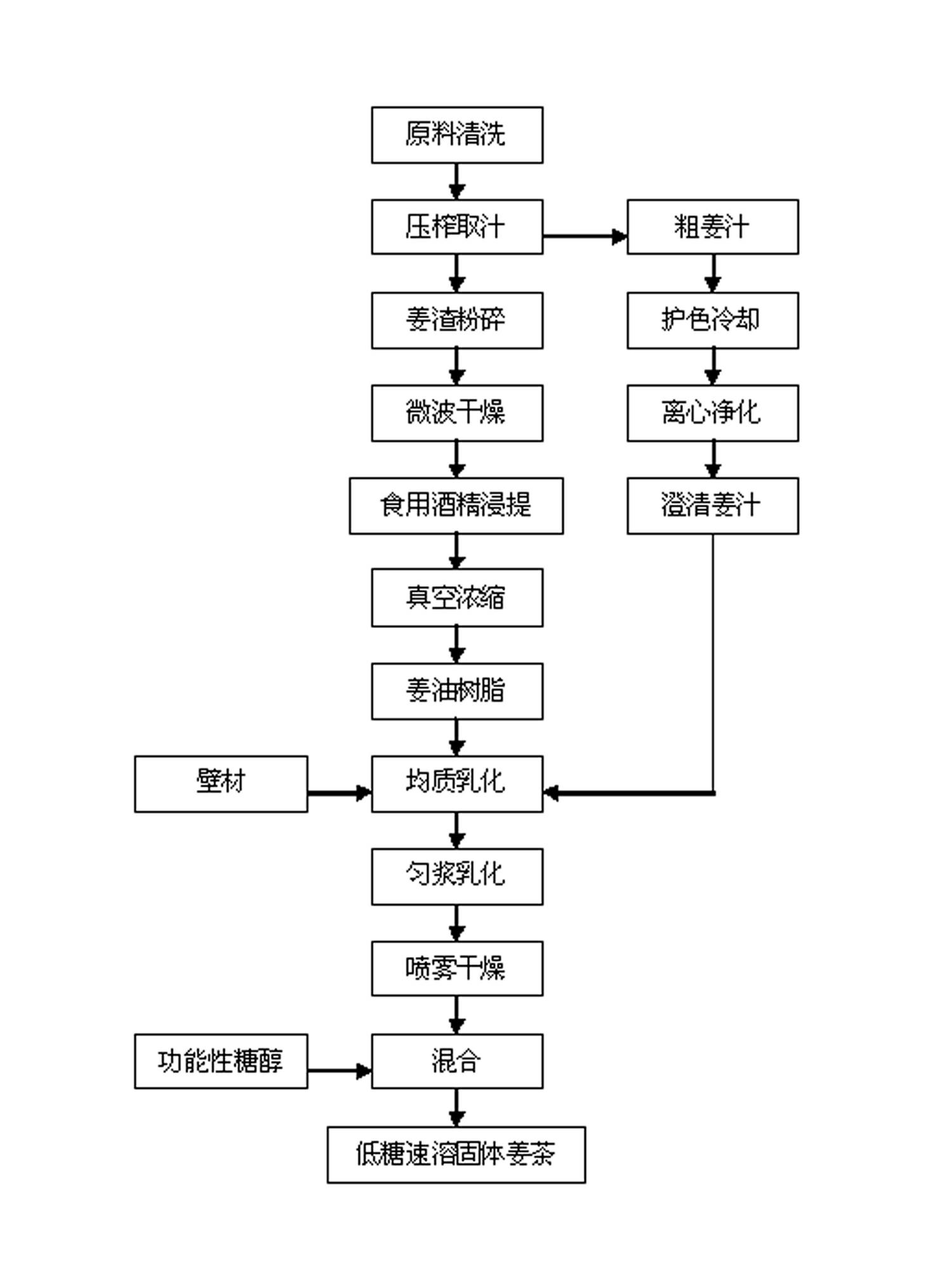

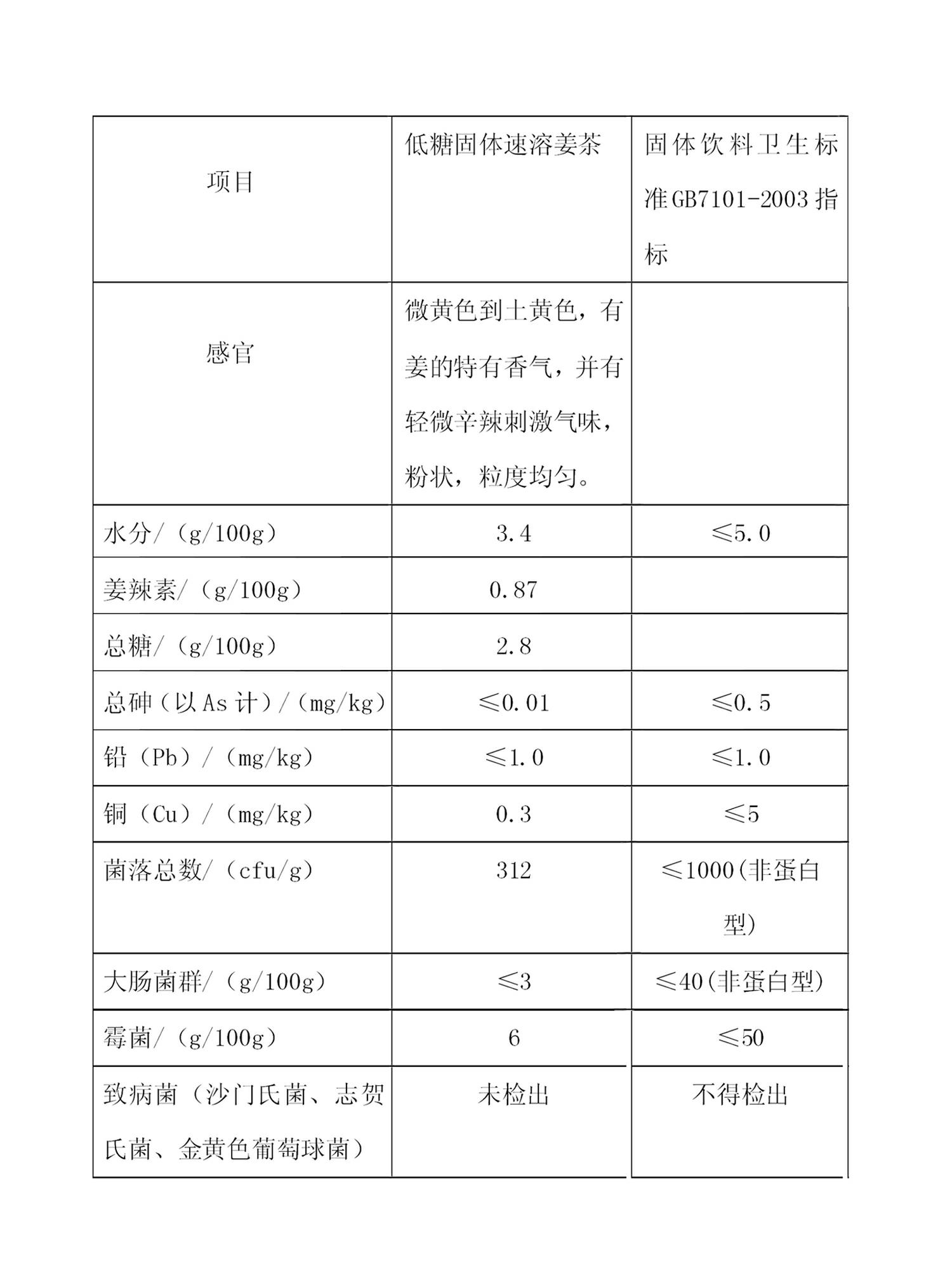

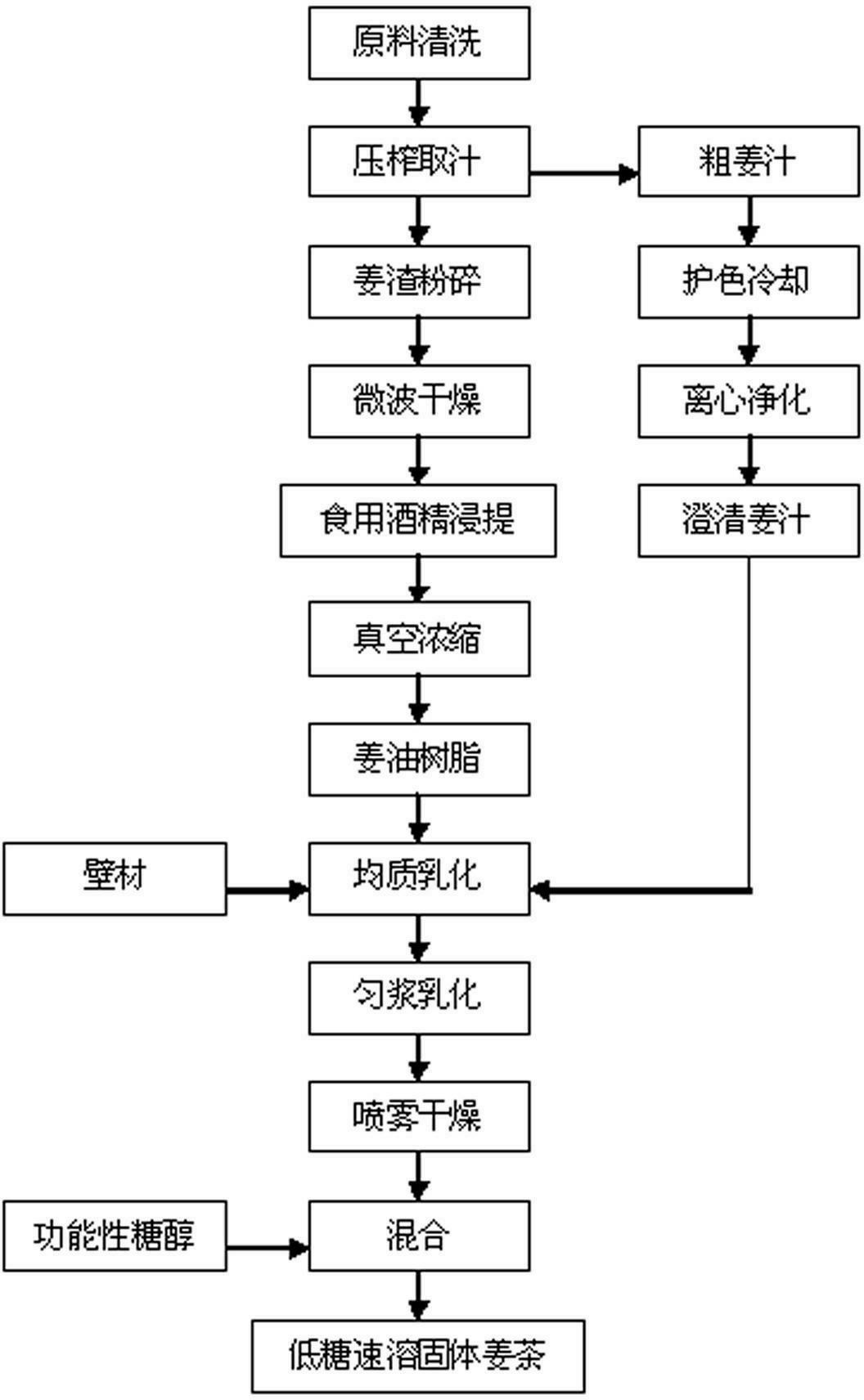

Preparation method of solid low-sugar ginger tea

The invention relates to a preparation method of solid low-sugar ginger tea. Full gingers are pressed to obtain partial juice, left gingers are quickly dried through microwaves, edible alcohol is used for soaking the dried left gingers so as to extract ginger oil resin, the ginger juice and the ginger oil resin are mixed to prepare microcapsule powder, and then the microcapsule powder is mixed with crystallized sugar alcohol to prepare the solid low-sugar instant ginger tea. According to the preparation method, ingredients of raw gingers can be maximally utilized and protected, the productionefficiency also can be improved, and the production cost can be reduced; the produced solid low-sugar instant ginger tea belongs to categories of low-sugar food and low-calorie food; the procedures are coherent and simple, technique conditions are moderate, the ginger juice is completely used, and the edible alcohol for extracting the ginger oil resin can be condensed and recycled; and the solid low-sugar instant ginger tea powder has characteristics of fineness, mobility, particular fragrance of the ginger, slight spice irritation, instant solubility, capability of being rapidly dissolved inhot water, stability in a drying state, and more than or equal to 90 percent of gingerol retention after being held in darkness for 6 months.

Owner:SHAOGUAN COLLEGE

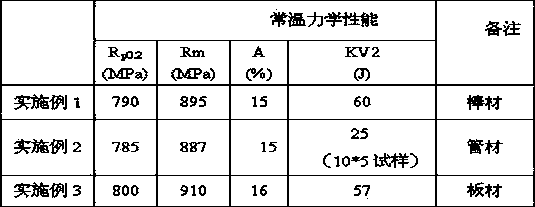

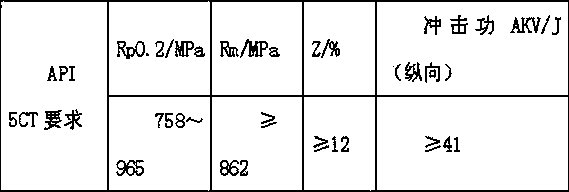

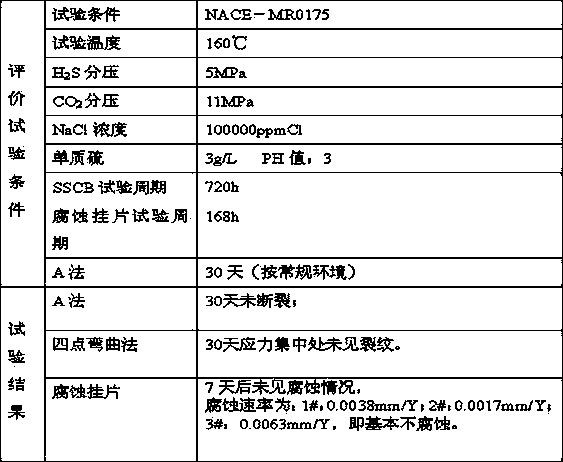

High-strength high-impact-toughness titanium alloy used for oil well and gas well, and preparation method thereof

The invention relates to high-strength high-impact-toughness titanium alloy comprising the chemical components of, by weight: 4.0-9.0% of Al, 0.5-5.0% of Mo, 1-5% of Nb, 1-5% of Zr, and balance of Ti. The preparation method comprises mixing, electrode rod pressing, vacuum consumption and twice smelting, such that an alloy ingot is prepared. The titanium alloy provided by the invention assists in well solving a problem of poor H2S and CO2 corrosion resistance of an existing P110 steel oil well and gas well pipe material. Also, 40% weight reduction can be realized, such that drilling rig power is greatly reduced. With the alloy, petroleum and natural gas exploration capacity of our nation can be greatly improved.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

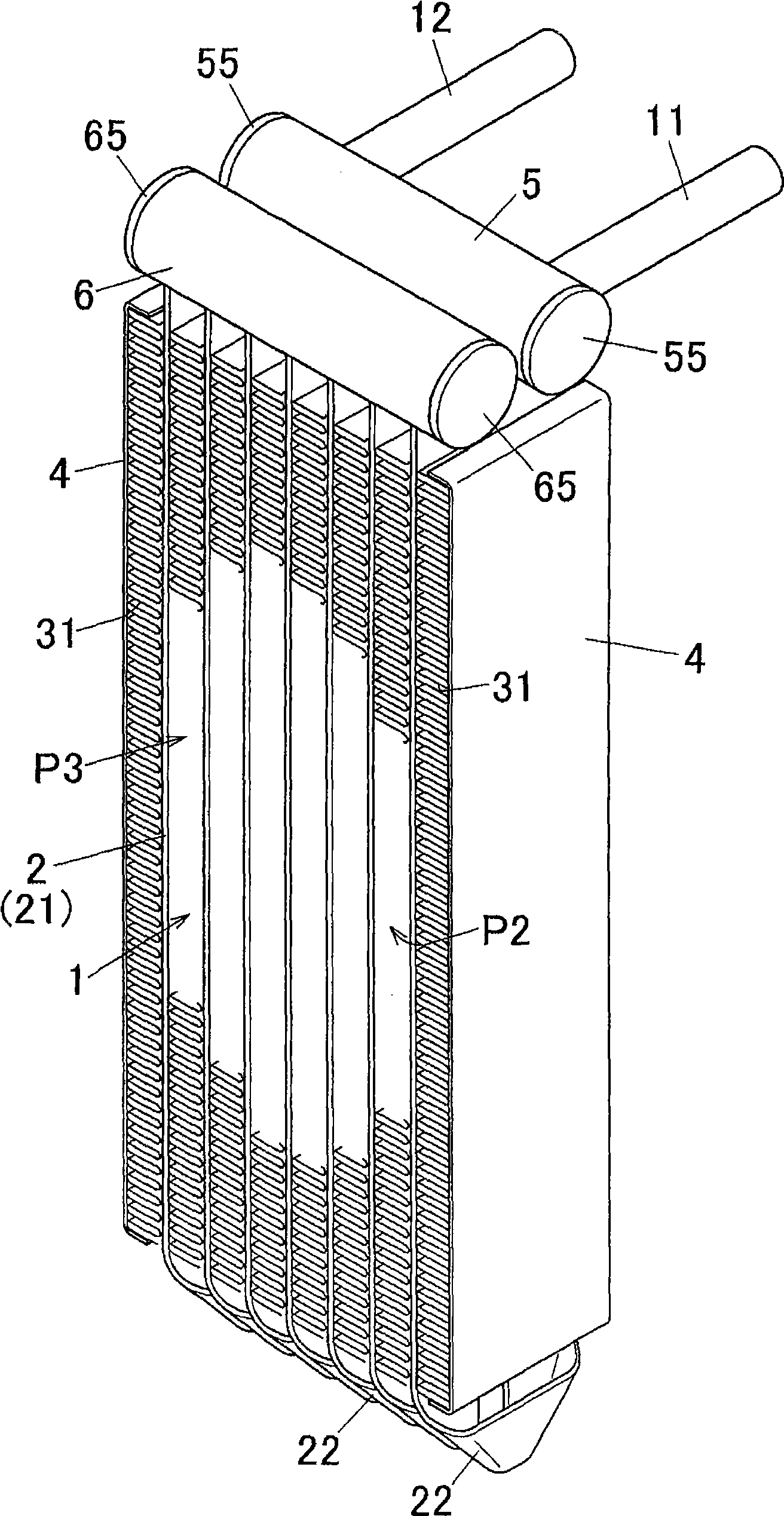

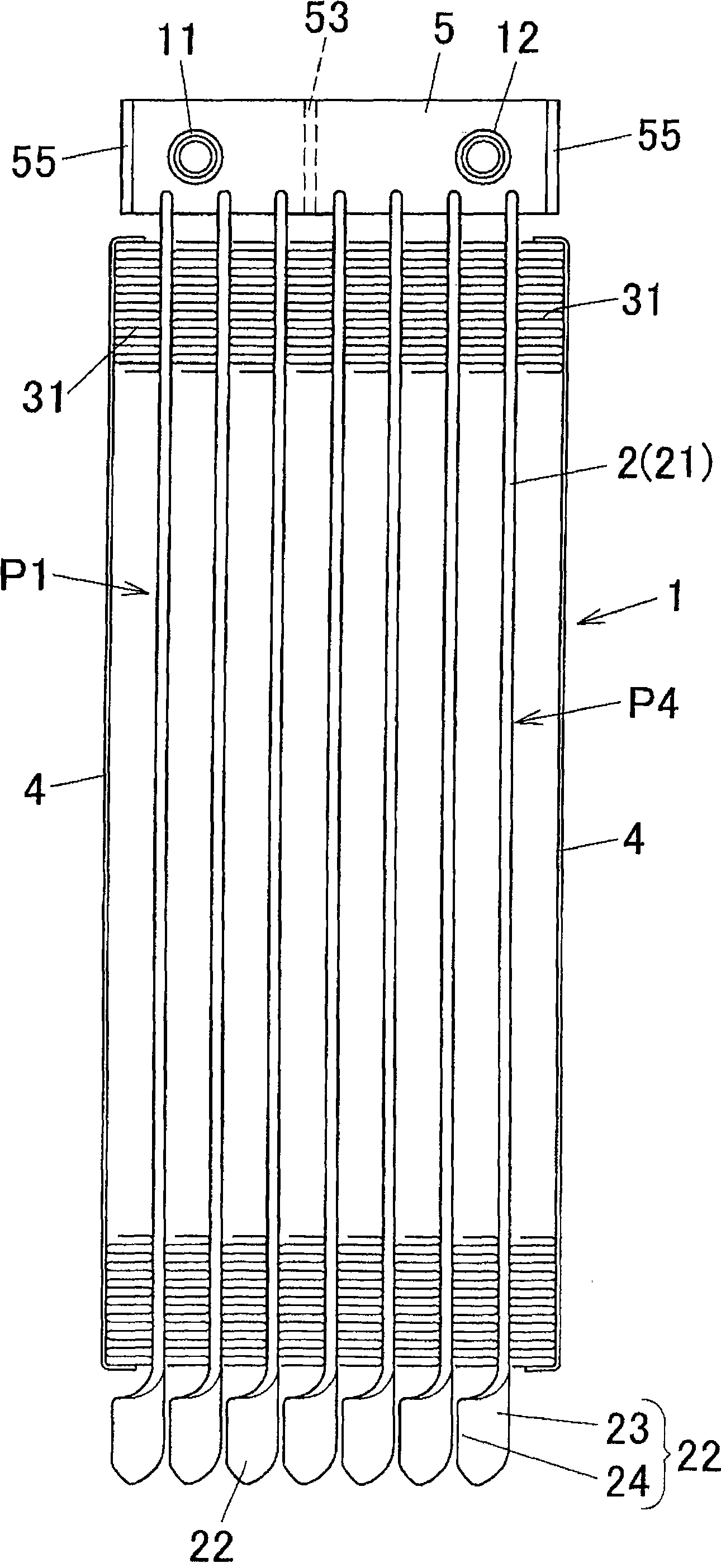

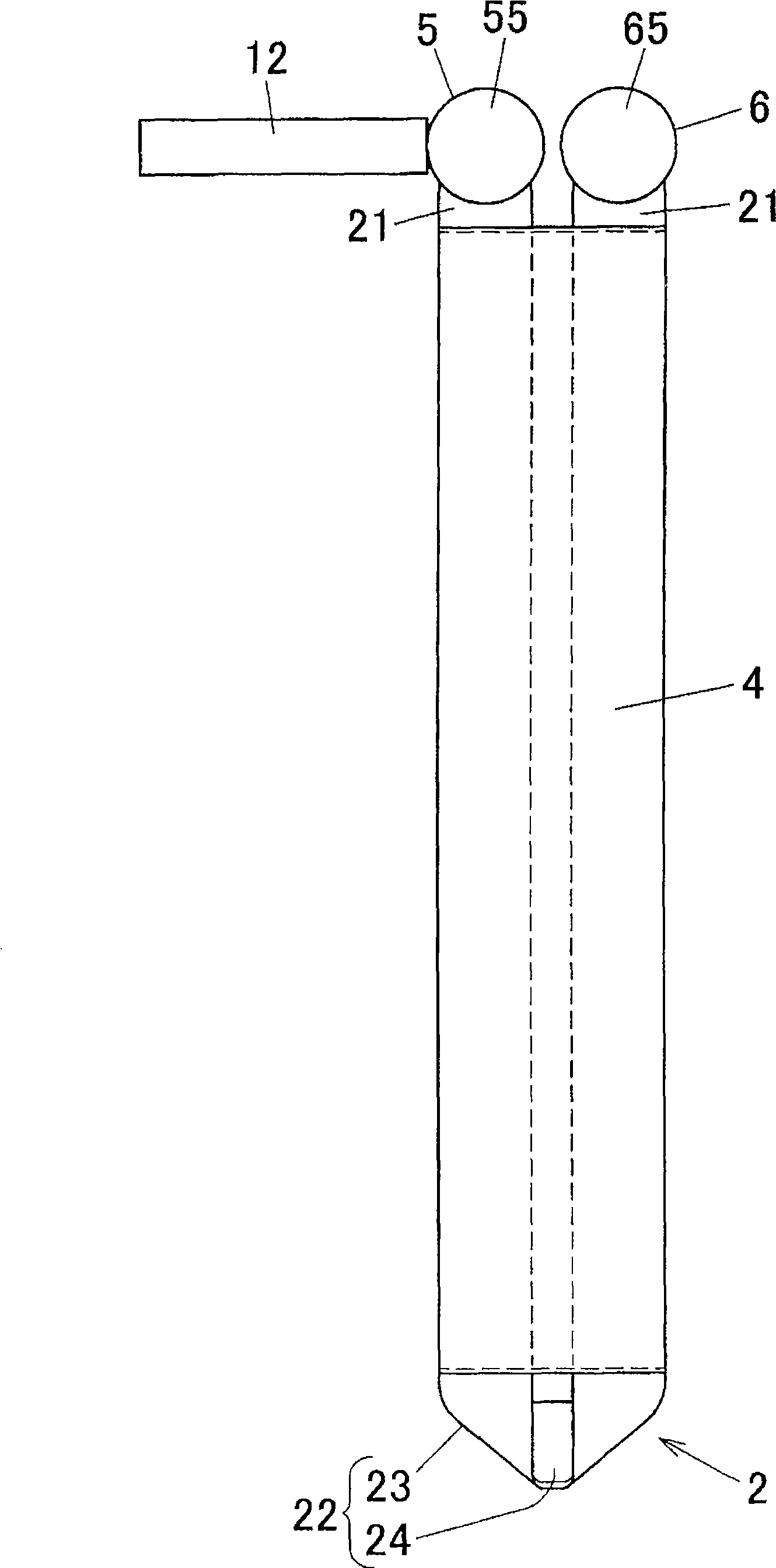

Heat exchanger

InactiveCN101532786AReduce in quantitySmall sizeStationary conduit assembliesTubular elementsBand shapeStraight tube

The present invention provides a heat exchanger, wherein a plurality of U-shaped heat-exchange tubes (2) are arranged along the tube thickness direction, the U-shaped heat-exchange tube has a pair of flat straight tube parts (21) in parallel in the width direction and a bending part (22) for communicating the pair of the straight tube parts (21). In the heat exchanger, the heat-exchange tube (2) is formed by bending two ends of a band-shaped flat tube component (20) angularly in an intermediate part which is used as the bending part (22), and the two ends of the flat tube component (20) is used as a pair of straight tube part (21). According to the heat exchanger of the invention, it is capable of reducing the component number and lightweighting.

Owner:SHOWA DENKO KK

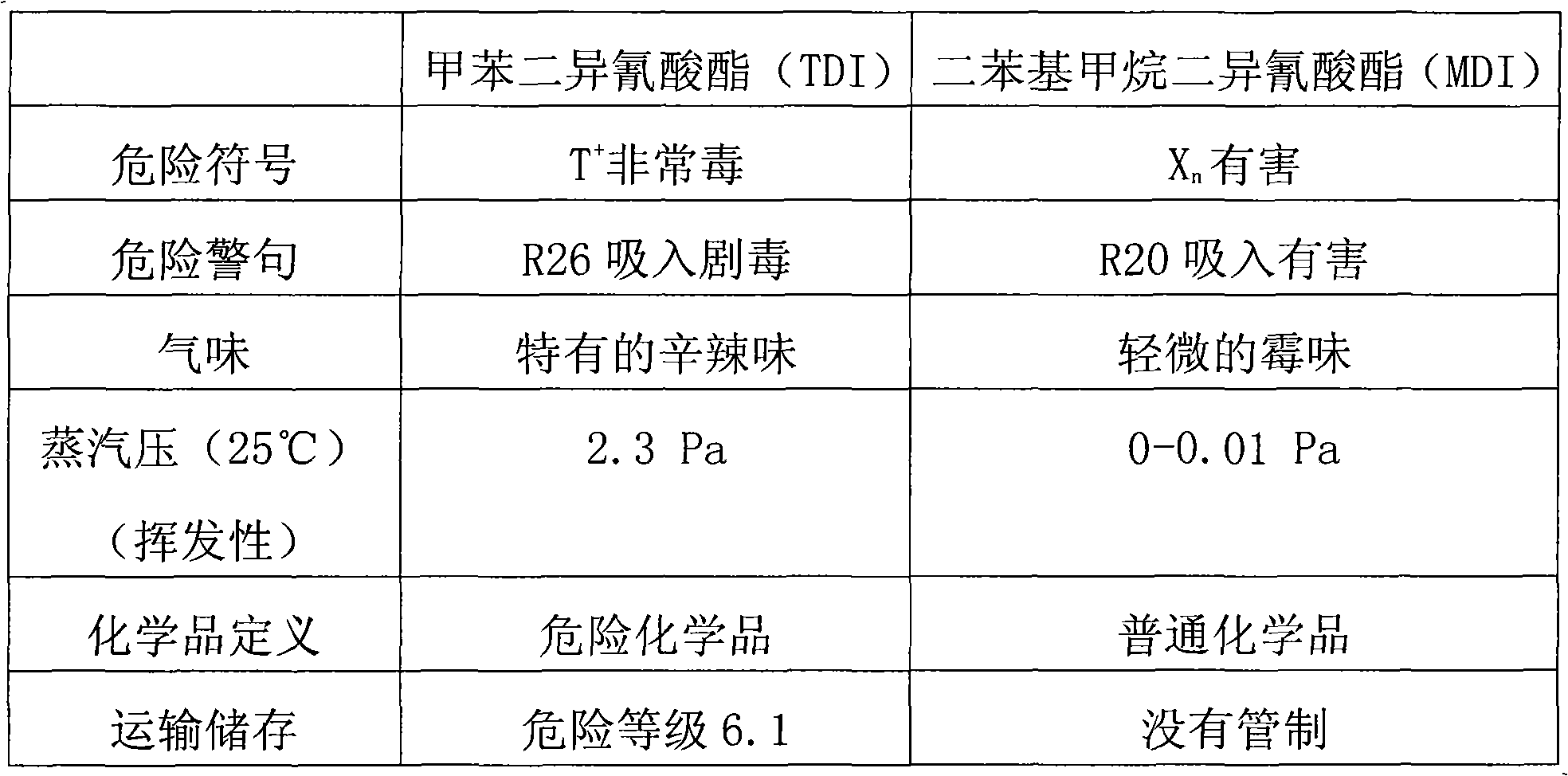

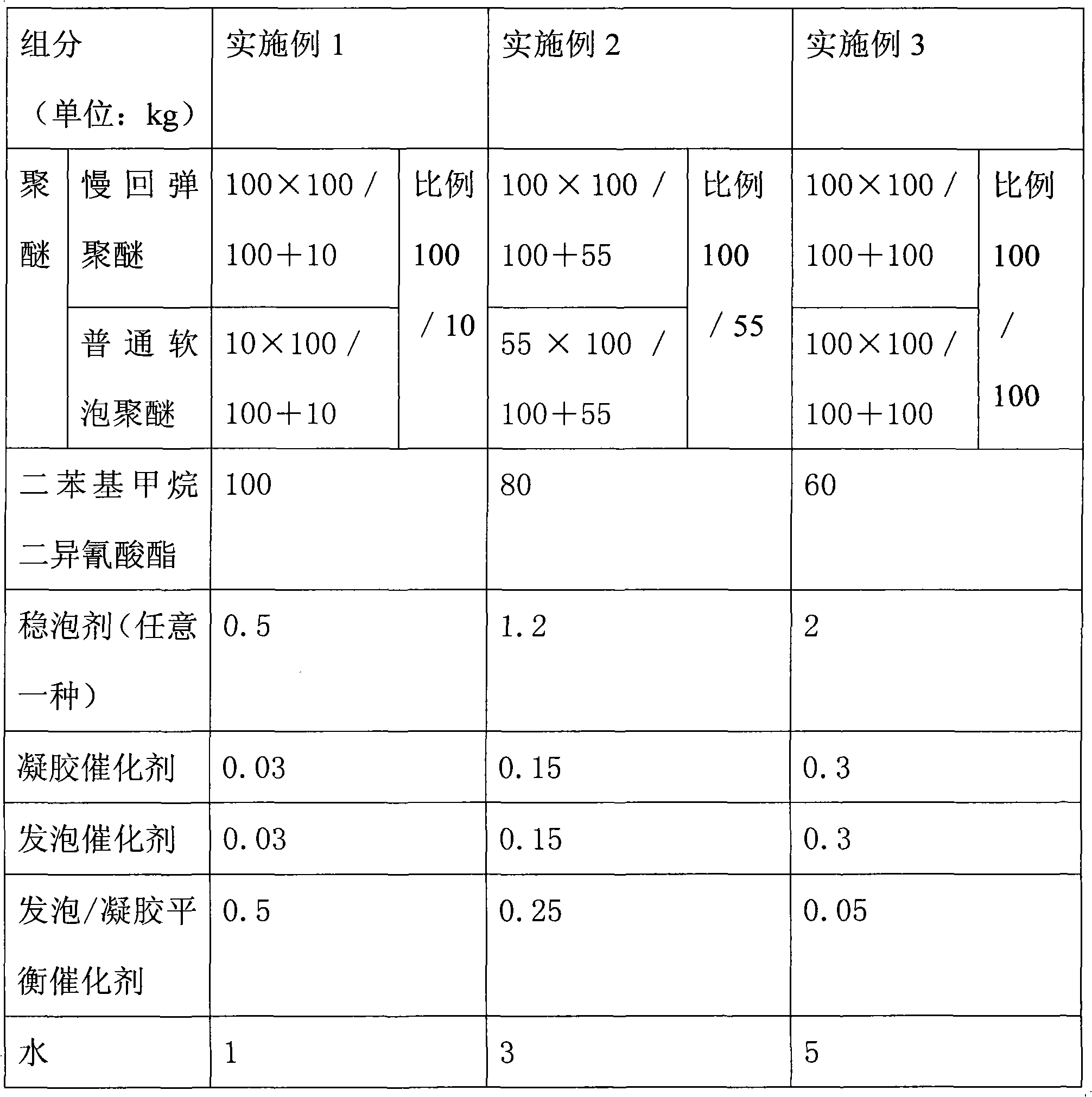

Slowly-recoverable polyurethane foam material

InactiveCN102115522AFeel goodWith decompression and anti-seismic functionHazardous substanceSynthetic materials

The invention relates to a high molecular synthetic material, in particular to a slowly-recoverable polyurethane foam material which is widely used as a filler. The slowly-recoverable polyurethane foam material comprises the following components in part by weight: 100 parts of polyether, 60 to 100 parts of diphenyl-methane-diisocyanate, 0.5 to 2 parts of foam stabilizer, 0.03 to 0.3 part of gel catalyst, 0.03 to 0.3 part of foam catalyst, 0.05 to 0.5 part of foam / gel equilibrium catalyst and 1 to 5 parts of water. The reaction activity of the diphenyl-methane-diisocyanate (MDI) is higher than that of toluene diisocynate (TDI), and the MDI can be fully reacted in the preparation process, so the final polyurethane product prepared from the MDI has a few residual harmful substances and nearly no toxicity, and also has properties of better handfeel, longer duration of slow recovery, better physical property, and higher flame retardancy.

Owner:上海人脊橡塑科技制品有限公司

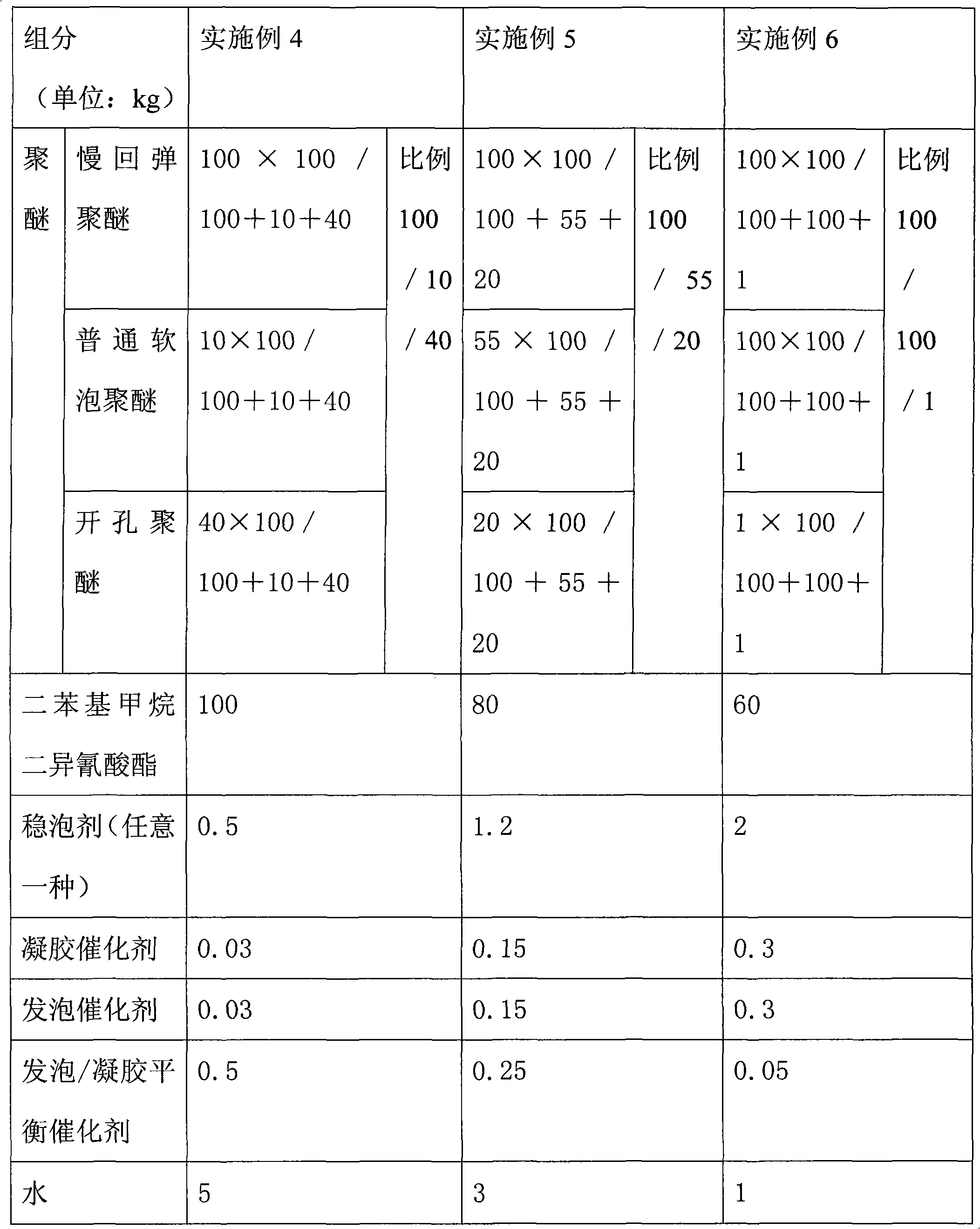

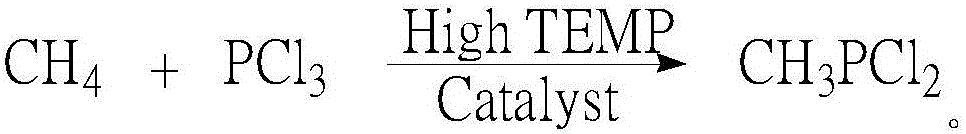

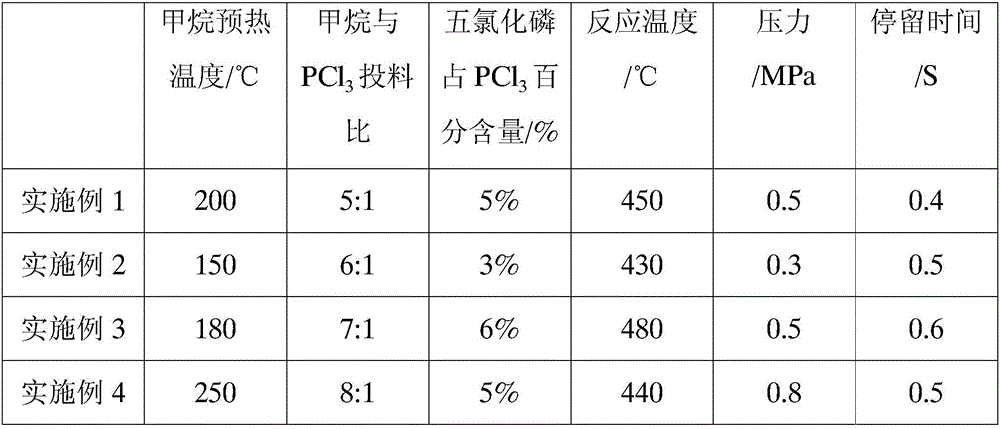

Green synthesis method of methyl phosphorus dichloride

InactiveCN106117267AImprove conversion rateImprove protectionGroup 5/15 element organic compoundsPhosphorus pentachloridePhosphorus trichloride

The invention discloses a green synthesis method of methyl phosphorus dichloride. The method comprises the following steps: by taking phosphorus pentachloride as a catalyst, heating phosphorus trichloride and phosphorus pentachloride into vapor, and preheating to 150-250 DEG C and mixing with methane and then entering a tubular reactor, and reacting for 0.1-1.0s under the conditions that the temperature is at 400-500 DEG C and the pressure is 0.3-1.2MPa, to obtain methyl phosphorus dichloride. After the catalyst is applied to methane and phosphorus trichloride to synthesize methyl phosphorus dichloride, the conversion rate of the phosphorus trichloride is effectively improved to 40%-50%, and the yield is 90%-95%; the adopted catalyst phosphorus pentachloride is decomposed into phosphorus trichloride and chlorine gas, the catalyst and the product is not required for separation, three wastes are not generated during the whole preparation, and all the materials are recycled, so that the resources are saved, the environment is beneficially protected, and the synthesis method is green.

Owner:ANHUI COSTAR BIOCHEM CO LTD

Method and system for manufacturing building materials by using stale garbage

ActiveCN108746152AEfficient separationAccurate sortingSolid waste disposalEnvironmental resistanceSocial benefits

The invention discloses a method and a system for manufacturing building materials by using stale garbage. According to the method, the building material is prepared by taking humic muck screened outfrom the stale garbage as a raw material, and compared with sorting of different components of the stale garbage in the prior art, the method has the advantage that the accuracy is higher so that theresidual value of available resources in the garbage can be fully played; according to the system, manual sorting, magnetic separation, hot air separation, screening and crushing devices are combined, the process is well-organized, high-efficiency separation of magnetic substances, combustibles, the humic muck, large plastic blocks, large rubber blocks and other recyclable objects in the stale garbage can be achieved, so that accurate sorting and highly recovery of recyclable resources in the stale garbage can be realized; and meanwhile, due to the fact that the content of the humic muck in the stale garbage is extremely high, the muck is regenerated into the building material, a large amount of soil taking land can be saved every year, and the extremely good environmental protection benefit and social benefit are achieved.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

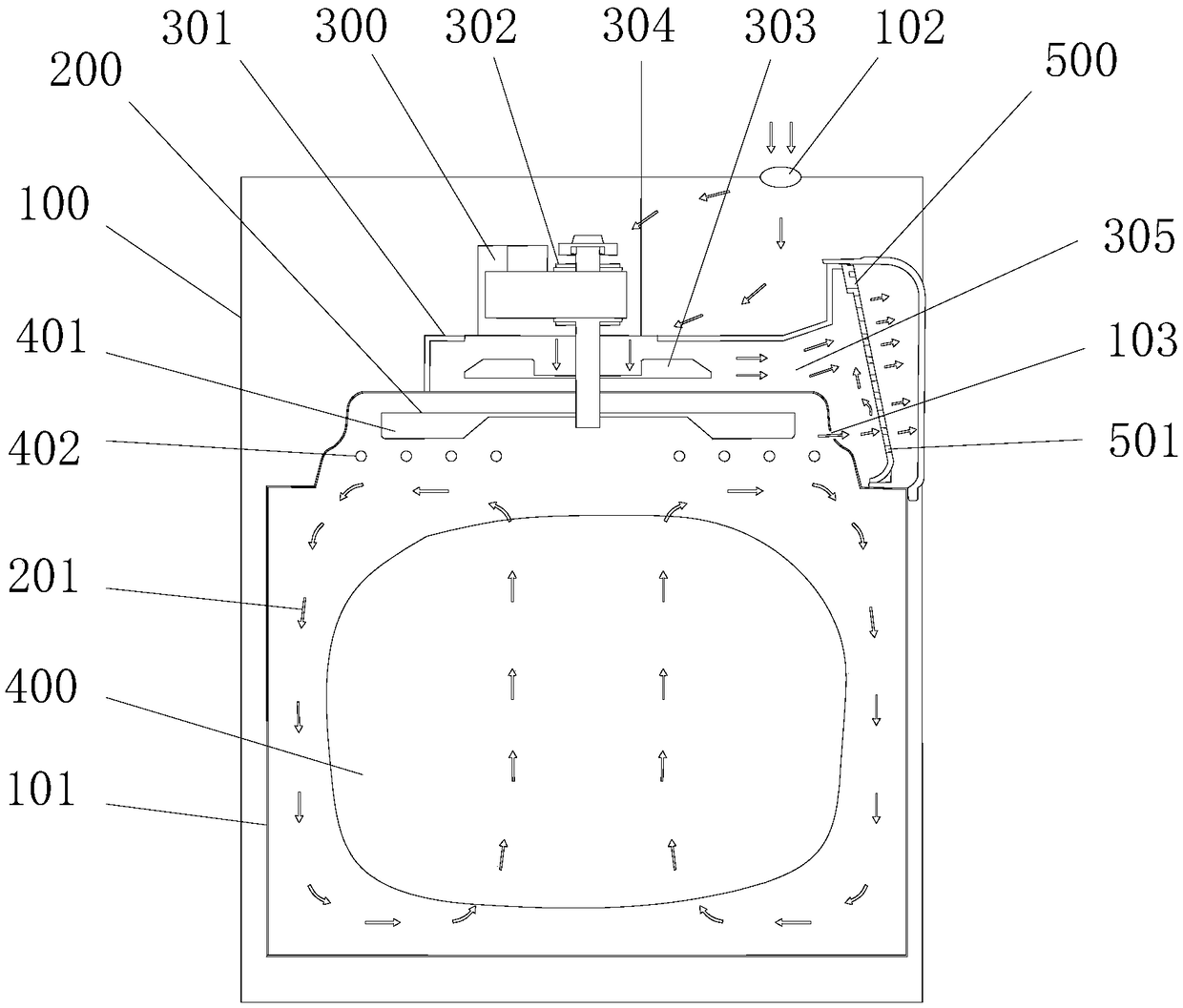

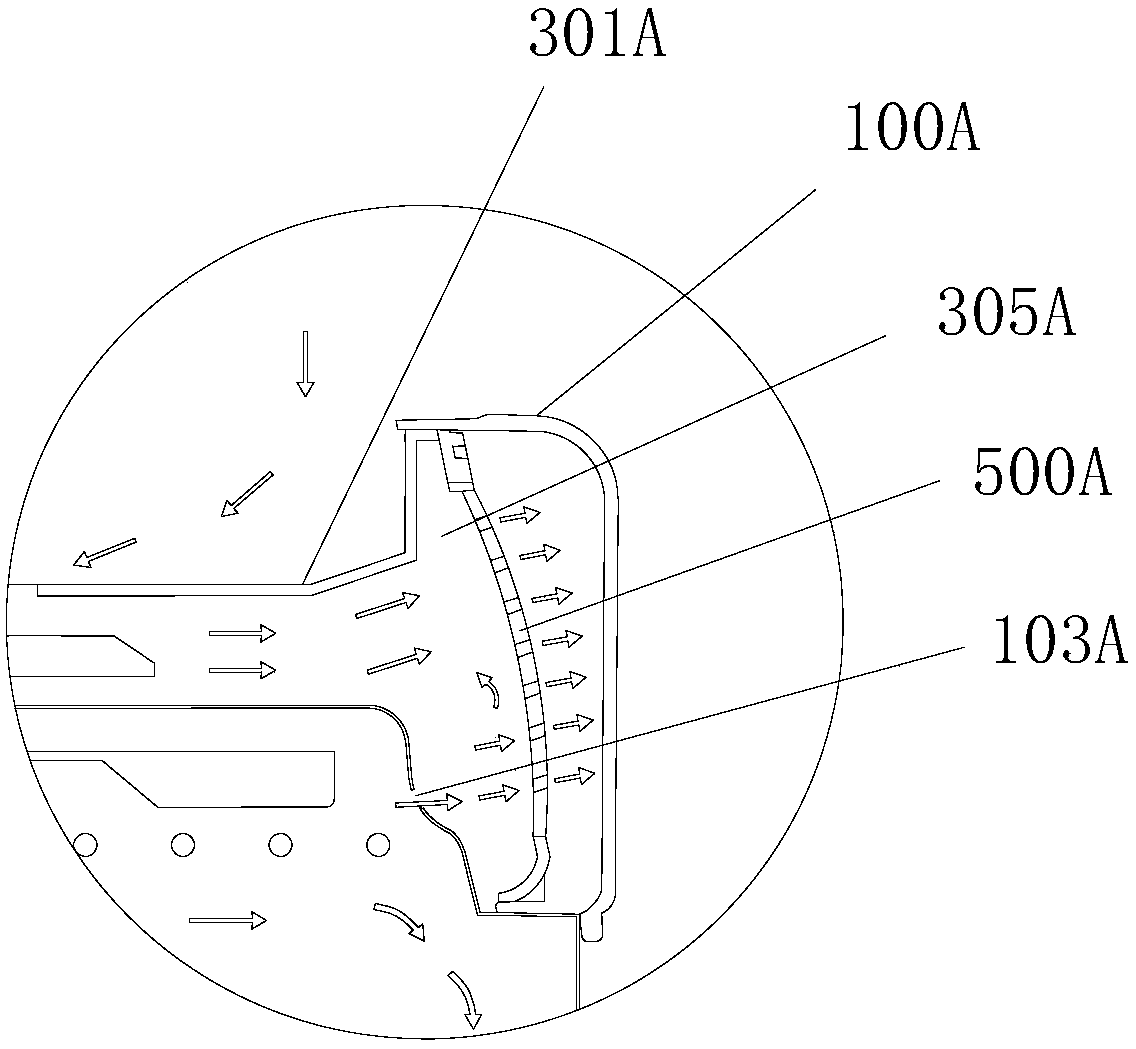

Food cooking equipment

PendingCN108720650AReduce the temperatureSpeed up the flowRoasters/grillsDeep fat fryersCold airWater vapor

The invention provides food cooking equipment which comprises a shell and a cold air through-flow device. The shell is provided with a food cooking chamber, the cold air through-flow device comprisesan air drawing cover with an air drawing port, the air drawing cover is arranged in the shell and arranged on the upper portion of the food cooking chamber, the cold air through-flow device further comprises a motor and an air drawing wheel, the motor is arranged on the outer upper portion of the air drawing cover, the air drawing wheel is arranged inside the air drawing cover, the motor is arranged at the air drawing port and drives the air drawing wheel to rotate, the air drawing cover is provided with an air exhausting channel, the air drawing wheel drives air to flow towards the motor to form cold air flow, and the cold air flow flows into the air drawing cover through the air drawing port and is exhausted from the air exhausting channel. The food cooking chamber is provided with a water vapor exhaust port, the water vapor exhaust port is communicated with the air exhausting channel, and an air distribution device is arranged in the air exhausting channel and at the downstream of the water vapor exhaust port, so that part of high-temperature gas in the water vapor exhaust port changes in the flowing direction. The temperature of the exhausted gas can be effectively reduced.

Owner:FOSHAN SHUNDE KUFU ELECTRIC APPLIANCES CO LTD

Disposable diaper

InactiveCN1496726AThere is no problem of being involved in manufacturing machinery, etc.Smooth preparation processAbsorbent padsHaberdasheryEngineeringMechanical engineering

Owner:UNI CHARM CORP

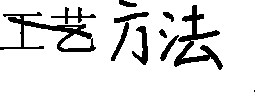

Laryngalgia anti-inflammation traditional Chinese medicinal preparation with improved taste and preparation method thereof

InactiveCN101167770AOvercome the numbnessOvercome bitternessPowder deliveryHydroxy compound active ingredientsToad VenomIrritation

The invention relates to a traditional Chinese medicine medicament for laryngalgia and antiphlogosis and process for preparation. The medicament is prepared by applying fluorescence method and dispersion method, wherein the fluorescence method applies beta-cyclodextrin as main additives and toad venom is processed through fluorescence, and then toad venom inclusion complex, other drugs and additives are prepared into medicament preparation. The dispersion method applies zein, acrylic resin and other slow-release materials, and the toad venom which is prepared into dispersion system, other drugs, and additives are prepared into medicament preparation. The medicament for laryngalgia and antiphlogosis of the invention improves the process of the prior Chinese patent medicament laryngalgia antiphlogistic pills and solves the problem of lasting mouth bitter and tongue mottling taste which is caused by toad venom, and thereby patients are pleasant to accept. Positive significance is achieved by taste masking and correcting to toad venom, and meanwhile laryngeal edema and other adverse effects which are caused by strong stimulation and hypersusceptibility of laryngalgia antiphlogistic pills are overcome.

Owner:CHONGQING PHARMA RES INST

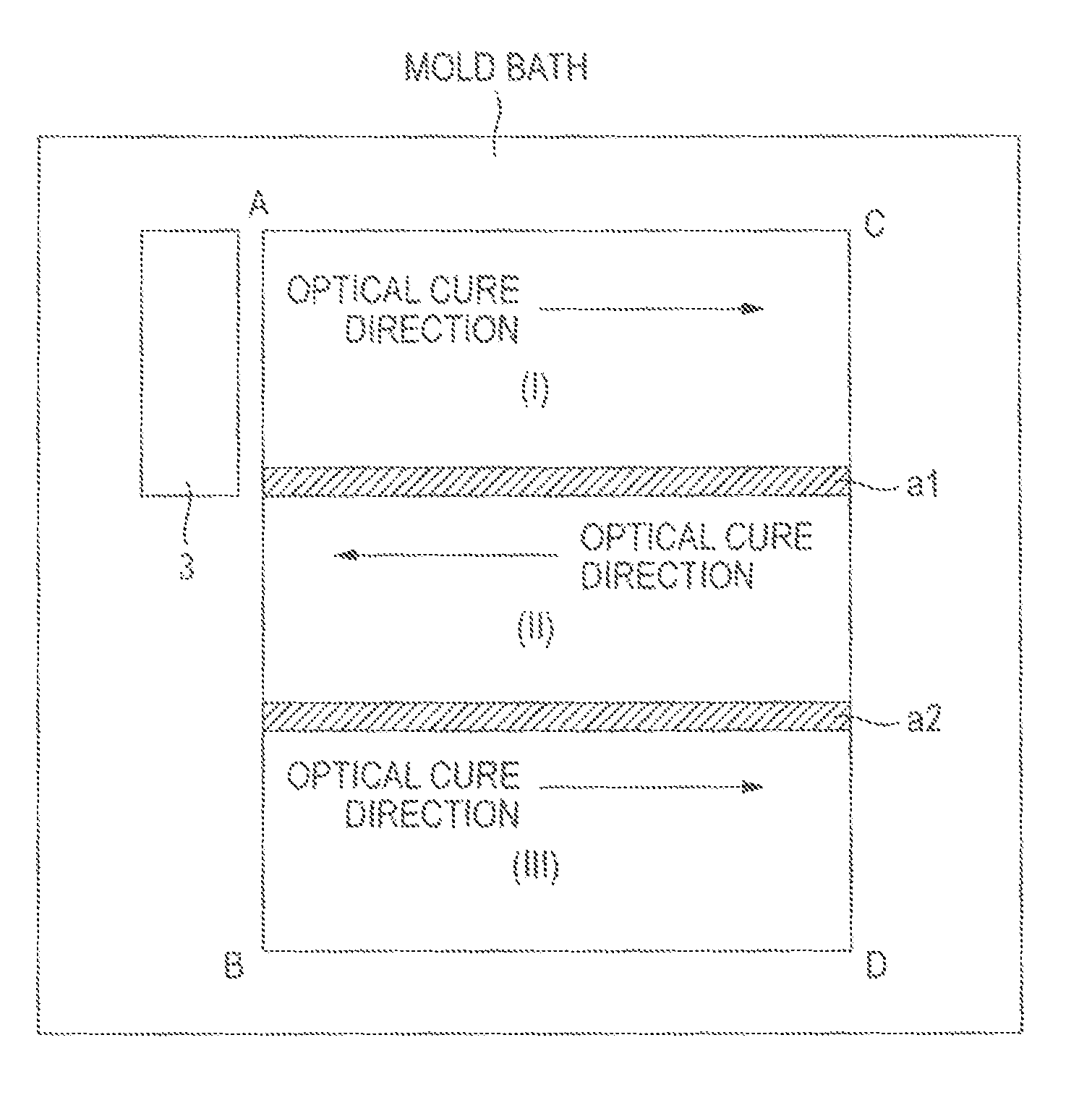

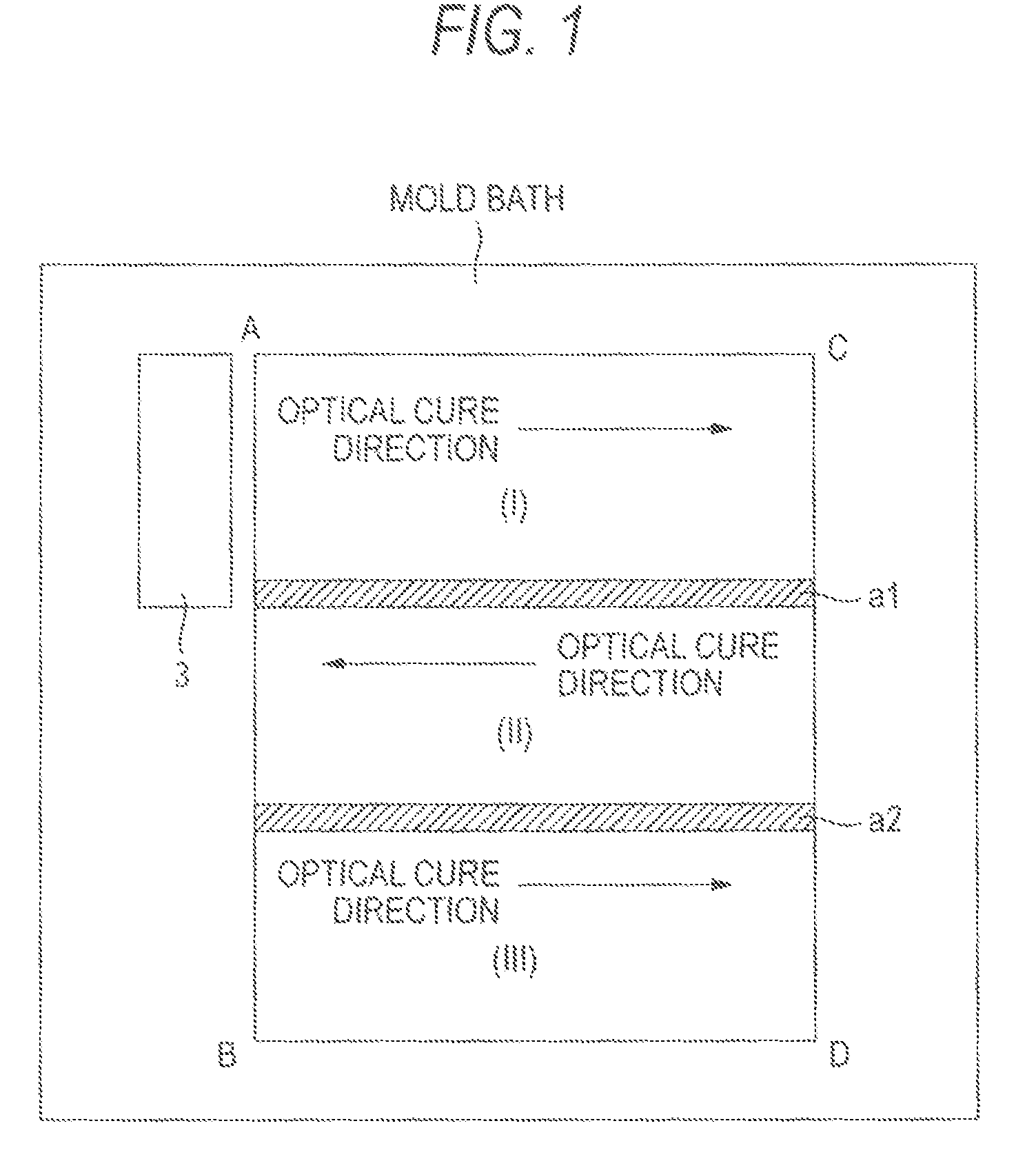

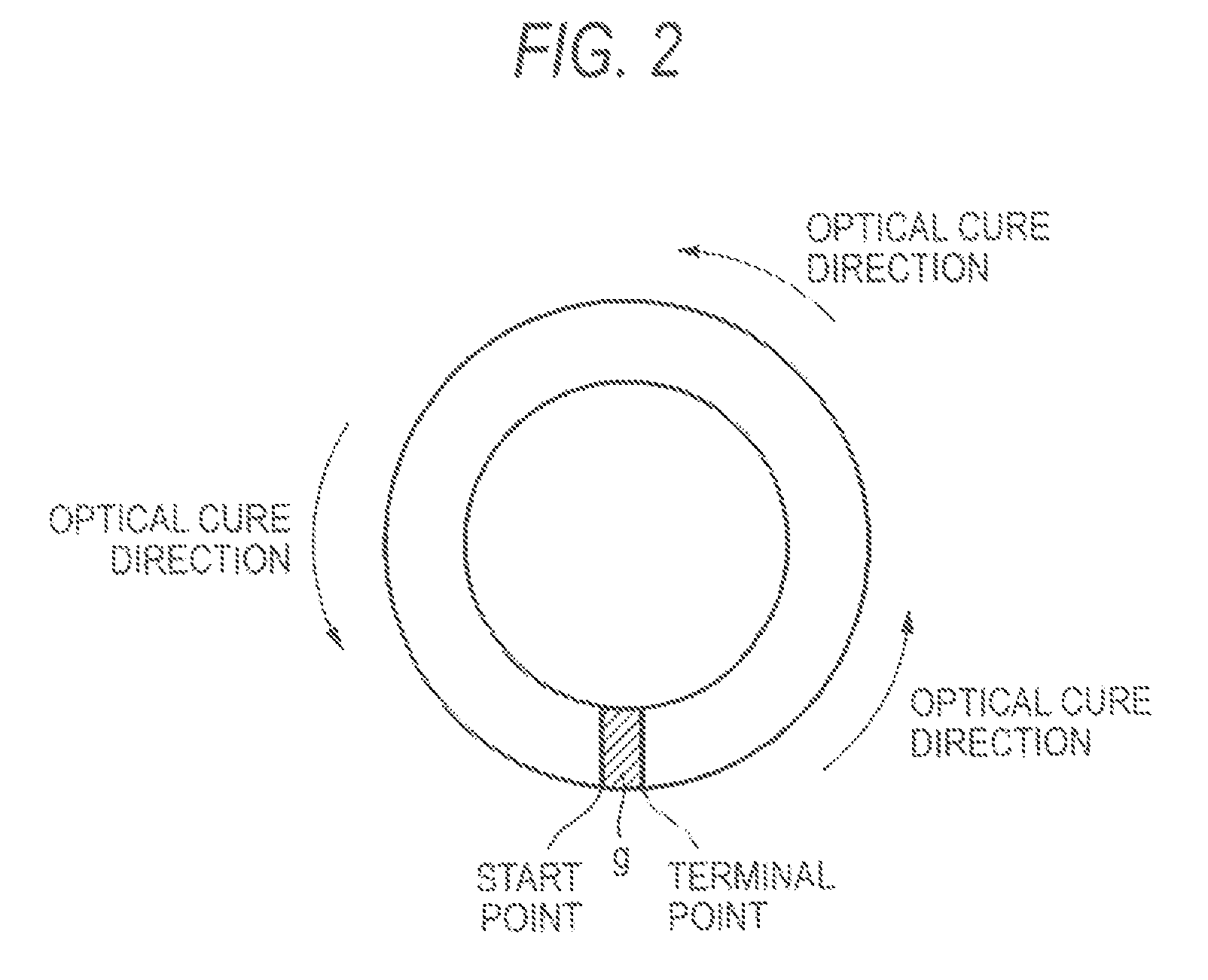

Stereolithographic method and apparatus

ActiveUS7931851B2Increase production capacityHigh rateAdditive manufacturing apparatusAuxillary shaping apparatusSynchronismPhysics

A method and an apparatus includes using a planar plotting mask which can continuously change a mask image; continuously moving the planar plotting mask with reference to the surface of the photocurable resin composition and exposing the surface of a photocurable resin composition to light by way of the planar plotting mask while continuously changing a mask image of the planar plotting mask in accordance with a cross-sectional profile pattern of an optically-cured resin layer to be formed and in synchronism with movement of the planar plotting mask, to thus form an optically-cured resin layer having a predetermined cross-sectional profile pattern; and performing building operation such that boundary areas among adjacent plotted areas in the optically-cured resin layer become unnoticeable in a finally-obtained stereolithographic three-dimensional object.

Owner:NABLESCO CORP

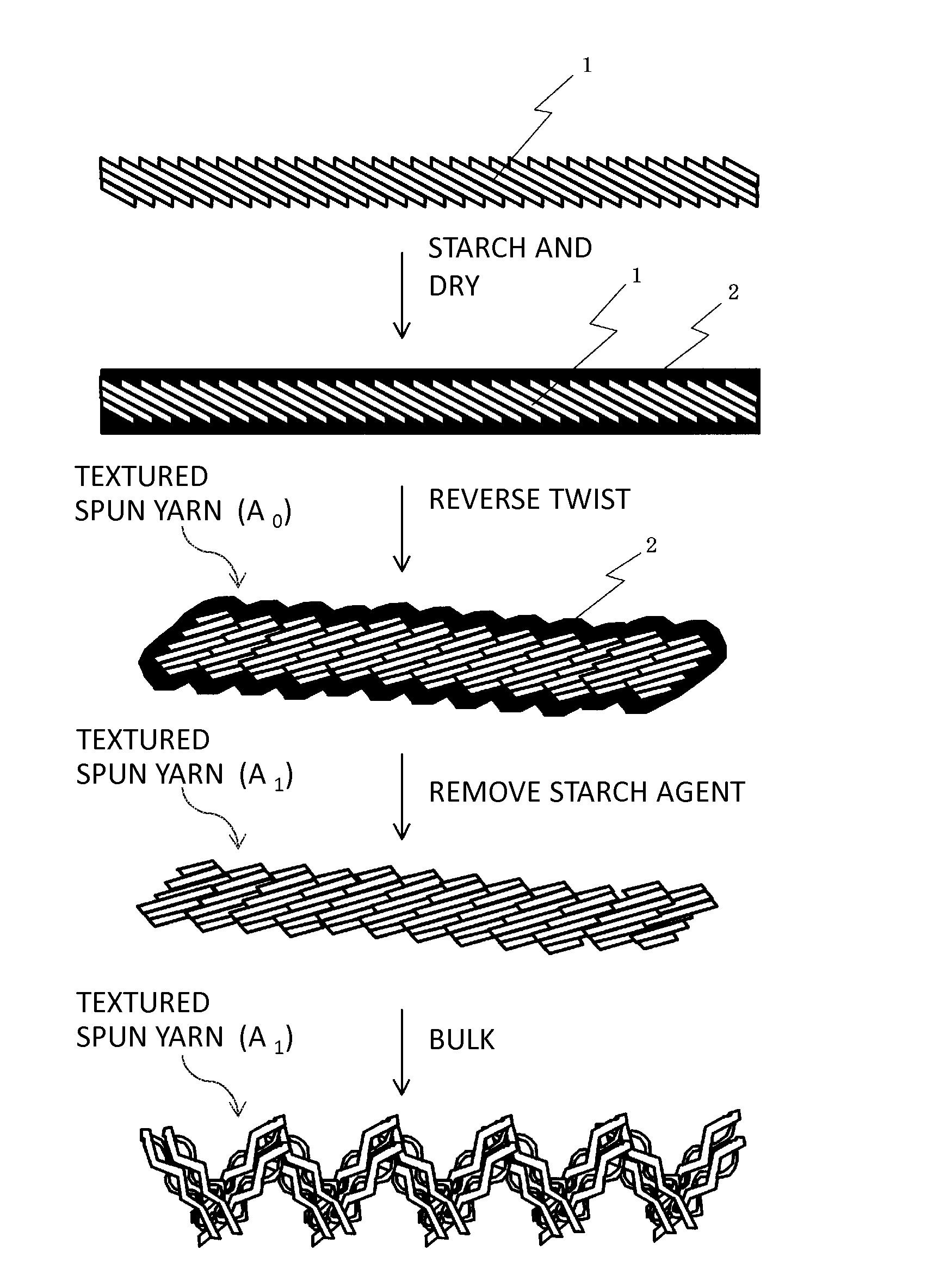

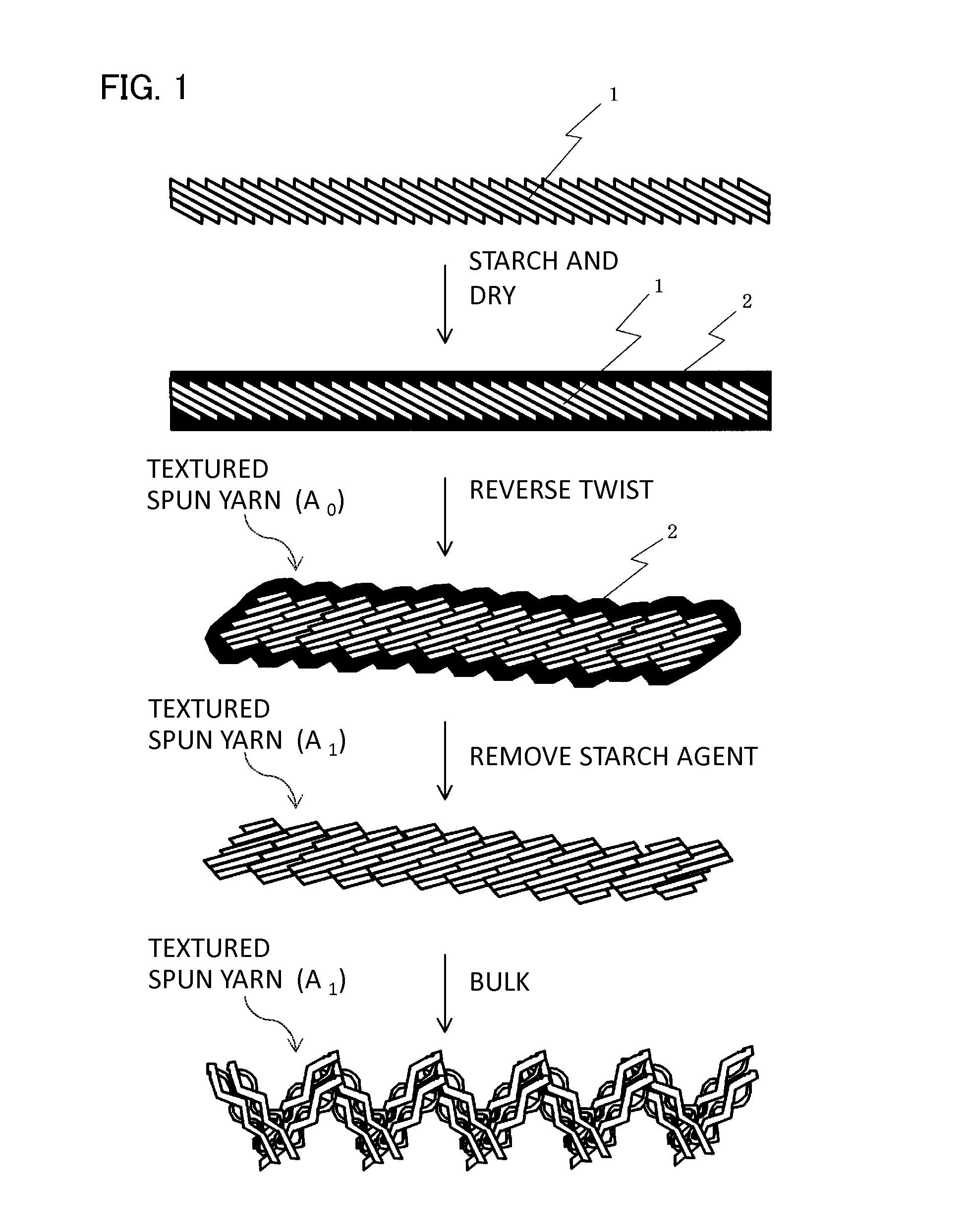

Textured spun yarn and woven or knitted fabric using same

ActiveUS20150068000A1Improve textureImprove breathabilityWeft knittingFibre treatmentYarnEngineering

Provided are a textured spun yarn (A0) obtained by twisting a starched and dried single spun yarn in the opposite direction to the twisting direction of the single spun yarn by the number of twists which is 1.3 to 3 times the number of twists of the single spun yarn, a textured spun yarn (A1) obtained by removing a starch agent in water from the textured spun yarn, a woven or knitted fabric obtained by dissolving and removing the starch agent in water from a woven or knitted fabric manufactured using the textured spun yarn (A0), and a woven or knitted fabric manufactured using the textured spun yarn (A1), and methods of manufacturing them.

Owner:ASANONENSHI CO LTD

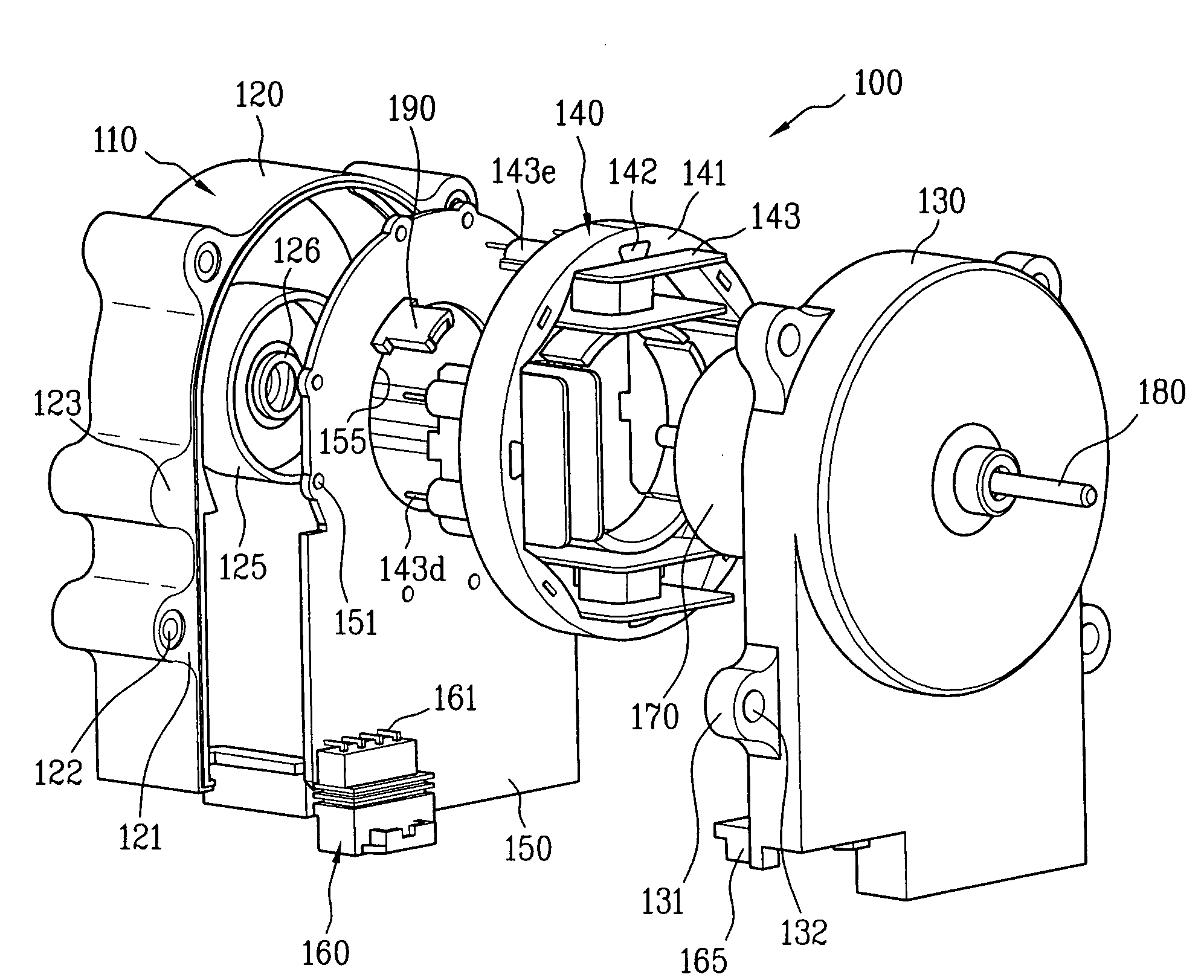

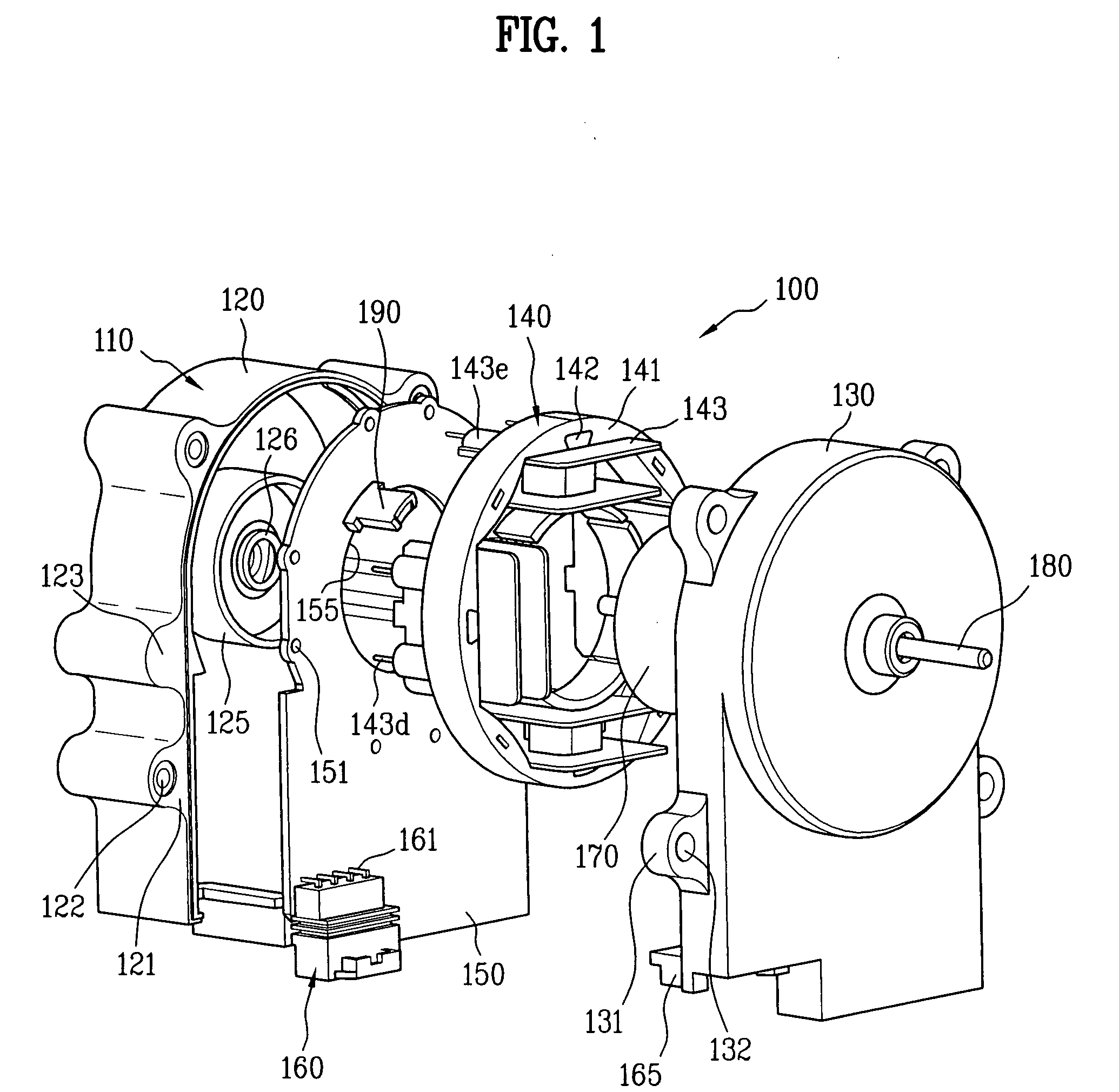

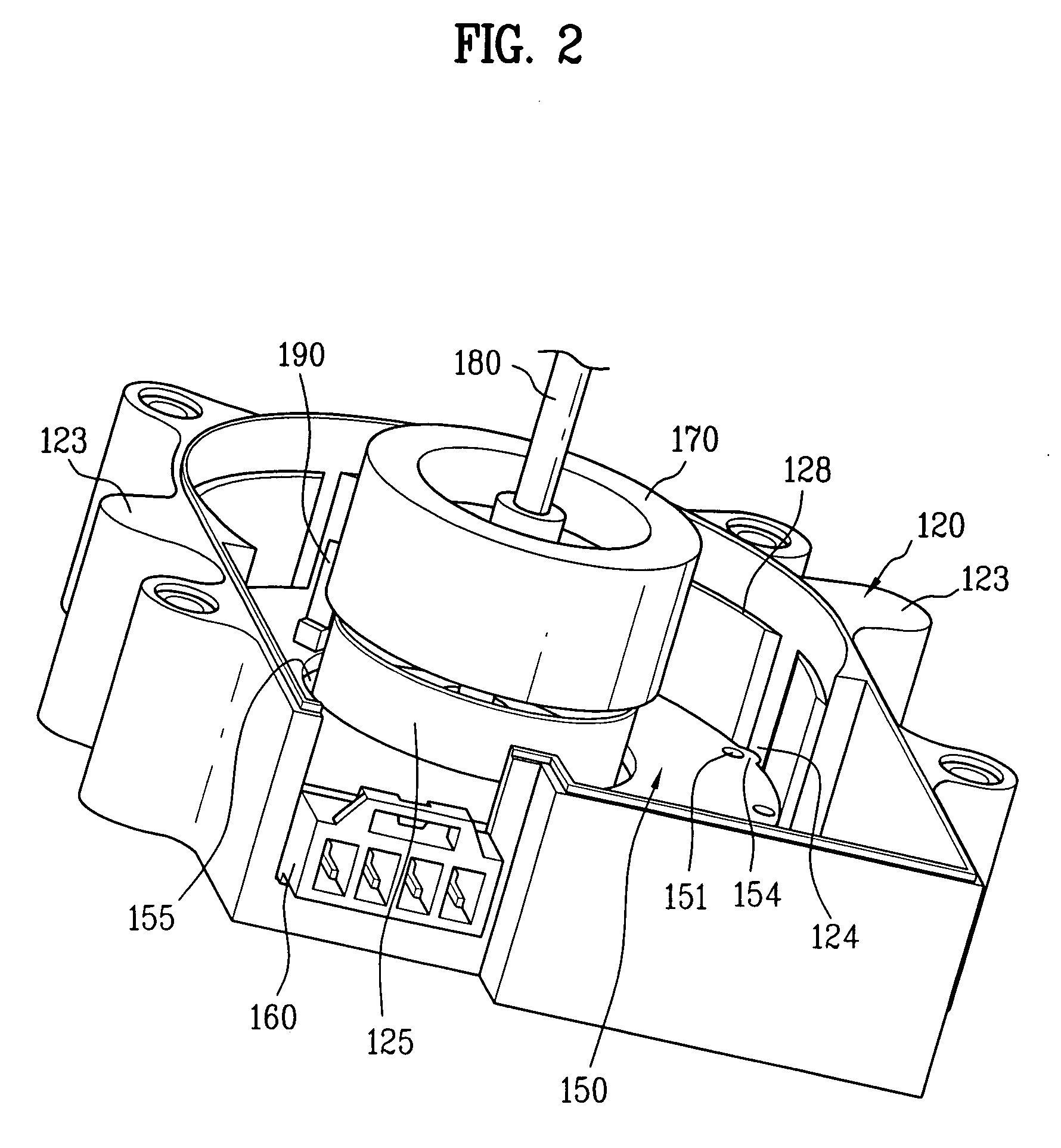

Motor

InactiveUS20080136287A1Smooth preparation processReduced space required for installationAssociation with control/drive circuitsWindingsStatorEngineering

A motor includes a stator core that forms a magnetic path and has a plurality of tooth parts along a circumferential direction; a tooth provided in each tooth part to wind a coil there around; and an extension part alternated with the tooth part along a circumferential direction of the stator core, convexly extending to an inner radial direction.

Owner:LG ELECTRONICS INC

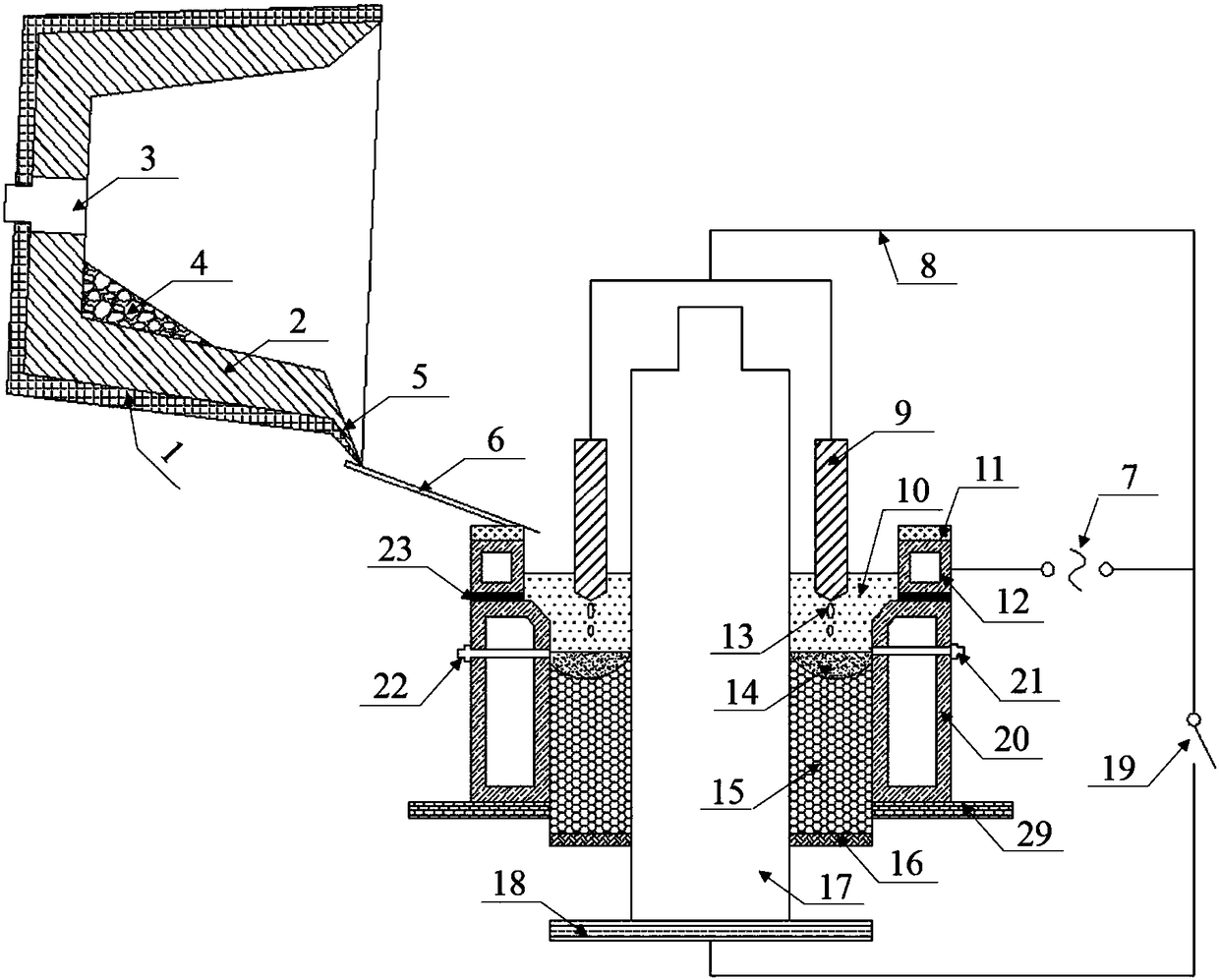

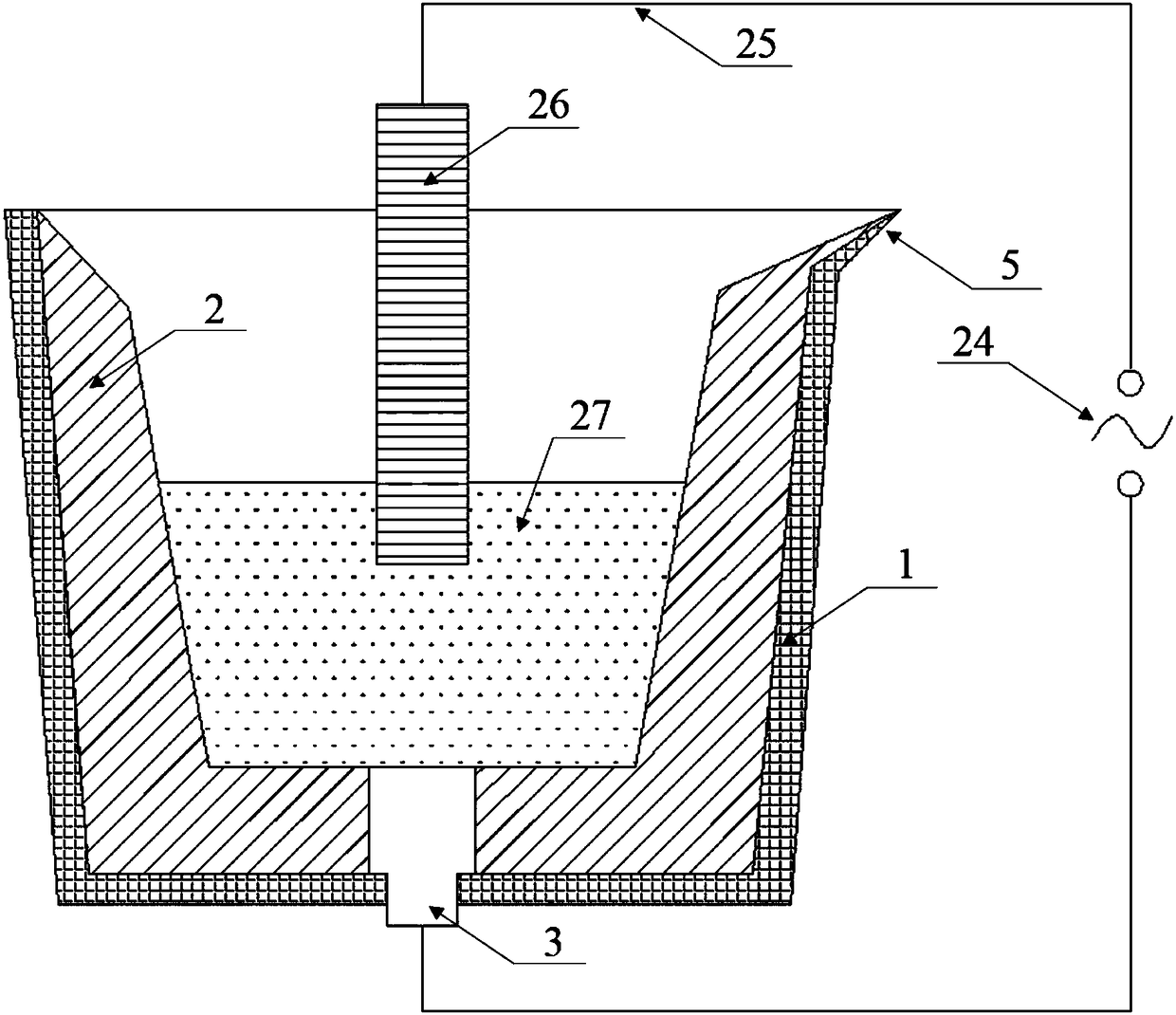

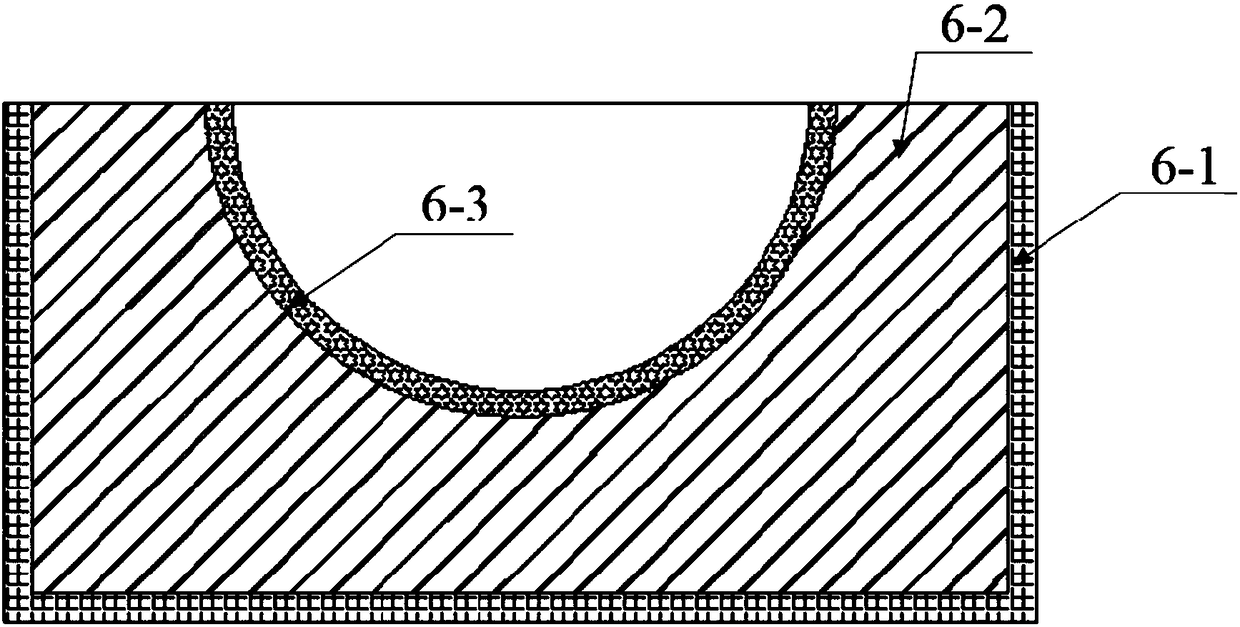

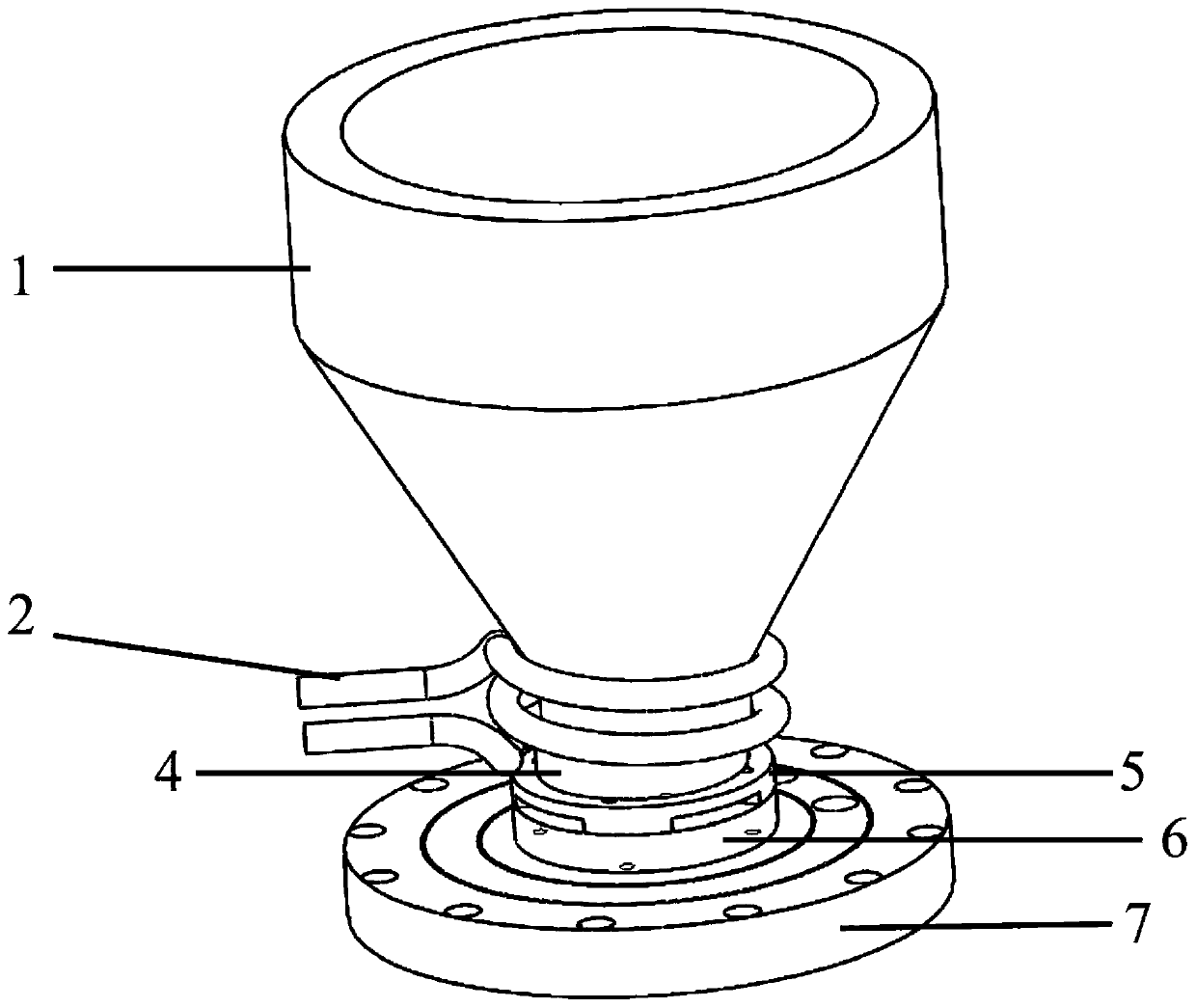

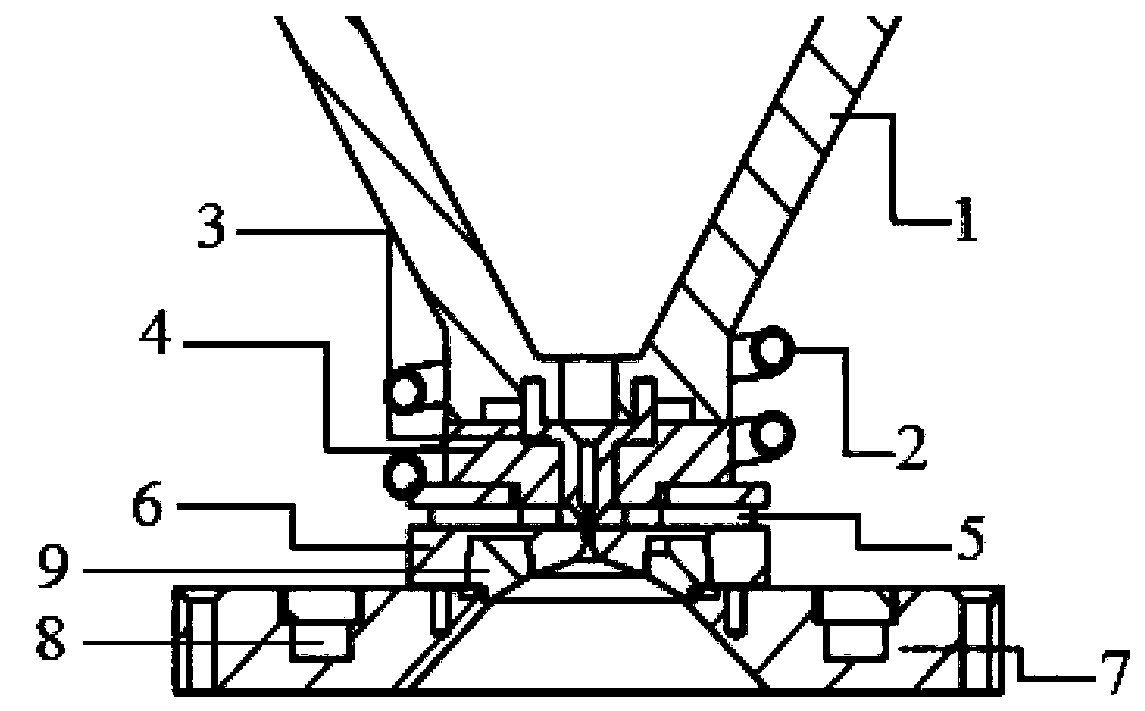

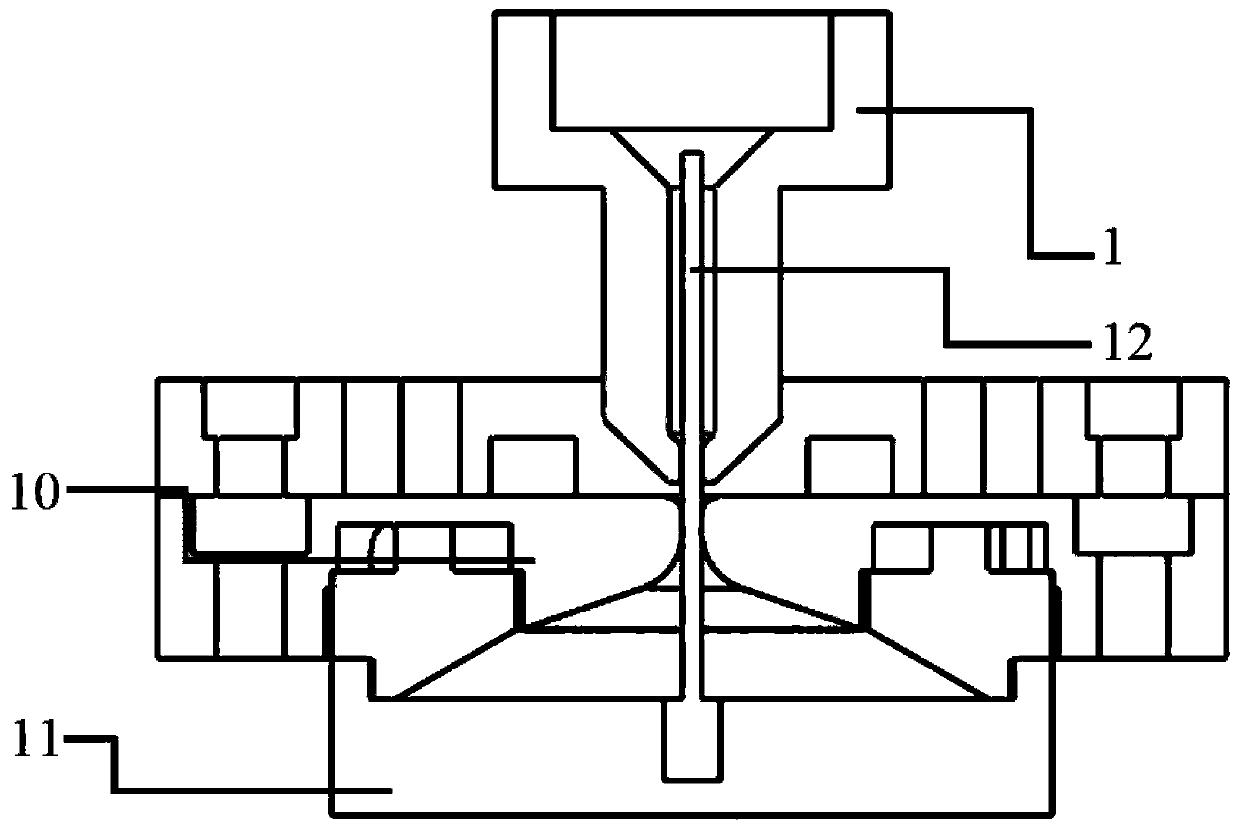

Metal powder preparation device

The invention discloses a metal powder preparation device which comprises a tundish insulation crucible, a diversion pipe, an atomizing nozzle and an atomizing spray tray which are connected in sequence. A bulge part is arranged at the top end of the diversion pipe, a sunken part corresponding to the bulge part is arranged at the bottom end of the tundish insulation crucible, and the bulge part is buckled with the sunken part. An insulation graphite sleeve is arranged on the diversion pipe in a sleeved mode, and the diversion pipe is fixedly connected with the insulation graphite sleeve. The insulation graphite sleeve is wound with a heating induction coil, the heating induction coil is a copper pipe, and the outer wall of the heating induction coil is wrapped with an insulating layer. One end of the heating induction coil is connected with a water inlet pipe, and the other end of the heating induction coil is connected with a water outlet pipe. The heating induction coil is connected with an alternating power supply. An air distributing ring is arranged on the diversion pipe in a sleeved mode, an air outlet of the air distributing ring communicates with an air inlet of the atomizing nozzle, and the atomizing nozzle is fixedly connected with the air distributing ring. A first water cooling channel is formed in the atomizing spray tray, and a second water cooling channel is formed in the atomizing nozzle. The metal powder preparation device can ensure the smooth preparation of metal powder.

Owner:SHANGHAI UNIV

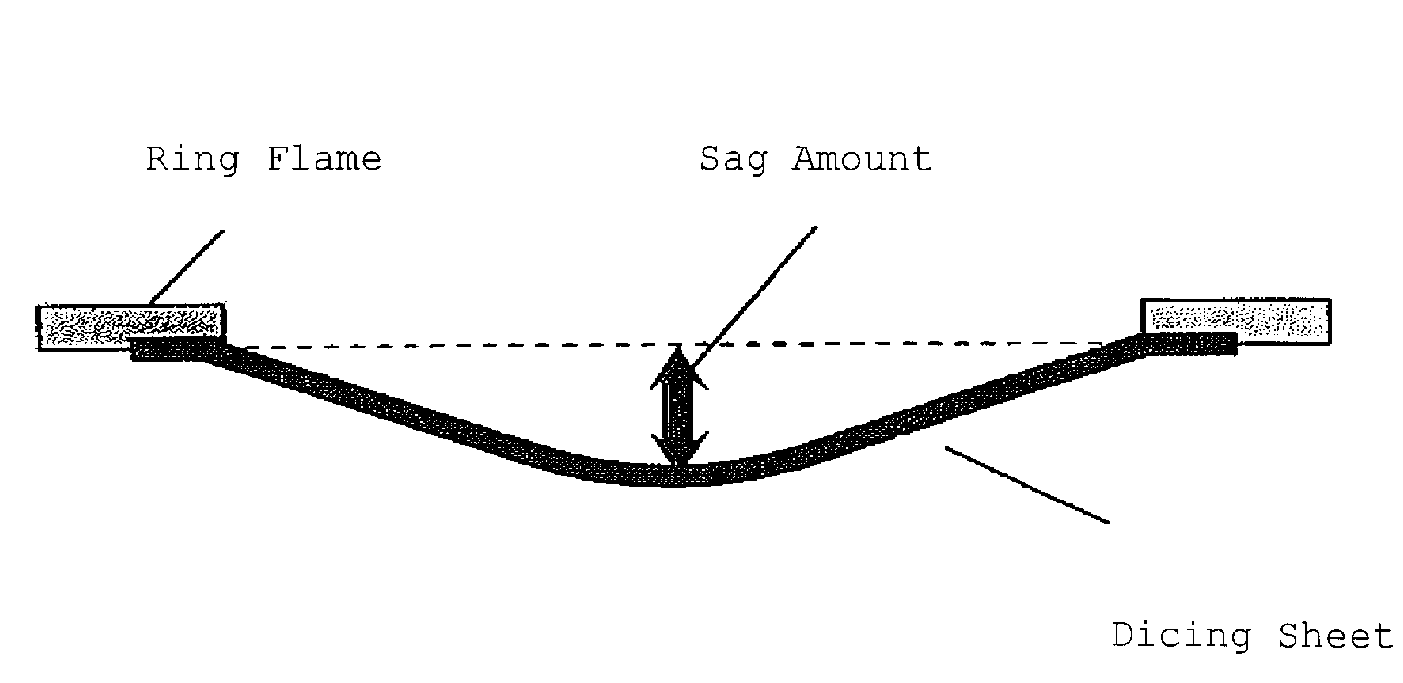

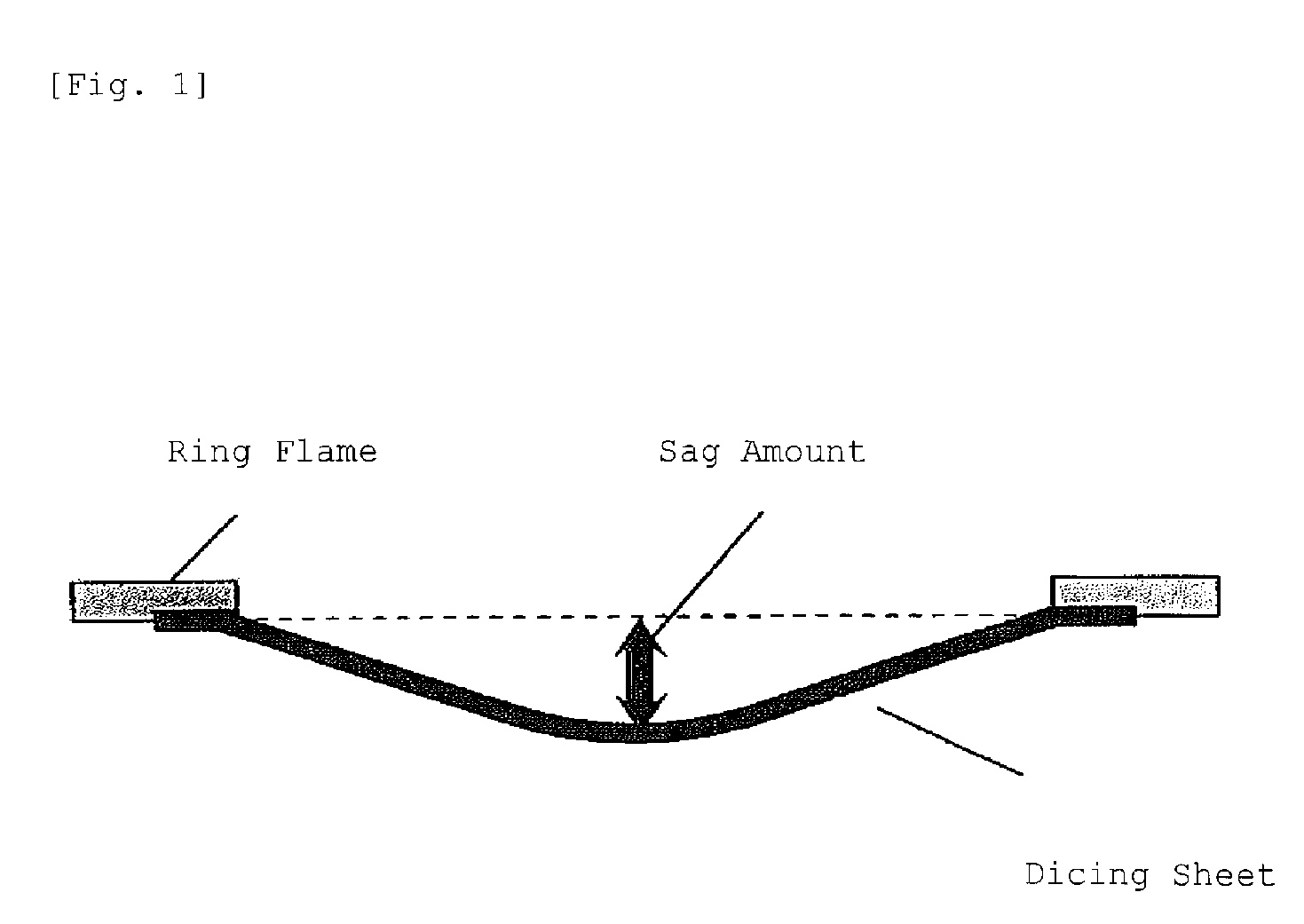

Laser dicing sheet and process for producing chip body

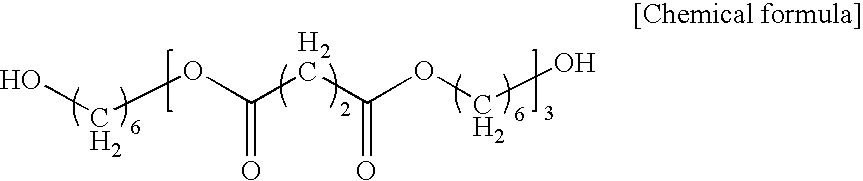

ActiveUS20080190904A1Reduce the amount of lightGuaranteed uptimeFilm/foil adhesivesSynthetic resin layered productsUrethane acrylateEngineering

An object of the present invention is to provide a laser dicing sheet which is capable of preventing cutting of dicing sheet by laser beam, damage of the chuck table and fusion of the dicing sheet to the chuck table.A laser dicing sheet according to the present invention comprising a base material comprising a polyurethane acrylate; and an adhesive layer formed on one surface thereof.

Owner:LINTEC CORP

Method for preparing highly filled polyvinyl chloride or polyolefin composite material from industrial solid waste

The invention discloses a method for preparing a high filling polyvinyl chloride or polyolefin composite material by employing industrial solid wastes and belongs to the field of chemical materials. According to the method, the industrial solid wastes and polyvinyl chloride or polyolefin serve as main raw materials, the industrial solid wastes are subjected to surface modification, the compatibility between the industrial solid wastes and the polyvinyl chloride or polyolefin is improved, the liquidity and processability of the composite material is improved by utilizing a compound plastifier, and the composite material is subjected to mixing and pelleting under the coaction of a proper amount of aids, so that the high filling polyvinyl chloride or polyolefin composite material is prepared. The method is simple in process, low in cost and high in additional value of products. The composite material has the characteristics of high filling amount of industrial solid wastes, enough strength and toughness, environment friendliness, stable performance and the like and can be widely applied to preparing green building materials and advanced engineering products in various fields of national economy.

Owner:TSINGHUA UNIV

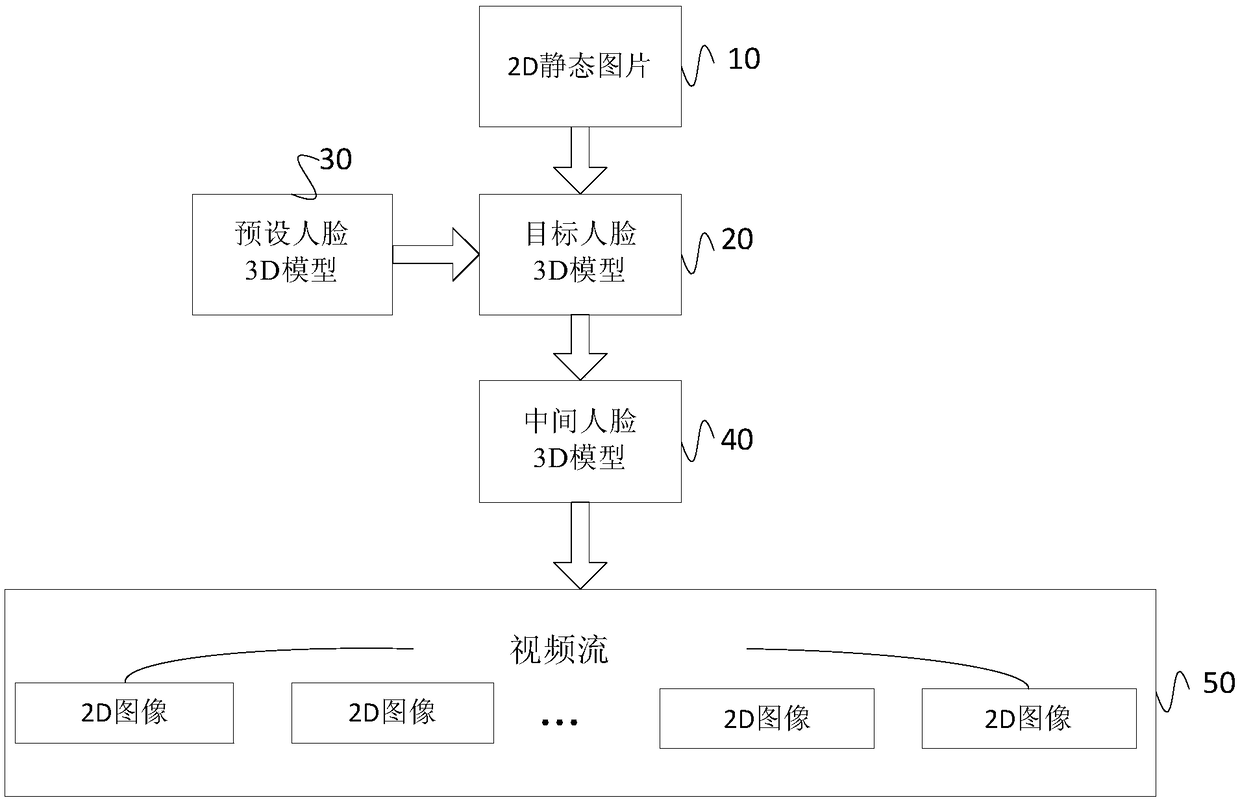

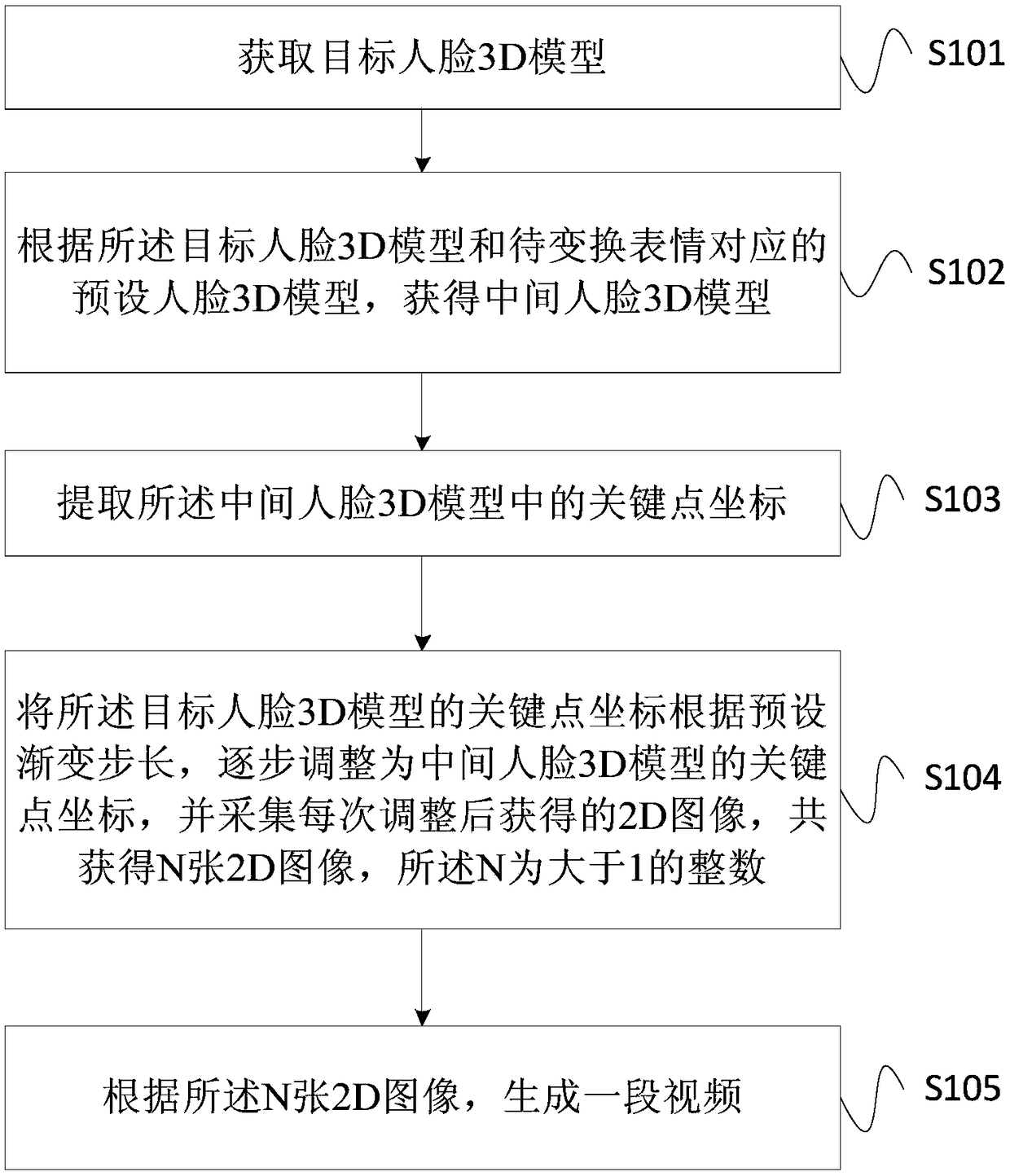

Video generation method, device, apparatus, and storage medium

PendingCN109064548ASmooth preparation processImprove the efficiency of video productionAnimationAcquiring/recognising facial featuresComputer graphics (images)Video based

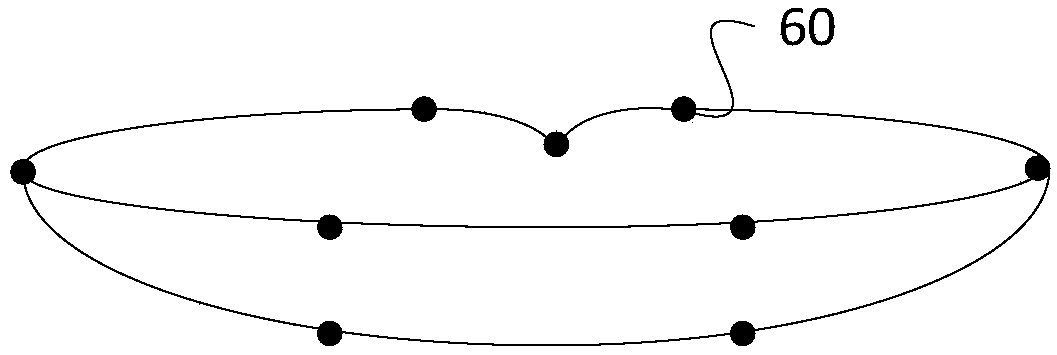

The invention provides a video generation method, a device, a device and a storage medium. The method comprises: obtaining an intermediate human face 3D model according to the target human face 3D model and a preset human face 3D model corresponding to the expression to be transformed, wherein the expression to be transformed is any one of a plurality of expressions; Extracting coordinates of keypoints in the intermediate human face 3D model; The coordinates of the key points include: a part of coordinates of a facial five-feature contour; The coordinates of key points of the target face 3D model are gradually adjusted to the coordinates of key points of the intermediate face 3D model according to a preset gradual change step size, and 2D images obtained after each adjustment are collected to obtain N 2D images, wherein N is an integer greater than 1; A video is generated from the N 2D images. The invention can realize the production of smooth video based on fewer static 2D diagrams,improves the production efficiency of the video, and can produce the expression change video of any static face.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

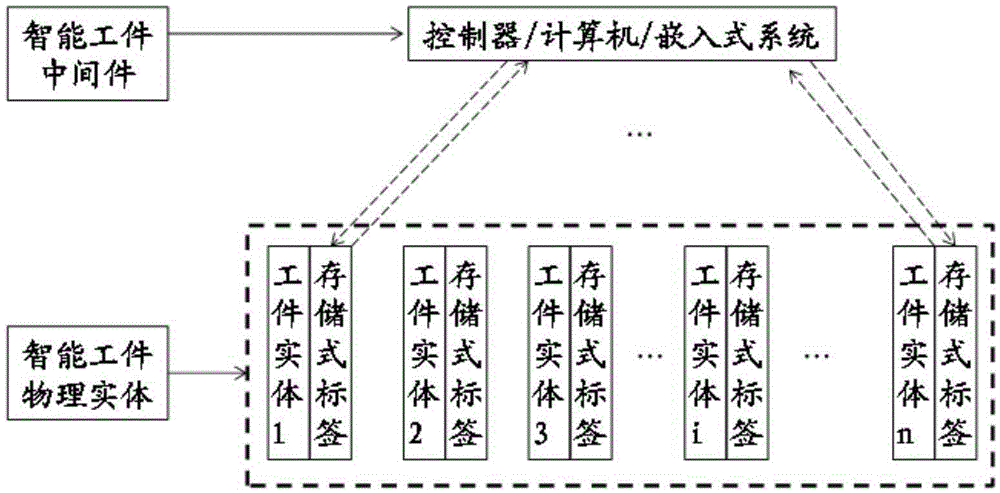

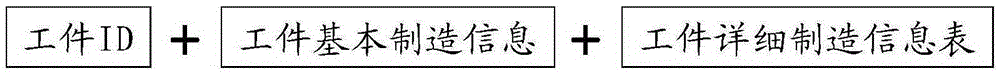

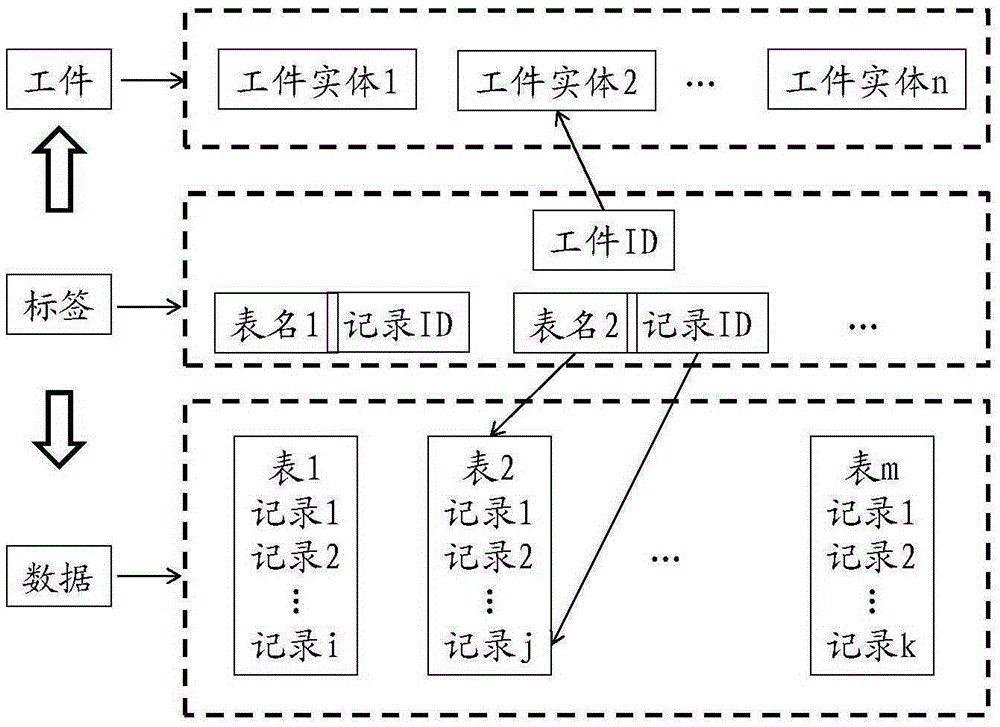

Method for realizing intelligent manufacturing system by using memory type RFID tags

InactiveCN105389610ASmooth preparation processShorten access timeRecord carriers used with machinesMemory typeIntelligent manufacturing system

A method for realizing an intelligent manufacturing system by using memory type RFID tags includes the following steps of: storing an ID code of a work piece, basic manufacturing information of the work piece, and detailed manufacturing information of the work piece into each memory type RFID tag; establishing a dynamic mapping relationship between each intelligent work piece and an intelligent manufacturing system data base through each memory type RFID tag; physically binding the memory unit memory type RFID tag of each intelligent work piece and a corresponding work piece entity to realize that each intelligent work piece has an independent memory unit; and finally realizing intellectualization of a manufacturing unit and intellectualization of a conveying device. According to the invention, intellectualization of the work pieces can be realized through the memory type RFID tags, and a work piece manufacturing process can be smooth in a manufacturing environment without network; and meanwhile, in the manufacturing process, the work pieces and the manufacturing system can perform a negotiation and dynamically adjust the manufacturing process.

Owner:XI AN JIAOTONG UNIV

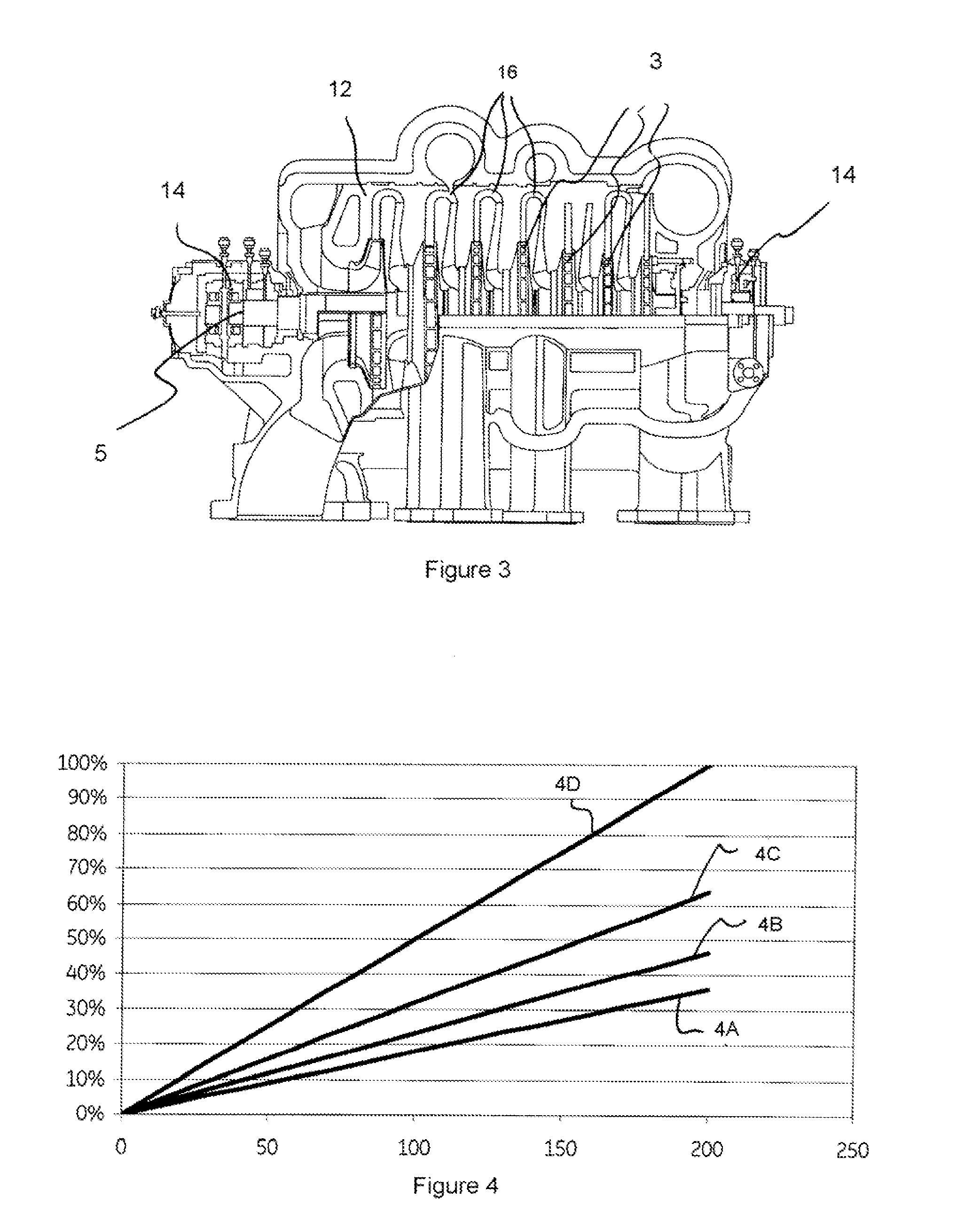

Production method of a coating layer for a piece of turbomachinery component, the component itself and the corresponding piece of machinery

InactiveUS20110014059A1Convenient coatingReduce the total massLiquid surface applicatorsPropellersImpellerTurbine wheel

Owner:NUOVO PIGNONE SPA

Laser Dicing Sheet and Manufacturing Method For Chip Body

InactiveUS20090261084A1Reduce the amount of lightGuaranteed uptimeElectric heatingSolid-state devicesEngineeringAcrylate ester

An object of the present invention is to provide a laser dicing sheet which is capable of preventing cutting of dicing sheet by laser beam, damage of the chuck table and fusion of the dicing sheet to the chuck table.A laser dicing sheet according to the present invention comprising a base material comprising a polyurethane acrylate; and an adhesive layer formed on one surface thereof.

Owner:LINTEC CORP

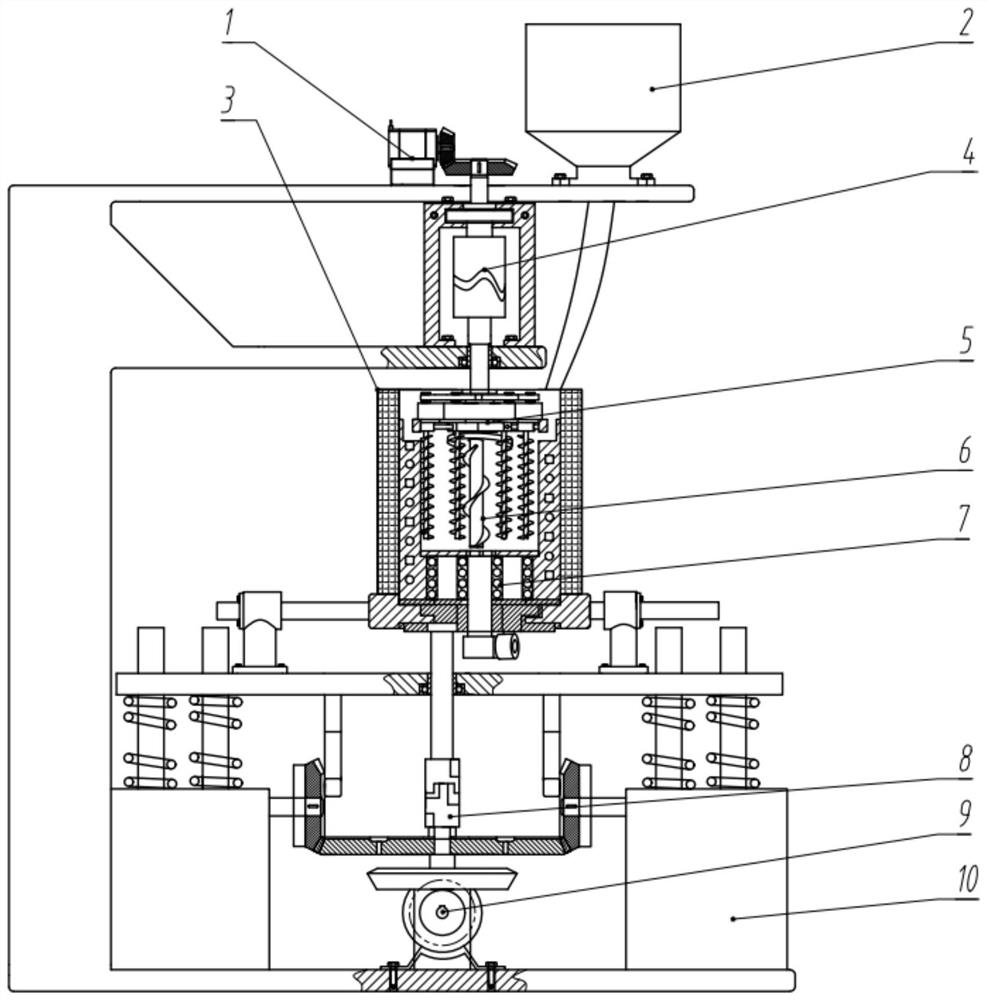

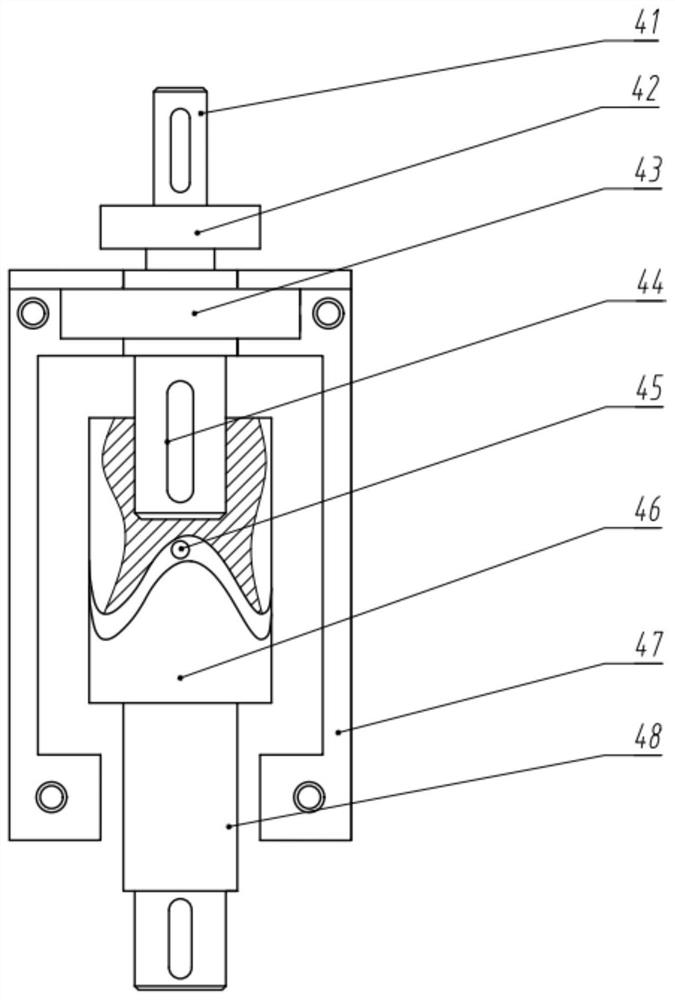

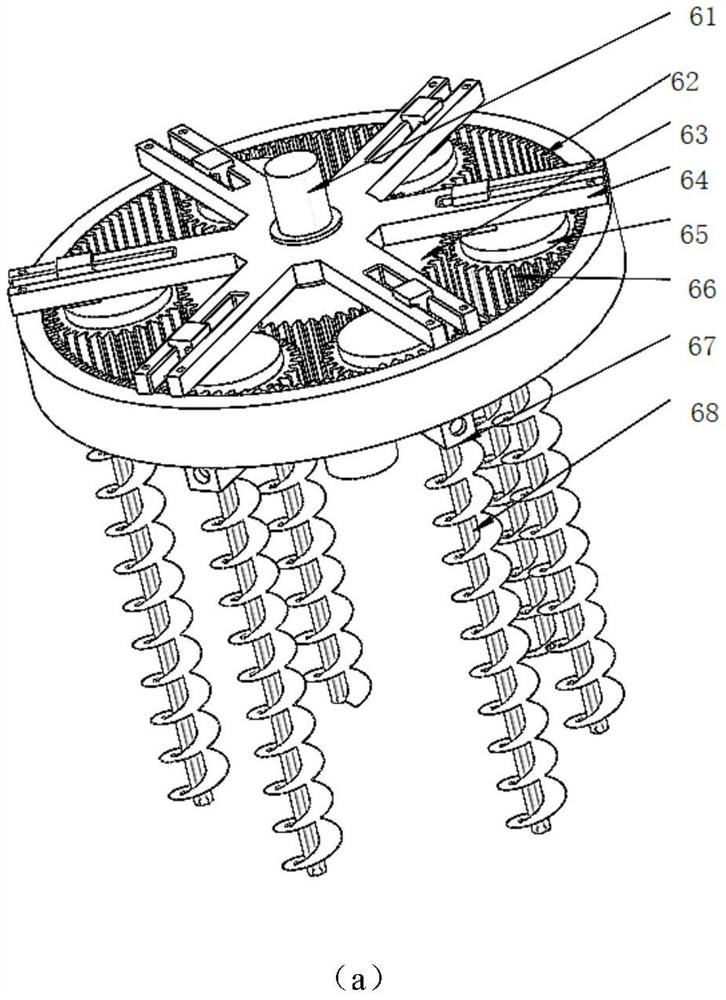

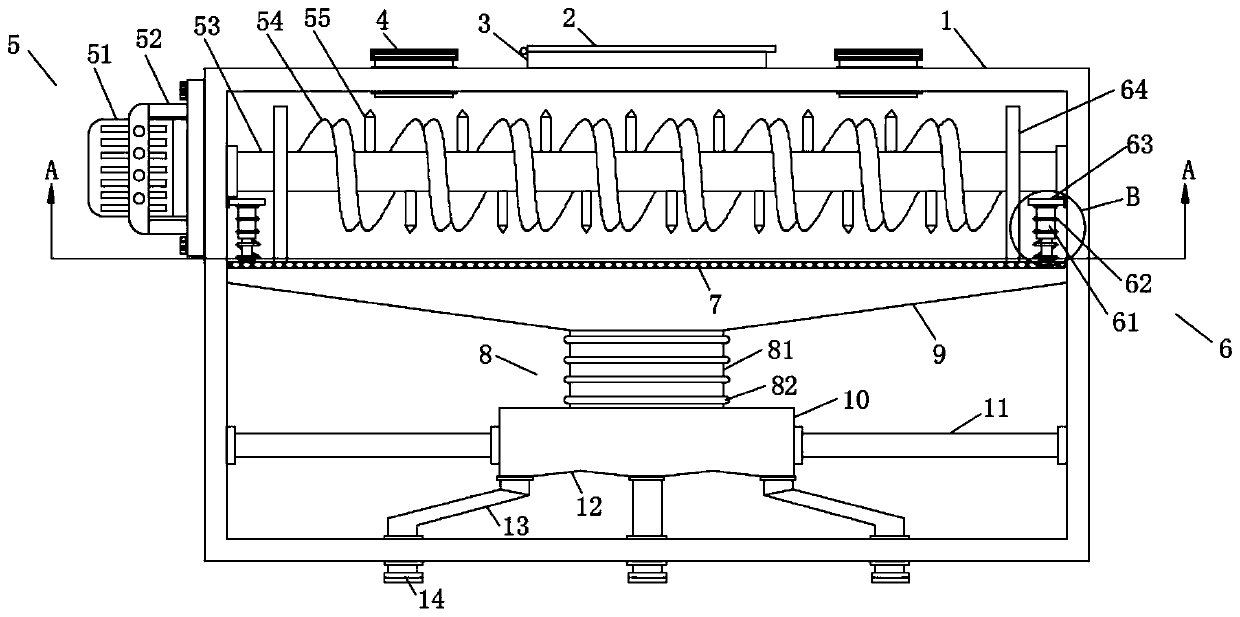

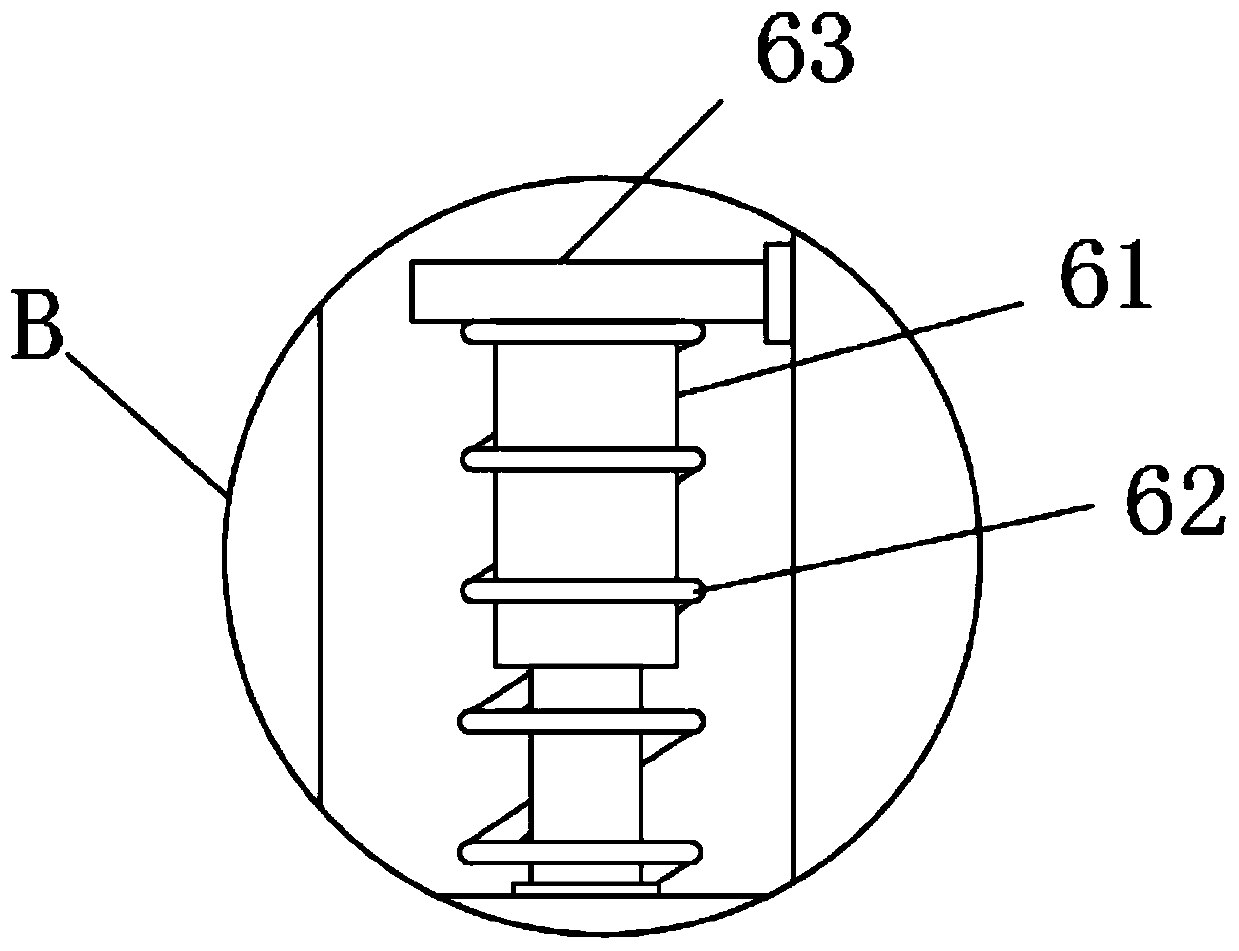

Rotary vibration coupling stirring device for preparing semi-solid slurry

PendingCN111889644AImprove efficiencyQuality improvementStirring devicesReciprocating motionRotational vibration

The invention discloses a rotary vibration coupling stirring device for preparing semi-solid slurry. The rotary vibration coupling stirring device comprises a first power system, a stirring vibrationdevice, a stirring disc inner layer stirring device, a material barrel, a stirring rotary vibration device, a material barrel rotary vibration device, a second power system and a support. According tothe rotary vibration coupling stirring device for preparing the semi-solid slurry, the stirring vibration device can enable a stirring rod to realize reciprocating motion in the Y direction while stirring, so that axial shearing force is generated; when the stirring rotary vibration device is used for stirring slurry in the stirring rod, reciprocating motion is generated in the X direction to form radial shear force; the material barrel rotary vibration device can drive the material barrel to rotate and generate reciprocating motion in the X direction and the Y direction at the same time, sothat the whole slurry rotates and vibrates; and under the combined action of the three devices as well as the local and overall organic combination, the slurry is stirred more thoroughly, and the efficiency and quality of preparing the semi-solid slurry of the metal and the alloy are improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

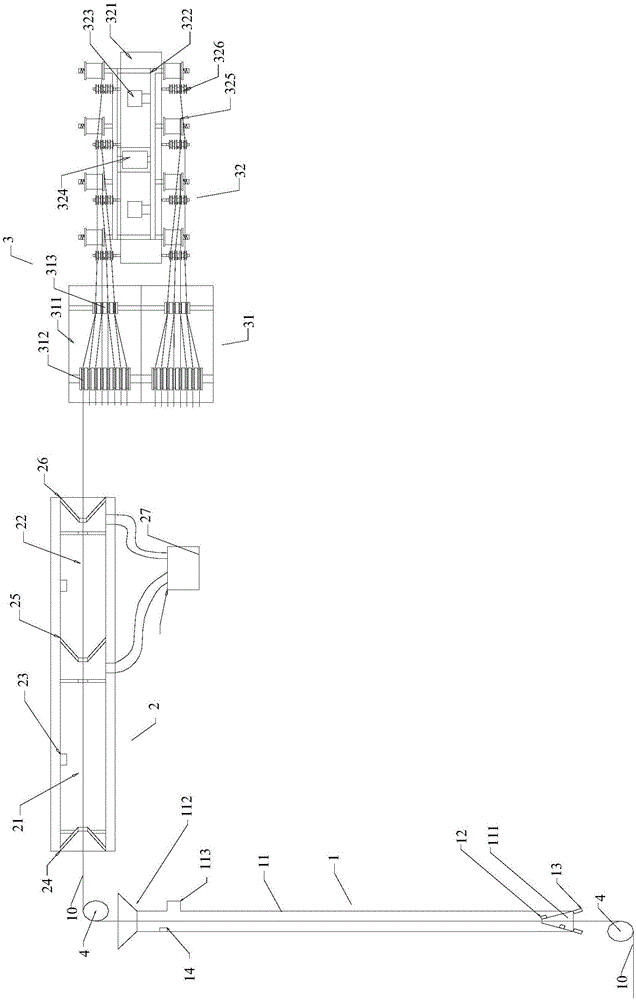

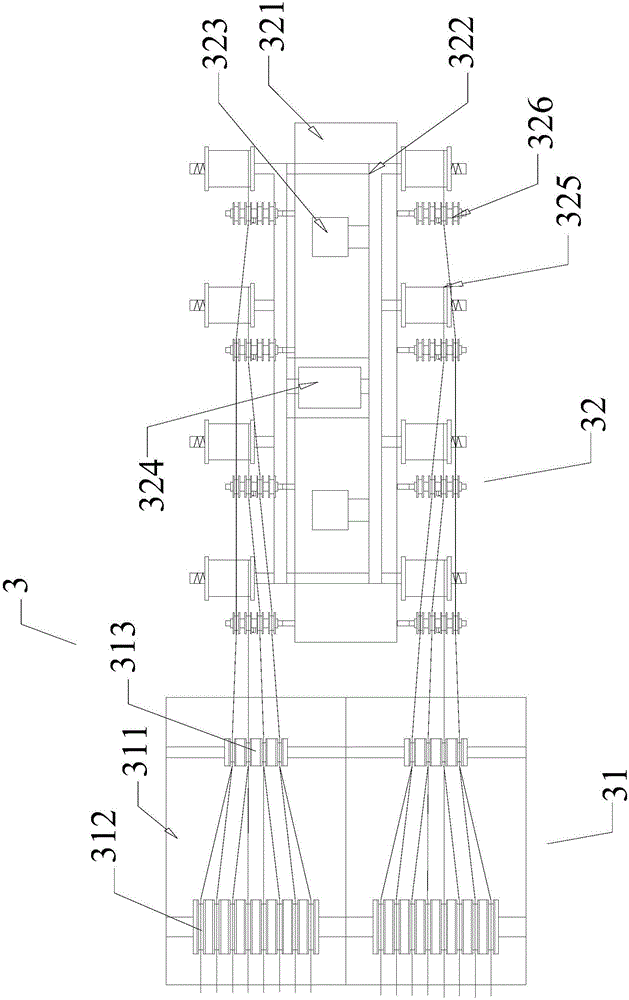

Preparing device for strengthening core

The invention provides a preparing device for a strengthening core. The preparing device comprises a gluing device, a heating curing device, a winding mechanism and a drive device. The gluing device is provided with containing space, an inlet and an outlet, and the inlet and the outlet communicate with the containing space. Glue is contained in the containing space. The gluing device is used for conducting liquid coating on the strengthening core entering the containing space from the inlet and moving out from the outlet. The heating curing device is used for conducting heating curing on the glued strengthening core, and the strengthening core with a protection layer is formed. The winding mechanism is used for winding the strengthening core with the protection layer. The drive device is connected with the strengthening core and used for driving the strengthening core to sequentially penetrate the gluing device and the heating curing device, and then the strengthening core with the protection layer is wound through the winding mechanism. The structure is simplified, labor force is reduced, time is saved, the production efficiency is improved, the product quality is improved, and glue waste is reduced.

Owner:SUZHOU ZHENRUICHANG MATERIAL TECH CO LTD

Molten iron pure spray particle magnesium desulfurization spray gun with vaporizing chamber in spearhead and preparation method of molten iron pure spray particle magnesium desulfurization spray gun

The invention discloses a molten iron pure spray particle magnesium desulfurization spray gun with a vaporizing chamber in a spearhead. The molten iron pure spray particle magnesium desulfurization spray gun comprises a connecting flange, a gun-barrel and a spearhead blowing vaporizing chamber, which are sequentially connected and communicated with each other, wherein the spearhead blowing vaporizing chamber is sequentially composed of a vaporizing chamber bell jar, an anchoring part group and a refractory castable lining from inside to outside; a bottom skirt is arranged at the lower end of the vaporizing chamber bell jar; and a plurality of air outlets are evenly formed in the bottom skirt in an emission shape. The method comprises the following steps: selecting a metal material to process and fabricate each component of the spray gun and removing rust for later use according to structural parameters of the spray gun; sequentially preparing a gun core and the vaporizing chamber bell jar; connecting the gun core and the vaporizing chamber bell jar by welding; and welding a reinforcing rib plate in a gap among the lower end of the gun core, the top of the vaporizing chamber bell jar and the refractory castable lining; and finally welding the anchoring part group, and pouring to obtain the spray gun. Compared with a conventional vaporizing chamber spray gun, the molten iron pure spray particle magnesium desulfurization spray gun disclosed by the invention has the advantages of being simple in structure, stable to blow, low in cost, efficient in desulfurization, long in service life and the like.

Owner:武汉钢铁有限公司

Distributing device for additive manufacturing equipment

ActiveCN111546634AAvoid cloggingSmooth preparation processSievingScreeningMechanical engineeringAdditive layer manufacturing

The invention discloses a distributing device for additive manufacturing equipment. The distributing device comprises a charging barrel, a feeding port is arranged at the center of the top end of thecharging barrel, a cover plate is hinged to the feeding port, warm air fans are arranged on the two sides of the feeding port, the two warm air fans are fixedly inserted into the top end of the charging barrel, air outlet ends of the two warm air fans are arranged in the charging barrel, a stirring device is arranged on the charging barrel, the stirring device corresponds to the feeding port, a screen is arranged below the stirring device, the screen and the charging barrel are connected through a lifting device, a hopper is fixedly connected inside the charging barrel and located below the screen, a collection box is arranged below the hopper, and a heating device is arranged between the collection box and the outlet end of the hopper. According to the distributing device, powder blocks in the powder can be quickly and fully crushed, the blockage phenomenon is prevented, the powder can be preheated and dried, the quality of the powder is guaranteed, the quality of a product is guaranteed, a plurality of hoppers can be fed at a time, and the feeding efficiency is greatly improved.

Owner:伊瓦特机器人设备制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com