Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59results about How to "Improve carburizing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite carbon containing pellet

InactiveCN1786202AGood carburizing effectCarburizing effect is stableProcess efficiency improvementChemical compositionRare earth

The invention belongs to ferrous metallurgy field. It mainly relates to steel smelting carbon containing ball, especially electric furnace using scrap steel making or cast steel carburetion. The compound carbon containing ball chemical compositions (wt%)are containing material 40-80%, metal oxide 10-42%, rare earth oxide 5-30%, bonding agent 2-10%, reinforcing agent 1-5%, expansion agent 1-5%, and steel products processing smear metal 1-4%. Its intensity is high; mono ball compressive strength can reach more than 5Mpa. It can be add into the molten steel to increase carbon, reduce inclusion, removing harmful gas, purify grain boundary, and refine grain to improve steel toughness.

Owner:李继宗 +2

Carburizing and quenching process

InactiveCN107245690AExtended service lifeShorten carburizing timeSolid state diffusion coatingQuenching agentsWear resistantHardness

The invention relates to a carburizing and quenching process, which belongs to the technical field of heat treatment of metal. The carburizing and quenching process comprises the steps of carburizing for the first time, carburizing for the second time, quenching for the first time, quenching for the second time, tempering at high temperature and tempering at low temperature. According to the carburizing and quenching process designed by the invention, two-time carburization is adopted during carburization, and the carburizing time of each time is shortened, so that the defects that metal hardness is low due to long-time heating and the anti-fatigue performance and the wear resistant performance are reduced can be effectively prevented, and the service life of a workpiece is greatly prolonged; in addition, two-time quenching is adopted, so that residual stress of the workpiece can be preferably released, and the service life is prolonged.

Owner:JIANGSU FENGDONG HEAT TREATMENT & SURFACE MODIFICATION ENG & TECH RES CO LTD

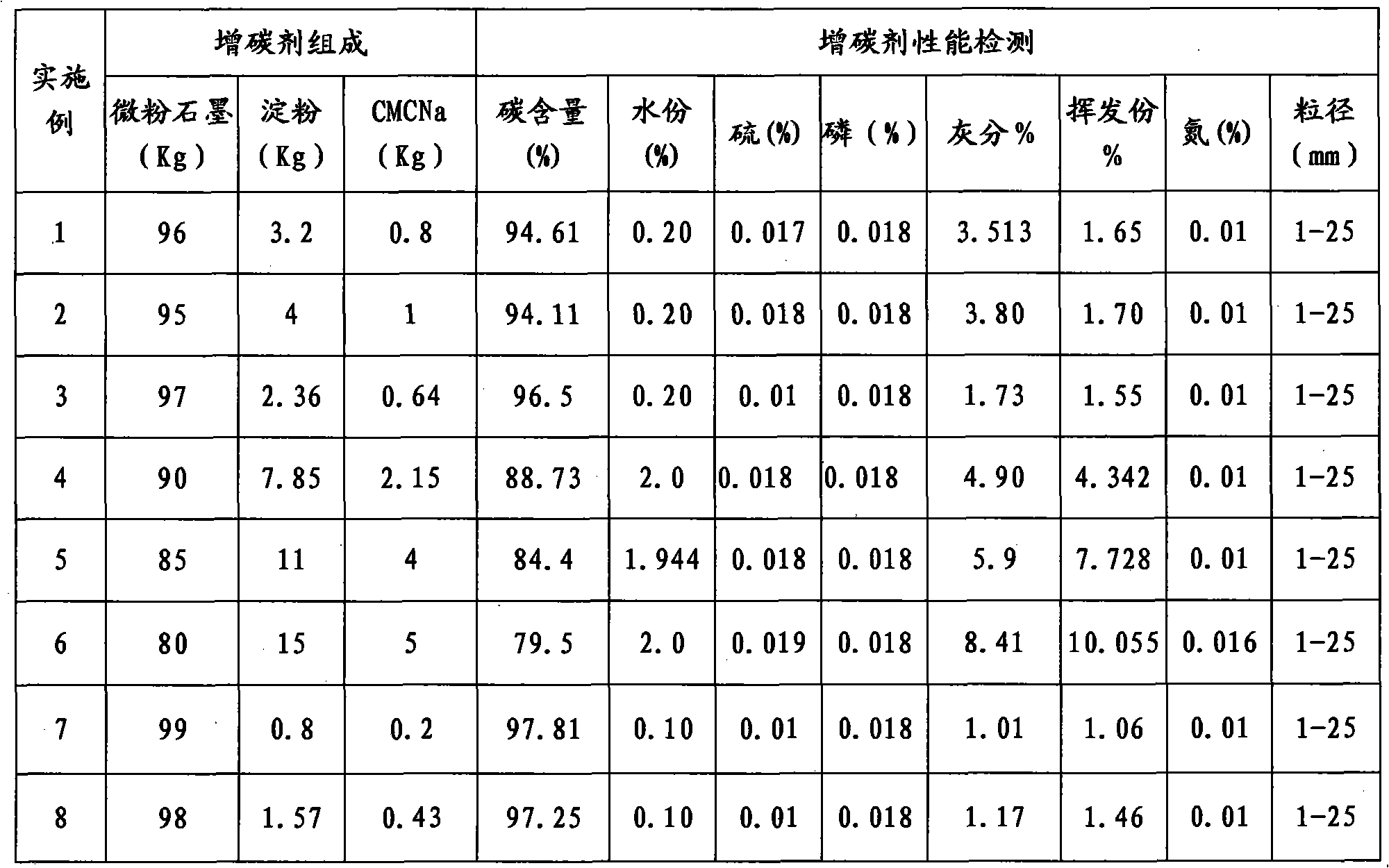

Micro powder graphite carburant, preparation method and use method thereof

The invention discloses a micro powder graphite carburant, a preparation method and a use method thereof, aiming at improving quality of carburant and solving the environment pollution caused by graphite tailing. The carburant in the invention contains 80-99% of micro powder graphite and balance of agglomerant, the micro powder graphite is graphite tailing, and the agglomerant is composed of starch and carboxymethylcellulose or sodium carboxymethylcellulose. The preparation method comprises batching, stirring, pelleting and drying. When the carburant is used in electric furnace above 5 tons, carburant and metal furnace materials are added to the lower part in the electric furnace along with batch materials. Compared with the prior art, the invention has the characteristics of high carbon, low sulphur, low phosphorus, low water content, high chemical activity and high carbon absorptivity, larger surface area is soaked in molten steel when in use, carbon absorptivity reaches above 96%, carbon content in smelt steel is obviously increased, steel melting cost is effectively reduced, and the environment pollution problem caused by graphite tailing is solved well.

Owner:ZHANJIANG JUXIN NEW ENERGY

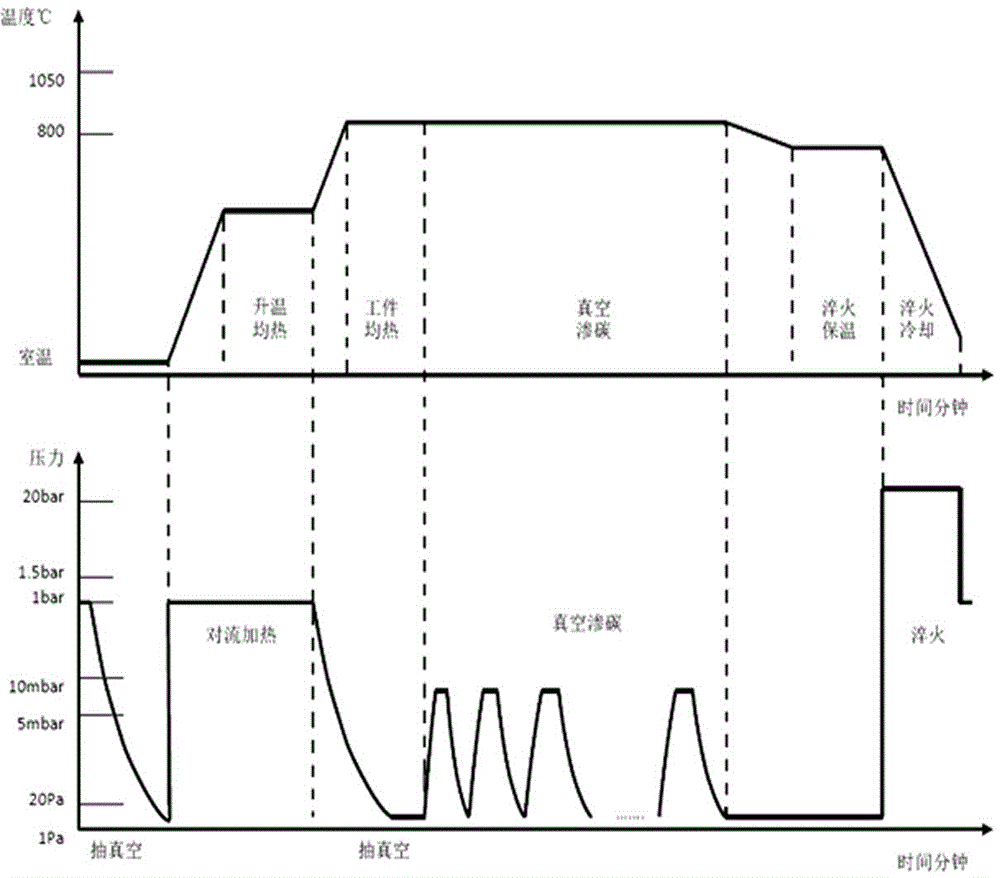

Low-pressure vacuum carburizing process

InactiveCN106756752AEffective control of surface carbon contentEffective control depthSolid state diffusion coatingMetallurgyPulse period

The invention discloses a low-pressure vacuum carburizing process. The low-pressure vacuum carburizing process comprises a temperature rising stage, a carburizing stage, a diffusing stage and a precooling stage. The temperature rising stage comprises the steps that a workpiece is vacuumized, and the vacuum degree is controlled within 1 Pa-20 Pa; and after vacuumizing is completed, heating is started, and the carburizing temperature ranges from 800 DEG C to 1050 DEG C. The carburizing stage comprises the steps that after the temperature of the workpiece reaches the set temperature of the process, acetylene gas is introduced into a furnace to maintain the carburizing gas partial pressure, which is named as a carburizing gas inflation pulse stage; after the carburizing gas inflation pulse stage is kept for a set time, vacuumizing is started, a certain time is kept under vacuum, which is named as a vacuumizing diffusion stage, and the carburizing gas inflation pulse stage and the vacuumizing diffusion stage are combined to serve as a carburizing pulse period; the whole carburizing stage is composed of a plurality of carburizing pulse periods; and when the carburized layer depth reaches the carburized layer depth set by the process, the carburizing pulse is stopped. The low-pressure vacuum carburizing process can effectively control the surface carbon content and the carburized layer depth of the workpiece, and the optimal carburizing effect of the workpiece is achieved.

Owner:上海先越冶金技术股份有限公司

Manufacturing method for automobile transmission gear

The invention discloses a manufacturing method for an automobile transmission gear, and relates to the field of manufacturing of automobile parts. The method comprises the following steps: (1) blank forging, (2) spheroidizing annealing, (3) turning machining, (4) hobbing, (5) gear shaving, (6) carburization, (7) quenching and tempering and (8) grinding machining. According to the method, spheroidizing annealing treatment is adopted, so that the cutting performance of the gear is improved, a structure with spheroidized or granular carbide uniformly distributed on a ferrite substrate is obtained for preparation for subsequent heat treatment; a gas carburization method is adopted, and volatile kerosene is used as a carburizer, so that carburization effects are effectively improved, the thickness of a carburized layer is increased, the surface of the gear is hard and wear-proof, and high toughness of the core of the gear is maintained; quenching and tempering heat treatment is adopted after carburization, so that the carburization effects are further consolidated, and the mechanical performance of the gear is improved.

Owner:JIANGXI UNIV OF TECH

Phosphorous pig iron carbon increasing method for aluminum electrolysis

The ferrophosphorus carburizing method is that waste anode carbon grain of granularity 1-5 mm is added into the intermediate frequency furnace to increase the carbon content in ferrophosphorus. The waste anode carbon grain from aluminum electrolyzing bath has greater specific weight of 1.6 g / cu cm, raised carburizing effect, less powder pollution, low carburizing cost, simple carburizing process and obviously increased carbon content in ferrophosphorus.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Carburant for manganese-carbon alloy

This invention relates to a recarburizer used in steelmaking process, especially relates to alloy recarburizer. Manganese and iron content is increased and specific gravity is increased so recarburization effect is improved. Technique plan is that manganese carbon alloy recarburizer is made by metal alloy powder and carbon material and binding agent. Metal alloy powder can be manganese iron powder or compound of manganese iron powder and iron powder. Carbon material is selected from coke, pitch coke, petroleum coke, carbon powder, coal dust and graphite. This product contains C 20~47%, Mn 35.01~55%, binding agent, silicasol 0.5~2%, it is mainlt used in liquid steel recarburization during steelmaking process.

Owner:上海盛宝冶金科技有限公司

Vermicular graphite cast iron material and preparation method and application thereof

ActiveCN110904381AHigh thermal conductivityImprove cooling effectProcess efficiency improvementBrakeManganese

The invention discloses a vermicular graphite cast iron material. The material comprises components in percentage by mass of, 3.0-3.9% of carbon, 2.3-3.0% of silicon, less than or equal to 0.4% of copper, less than or equal to 0.01% of chromium, less than or equal to 0.02% of sulfur, less than or equal to 0.07% of phosphorus, less than or equal to 0.5% of manganese and the balance of iron and inevitable impurities. The vermicular graphite cast iron material is not prone to cracking and good in heat dissipation performance, the tensile strength reaches up to 523 Mpa, and the vermiculation ratereaches up to 95%. The invention further discloses a preparation method of the vermicular graphite cast iron material, a ladle bottom pouring method is adopted, a transfer ladle is placed on one sideof a dam, the transfer ladle contains vermiculizer, inoculant and the like, so the prepared vermicular graphite cast iron material is excellent in performance and high in vermicular graphite rate. Thematerial is advantaged in that the vermicular graphite cast iron is applied to production of brake drums, brake discs, speed reducer shells or molds, so the brake drums, the brake discs, the speed reducer shells or the molds are excellent in performance, and the service life is prolonged.

Owner:JIANGXI JIUWANG AUTO PARTS MFG CO LTD

Composite material for engine exhaust valve

The invention discloses a composite material for an engine exhaust valve. The composite material for the engine exhaust valve is prepared from the following raw materials in parts by weight: 95 to 98 parts of aluminum, 2.3 to 3 parts of manganese, 0.4 to 0.5 part of silicon, 0.2 to 0.3 part of molybdenum, 0.1 to 0.2 part of titanium, 0.06 to 0.07 part of beryllium, 0.1 to 0.2 part of nickel, 0.07 to 0.1 part of tin, 0.06 to 0.1 part of hexadecyl trimethyl ammonium bromide, 3 to 5 parts of graphene oxide, 5 to 8 parts of zirconium hydride, 1.2 to 1.6 parts of hexachloroethane, 0.23 to 0.26 part of polyvinyl alcohol, 0.6 to 0.8 part of diamond micro-powder, 0.7 to 0.9 part of activated carbon, 0.2 to 0.4 part of manganese oxide, 0.9 to 1.3 parts of nano zirconium diboride, not more than 0.01 part of impurity and a proper volume of deionized water. The engine exhaust valve obtained by casting an aluminum alloy material provided by the invention has the advantages of a light weight, high strength, oxidation corrosion resistance, high temperature resistance and the like, and extremely has application value.

Owner:HEFEI HAIYUAN MACHINERY

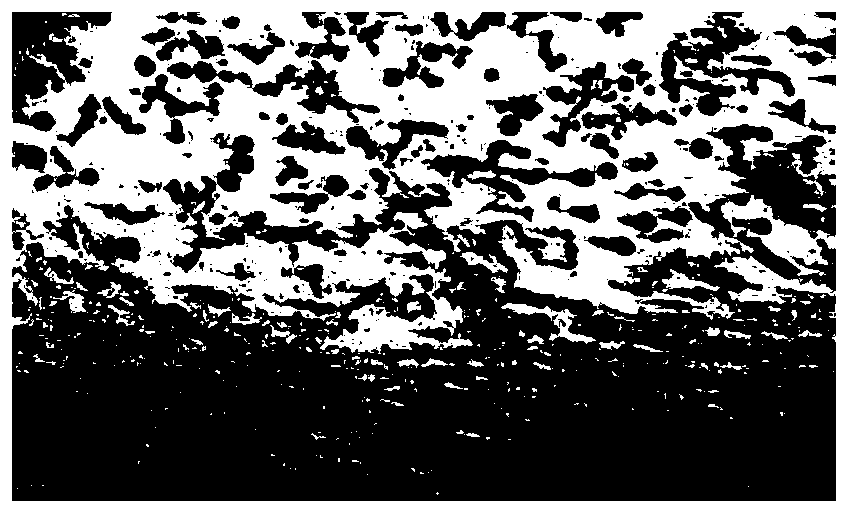

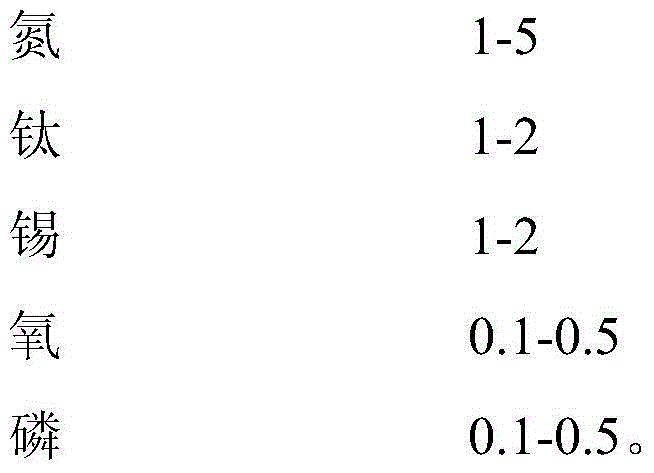

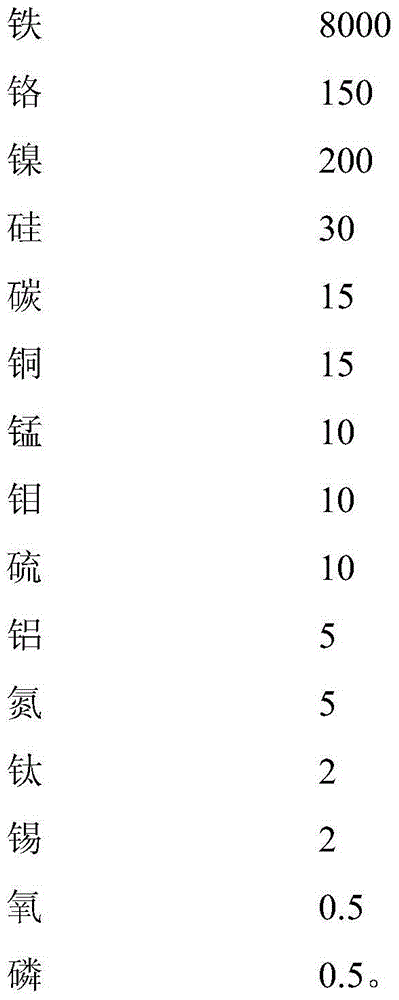

Carburized bearing steel

The invention relates to a carburized bearing steel, which consists of the following components by weight: iron, silicon, chromium, nickel, carbon, copper, manganese, molybdenum, sulfur, aluminum, nitrogen, titanium, tin, oxygen and phosphorus. The carburized bearing steel has high relative purity and long contact fatigue life, and the content of trace elements has no influence to purity while optimizing the comprehensive performance of carburized bearing steel. The carburized bearing steel has good comprehensive mechanical properties, and has hardness, strength, elongation and shrinkage degree superior to ordinary bearing steel, thus being suitable for extensive application.

Owner:DALIAN FEIMA OFFICE FURNITURE

Metal ceramic surface treating method

The invention discloses a metal ceramic surface treating method. The metal ceramic surface treating method is characterized by comprising the following steps: putting a ceramic green body into a vacuum container which is filled up with a carbon source gas, performing carburizing treatment at a temperature higher than or equal to the ceramic sintering temperature under vacuum degree of 9<-2>-10<-2>MPa, and taking out a ceramic product after preserving the heat for 2-4 hours, thereby ending the carburizing treatment. The metal ceramic surface treating method has the advantage that a carbon source is infiltrated into the ceramic green body under a vacuum state that the temperature of the high-purity carbon source is higher than the ceramic sintering temperature, the carburizing effect is superior to a common carburizing effect, and the operation is simple and convenient.

Owner:ZHOUSHAN MAOXIANG CEMENTED CARBIDE

Aluminium-matrix composite material for automobile transmission gear, and preparation method thereof

The invention discloses an aluminium-matrix composite material for an automobile transmission gear, and a preparation method thereof. The aluminium-matrix composite material is prepared from the following raw materials in parts by weight: 95-98% of aluminium, 0.1-0.14% of germanium, 1-1.2% of manganese, 0.13-0.16% of titanium, 0.3-0.35% of copper, 0.04-0.06% of lithium, 0.2-0.3% of zinc, 0.06-0.1% of cetyl trimethyl ammonium bromide, 3-5% of graphene oxide, 5-8% of zirconium hydride, 0.85-1% of hexachloroethane, 0.4-0.6% of calcareous shale, 0.24-0.3% of sodium alginate, 0.2-0.4% of calcium silicide, 2.3-2.4% of silicon dioxide, not greater than 0.01% of impurities, and an appropriate amount of deionized water. According to the aluminium-matrix composite material disclosed by the invention, improvement for the comprehensive performance of an industrial aluminium alloy is effectively realized through improvement for a casting process, and the requirements of a high load, a light weight and good toughness of the automobile transmission gear can be met; and the aluminium-matrix composite material is low in preparation cost and worthy of popularization.

Owner:安徽瑞林精科股份有限公司

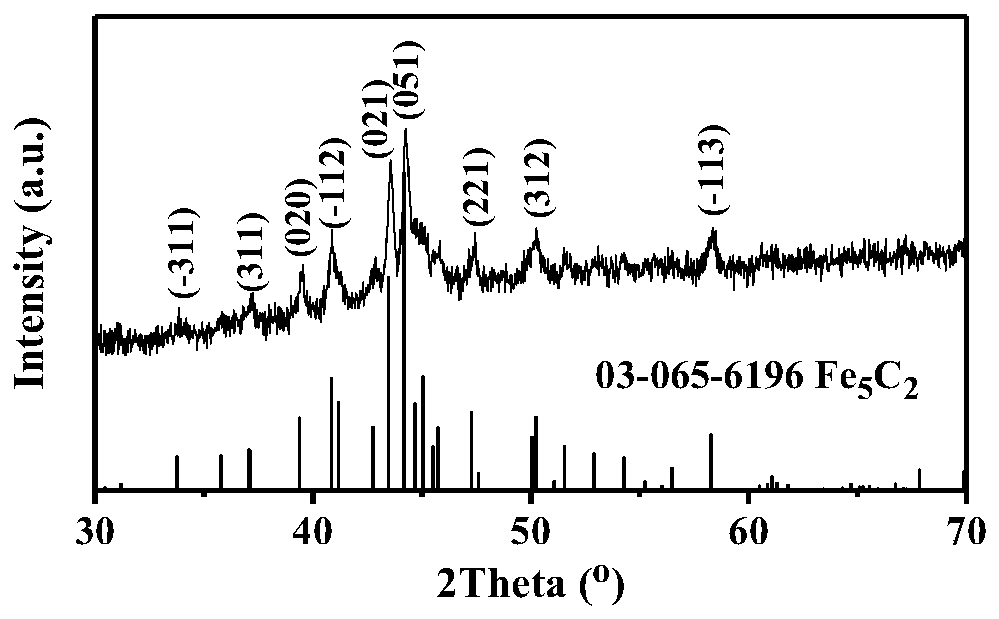

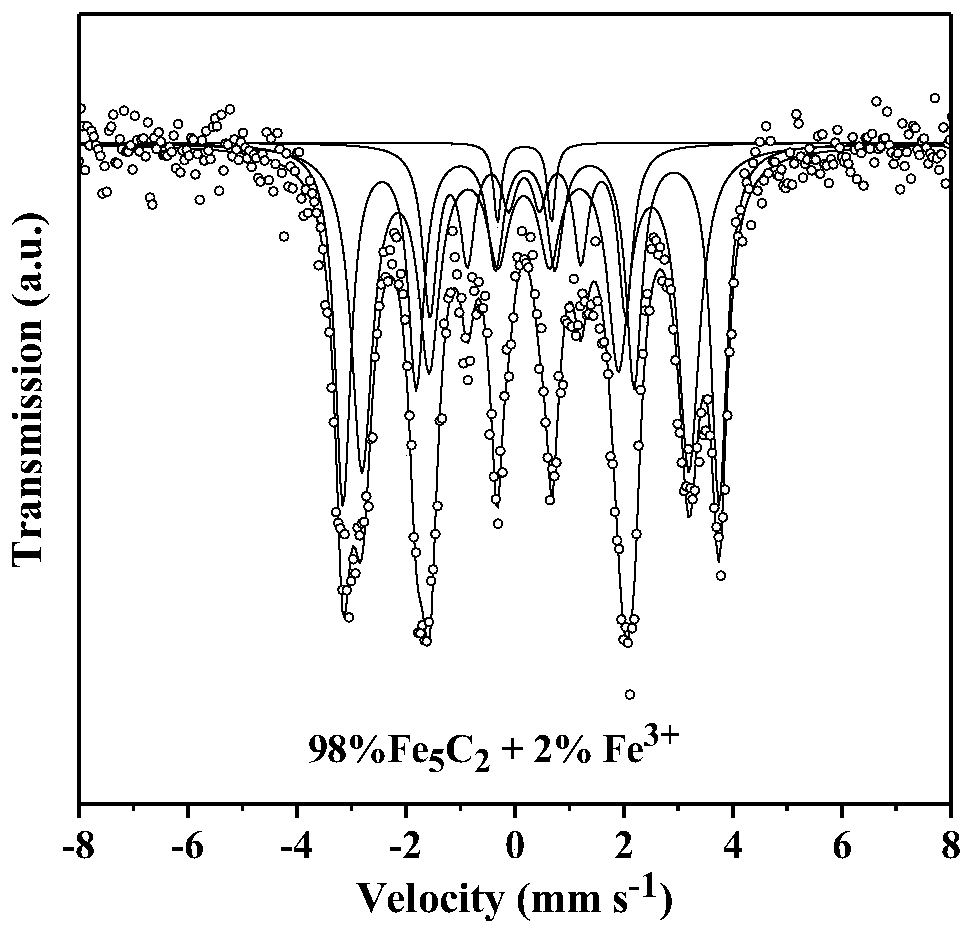

Preparation method of high-purity Fe5C2 nanoparticles and application of high-purity Fe5C2 nanoparticles in Fischer-Tropsch synthesis reaction

ActiveCN110627067AGuaranteed infiltrationInfiltrate in timePhysical/chemical process catalystsCarbon compoundsReaction temperatureCarbonization

The invention provides a preparation method of high-purity Fe5C2 nanoparticles and an application of the high-purity Fe5C2 nanoparticles in a Fischer-Tropsch synthesis reaction. The preparation of thehigh-purity Fe5C2 nanoparticles comprises the steps: conventional cheap iron oxide is used as a precursor, and reactive gas containing hydrogen and carbon monoxide is used for reducing and carburizing iron oxide; and based on the synergistic regulation and control of the size of the iron oxide precursor, the hydrogen-carbon ratio of the reaction gas in the carbonization process, the heating rate,the reaction temperature and the like, the iron oxide essentially has appropriate oxygen atom removal, carbon atom infiltration and carbon deposition process rate and degree in the reaction process,and the high-purity Fe5C2 nanoparticles are obtained. The Fe5C2 nanoparticles provided by the invention are applied to the Fischer-Tropsch synthesis reaction, and have high catalytic activity, high C2-C4 light olefin yield and high stability.

Owner:DALIAN UNIV OF TECH

High-heat-dissipation aluminum base composite material for automotive engine

The invention discloses a high-heat-dissipation aluminum base composite material for an automotive engine. The high-heat-dissipation aluminum base composite material for the automotive engine is prepared from the following raw materials in parts by weight: 95 to 98 parts of aluminum, 2 to 3 parts of glass fiber, 0.3 to 0.5 part of copper, 0.1 to 0.2 part of nickel, 1 to 1.2 parts of zinc, 0.8 to 1 part of zirconium, 0.2 to 0.3 part of molybdenum, 1 to 1.4 parts of iron, 0.06 to 0.1 part of hexadecyl trimethyl ammonium bromide, 3 to 5 parts of graphene oxide, 5 to 8 parts of zirconium hydride, 0.86 to 1 part of hexachloroethane, 1.1 to 1.5 parts of quickened lime, 0.2 to 0.4 part of potassium sulfide, 0.25 to 0.3 part of polyvinylpyrrolidone, 0.3 to 0.4 part of ferrous sulfate, 1.1 to 1.6 parts of nano aluminum nitride, not more than 0.01 part of impurity and a proper volume of deionized water. The aluminum material provided by the invention is good in high strength, abrasion-resisting performance and heat dissipation performance, has no resilience after being shaped, and is stable in size; and a manufacturing process accords with green and environment-friendly processesing, can meet the demands of the automotive engine, and moreover, can be used for large scale production.

Owner:安徽瑞林精科股份有限公司

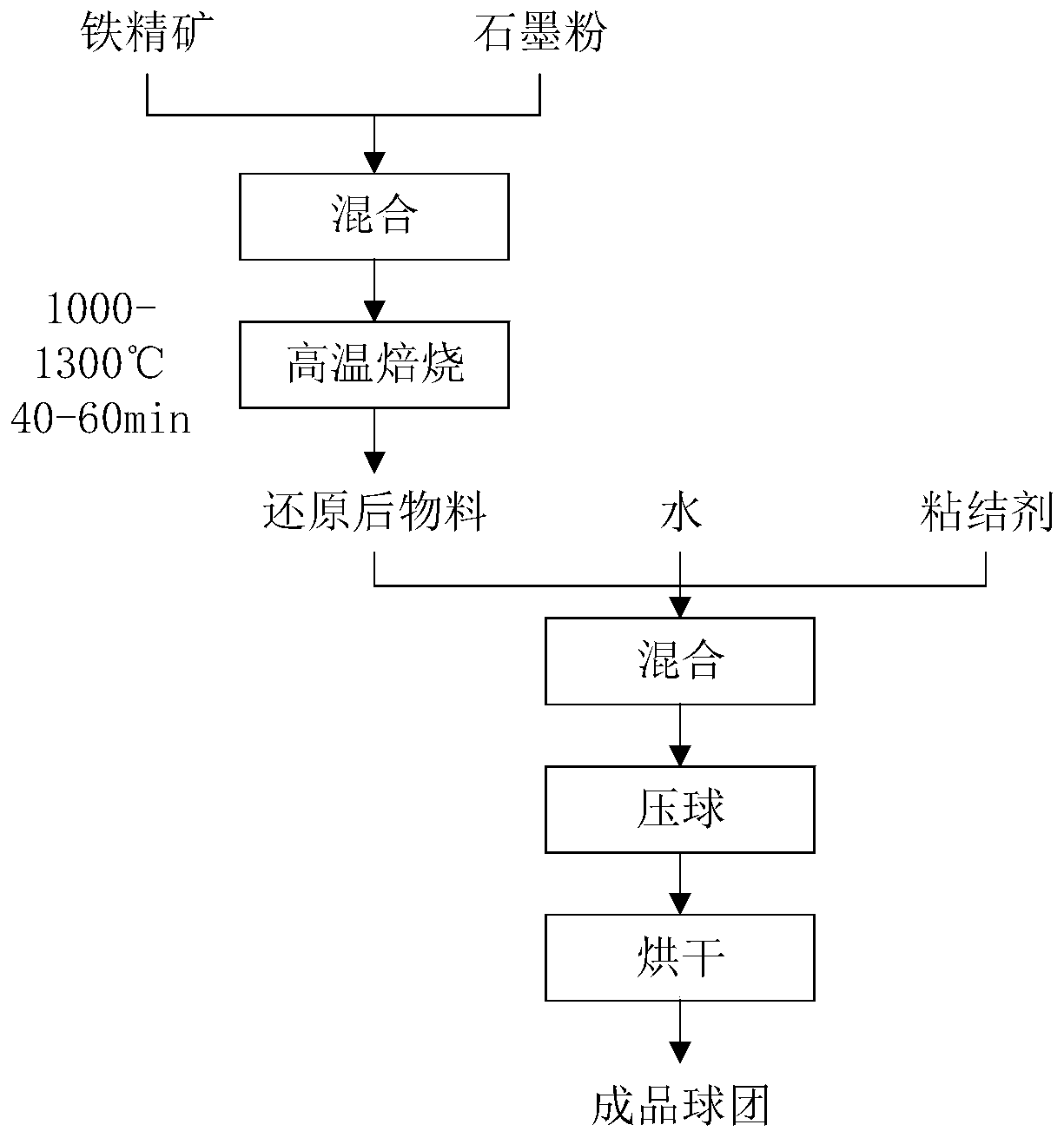

Prepraiton method of high-carbon metallized pellets for electric furnace

The invention discloses a preparation method of high-carbon metallized pellets for electric arc furnace smelting. The preparation method comprises the steps that carbon-containing powder is added intoiron concentrate for material preparation according to the mass ratio of carbon to iron of 1.5-2:1, prereduction is carried out at a reduction temperature of 1000-1300 DEG C for 40-60min, the reduction product is ground to 0.4-0.5 mm granularity, 4-6% of a binding agent and 9-12% of water are added, the mixture is mixed evenly, pressed into pellets and dried at the temperature of 120-140 DEG C for 60-90min, the high-carbon metallized pellets are obtained, and the pellets can reach the falling strength of 3-4 and reach the density of 2.6-3.3g / cm<3>. Molten steel can be stably and efficiently recarburized by the pellets below the slag-steel interface, the problems that the density of conventional carburant is insufficient, the carburant rapidly floats on the surface of furnace slag after being added, and the carburizing effect is poor are solved, meanwhile, the pellets can perform a good carbon-oxygen reaction below the slag-steel interface to remove inclusions and gas, formation of a large amount of foam slag is promoted, electric arc is stabilized, smelting time is shortened, iron loss is effectively reduced, steel material consumption is remarkably reduced, the metal yield is improved, and the smelting cost is reduced.

Owner:UNIV OF SCI & TECH BEIJING

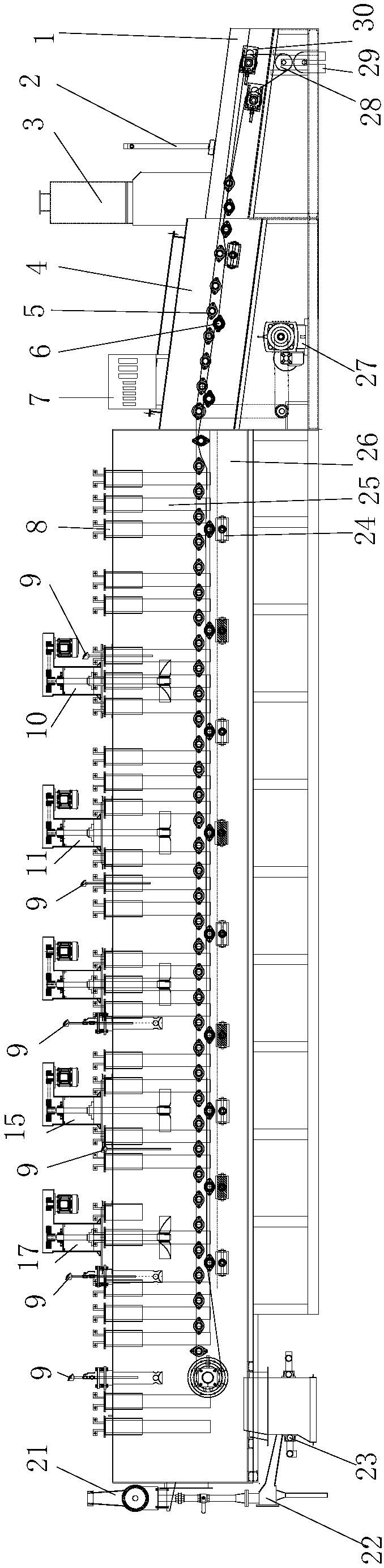

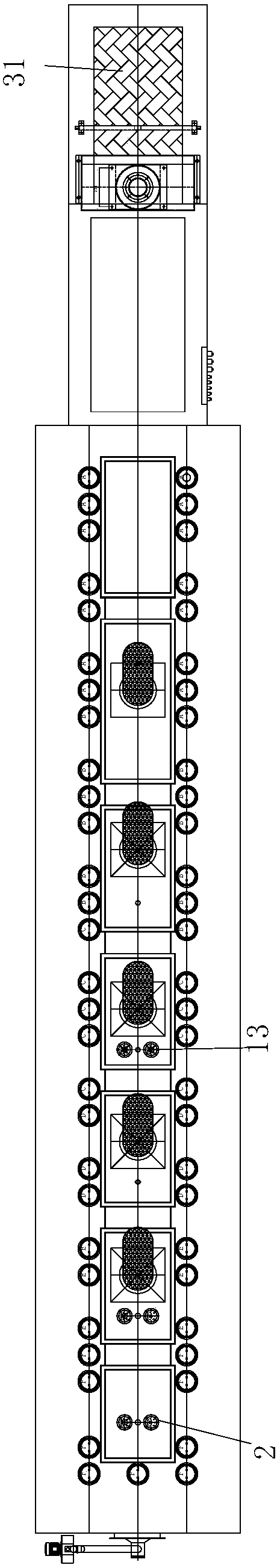

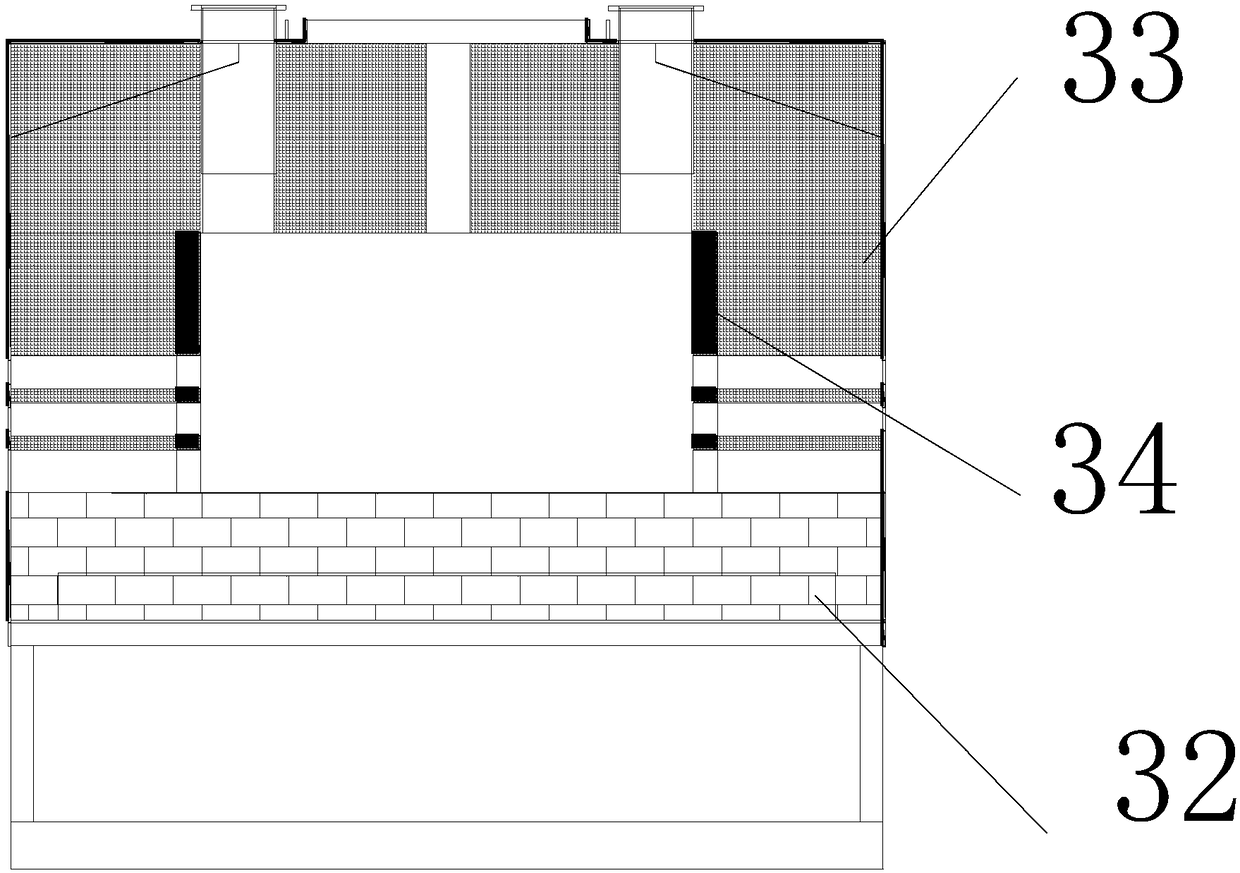

Full-fiber energy-saving type carrier roller type mesh-belt furnace

InactiveCN108203801AIncrease the wind directionGuaranteed stabilitySolid state diffusion coatingFurnace typesFiberFailure rate

The invention provides a full-fiber energy-saving type carrier roller type mesh-belt furnace, which comprises a furnace body. A preheating system is arranged at one end of the furnace body, and is connected with a feeding table; a conveying system is arranged on the feeding table, and stretches into the furnace body from one end of the feeding table through the preheating system; a material is fedfrom the feeding table, is conveyed to the preheating system through the conveying system, and enters the furnace body after being preheated; a plurality of booster fans, circulating fans and heatingelements are arranged on the top part of the furnace body and stretch into the furnace body; and a waste gas exhaust device is arranged at one end, far away from the feeding table, of the furnace body. According to the full-fiber energy-saving type carrier roller type mesh-belt furnace provided by the invention, a heat treatment effect can be improved, the production processing cost is reduced, the furnace is simple and convenient to maintain, and the failure rate is reduced.

Owner:大连圣洁热处理科技发展有限公司

High-heat-resistant and corrosion-resistant aluminum matrix composite for automobile exhaust valve

The invention discloses a high-heat-resistant and corrosion-resistant aluminum matrix composite for an automobile exhaust valve. The high-heat-resistant and corrosion-resistant aluminum matrix composite is prepared from the following raw materials in parts by weight: 95-98 parts of aluminum, 0.1-0.2 part of stannum, 0.04-0.06 part of selenium, 0.06-0.08 part of germanium, 0.1-0.2 part of nickel, 1-1.3 parts of copper, 1.8-2.4 parts of zinc, 0.11-0.13 part of titanium, 0.06-0.1 part of cetyltrimethylammonium bromide, 0.2-0.25 part of bismuth, 3-5 parts of graphene oxide, 5-8 parts of zirconium hydride, 0.9-1.2 parts of hexachloroethane, 0.25-0.3 part of xanthan gum, 1.2-1.6 parts of black manganese ores, 2-3 parts of barium carbonate, 0.6-0.8 part of sodium sulfide, less than or equal to 0.01 part of impurities and a proper amount of deionized water. An aluminum alloy material disclosed by the invention has the advantages of good heat resistance, corrosion resistance and wear resistance, has the advantages of durability and long service life when being used for the automobile exhaust valve and is capable of reducing the cost so as to be worthy of popularization.

Owner:安徽瑞林精科股份有限公司

Method for obtaining high particle size carburant through by-product of graphitization furnace

InactiveCN108059156ADoes not affect product qualitySame insulation effectCarbon compoundsProcess efficiency improvementSteelmakingMaterials science

The invention discloses a method for obtaining a high particle size carburant through a by-product of a graphitization furnace. The method comprises the following steps: crushing, screening, stock binloading, mixing, preparation before charging, charging, graphitization, collecting carburant crude products, preliminary sieving, sieving and recycling; on the premise that the product quality of a negative electrode material is not affected, the same heat preservation effect is achieved by adding certain volume ratio of calcined coke with the particle size being (2-6)mm into a graphitization furnace heat preservation material, and a calcined coke by-product with increased particle size can be obtained. The carburant meeting the requirements of steelmaking carburants and having a recarburization effect can be obtained through the simple sieving of the by-product, moreover, a sieved small particle size carburant fine powder can be recycled, the production cost is greatly reduced, the production process is simple, and the yield is high. Through the method, a single carburant processing process is not required, so that exhaust emission is reduced, and the method is beneficial to environmental protection.

Owner:吉林市松江炭素有限责任公司

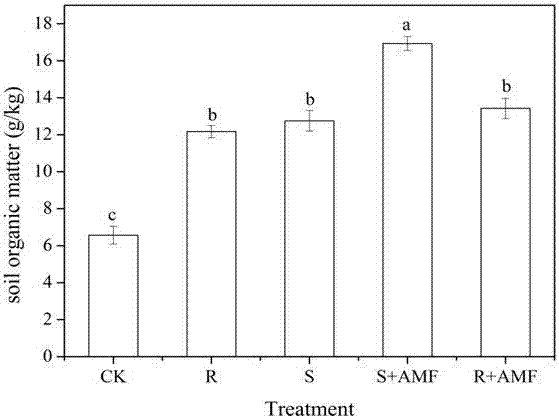

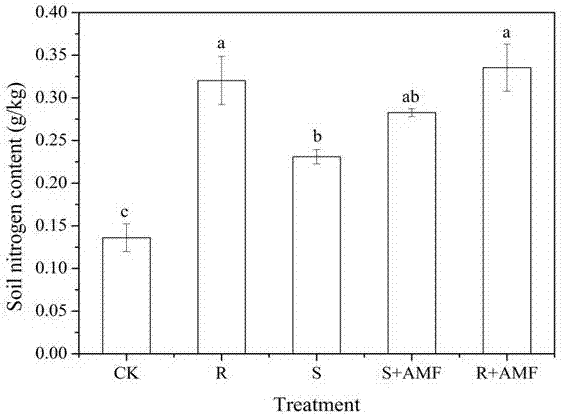

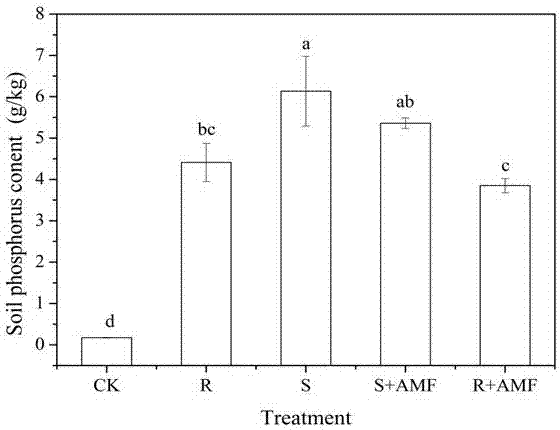

Soil quality improving method via arbuscular mycorrhizal fungi and scented flowers

InactiveCN106922243AAvoid wastingAvoid pollutionBio-organic fraction processingOrganic fertiliser preparationArbuscular mycorrhizal fungiCompost

The invention discloses a soil quality improving method via arbuscular mycorrhizal fungi and scented flowers to solve problems of soil fertility decrease and crop output reduction due to low soil organic carbon content of the loess plateau. The method comprises steps of first, expanding propagation of arbuscular mycorrhizal fungi, second, composting rose dregs; third, sieving field soil and performing high-temperature disinfecting to acquire sterile soil, and adding mineral substances to the soil to sterile soil according to a 1.5%-2% of mass proportion, and inoculating the expanded-propagation arbuscular mycorrhizal fungi to the sterile soil according to a proportion of 0.05 to 0.1%. Compared with a traditional rose dreg utilization, direct use of crude rose dregs is avoided and the rose dregs are composted and decomposed first, then arbuscular mycorrhizal fungi are inoculated during returning application; rose dreg minerlization in the soil is accelerated; and further the rose dreg utilization rate is improved.

Owner:LANZHOU UNIVERSITY

Composite carbon containing pellet

InactiveCN100355910CImprove carburizing effectCarburizing effect is stableProcess efficiency improvementChemical compositionRare earth

Owner:李继宗 +2

Phosphorous pig iron carbon increasing method for aluminum electrolysis

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Carburant for manganese-carbon alloy

This invention relates to a recarburizer used in steelmaking process, especially relates to alloy recarburizer. Manganese and iron content is increased and specific gravity is increased so recarburization effect is improved. Technique plan is that manganese carbon alloy recarburizer is made by metal alloy powder and carbon material and binding agent. Metal alloy powder can be manganese iron powder or compound of manganese iron powder and iron powder. Carbon material is selected from coke, pitch coke, petroleum coke, carbon powder, coal dust and graphite. This product contains C 20~47%, Mn 35.01~55%, binding agent, silicasol 0.5~2%, it is mainlt used in liquid steel recarburization during steelmaking process.

Owner:上海盛宝冶金科技有限公司

Porous efficient carburant blended with nano-copper for reusing waste graphite electrode and preparation method of porous efficient carburant

The invention relates to the field of carburant, in particular to porous efficient carburant blended with nano-copper for reusing a waste graphite electrode and a preparation method of the porous efficient carburant. The waste graphite electrode is used as a carbon material of the carburant. Water glass, ammonium bicarbonate, polyethylene glycol 400 and other materials are used for preparing a low-impurity composite binder. The materials baked at high temperature are of a tight porous structure. The added nano-copper has the effect of promoting graphitization. The recarburization effect of the materials is improved, and the mechanical property is improved. Silicon particles are pasted on the surfaces of the materials after silica gel sprayed on the surfaces of the blank materials is dried, so that molten liquid graphitization is further promoted, blank liquidity is improved, and rapid melting is achieved. The carburant prepared by the preparation method is high in carbon content, stable in morphological property, good in recarburization effect, high in cost performance and capable of effectively improving metal product quality.

Owner:TONGLING MINGCHENG FOUNDRY

Cast steel material with added rare earth elements for automobile axle

InactiveCN105986166AAchieve compositeImprove liquidityProcess efficiency improvementRare-earth elementSlag

The invention discloses a cast steel material with added rare earth elements for an automobile axle. The cast steel material is prepared from, by weight, 95-98 parts of waste steel (the content of iron is not smaller than 98%), 2-3 parts of Z18 pig iron, 0.4-0.45 part of crystalline silicon, 0.3-0.35 part of carbon, 0.02-0.024 part of scandium, 0.03-0.04 part of yttrium, 1.5-1.7 parts of manganese, 2-2.3 parts of chromium, 0.03-0.04 part of antimony, 0.8-0.86 part of calcium silicide, 0.3-0.34 part of yellow phosphorus slag, 0.6-0.7 part of nano-graphite powder, 0.43-0.48 part of a hot melt adhesive and smaller than or equal to 0.01 part of impurities. By means of the cast steel material, due to the fact that the rare earth elements such as scandium and yttrium are used, grains can be refined, the material organization can be more compact, and wear resistance of the material is improved; and due to scientific and reasonable matching design and producing and processing technologies, the prepared cast steel material has the good comprehensive performance, and the cast steel material is very suitable for producing an automobile axle part.

Owner:ANHUI YUEZHONG AUTO BODY EQUIP

Abrasion-resistant composite material for automobile brake pads

The invention discloses an abrasion-resistant composite material for automobile brake pads. The abrasion-resistant composite material for automobile brake pads is prepared from, by weight, 95-98 parts of aluminum, 0.03-0.05 part of cobalt, 3-3.5 parts of iron, 0.3-0.4 part of zinc, 1.2-2 parts of copper sulphide, 0.3-0.4 part of molybdenum, 0.1-0.2 part of nickel, 0.24-0.3 part of magnesium, 0.06-0.1 part of hexadecyl trimethyl ammonium bromide, 3-5 parts of graphene oxide, 5-8 parts of zirconium hydride, 0.88-1 part of hexachloroethane, 0.2-0.3 part of titanium dioxide, 0.24-0.3 part of sodium carboxymethylcellulose, 0.55-0.8 part of tungsten disulfide, 0.6-0.8 part of carbide slag, 0.01 or less of impurities and a proper amount of deionized water. The prepared alloy material has good strength, corrosion resistance, abrasion resistance, high-temperature stability and thermal stability, and is durable and high in safety when applied to automobile brake pads.

Owner:HEFEI HAIYUAN MACHINERY

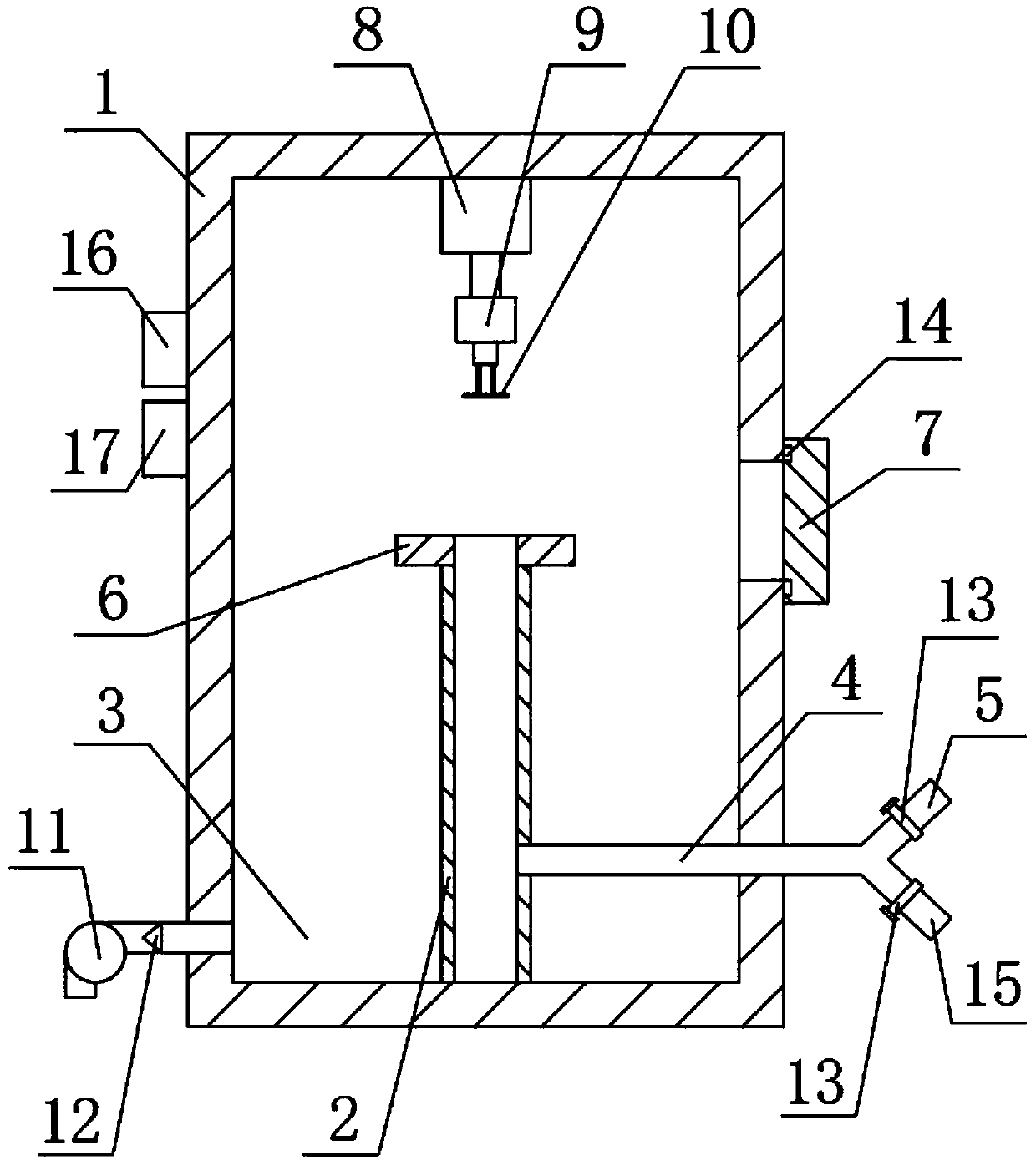

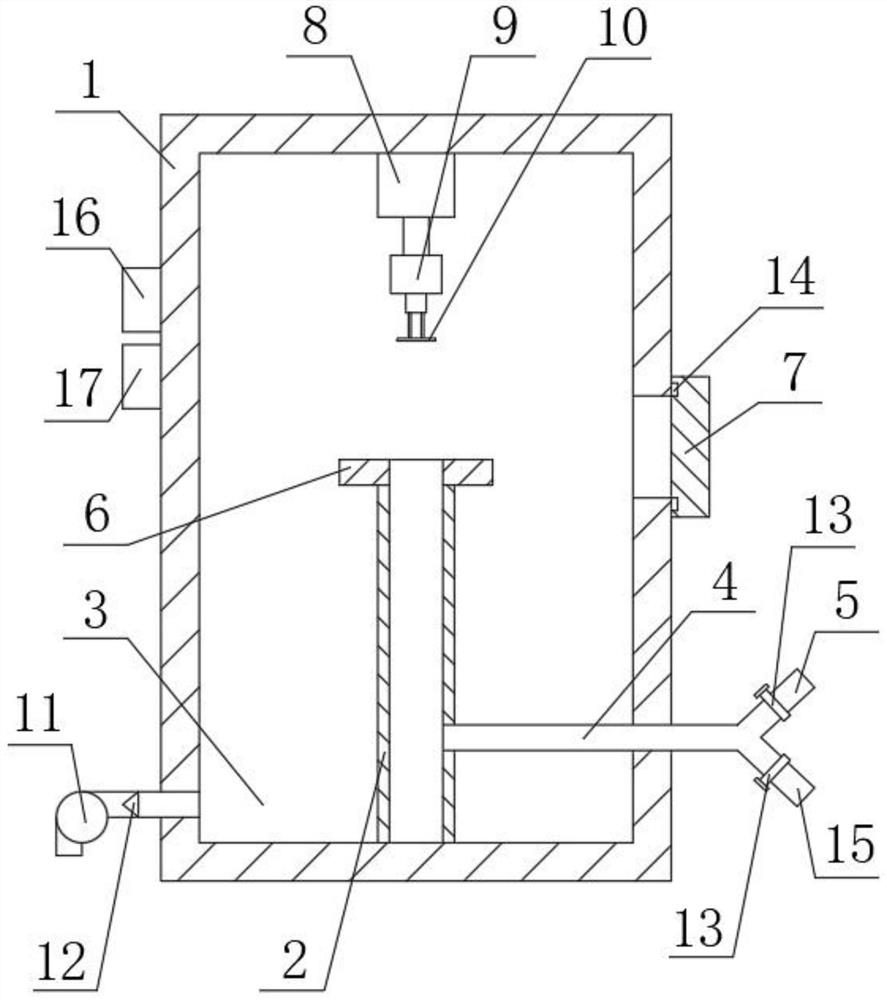

Half axle gear inner spline carburizing and quenching method and carburizing and quenching equipment

ActiveCN110541139AImproved carburizing and quenchingUniform carburizing and quenchingSolid state diffusion coatingFurnace typesRoom temperatureNitrogen

The invention discloses a half axle gear inner spline carburizing and quenching method and carburizing and quenching equipment. The half axle gear inner spline carburizing and quenching method comprises the steps that a half axle gear is in cup joint with a compensation sleeve and is placed in an interior low-pressure quenching furnace, then, the inner spline is heated to 900 DEG C, the position of the inner spline is inflated with dimethylmethane, and the process is continuously conducted for 240 min; then, the temperature of the inner spline is reduced to 840 DEG C, and continuous inflationof the dimethylmethane is conducted for 45 min; heating and inflation of the dimethylmethane are stopped, inflation of high-pressure and high-purity nitrogen is conducted instead, the process is continuously conducted for 20 min, and finally the half axle gear is taken out of the quenching furnace and cooled to the room temperature; the carburizing and quenching equipment comprises the quenching furnace, a hollow containing column is arranged in the quenching furnace, and the bottom of the quenching furnace is connected with an air suction pipe; the side face of the containing column is connected with a first branch pipe and a second branch pipe through an air inlet pipe in the tangential direction; and the top end of the quenching furnace is connected with a telescopic cylinder, and a resistance type heating coil is fixed to the bottom of the telescopic cylinder through a motor. By means of the half axle gear inner spline carburizing and quenching method and the carburizing and quenching equipment, the carburization effect at the inner spline position can be improved, and the advantage of small inner spline deformation is achieved.

Owner:ZHEJIANG PUJIANG GEAR

Corrosion-resistant cast steel material for automobile parts

The invention discloses a corrosion-resistant cast steel material for auto parts, which is made of the following raw materials in parts by weight: steel scrap (iron content not less than 98%) 95-98, Z18 pig iron 2-3, crystalline silicon 0.7-0.75, Carbon 0.3-0.35, niobium 0.04-0.05, titanium 0.4-0.5, manganese 1.2-1.3, chromium 0.04-0.05, calcium silicide 0.8-0.86, gelatin 0.2-0.23, lime powder 0.2-0.24, calcium fluoride 0.3-0.4, heavy Crystal 0.5-0.55, impurity ≤ 0.01. The invention can improve the intergranular corrosion and improve the corrosion resistance of the cast steel material by rationally configuring the ratio of element components and the production process, and adding elements such as titanium and niobium; The auto parts produced are corrosion-resistant, low-temperature resistant, and have a long service life.

Owner:ANHUI YUEZHONG AUTO BODY EQUIP

Recarburization ball for prebaked anode casting, preparation method of recarburization ball and phosphorous pig iron recarburization method

The invention relates to the field of aluminum electrolysis production, in particular to a recarburization ball for prebaked anode casting, a preparation method of the recarburization ball and a phosphorous pig iron recarburization method. The recarburization ball for prebaked anode casting is prepared by pressing 95.5%-98.5% of a carbon material, 1.0%-3.5% of a binder and 0.5%-1% of carbonate by mass percent into a pellet. The carbon material is cathode milling face powder generated in the aluminum cathode processing process. The preparation method is simple, the prepared recarburization ball is low in cost, and the recarburization effect on phosphorous pig iron is good. The phosphorous pig iron recarburization method comprises the steps that a recarburization agent and a phosphorous pig iron raw material are added into an intermediate frequency furnace in a layered manner, and then smelting is carried out. The method is high in carbon absorptivity and good in recarburization effect, and it can be guaranteed that the new phosphorous pig iron carbon content is controlled to range from 3.0% to 3.5%; meanwhile, material flying losses in the phosphorous pig iron recarburization process can be effectively reduced, and the workshop environment can be improved; and the flowability phosphorous pig iron liquid is good, and the obtained phosphorous pig iron meets the requirement of phosphorous pig iron for prebaked anode casting.

Owner:SHANDONG NANSHAN ALUMINUM +1

Efficient recarburization accelerant

The invention provides an efficient recarburization accelerant. The efficient recarburization accelerant is characterized in that the efficient recarburization accelerant is composed of metal powder,a carbon material and a binding agent. The binding agent is composed of an organic binder body and an inorganic binder body. The inorganic binder body is at least one of orthosilicic acid, silicate and clay. The organic binder body comprises the following components of, by weight, 10-16 parts of sodium carboxymethylcellulose, 10-16 parts of cellulose acetate butyrate, 0.5-3 parts of starch, 1-3 parts of poval, 2-5 parts of borax and 3-6 parts of paraffin. The efficient recarburization accelerant is wide in application, can be used for recarburization in the smelting process of carbon steel, plain carbon steel, alloy steel, special steel, gray pig iron, nodular cast iron and the like, synergistic effects occur among the components, the absorption rate of recarburization can be sharply improved, the particle sizes are even, the quality is stable, using is convenient, no flying dust is generated, safety and environmental protection are achieved, and the recarburization effect is excellent.

Owner:JIANGSU JIEDI ROBOT

A carburizing and quenching method and carburizing and quenching equipment for internal splines of a side shaft gear

ActiveCN110541139BImproved carburizing and quenchingUniform carburizing and quenchingSolid state diffusion coatingFurnace typesMetallurgyGear wheel

The invention discloses a carburizing and quenching method and carburizing and quenching equipment for internal splines of a side shaft gear. Heat to 900°C, and feed propane at the position of the inner spline for 240 minutes; then lower the temperature of the inner spline to 840°C, and continue feeding propane for 45 minutes; stop heating and feed propane, and switch to Inject high-pressure high-purity nitrogen for 20 minutes, and finally take out the half-shaft gear from the quenching furnace to cool to room temperature; the equipment includes a quenching furnace, which is equipped with a hollow placement column, and the bottom of the quenching furnace is connected to an exhaust pipe; the side of the placement column The first branch pipe and the second branch pipe are connected through the air intake pipe in the tangential direction; the top of the quenching furnace is connected with a telescopic cylinder, and the bottom end of the telescopic cylinder is fixed with a resistance heating coil through a motor. The invention not only can improve the carburizing effect at the position of the inner spline, but also has the advantage of less deformation of the inner spline.

Owner:ZHEJIANG PUJIANG GEAR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com