Device and method for preparing bimetallic compounding roll by electric slag remelting method

A composite roll and electroslag remelting technology, which is applied in the field of metallurgy, can solve problems such as the bonding defects of the double-metal interface of the roll core, and achieve the effect of avoiding excessive melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

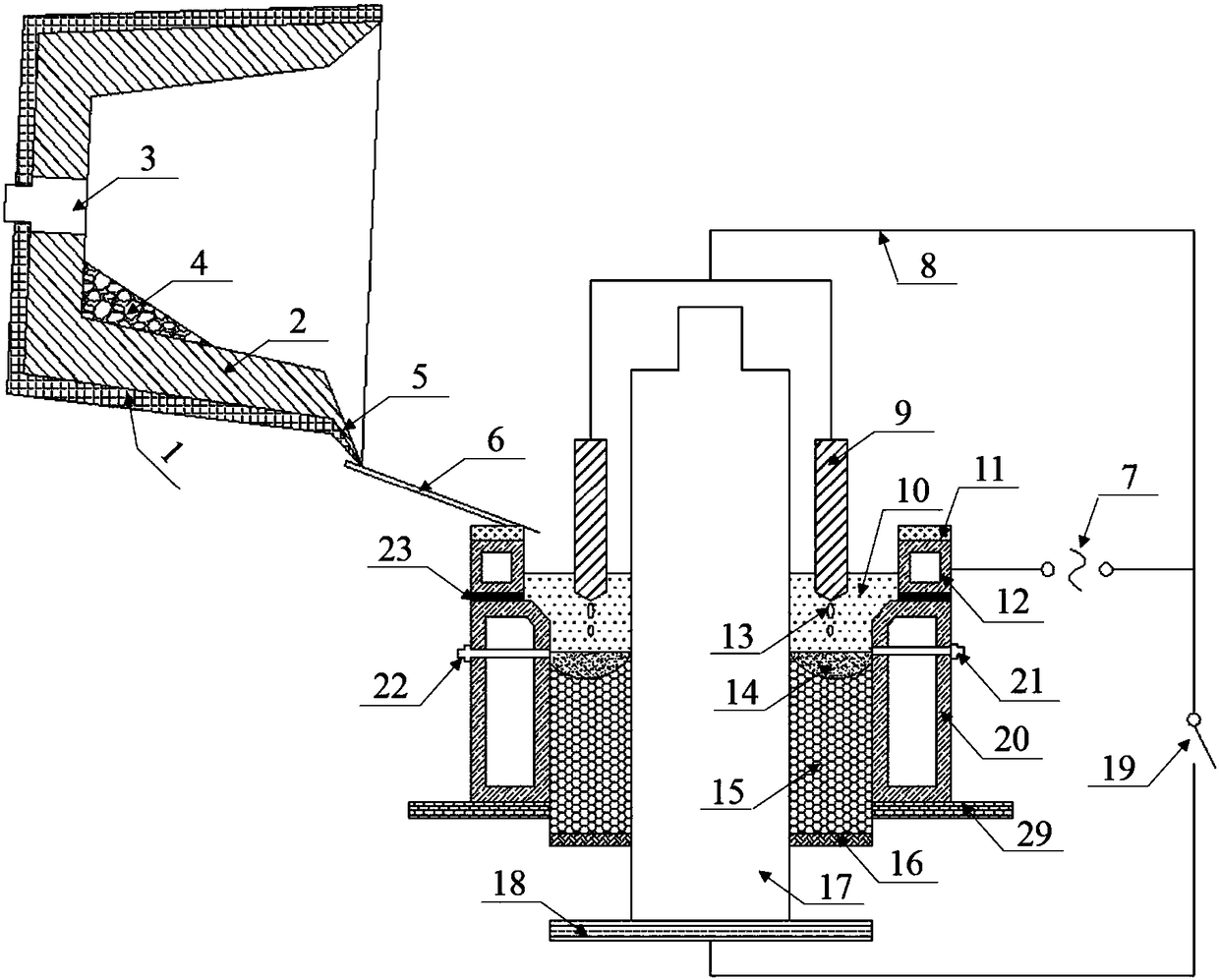

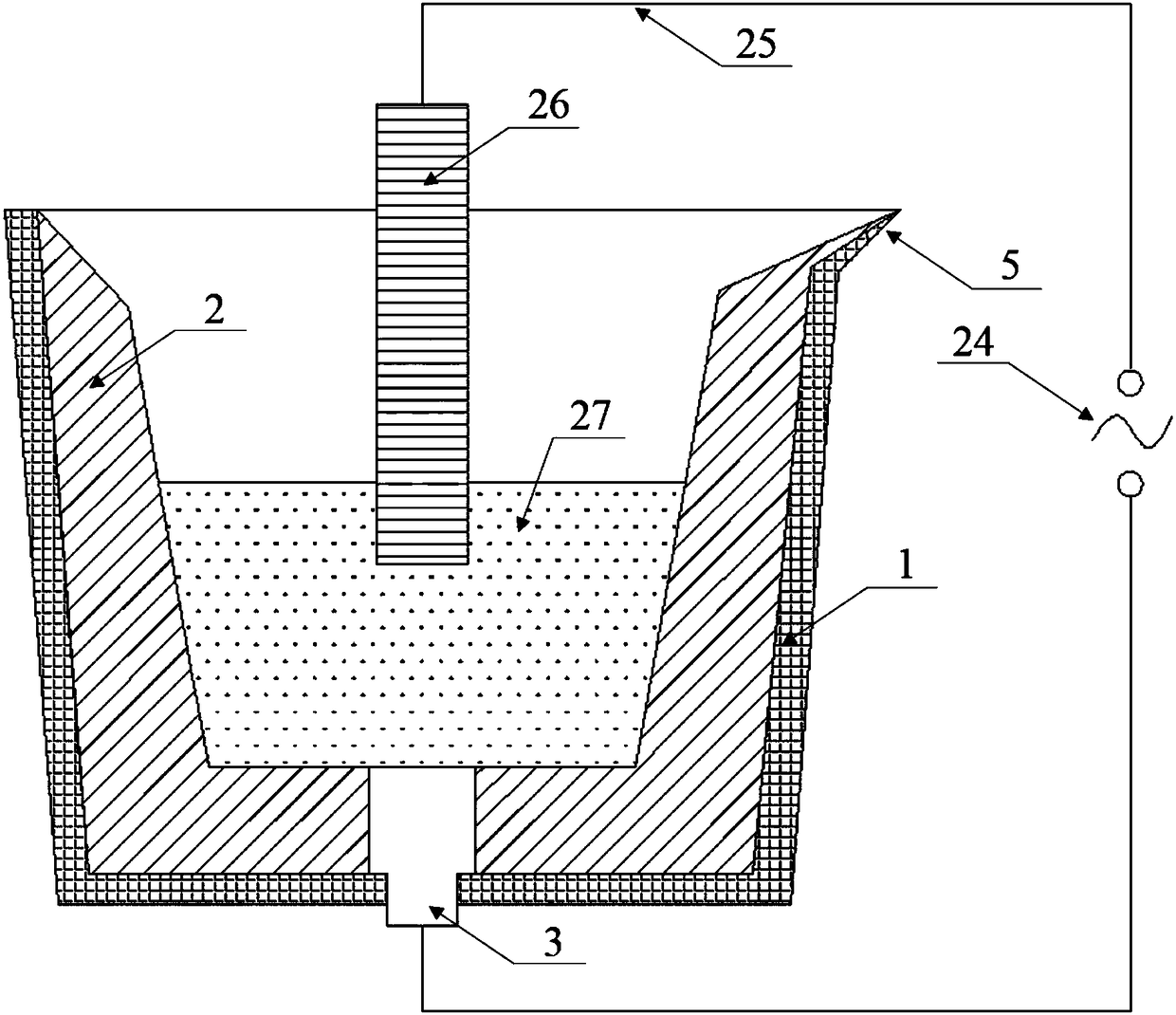

[0073] The material of the working layer of the roll is GCr15 steel, the diameter of the consumable electrode is Φ30mm, and the length is 1500mm. A total of 20 consumable electrodes are evenly welded around the roll core; the distance between the consumable electrode and the surface of the roll core is 10mm; The roll core material used is 45# carbon steel, the roll core diameter is Φ240mm, and the length is 750mm;

[0074] The slag composition used is CaF in mass percentage 2 40-55%, CaO 15-25%, Al 2 o 3 20-30%, MgO 0-5%, SiO 2 0~10%;

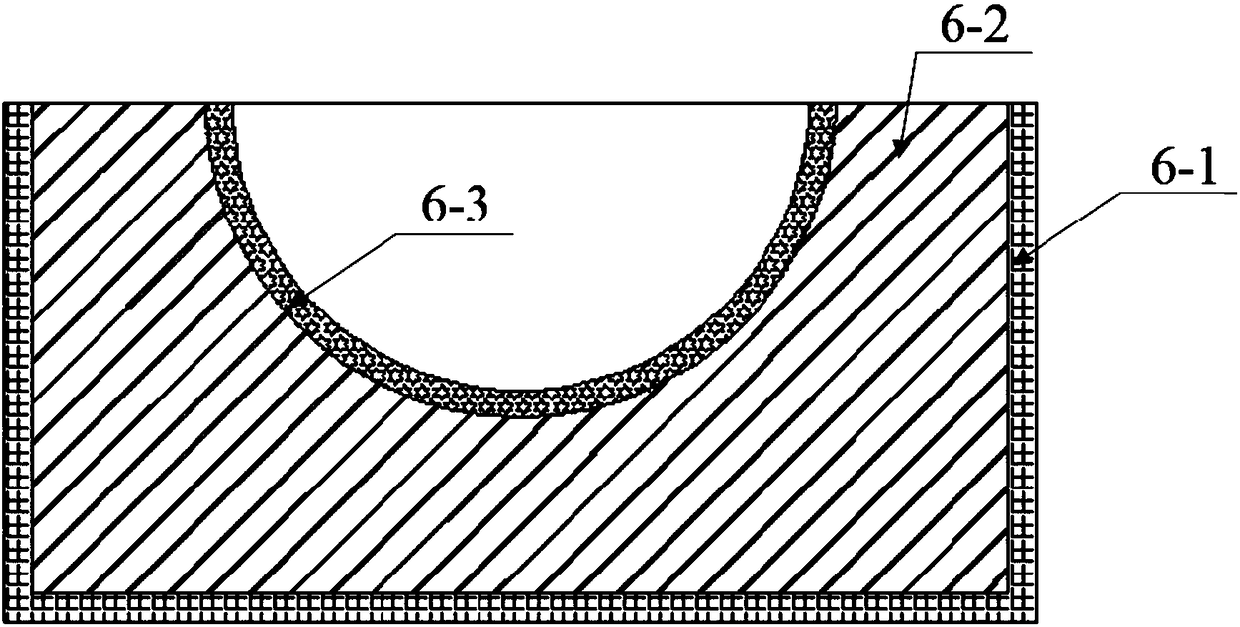

[0075] In the T-shaped crystallizer used, the inner diameter of the upper crystallizer is Φ420mm, the inner diameter of the lower water-cooled crystallizer is Φ350mm, and the diameter of the prepared bimetallic composite roll is Φ350mm; the inner wall surface of the upper crystallizer and the lower water-cooled crystallizer is equipped with a transition section; The thickness of the working layer is 55mm;

[0076] The molten slag from t...

Embodiment 2

[0090] The material of the working layer of the roll is high-speed steel, and the material of the core of the roll is ductile iron; based on the characteristics of the low solid / liquidus temperature of the core ductile iron, the slag composition used is calculated and optimized by FactSage software. Melting point slag system, its composition is CaF in mass percentage 2 40-50%, CaO 30-40%, Al 2 o 3 5~15%, SiO 2 5-10%;

[0091] All the other methods are the same as in Example 1, and the appearance photo of the bimetal composite roll cast slab is as follows Figure 9 As shown, with the use of the power supply circuit and the low melting point slag system, the temperature of the slag pool can be effectively controlled. After anatomical analysis, the bonding interface also has defects such as no pores, inclusions, and cracks.

Embodiment 3

[0093] The consumable electrode used in Example 2 and the roller core composition are the same, the slag composition used and the depth of the lower edge of the conductive graphite block that the slag pool has not crossed the conductive crystallizer are the same; the consumable electrode used has a diameter of Φ50mm and a length of 2000mm. 24 consumable electrodes are evenly welded;

[0094] Roll core diameter Φ590mm, length 1000mm;

[0095] The inner diameter of the upper crystallizer of the T-shaped crystallizer is Φ820mm, the inner diameter of the lower water-cooled crystallizer is Φ750mm, and the diameter of the prepared bimetallic composite roll is Φ750mm;

[0096] Composite working layer thickness 80mm;

[0097]The method is the same as in Example 1, and the interface of the bimetal composite roll also has defects such as no pores, inclusions, cracks, etc., and has received good application results in steel rolling production.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com