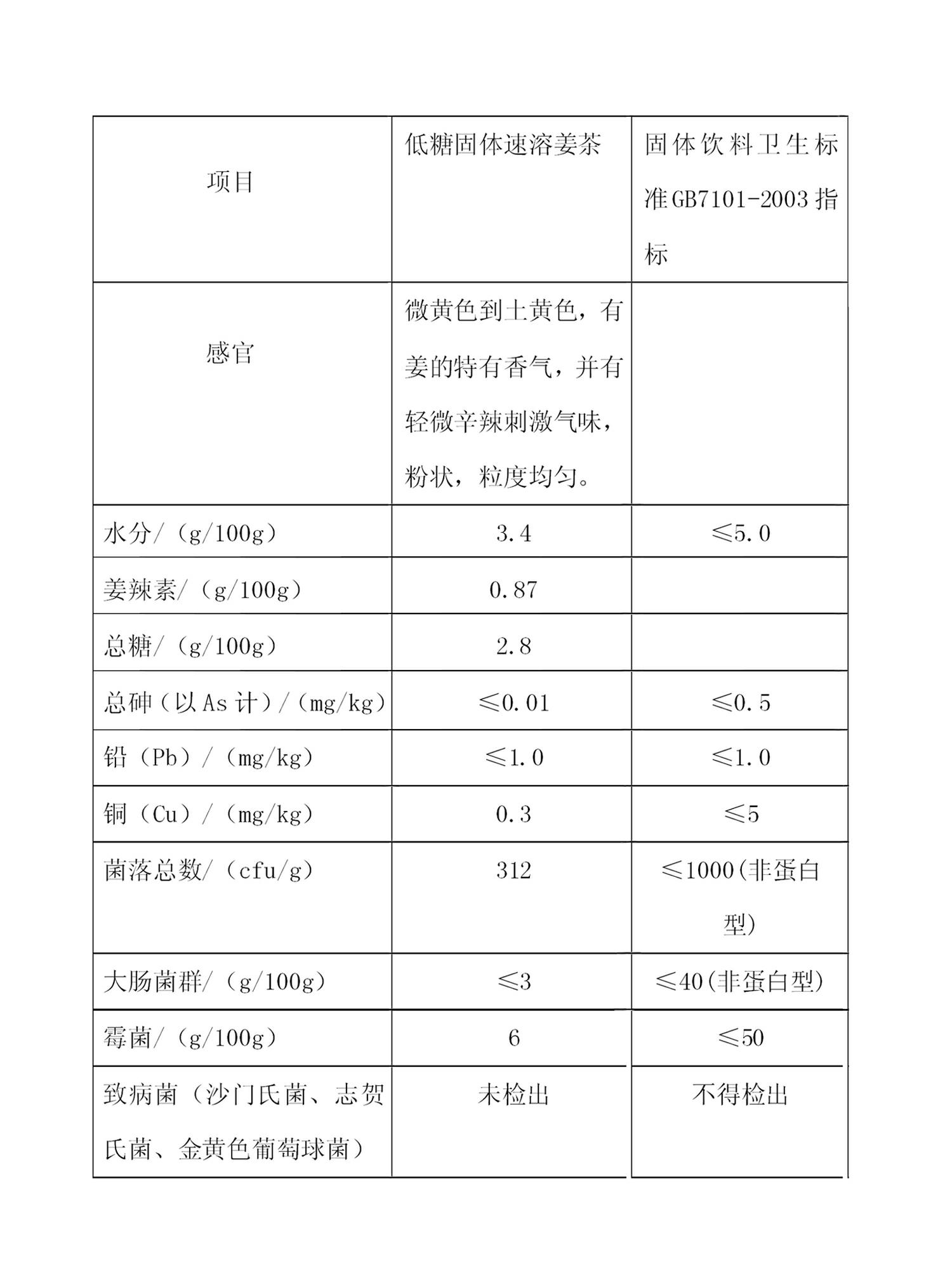

Preparation method of solid low-sugar ginger tea

An instant ginger tea, solid technology, applied in the direction of tea substitutes, etc., can solve the problems of not reaching the level of production and application, and achieve the effect of avoiding re-condensation and stratification, solving scaling problems, and avoiding the loss of flavor and functional components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

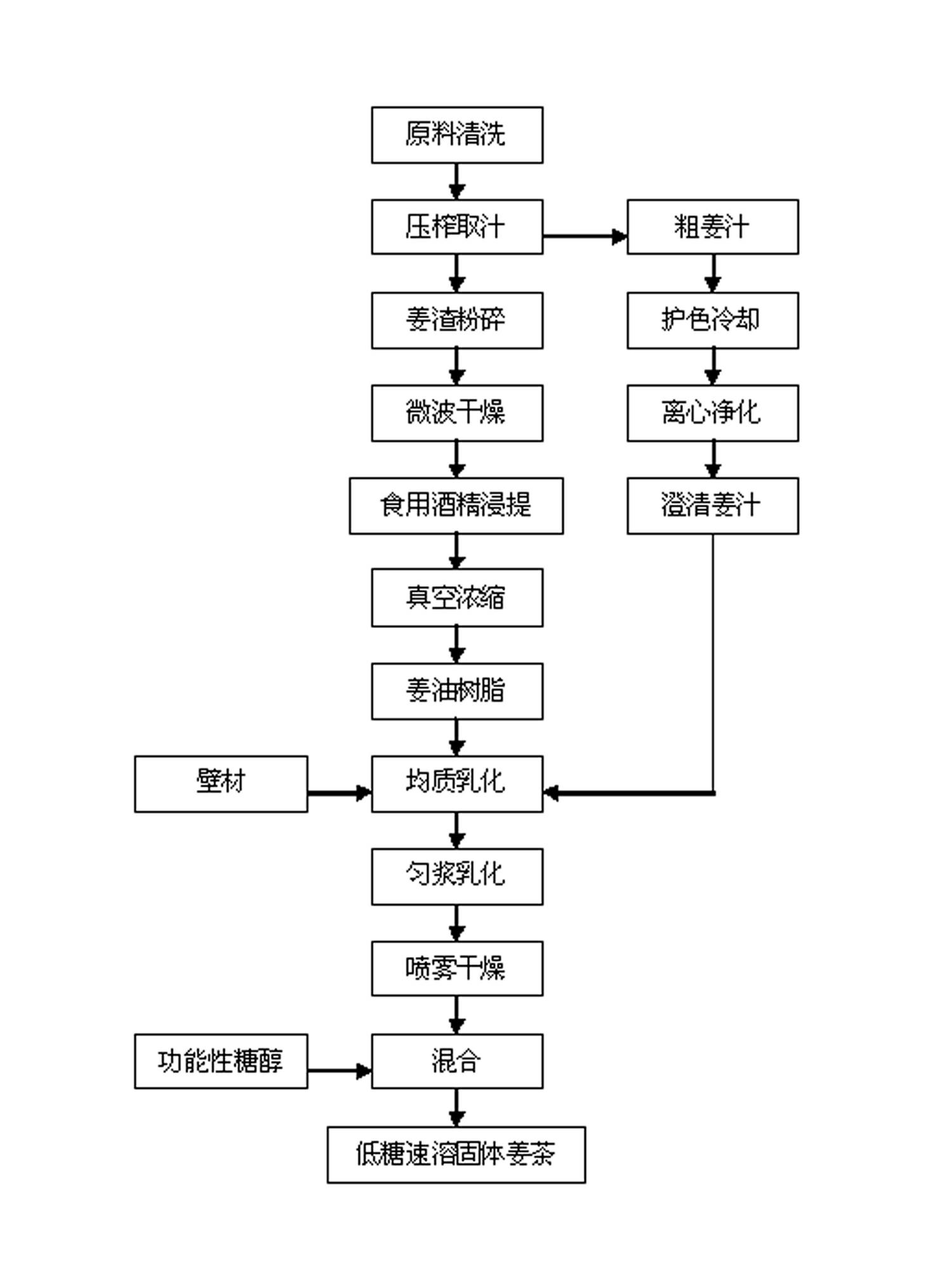

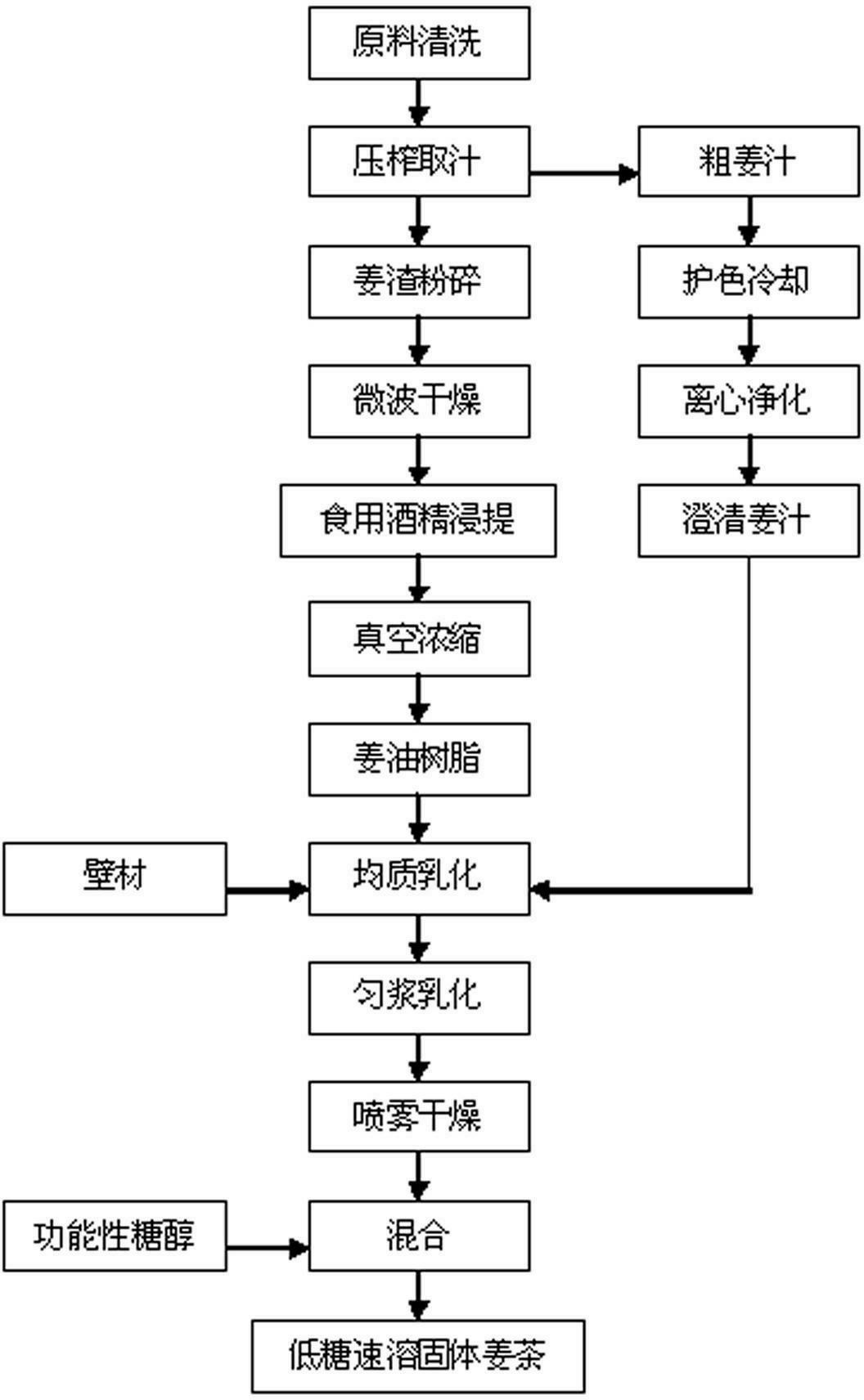

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of ginger oleoresin microcapsules comprises the following steps: the preparation materials of the microcapsules include sucralose, arabic gum, maltodextrin, ginger oleoresin and clarified ginger juice, the mass ratio of which is 1:15-30:70 ~130: 18~25: 250~350. The maltodextrin used in it is required to belong to the MD10 grade, and it is best to use ultra-low sugar maltodextrin (DE value 4.0-6.5). First, dissolve sucralose, arabic gum and maltodextrin in ginger juice, slowly add ginger oleoresin in the state of high-speed homogenization, emulsify into a uniform emulsion, and then slowly in the state of ≥10000r / min high-speed homogenization Slowly add ginger oleoresin to emulsify into a uniform emulsion, and then spray dry the ginger oleoresin emulsion synchronously in the state of homogenization and emulsification at a medium speed of 3000-6000r / min. The conditions for spray drying are: the inlet air temperature is 180-250°C, the outlet air temp...

Embodiment 1

[0041] 1) Preliminary pressing of whole ginger: select 163kg of old ginger harvested after frost and stored in the next year, wash and remove mud and sand, use a screw juicer to press the whole ginger, adjust the gap of the slag discharge port to 2-3mm, and squeeze out by hand It is advisable that the ginger dregs have no obvious ginger juice. Collect crude ginger juice from the juice outlet, add 0.03% ascorbic acid and 0.05% citric acid to the obtained ginger juice in time to protect the color, and let it stand and refrigerate at 0-8°C for 16 hours.

[0042] 2) Centrifugal separation: Centrifuge the ginger juice after standing still for 20 minutes at a centrifuge speed of 5000-8000r / min to obtain 59kg of ginger juice and coarse starch.

[0043] 3) Microwave drying of ginger residue: Grind 85kg of ginger residue obtained by pressing into 20-mesh particle size, and dry it in a 25 kw belt-type microwave dryer for 25-40min to obtain 38kg of ginger residue powder, the moisture con...

Embodiment 2

[0049] 1) Prepare ginger oleoresin microcapsule powder according to step 1) to step 6) of Example 1.

[0050] 2) Preparation of low-sugar solid instant ginger tea: weigh 1.5 kg of ginger oleoresin microcapsule powder and 10 kg of crystalline maltitol in a dry environment. Place in a V-shaped mixer and mix for 25 minutes. Then carry out sealed packing by every sachet 20g. The measured value of gingerol content in the low-sugar solid instant ginger tea prepared by this method is 528mg / 100g. It can be quickly dissolved in boiling water, and after being brewed into 10 times the quality of hot drinks, it has moderate sweetness, strong spicy feeling, and strong ginger flavor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com