Method for increasing semi-steel heat source

A heat source, steel water technology, applied in the direction of manufacturing converters, etc., can solve the problems of high cost and poor carbon increase effect, and achieve the effect of ensuring utilization rate, good utilization rate, and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

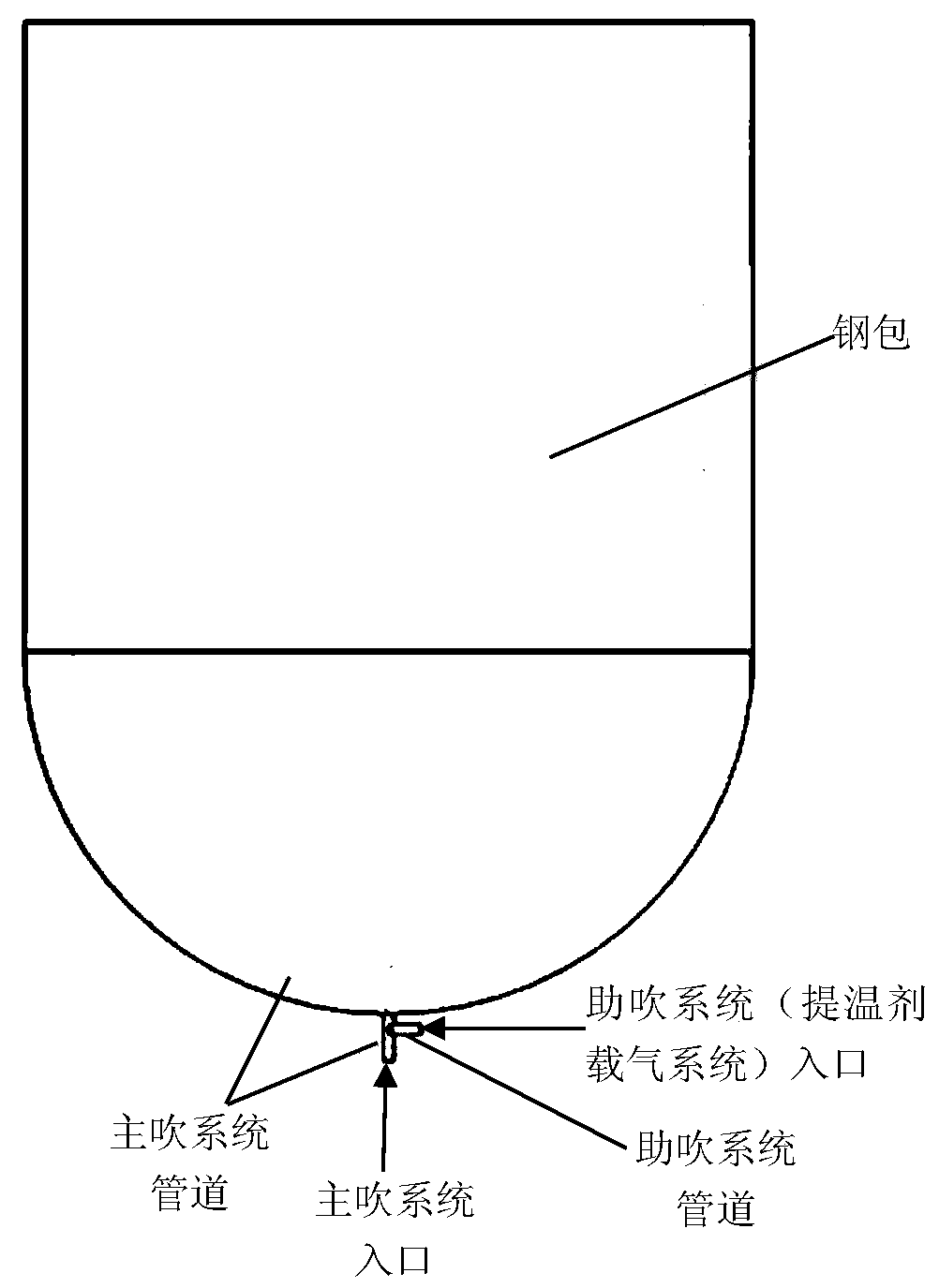

Image

Examples

Embodiment 1

[0026] In a steel factory, semi-steel was produced from a 120-ton vanadium-extracting converter. The semi-steel ladle contained 140 tons of molten iron, and 200kg of the mixture of the above-mentioned recarburizer and silicon raw material was injected. The comparison of the composition of the semi-steel before and after is shown in Table 1:

[0027] Table 1 Comparison of semi-steel composition and temperature before and after

[0028] semi-steel C / % Si / % V / % Mn / % temperature / ℃ Before carburization 3.15 0.02 0.03 0.02 1325 After carbonization 3.22 0.07 0.03 0.02 1323

[0029] During the semi-steel process of the vanadium extraction converter, the gas injection pressure of the auxiliary blowing system is 0.3Mpa, and the mixed material can enter the main pipeline smoothly. The injection pressure of the main blowing system is 0.55Mpa, and the injection speed is 50kg / min. The C content is 3.2% before spraying the mixed material. After only ...

Embodiment 2

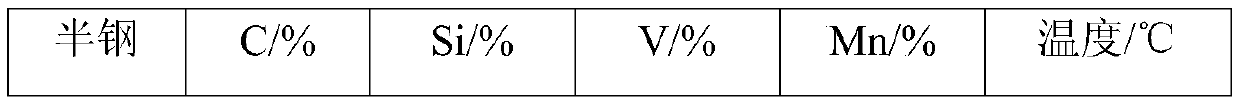

[0031] In a steel factory, semi-steel was produced from a 120-ton vanadium-extracting converter. The volume of semi-steel ladle was 140t of molten iron, and 300kg of the mixture of the above-mentioned recarburizer and silicon raw material was injected. The composition of the semi-steel before and after is compared as shown in Table 2:

[0032] Table 2 Comparison of semi-steel composition and temperature before and after

[0033]

[0034]

[0035] During the semi-steel process of the vanadium extraction converter, the gas injection pressure of the auxiliary blowing system is 0.35Mpa, and the mixed material can enter the main pipeline smoothly. The injection pressure of the main blowing system is 0.57Mpa, and the injection speed is 55kg / min. The C content is 3.22% before spraying the mixed material, and only spraying 300kg mixed material, the C content of the semi-steel increases by 0.11%, and the silicon content of the semi-steel increases by 0.09%, which can achieve a goo...

Embodiment 3

[0037] In a steel factory, semi-steel was produced from a 120-ton vanadium-extracting converter. The volume of semi-steel molten iron was 140 tons of molten iron, and 270 kg of the above-mentioned mixture of carburizer and silicon raw material was injected. The composition of the semi-steel before and after is compared as shown in Table 3:

[0038] Table 3 Comparison of semi-steel composition and temperature before and after

[0039] semi-steel C / % Si / % V / % Mn / % temperature / ℃ Before carburization 3.18 0.02 0.03 0.02 1310 After carbonization 3.27 0.10 0.03 0.02 1305

[0040] During the semi-steel process of the vanadium extraction converter, the gas injection pressure of the auxiliary blowing system is 0.31Mpa, and the mixed material can enter the main pipeline smoothly. The injection pressure of the main blowing system is 0.52Mpa, and the injection speed is 50kg / min. The C content is 3.2% before spraying the mixed material, and only 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com