Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Reduce flying loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-temperature-resistance high-toughness as-cast ductile iron, and production method and application thereof

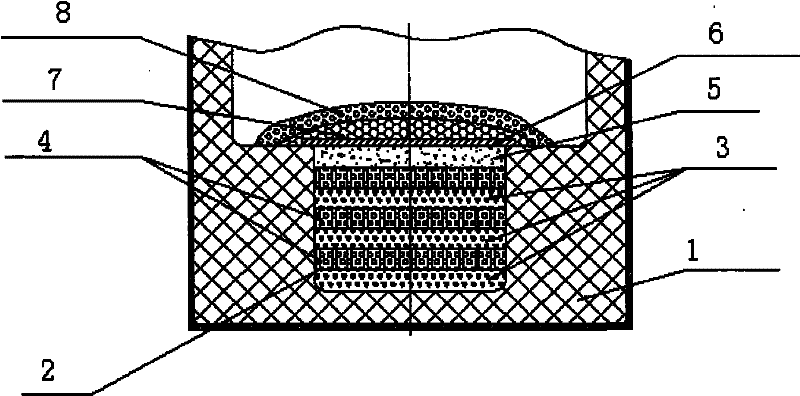

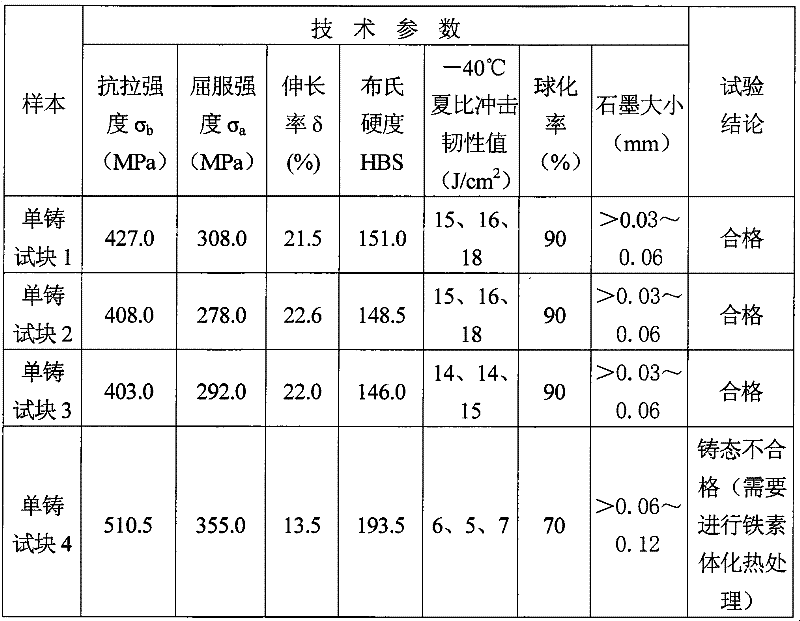

The invention discloses low-temperature-resistance high-toughness as-cast ductile iron, which comprises the following chemical ingredients in percentage by weight: 3.4 to 3.6 percent of C, 2.0 to 2.3 percent of Si, at most 0.2 percent of Mn, at most 0.02 percent of P, at most 0.01 percent of S, 0.035 to 0.05 percent of Mg residue, 0.015 to 0.025 percent of sigma Re residue, 0.05 to 0.1 percent of Sr, 0.15 to 0.25 percent of Ni, 0.10 to 0.15 percent of Ti and the balance Fe. The invention also discloses a production method and application of the low-temperature-resistance high-toughness as-cast ductile iron to the preparation of wind-power generator accessories, automobile accessories, boat accessories and petrochemical engineering. The low-temperature-resistance high-toughness as-cast ductile iron produced by the method provided by the invention can reach each technical index of QT400-18L of GB / T1348-2009 in the cast state, the graphitizing annealing heat treatment is avoided, the energy consumption is reduced, and meanwhile, the low-temperature-resistance high-toughness as-cast ductile iron has the outstanding advantages of stable quality and the like, and the operation is simple and convenient.

Owner:四川海工科技有限公司

On-line hot preparation method of glass batch

InactiveCN101913752AImprove thermal conductivityIncrease the reaction areaCharging furnaceGlass productionAdhesiveRefractory

The invention discloses an on-line hot preparation method of a glass batch. The method comprises the following steps of: adding a proper quantity of adhesives to a traditional glass batch and pressing the mixture into a block material; preheating to decompose the molded block material in a firing kiln to form a sintered block consisting of silicate and silicon dioxide, immediately pulverizing the block into granules in the hot state; conveying and uniformly scattering the granules into a filling pocket; and pushing into a glass kiln for melting. The on-line hot preparation method of the glass batch can greatly improve the heat conductivity coefficient of the batch, improve the melting rate of the glass kiln, increase the glass capacity and achieve the purpose of saving energy. The compacted glass batch block reduces flying dust in the glass kiln, prolongs the service life of refractory materials, prevents the blockage of a regenerative chamber, purifies the operating environment, reduces the flying loss of the batch and stabilizes the glass component. The method ensures that the melting rate can be improved by 20-30 percent. Compared with a traditional method, the method ensures that the fuel consumed for producing the same quantity of glass can be saved by 10-20 percent.

Owner:杭州蓝星新材料技术有限公司

Method for using petroleum coke fine powder in preparation of prebaked anode used for aluminum electrolysis

Belonging to production methods of carbon products, the invention discloses a method for using petroleum coke fine powder in preparation of a prebaked anode used for aluminum electrolysis, especially a production method of a prebaked anode used for aluminum electrolysis. According to the method for using petroleum coke fine powder in preparation of a prebaked anode used for aluminum electrolysis, the treatment method consists of: conducting screening with a standard sieve with a mesh of 1mm, drying the screened fine material with a size less than 1mm at a temperature of 90-120DEG C for 1-2h, then carrying out grinding to obtain fine powder with a size less than 0.074mm. The method employs the following materials: 82-84% of calcined coke, 14% of asphalt, and 2-4% of the fine powder. The method provided in the invention utilizes the petroleum coke containing 9-14% of volatile matters, which are mainly light low molecular carbon compounds, and makes use of the intrinsic self-binding and self-sintering properties of the petroleum coke, thereby reducing the adding amount of a binder in traditional carbon product formulas. Therefore, the method saves the calcination cost and the binder cost, and also reduces the calcination loss, dust loss as well as the discharge of calcined asphalt fume.

Owner:济南海川投资集团有限公司

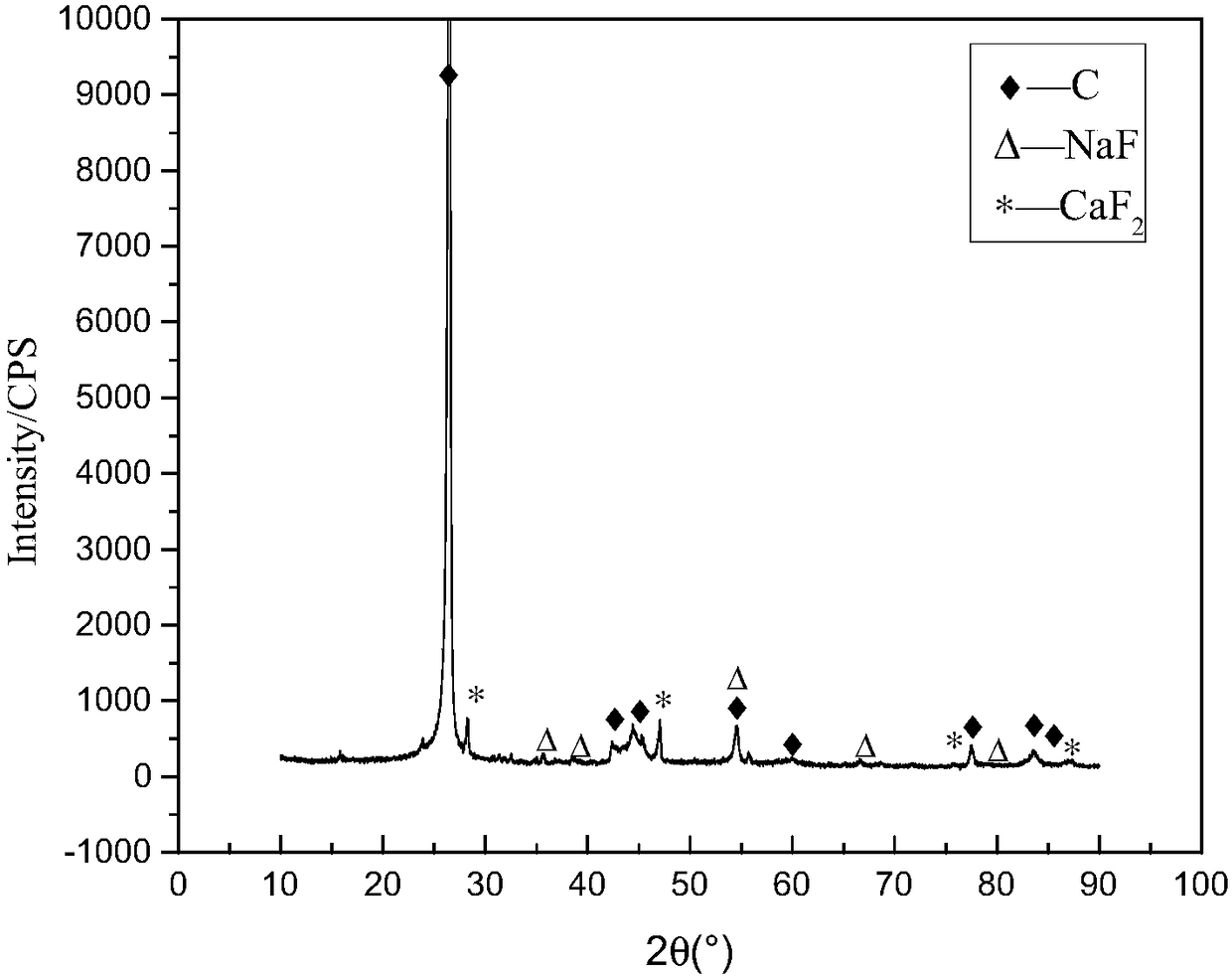

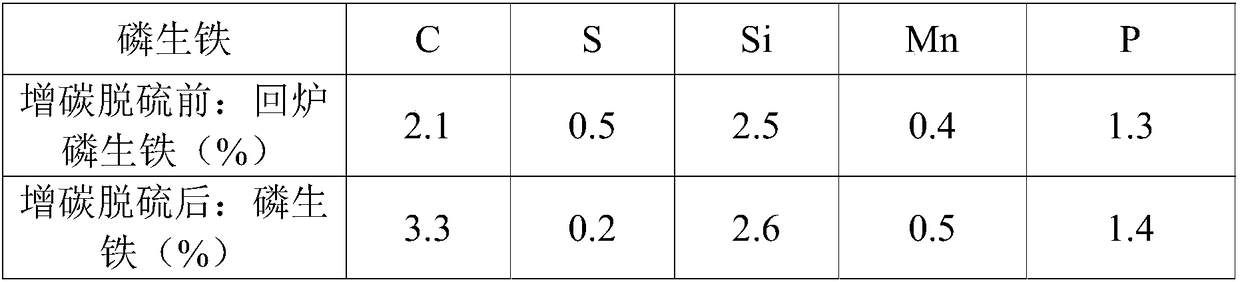

Phosphorous pig iron carbon increasing method for aluminum electrolysis

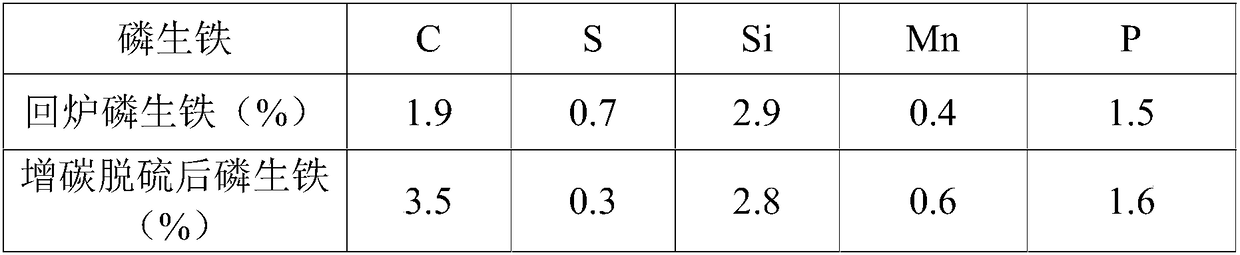

The ferrophosphorus carburizing method is that waste anode carbon grain of granularity 1-5 mm is added into the intermediate frequency furnace to increase the carbon content in ferrophosphorus. The waste anode carbon grain from aluminum electrolyzing bath has greater specific weight of 1.6 g / cu cm, raised carburizing effect, less powder pollution, low carburizing cost, simple carburizing process and obviously increased carbon content in ferrophosphorus.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

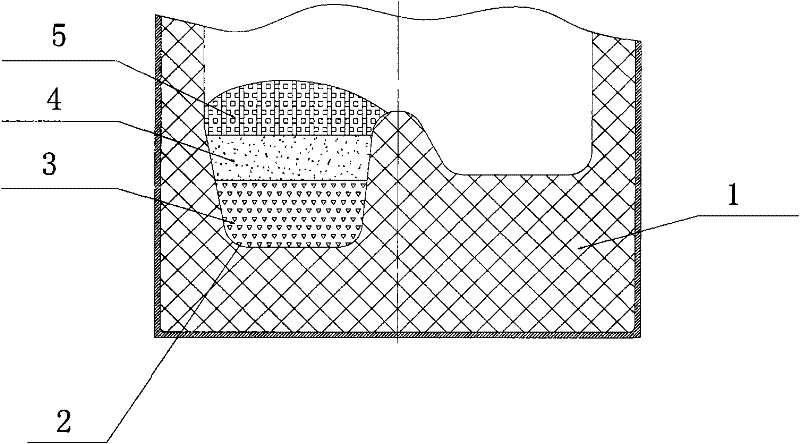

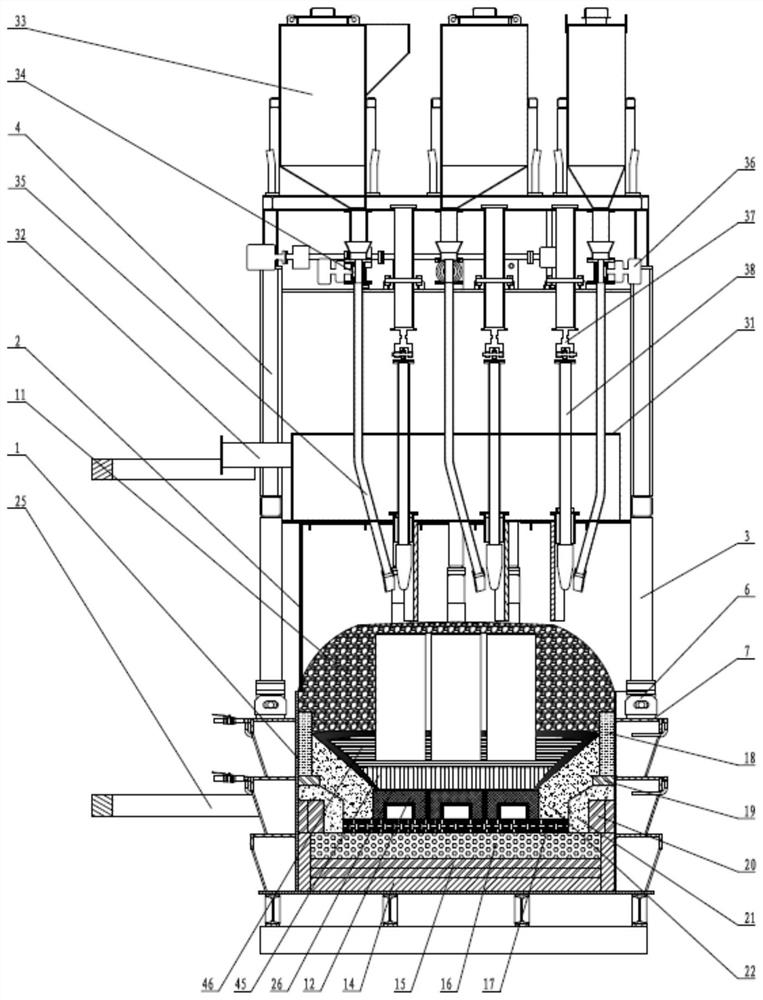

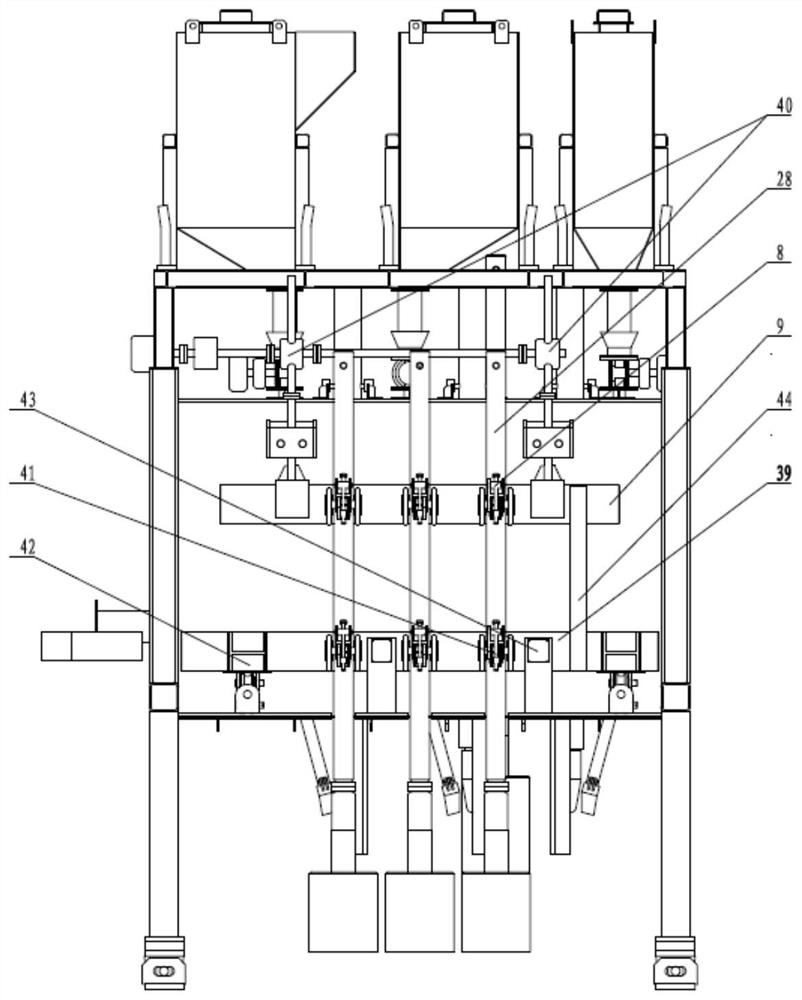

Rare earth electrolytic tank for producing rare earth and alloys thereof

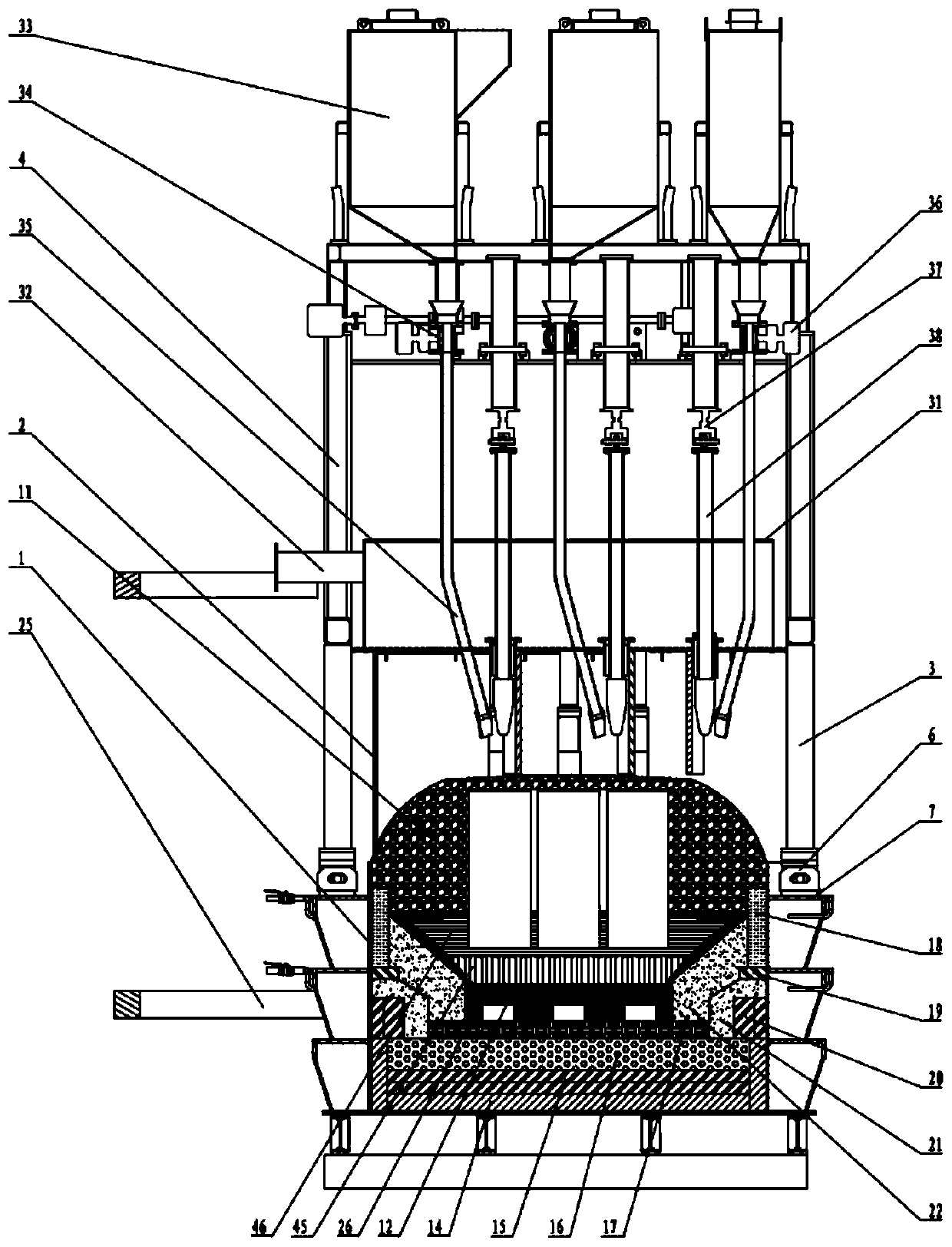

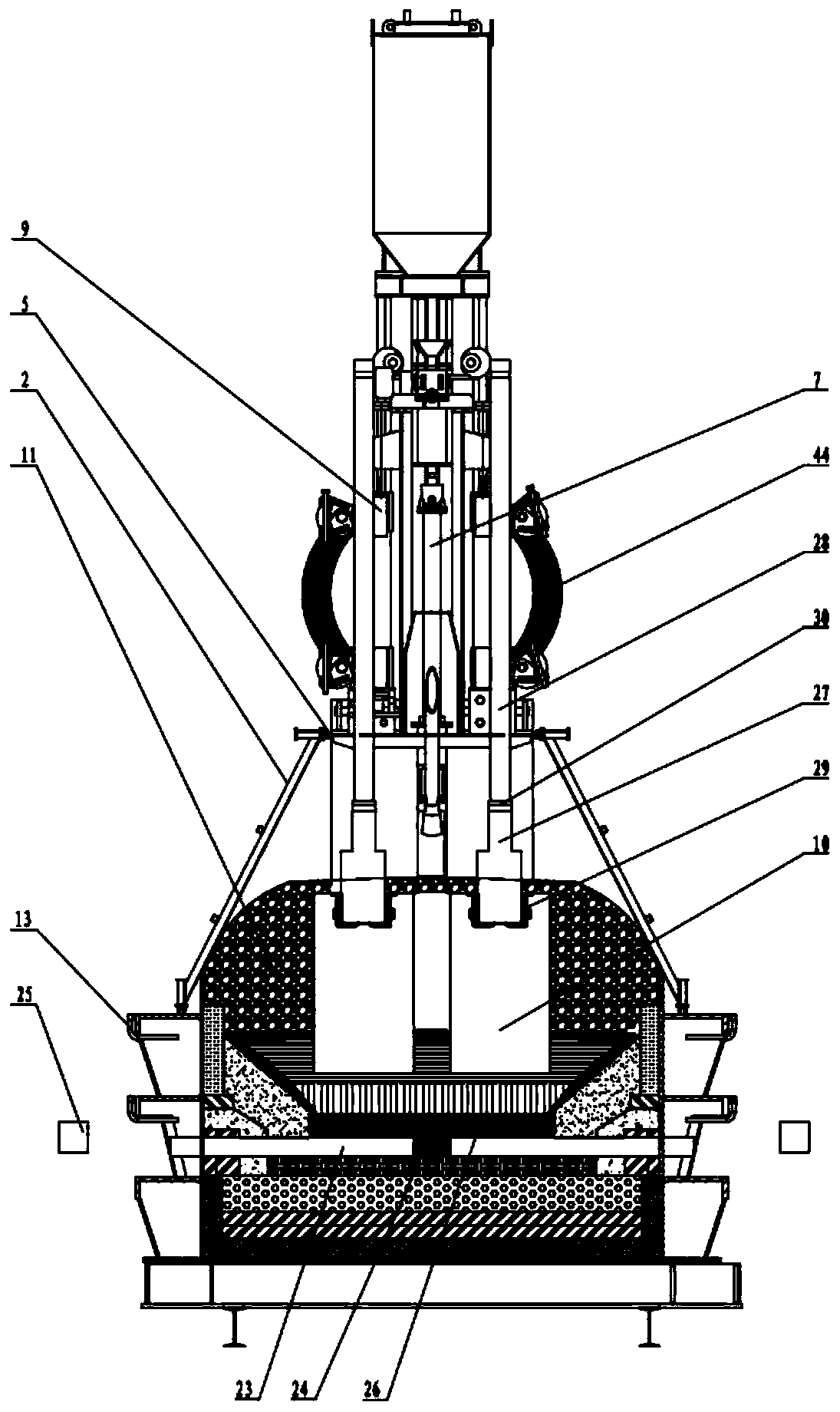

The invention discloses a rare earth electrolytic tank for producing rare earth and alloys thereof. The rare earth electrolytic tank comprises an electrolytic tank body, a cathode group structure, ananode group structure and a tank upper portion structure, wherein the electrolytic tank body comprises a tank shell and a tank lining, the tank upper portion structure comprises a vertical column girder frame, a material feeding system, a shell ramming system, an anode lifting and busbar switching system and a tank hood plate, the upper end of the anode group structure is connected with the anodelifting and busbar switching system, anode blocks at the lower end are vertically inserted in electrolyte inside the tank body, the parts, exposed outside the electrolyte level face, of the anode blocks are covered by an anode covering material, the anode lifting and busbar switching system is used for adjusting the polar distance between the anode blocks and the cathode group structure, the material feeding system, the shell ramming system and the anode lifting and busbar switching system are integrated into an intelligent tank control system, the upper edge of the tank hood plate is connected with the edge of the side portion of a horizontal hood plate, and the lower edge of the tank hood plate is connected with the upper surface of the tank shell to realize closeness of the electrolytictank. By means of the rare earth electrolytic tank for producing the rare earth and the alloys thereof, rare earth electrolytic tank automatic continuous, high-efficiency, low-energy-consumption, low-cost and clean production is realized.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Aluminum electrolytic cell crust breaking and discharging integrated device

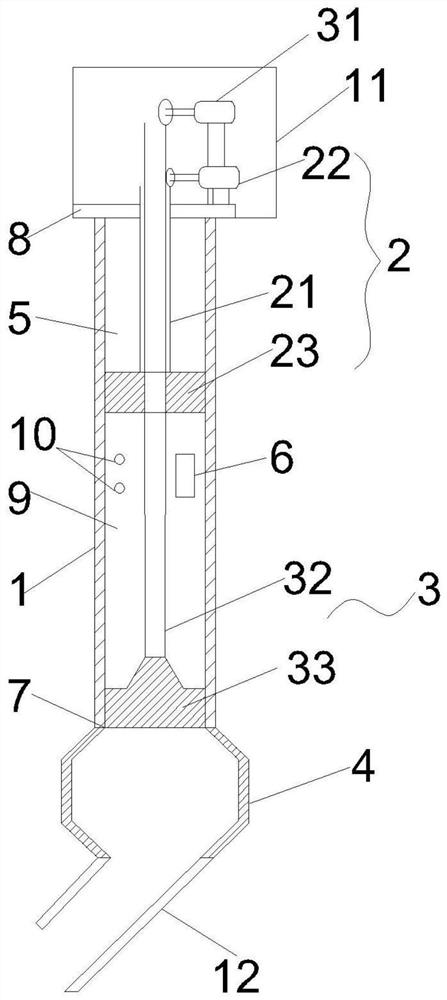

The invention relates to an aluminum electrolytic cell crust breaking and discharging integrated device. The aluminum electrolytic cell crust breaking and discharging integrated device comprises a constant-volume device. The constant-volume device is provided with a frame body extending upwards and a material guide barrel vertically extending downwards, and the bottom of the material guide barrelis provided with an opening. A linear driving part is fixed to the frame. The inner wall of the material guide barrel is provided with an annular sealing element. The output end of the linear drivingpart is connected with a moving guide rod. The moving guide rod penetrates through a feed port, a discharge port and an opening of the annular sealing element in sequence from top to bottom. The lowerend of the moving guide rod is connected with a crust breaking hammer head. A first piston matched with the feed port, a second piston matched with the discharge port and a third piston matched withthe opening of the annular sealing element are sequentially arranged on the moving guide rod from top to bottom. The aluminum electrolytic cell crust breaking and discharging integrated device can accurately position a discharge port fire eye, can effectively prevent the situation that material shortage of an electrolytic cell occurs due to flying of aluminum oxide powder and improve the working efficiency and is convenient to maintain; the equipment cost and operating cost can be reduced, and the manual labor intensity can be reduced.

Owner:CENT SOUTH UNIV

Alkali replenishing method during alumina production

InactiveCN1389400AReduce flying lossReduce manufacturing costAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium oxides/hydroxidesSlurryL&D process

The present invention relates to a method for supplementing alkali in the course of alumina production by adopting pure sintering process, parallel process, series connection process and mixed connection process, and said method includes: dissolving alkali powder Na2CO3 to obtain high-content alkali liquor whose Na2O concentration is 123.5 g / l-247.1 g / l, then using alkali liquor transfer pump to feed said alkali liquor into the alkali liquor storage tank to prepare raw stock slurry whose Na2O concentration is 127.14g / l-195.6g / l, then adding the alkali into conventional alumina production process with raw stock slurry. Said ivnention can be substituted for traditional dry alkali-supplementing method, not only reduce production cost, but also raise production efficiency.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Phosphorous pig iron carbon increasing method for aluminum electrolysis

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

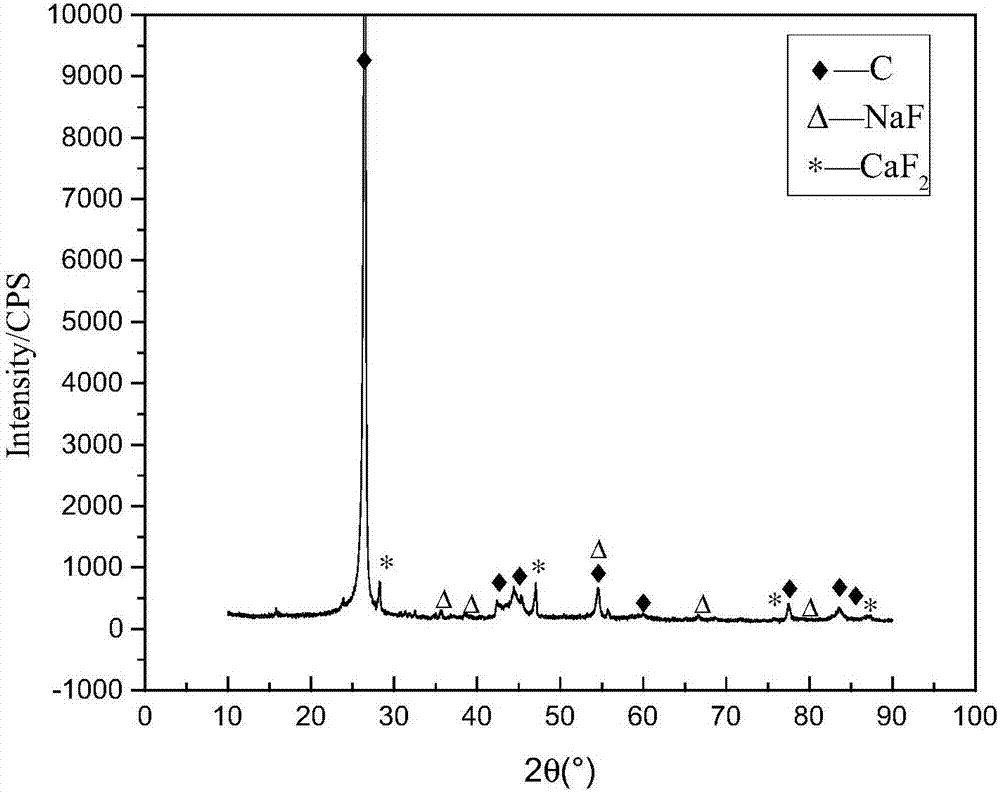

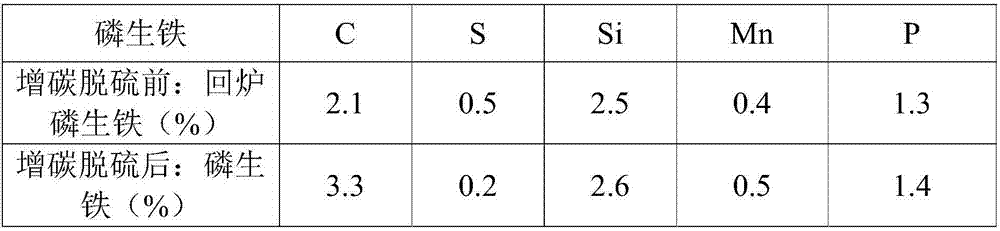

Environment-friendly phosphorous pig iron additive, preparation method of environment-friendly phosphorous pig iron additive and phosphorous pig iron recarburization and desulphurization method

ActiveCN106868246AGood effect of carbon increase and desulfurizationPromote water flowSolid carbonIntermediate frequency

The invention relates to the field of aluminum electrolysis production, in particular to an environment-friendly phosphorous pig iron additive, a preparation method of the environment-friendly phosphorous pig iron additive and a phosphorous pig iron recarburization and desulphurization method. The environment-friendly phosphorous pig iron additive is prepared by pressing 95.5%-98.5% of a carbon material, 1.0%-3.5% of a binder and 0.5%-1% of carbonate by mass percent into a pellet. The carbon material is solid carbon obtained by carrying out vacuum metallurgy treatment on waste cathode carbon blocks. The preparation method is simple, the prepared additive is low in cost, and the recarburization and desulphurization effect on phosphorous pig iron is good. The phosphorous pig iron recarburization and desulphurization method comprises the steps that the additive and a phosphorous pig iron raw material are added into an intermediate frequency furnace in a layered manner, and then smelting is carried out. The method is high in carbon absorptivity and good in desulphurization effect, meanwhile, material flying losses in the phosphorous pig iron recarburization and desulphurization process can be effectively reduced, and the workshop environment can be improved; and the flowability phosphorous pig iron liquid is good, and the obtained phosphorous pig iron meets the requirement of phosphorous pig iron for prebaked anode casting.

Owner:SHANDONG NANSHAN ALUMINUM +1

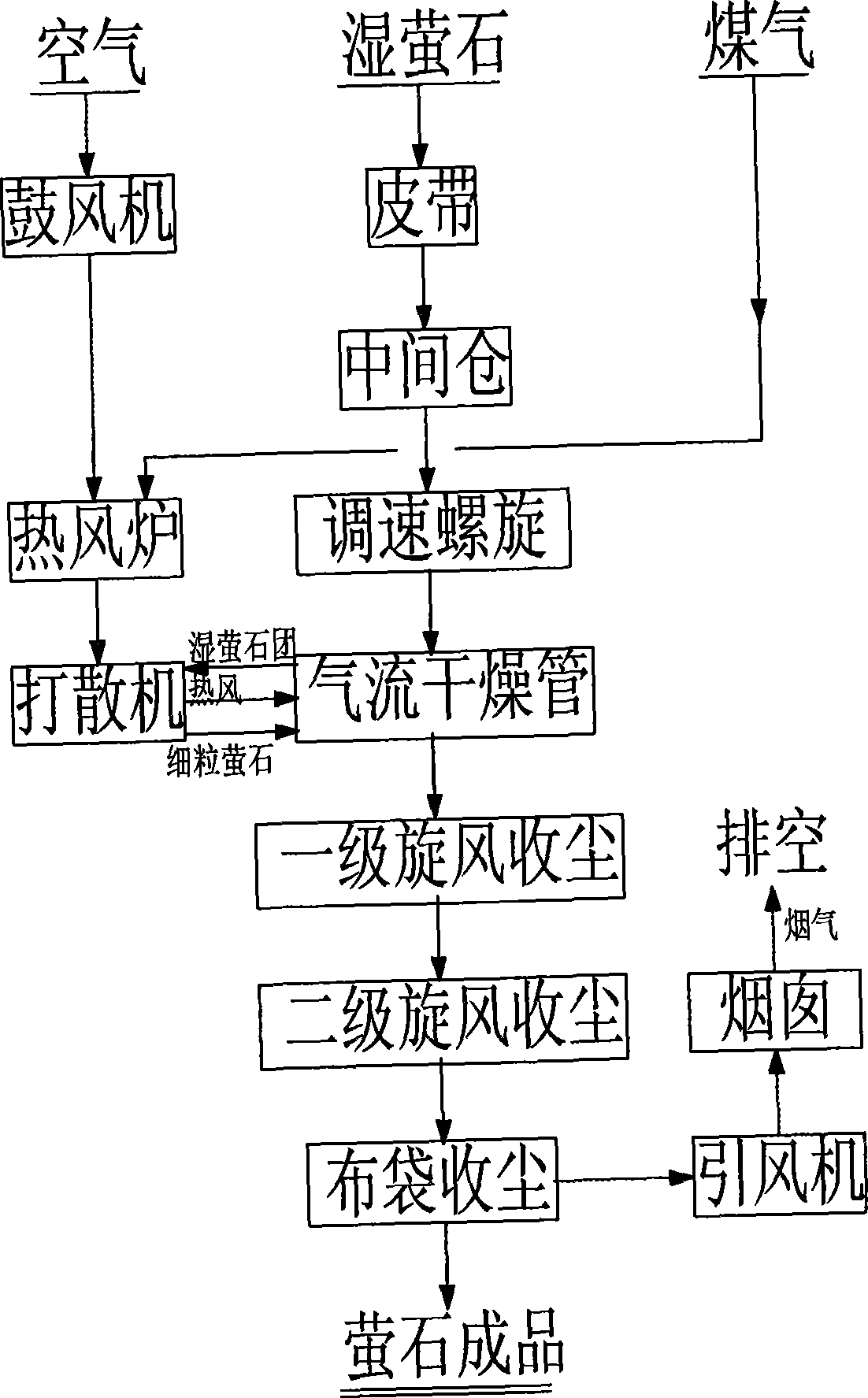

Method for drying fluorspar

InactiveCN101251329AReduce energy consumptionLess flyingDrying solid materials with heatHearth type furnacesCombustion chamberEngineering

The invention discloses a method for drying fluorite, comprising the following steps that: a wet fluorite is placed into a middle storage hopper and then into an air stream drying device, the small particles material is directly dried by the high-temperature air stream from a combustion chamber, is dedusted by the whirlwind and is sent to the finished product storage hopper, the wet conglobated material which is not dried by the hot air stream completely is dried by the hot wind and freely falls at the same time, the smashed small particles are blown up again to be dried, the dried particles are dedusted by the whirlwind and then are sent to the finished product material. Compared with the prior method for drying the fluorite, the new fluorite air stream drying technique of the invention has small investment, small occupied area, high operating thermal efficiency, low energy consumption, small pollution, low labor intensity of workers, easy control and operation and relatively great technical superiority; therefore, the new fluorite air stream drying technique is a breakthrough of the prior manufacturing technique.

Owner:河南未来铝业(集团)有限公司

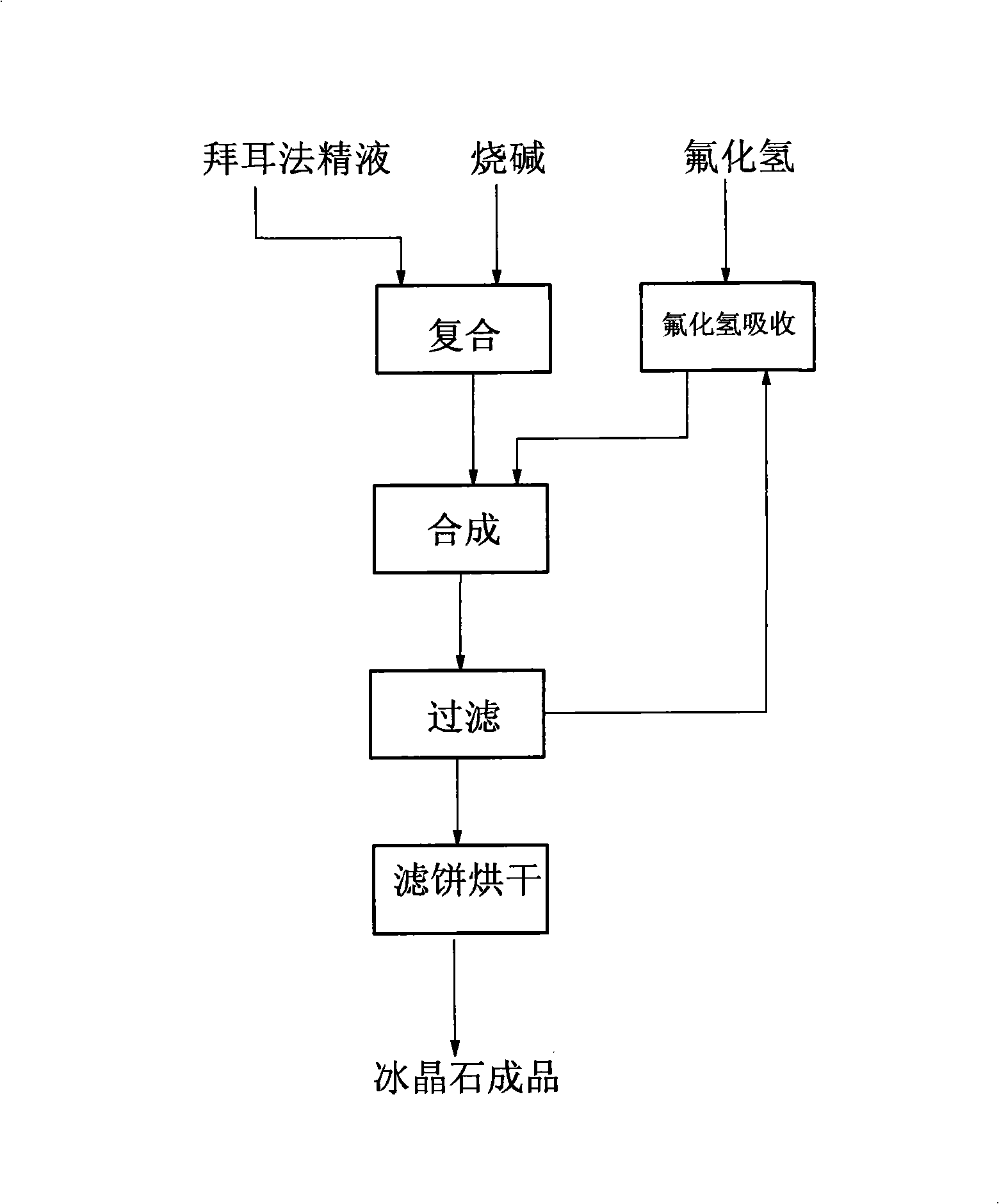

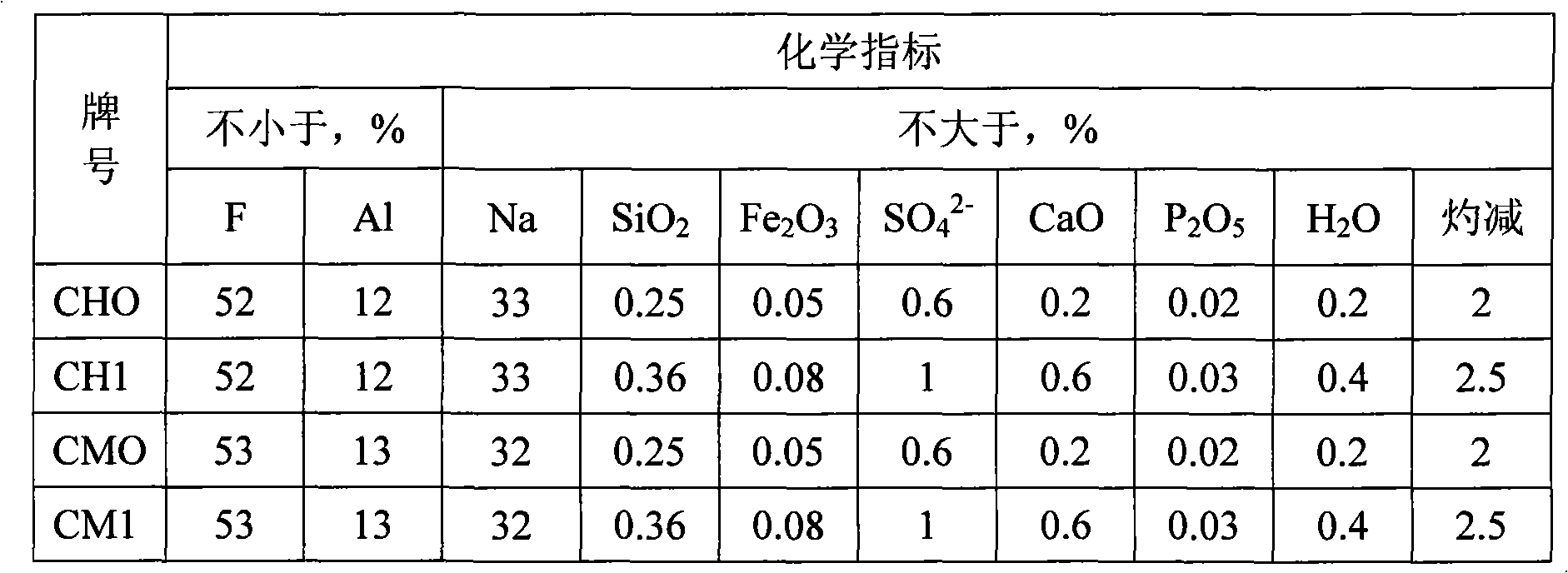

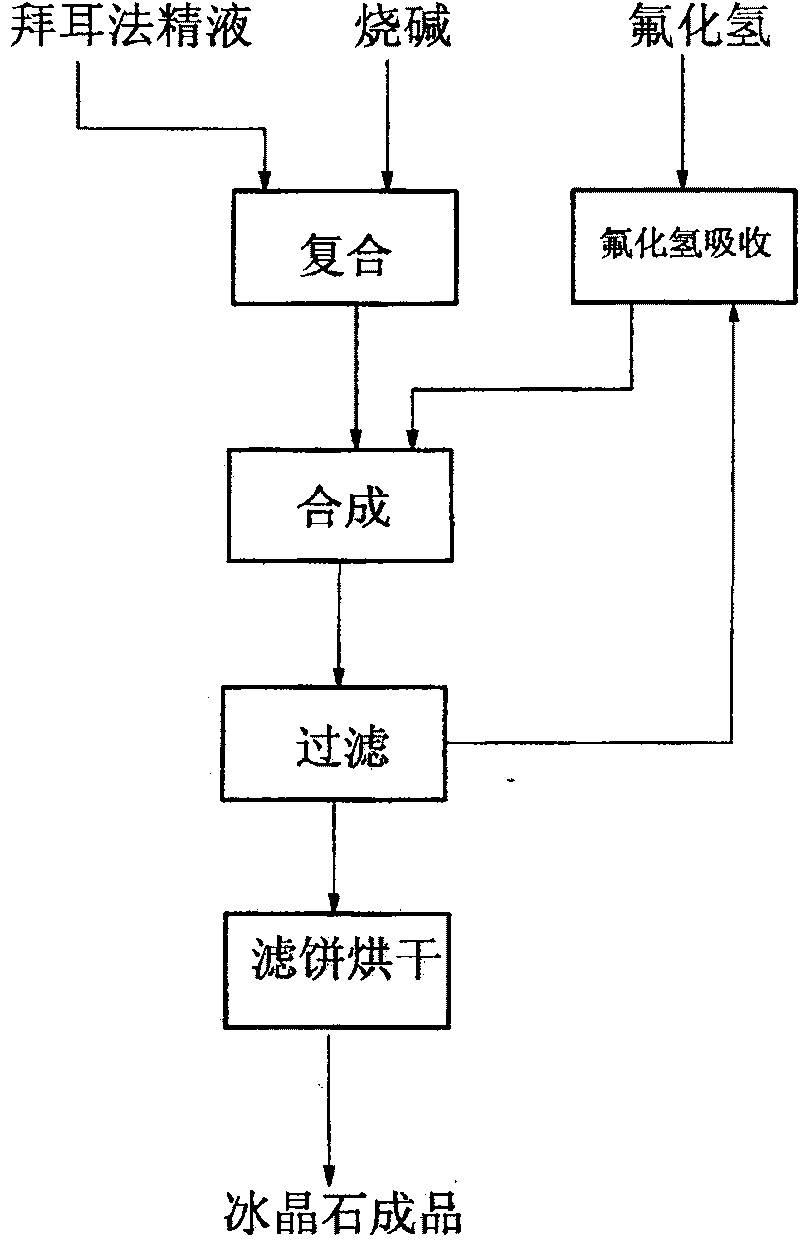

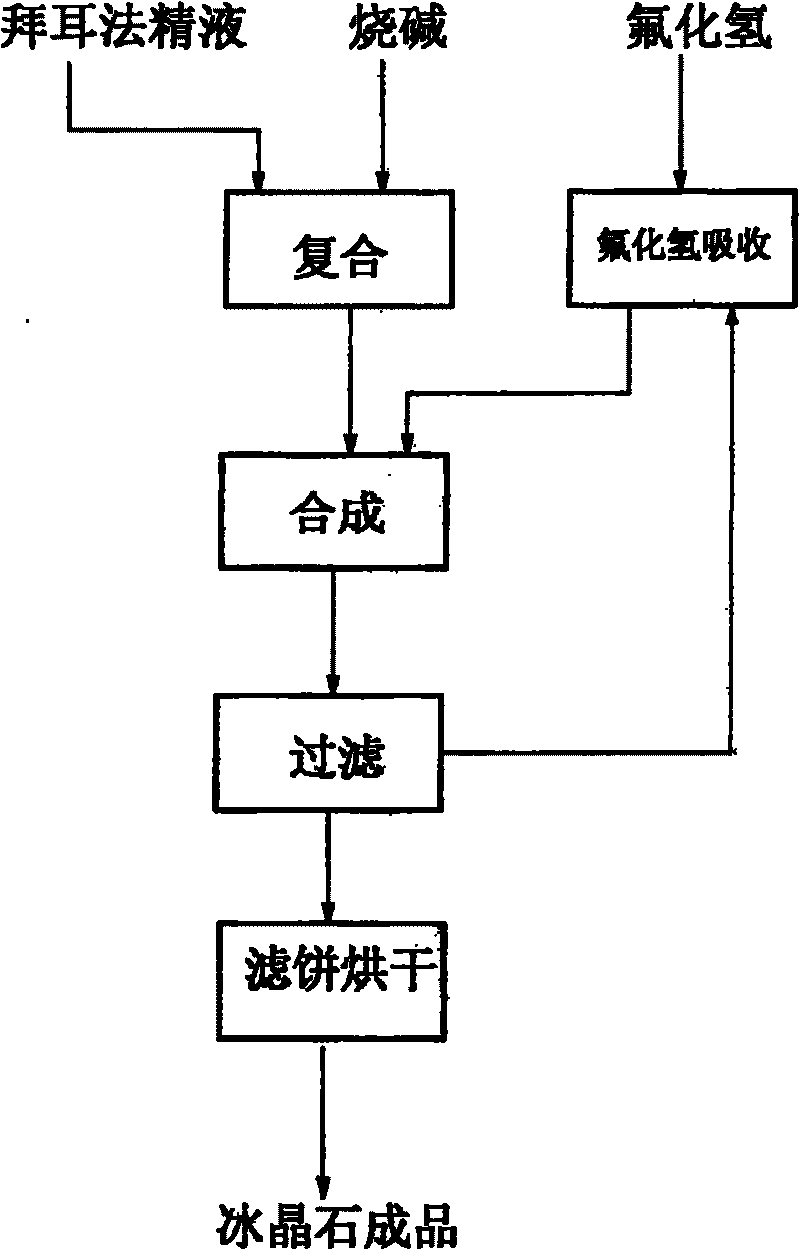

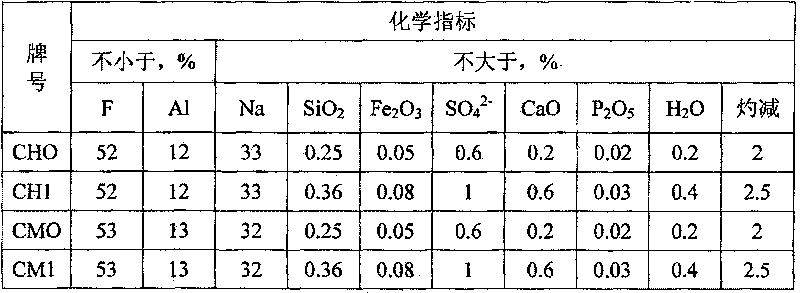

Method for producing large grain size cryolite

InactiveCN101264917AMolecular ratio adjustableMeet the needs of developmentAluminium fluoridesHydrofluoric acidReaction temperature

The invention discloses a production method for a large grain size cryolite, which is characterized in that Bayer process concentrate solution, caustic soda, and hydrofluoric acid are used as raw materials, and the proportion of raw materials is represented in the equation that Al: Na: F equals to 1:1.8-3:5-6; when compounding, the caustic soda is added into the Bayer process concentrate solution with a temperature of 90-95 DEG C, and mixed evenly to obtain the composite solution; then, the composite solution and hydrofluoric acid are gradually added into a synthesis tank, and the material feeding and agitation are carried out in the meantime, the reaction temperature is maintained between 85 and 95 DEG C, and the PH value of the reaction solution is smaller than or equal to 2; after feeding materials, the mixture undergoes an ageing process for 20 to 30 minutes; finally, the slurry is filtered, the filter cake is dried until the water content drops below 0.2%, thus acquiring the finished cryolite. The production method has the advantages that: as wet method is adopted during the production, the reaction is conducted under normal temperature, the process is simple, and easy to operate and control; the heat source is derived from the reaction heat, and the need to add a heating apparatus is avoided; by adjusting the parameters, such as the reaction temperature, PH value and ageing time, the product D50 grain size can be increased by more than 10 Mu m compared with the prior art up to 26-30 Mu m; the molecular ratio of NaF to AlF3 is adjustable, thus meeting the demands of electrolytic aluminum industry.

Owner:河南未来铝业(集团)有限公司

Recarburization ball for prebaked anode casting, preparation method of recarburization ball and phosphorous pig iron recarburization method

The invention relates to the field of aluminum electrolysis production, in particular to a recarburization ball for prebaked anode casting, a preparation method of the recarburization ball and a phosphorous pig iron recarburization method. The recarburization ball for prebaked anode casting is prepared by pressing 95.5%-98.5% of a carbon material, 1.0%-3.5% of a binder and 0.5%-1% of carbonate by mass percent into a pellet. The carbon material is cathode milling face powder generated in the aluminum cathode processing process. The preparation method is simple, the prepared recarburization ball is low in cost, and the recarburization effect on phosphorous pig iron is good. The phosphorous pig iron recarburization method comprises the steps that a recarburization agent and a phosphorous pig iron raw material are added into an intermediate frequency furnace in a layered manner, and then smelting is carried out. The method is high in carbon absorptivity and good in recarburization effect, and it can be guaranteed that the new phosphorous pig iron carbon content is controlled to range from 3.0% to 3.5%; meanwhile, material flying losses in the phosphorous pig iron recarburization process can be effectively reduced, and the workshop environment can be improved; and the flowability phosphorous pig iron liquid is good, and the obtained phosphorous pig iron meets the requirement of phosphorous pig iron for prebaked anode casting.

Owner:SHANDONG NANSHAN ALUMINUM +1

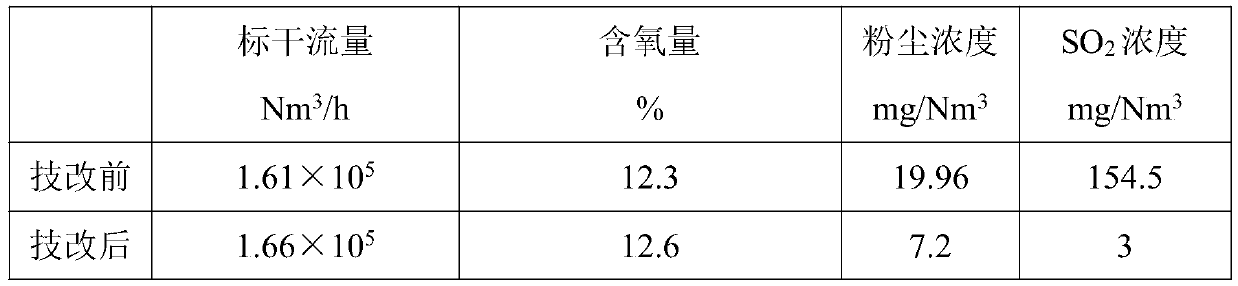

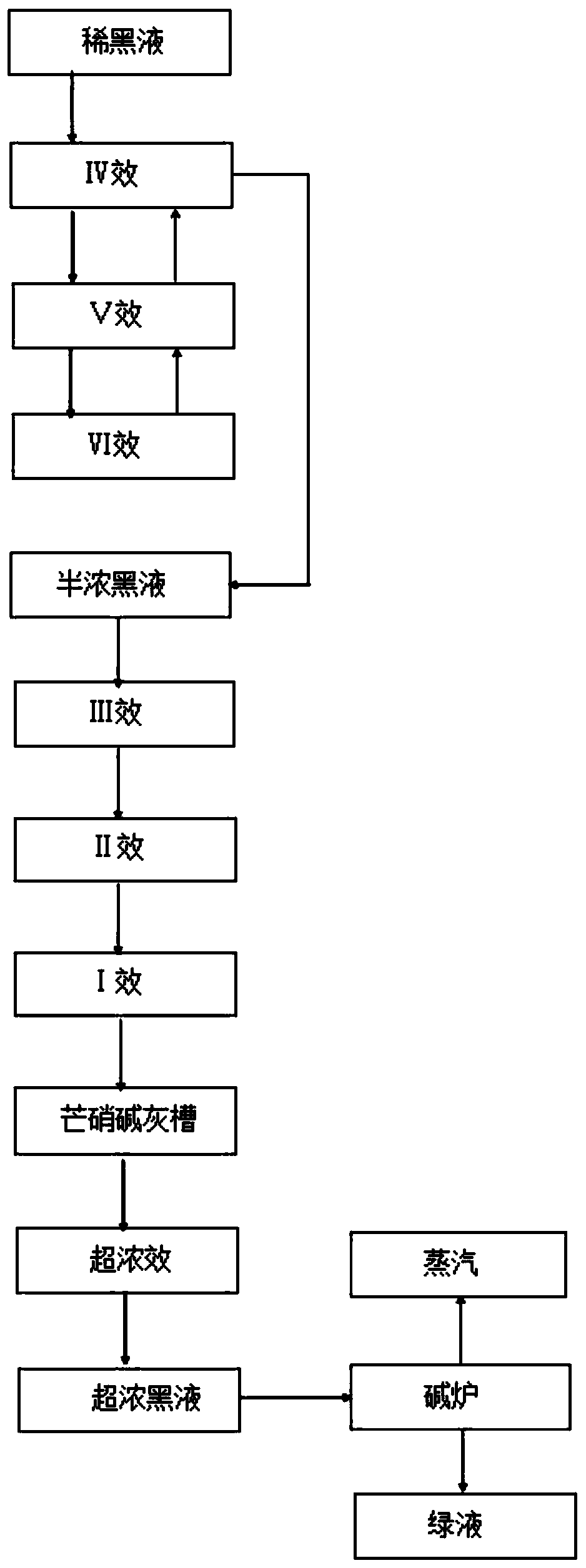

Production method for effectively reducing emission of dust and sulfur dioxide in flue gas of alkali recovery furnace

InactiveCN110975525AIncrease temperatureAccelerate evaporationGas treatmentDispersed particle separationFlue gasDust control

The invention discloses a production method for effectively reducing the emission of dust and sulfur dioxide in flue gas of an alkali recovery furnace. The production method comprises the following steps: (1) a black liquid ultra-concentration technology, wherein thickening crystallization effect is newly added to increase the concentration of a black liquid, and an ultra-thick combustion technology is adopted to change an alkali furnace air supply system and achieve stable and efficient combustion; (2) a dust remover technology, wherein a wet type electric dust remover is additionally arranged to cooperatively remove dust on the premise of a dry type electric dust remover so as to reduce the dust concentration in flue gas; and (3) a dilute white liquid desulfurization technology, whereina causticized dilute white liquid is added into the wet type electric dust remover to serve as a circulating liquid to absorb SO2 in the flue gas so as to further reduce the discharge amount of the SO2. According to the invention, the method meets the national alkali recovery boiler flue gas emission standard, wherein the SO2 emission concentration is not higher than 200 mg / Nm<3>, and the dust emission concentration is not higher than 20 mg / Nm<3>; and the SO2 and the dust achieve the purpose of ultralow emission after technical improvement, and good social and ecological benefits are achieved.

Owner:FUJIAN QINGSHAN PAPER INDUSTRY CO LTD

Low-temperature-resistance high-toughness as-cast ductile iron, and production method and application thereof

The invention discloses low-temperature-resistance high-toughness as-cast ductile iron, which comprises the following chemical ingredients in percentage by weight: 3.4 to 3.6 percent of C, 2.0 to 2.3 percent of Si, at most 0.2 percent of Mn, at most 0.02 percent of P, at most 0.01 percent of S, 0.035 to 0.05 percent of Mg residue, 0.015 to 0.025 percent of sigma Re residue, 0.05 to 0.1 percent ofSr, 0.15 to 0.25 percent of Ni, 0.10 to 0.15 percent of Ti and the balance Fe. The invention also discloses a production method and application of the low-temperature-resistance high-toughness as-cast ductile iron to the preparation of wind-power generator accessories, automobile accessories, boat accessories and petrochemical engineering. The low-temperature-resistance high-toughness as-cast ductile iron produced by the method provided by the invention can reach each technical index of QT400-18L of GB / T1348-2009 in the cast state, the graphitizing annealing heat treatment is avoided, the energy consumption is reduced, and meanwhile, the low-temperature-resistance high-toughness as-cast ductile iron has the outstanding advantages of stable quality and the like, and the operation is simpleand convenient.

Owner:四川海工科技有限公司

An integrated device for shelling and unloading aluminum electrolytic cell

The invention relates to an aluminum electrolytic cell crust breaking and discharging integrated device. The aluminum electrolytic cell crust breaking and discharging integrated device comprises a constant-volume device. The constant-volume device is provided with a frame body extending upwards and a material guide barrel vertically extending downwards, and the bottom of the material guide barrelis provided with an opening. A linear driving part is fixed to the frame. The inner wall of the material guide barrel is provided with an annular sealing element. The output end of the linear drivingpart is connected with a moving guide rod. The moving guide rod penetrates through a feed port, a discharge port and an opening of the annular sealing element in sequence from top to bottom. The lowerend of the moving guide rod is connected with a crust breaking hammer head. A first piston matched with the feed port, a second piston matched with the discharge port and a third piston matched withthe opening of the annular sealing element are sequentially arranged on the moving guide rod from top to bottom. The aluminum electrolytic cell crust breaking and discharging integrated device can accurately position a discharge port fire eye, can effectively prevent the situation that material shortage of an electrolytic cell occurs due to flying of aluminum oxide powder and improve the working efficiency and is convenient to maintain; the equipment cost and operating cost can be reduced, and the manual labor intensity can be reduced.

Owner:CENT SOUTH UNIV

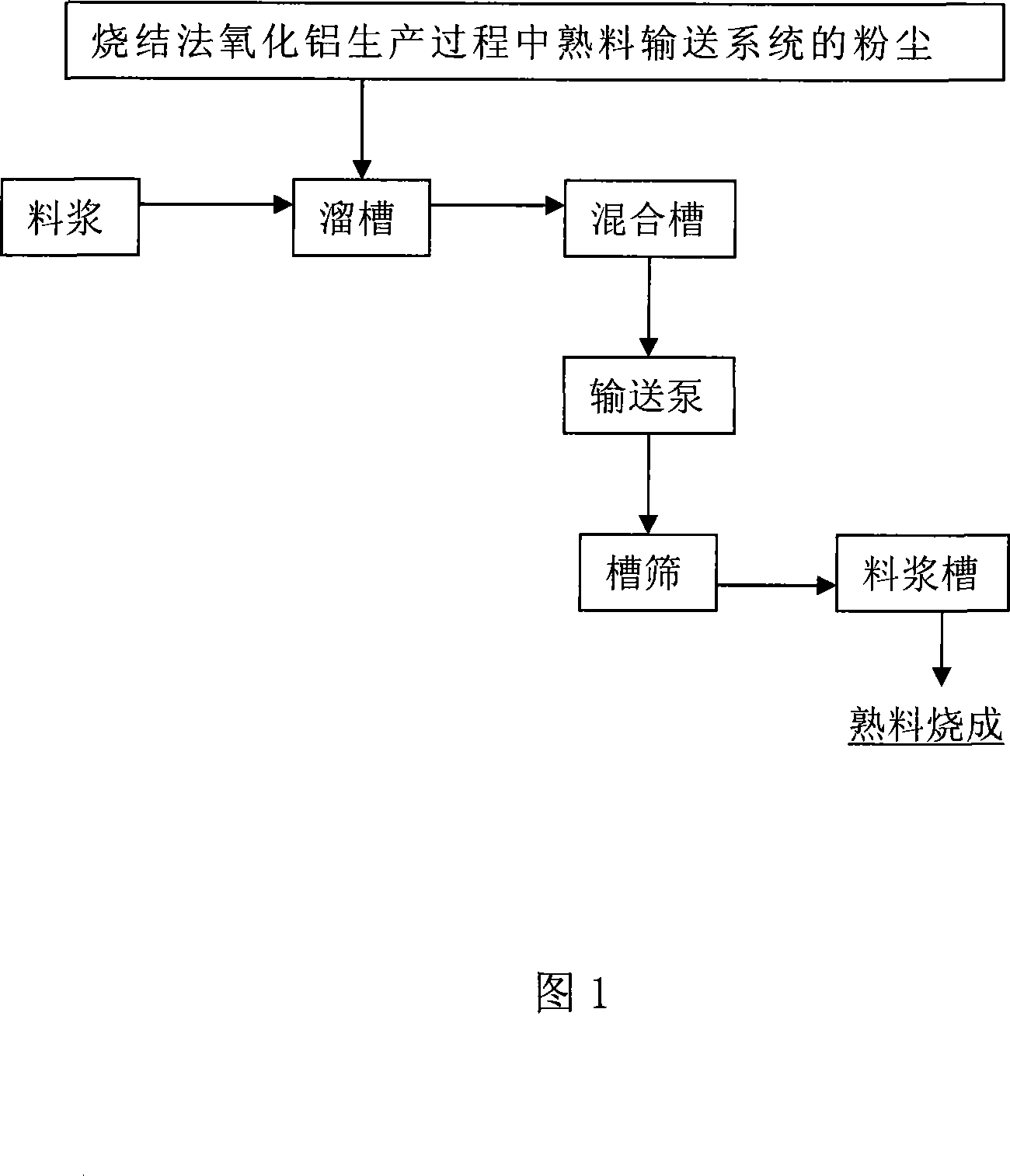

Method for treating clinker dust by sintering process

InactiveCN101157468ASolve the whereabouts problemEfficient recyclingSolid waste disposalAluminium oxides/hydroxidesTreatment issuesSlurry

A processing method for clinker dust of the sintering method relates to a method for utilizing dust of a clinker transmitting system in the process of aluminum oxide production by the sintering method. The invention is characterized in that dust of the clinker transmitting system in the process of aluminum oxide production by the sintering method is returned to a slurry tank in clinker burning process and then sent to a clinker kiln for sintering. The method of the invention solves the treatment issue of dust of the clinker transmitting system in the process of aluminum oxide production by the sintering method, reduces the influence on the following production processes and also improves the poor field environment sanitation caused by dust in sales. Through secondary sintering of dust of the clinker transmitting system in the process of aluminum oxide production by the sintering method, aluminum oxide and sodium oxide in the dust of the clinker transmitting system in the process of aluminum oxide production by the sintering method can be effectively reclaimed.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

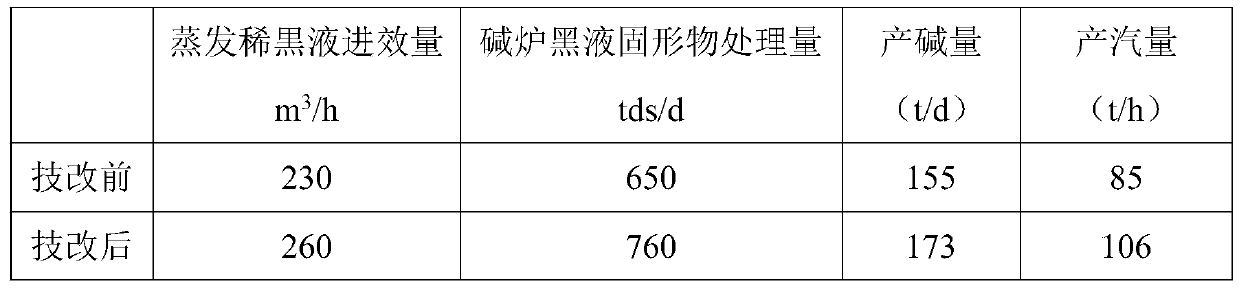

Production method for improving productivity of alkaline furnace

InactiveCN111017959AWell mixedImprove heat transfer coefficientAir supply regulationAlkali metal hydroxidesBlack liquorAir volume

The invention discloses a production method for improving productivity of an alkaline furnace. The method comprises the following steps: (1) evaporating and concentrating of black liquor, wherein coniferous wood dissolving pulp black liquor is evaporated and concentrated by using I effect, II effect, III effect, IV effect, V effect, VI effect and super-concentration effect, so that the concentration of the treated black liquor is over 72%; (2) air volume and air pressure proportioning, wherein the primary air volume is 40000 Nm<3> / h, the primary air pressure is 1000 pa, the secondary air volume is 45000 Nm<3> / h, the secondary air pressure is 1200 pa, the tertiary air volume is 32000 Nm<3> / h, and the tertiary air pressure is 1800 pa; and (3) jet combustion, wherein black liquor jet combustion is performed by setting the aperture of a black liquor spray gun at 20 mm and setting the jet pressure at 0.08 Mpa. According to the invention, the problem of insufficient productivity of an alkalirecovery system is solved, and through adjustment of the production process, the black liquor treatment capacity is effectively improved, and the alkali yield and the steam yield are increased.

Owner:FUJIAN QINGSHAN PAPER INDUSTRY CO LTD

Method for producing large grain size cryolite

InactiveCN101264917BMolecular ratio adjustableMeet the needs of developmentAluminium fluoridesHydrofluoric acidRoom temperature

The invention discloses a production method for a large grain size cryolite, which is characterized in that Bayer process concentrate solution, caustic soda, and hydrofluoric acid are used as raw materials, and the proportion of raw materials is represented in the equation that Al: Na: F equals to 1:1.8-3:5-6; when compounding, the caustic soda is added into the Bayer process concentrate solutionwith a temperature of 90-95 DEG C, and mixed evenly to obtain the composite solution; then, the composite solution and hydrofluoric acid are gradually added into a synthesis tank, and the material feeding and agitation are carried out in the meantime, the reaction temperature is maintained between 85 and 95 DEG C, and the PH value of the reaction solution is smaller than or equal to 2; after feeding materials, the mixture undergoes an ageing process for 20 to 30 minutes; finally, the slurry is filtered, the filter cake is dried until the water content drops below 0.2%, thus acquiring the finished cryolite. The production method has the advantages that: as wet method is adopted during the production, the reaction is conducted under normal temperature, the process is simple, and easy to operate and control; the heat source is derived from the reaction heat, and the need to add a heating apparatus is avoided; by adjusting the parameters, such as the reaction temperature, PH value and ageing time, the product D50 grain size can be increased by more than 10 Mu m compared with the prior art up to 26-30 Mu m; the molecular ratio of NaF to AlF3 is adjustable, thus meeting the demands of electrolytic aluminum industry.

Owner:河南未来铝业(集团)有限公司

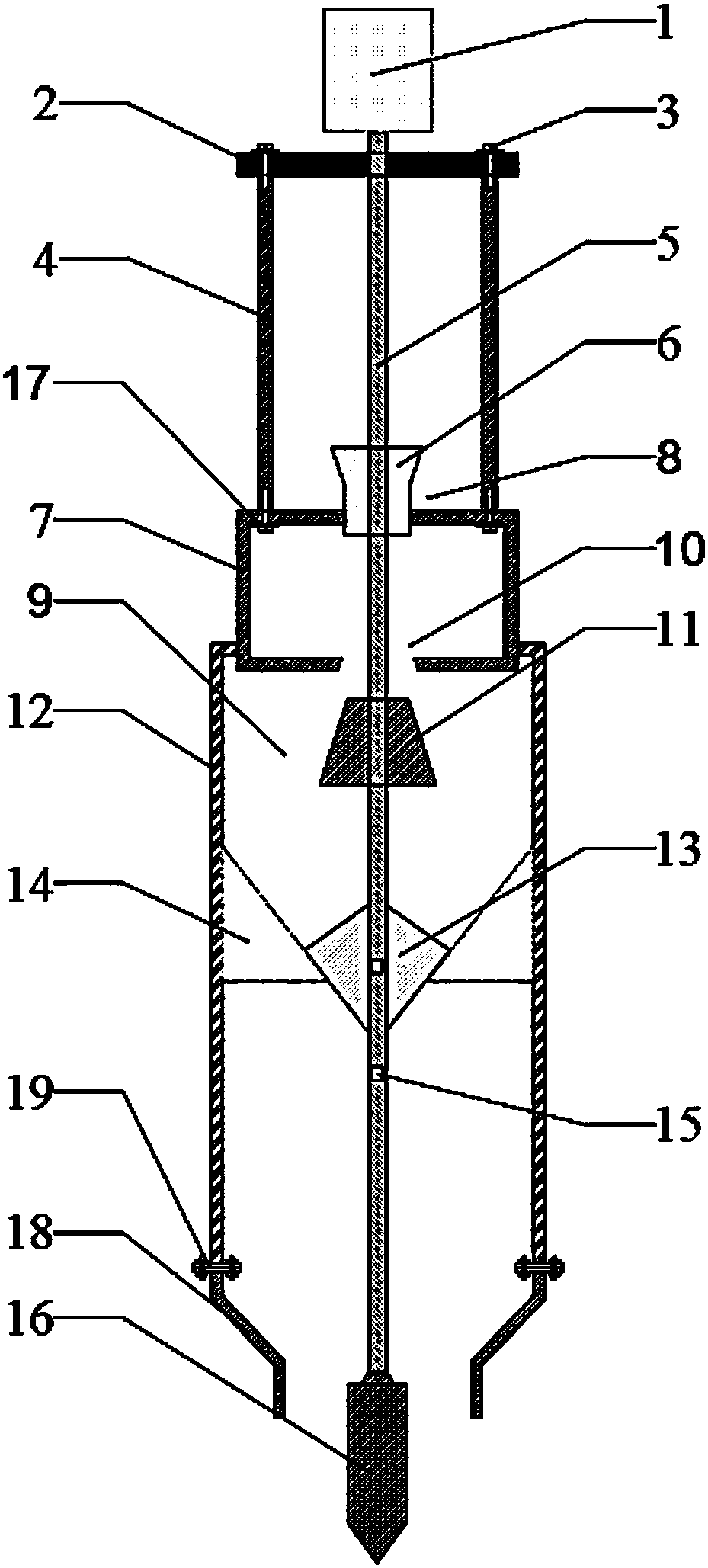

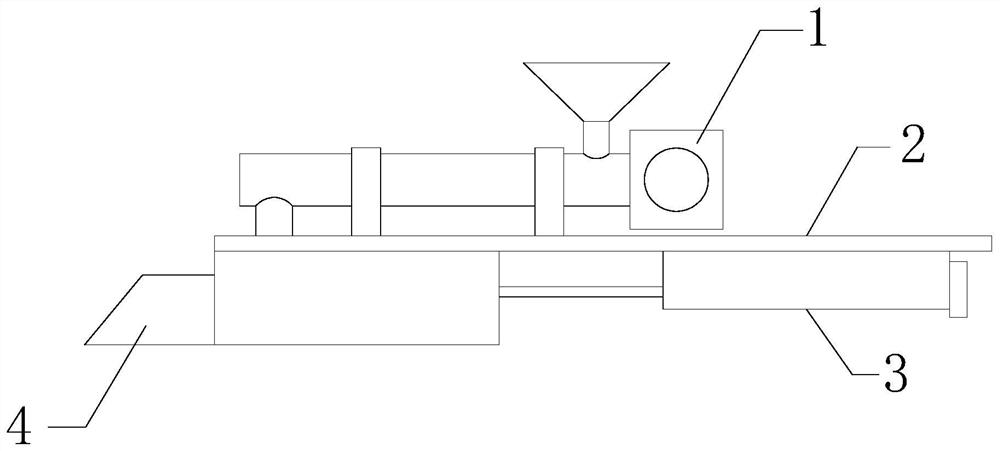

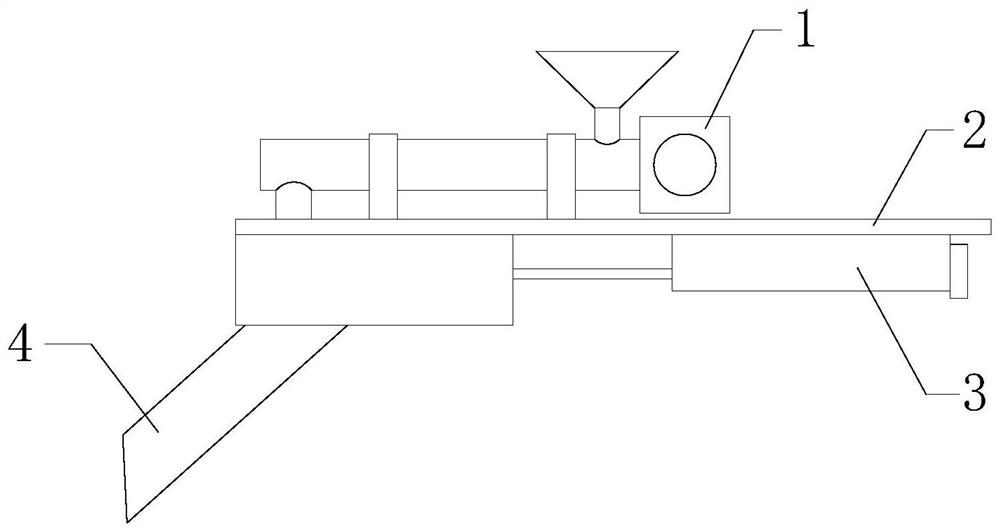

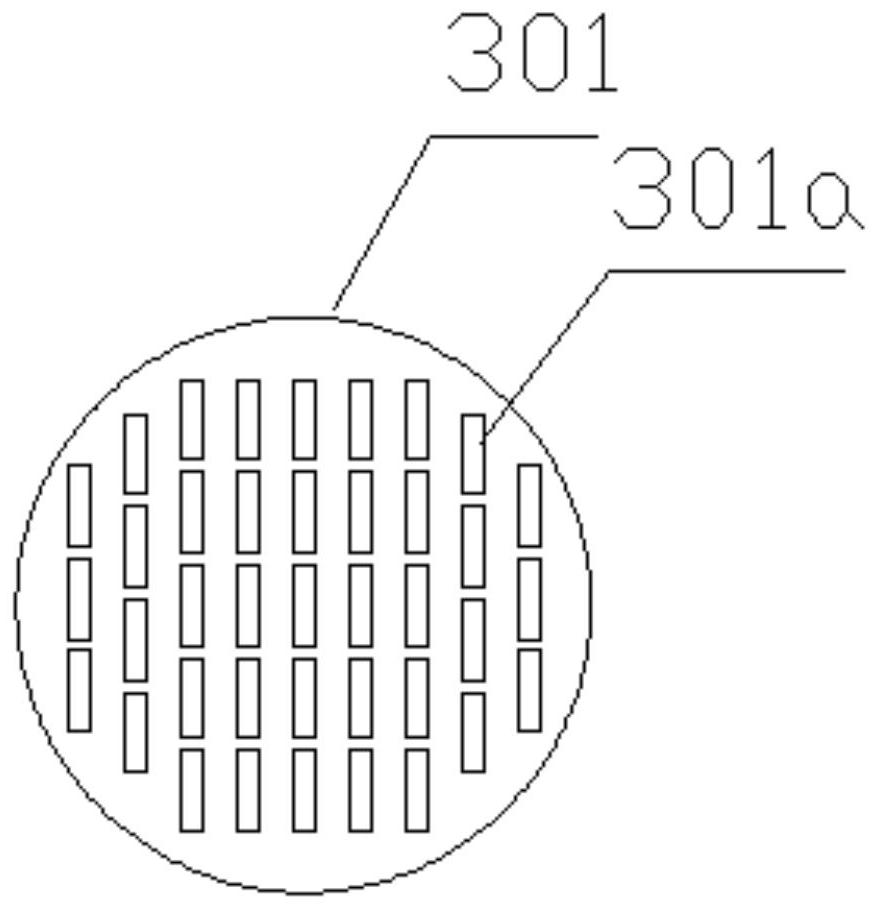

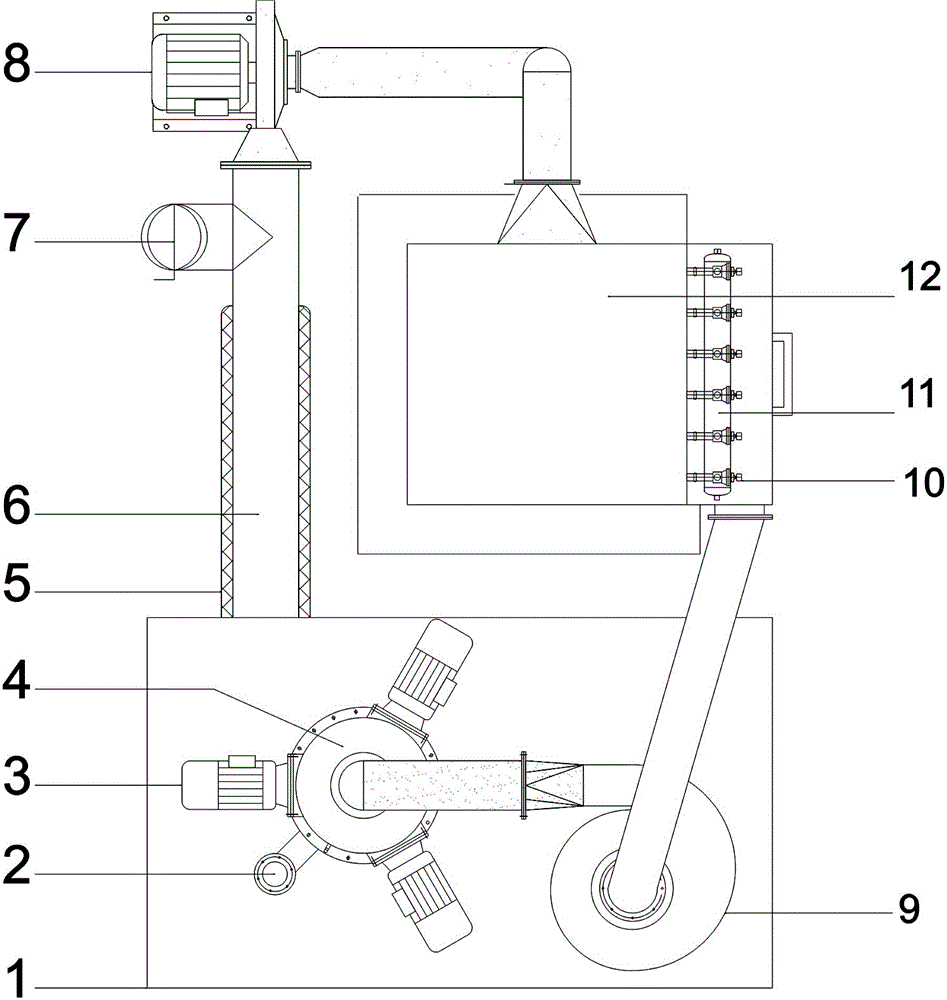

Pulse feeder

The invention provides a pulsating feeder, comprising an installation platform, a screw feeding mechanism, a pulsation generator and a feeding head, the screw feeding mechanism is arranged on the top of the installation platform, the pulsation generator is arranged on the bottom of the installation platform, and the The feeding hopper is used to receive the material conveyed by the screw feeding mechanism and transfer it into the molten pool of the electrolytic furnace, and the feeding head is driven by the pulse generator. The contact area between the powder and the rising hot air flow reduces the flying loss of the powder. At the same time, the feeding hopper is a certain distance away from the electrolysis furnace mouth and does not come into contact with the high-temperature molten salt, which can protect the feeding hopper.

Owner:江西南方稀土高技术股份有限公司

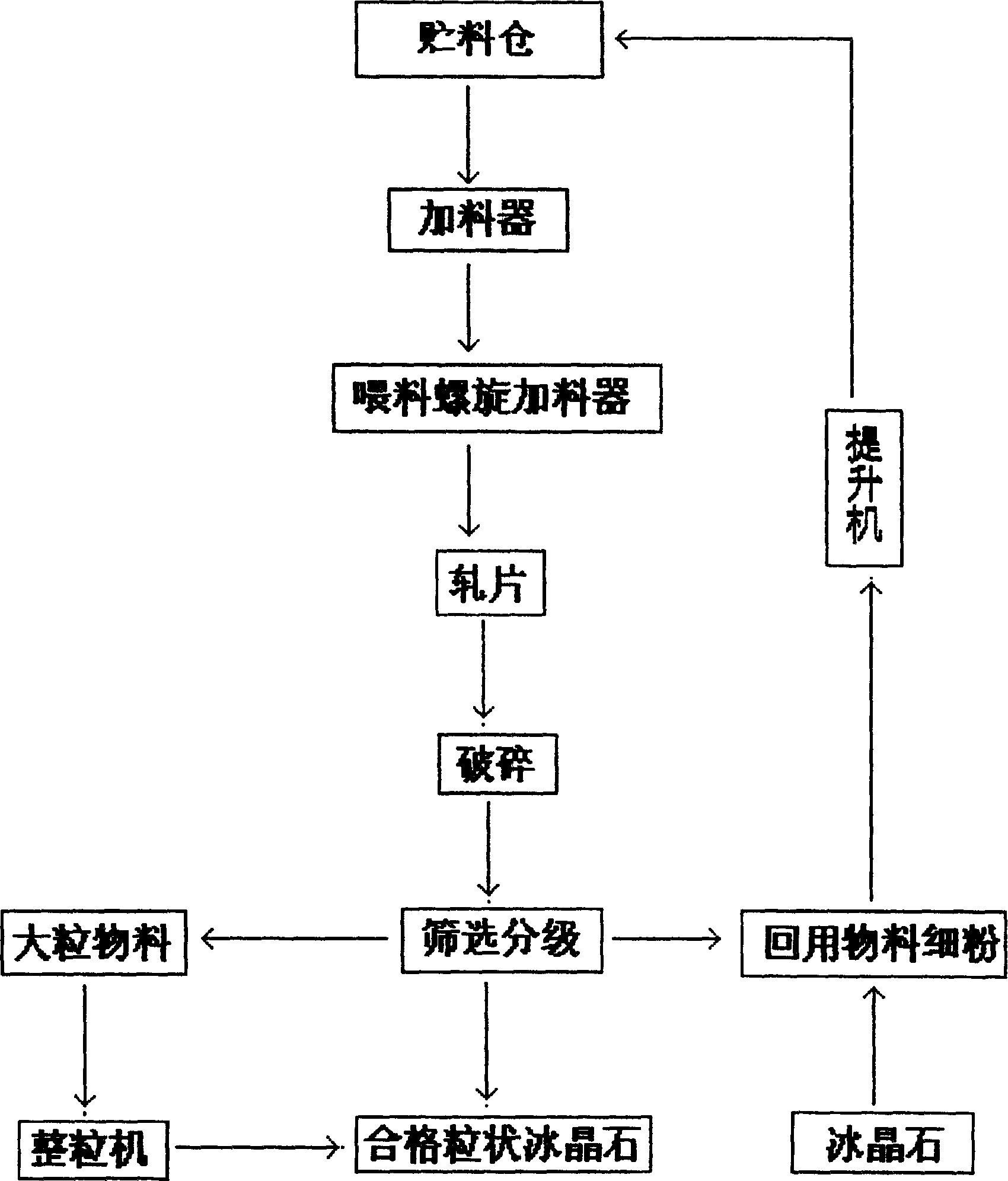

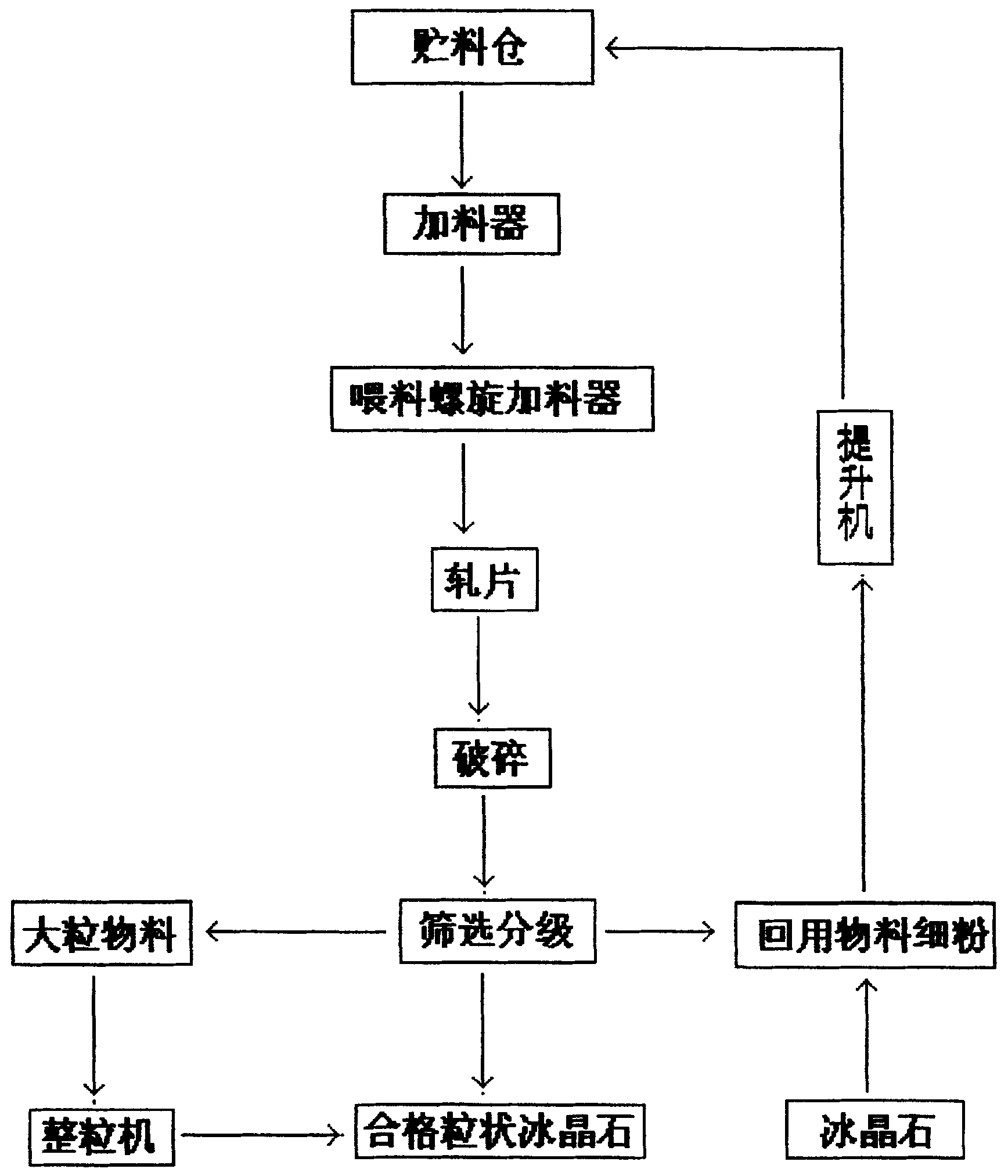

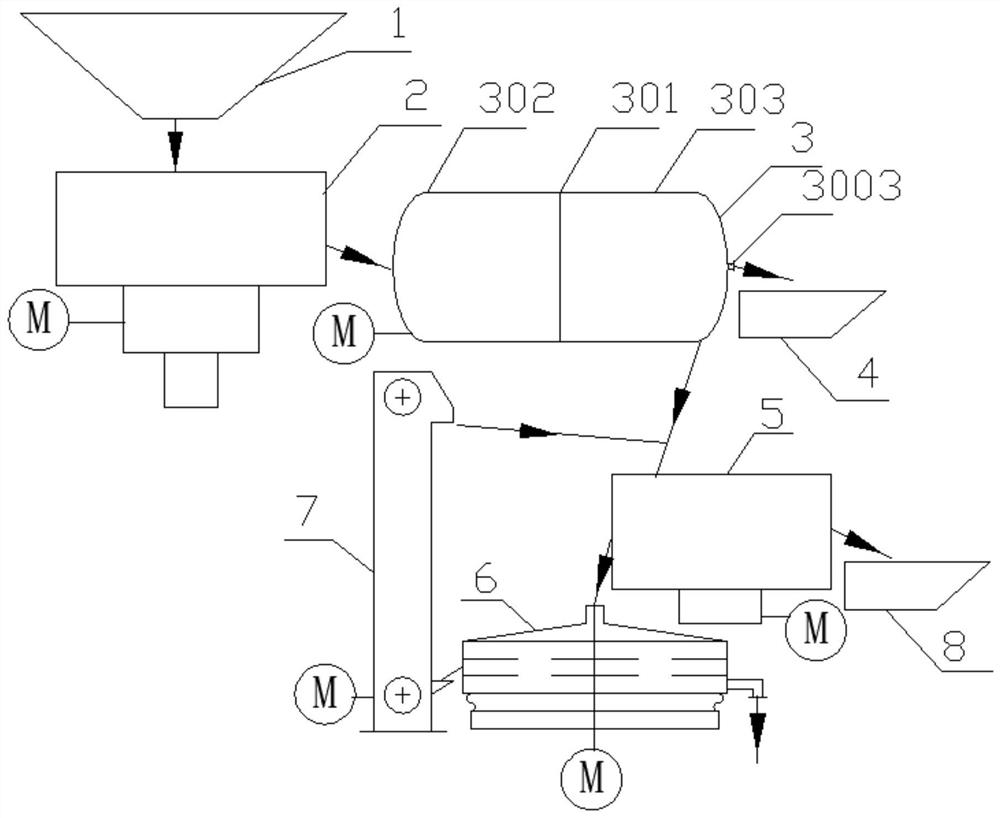

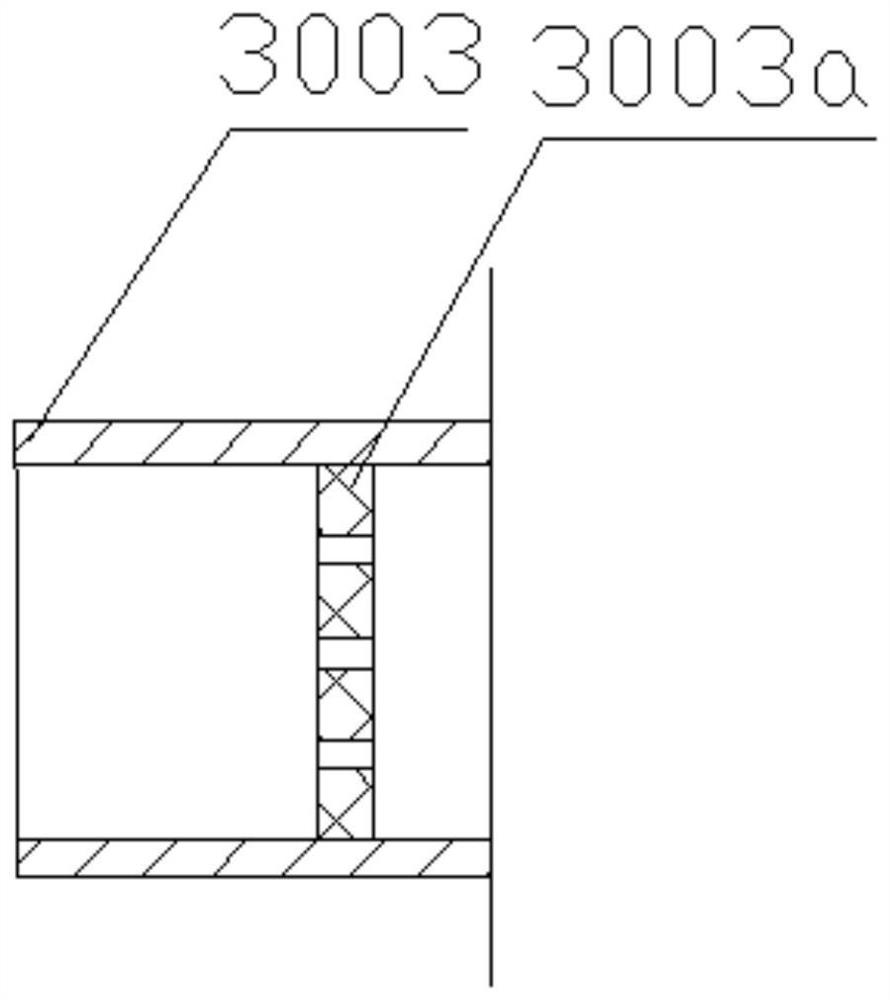

Method for producing granular cryolite

InactiveCN1294082CUniform and adjustable particle sizeHigh hardnessGranulation by pressingAluminium fluoridesElectrolysisHardness

Owner:DO FLUORIDE CHEM CO LTD

Method for preparing nano calcium carbonate/rubber composite materials

The invention discloses a method for preparing nanocalcium carbonate / rubber composite material, which takes calcium oxide, carbon dioxide and rubber latex as main stock, combining the preparing technology for nanocalcium carbonate and rubber together. The method comprises preparing the calcium hydroxide from calcium oxide, then adding carbon dioxide for charring and getting suspending liquid, then mixing the suspending liquid with rubber latex, through coprecipitation / coagulate, dehydration, drying etc getting the nanocalcium carbonate / rubber composite material.The method is characterized by the simple preparing process and the low production cost, the high performance because of the high degree of scatter of the the flying-off loss and nanocalcium carbonate and the decrease of the environmental pollution.

Owner:华南热带农业大学 +1

A method and device for improving the particle size of high-chromium and low-iron vanadium fine slag

A method and device for increasing the granularity of high-chromium, low-iron and vanadium slag. Low-chromium, high-iron and vanadium slag is added to a silo, and an irregular-shaped steel block formed by low-chromium, high-iron and vanadium slag is obtained by ball milling through a disc feeder as a grinding body. Add steel balls to the rough bin of the ball mill, add high-chromium and low-iron vanadium slag and soda ash into the bin, and continuously add them into the rough bin of the ball mill through a disc feeder; The particles and powder obtained by the joint ball milling of the grinding bodies enter the fine chamber of the ball mill through the compartment plate; add steel balls into the fine chamber of the ball mill, continue the ball milling, and then magnetically separate and sieve to obtain high chromium and low iron vanadium fine slag. The operation is easy, the process is reasonable, the grinding time is short, the particle size of the vanadium concentrate is fine, the proportion of the 140-mesh sieve is increased, the roasting effect of the vanadium concentrate is good, the conversion rate of vanadium is high, the output is large, and it has low cost and high benefit.

Owner:CITIC JINZHOU METAL

Tail gas cyclic utilizing device during calcium carbonate processing

InactiveCN106423596ADoes not consume energyReduce flying lossVortex flow apparatusDirt cleaningExhaust gasCalcium carbonate

A tail gas cyclic utilizing device during calcium carbonate processing comprises a rack which is provided with a grading machine, a centrifugal fan, a dust remover and a cyclone separator; the grading machine is connected with the centrifugal fan through an air returning pipeline; the centrifugal fan is connected with the dust remover through a pipeline; the dust remover is connected with the cyclone separator through an air returning pipeline; the cyclone separator is connected with the grading machine through a pipeline; and the cyclone separator is connected with a storehouse pump. According to the tail gas cyclic utilizing device during calcium carbonate processing, a negative pressure state is kept in the device all the time while fine powder is extracted on the basis of the cyclone dust suction principle, , the dust flying problem of an unloading port is solved, the dust flying losses are reduced, the environment pollution is reduced, and the overall grading effect of the airflow grading machine is improved.

Owner:NEWORLD PHARMA

Method for preparing high-purity anhydrous aluminum chloride

InactiveCN104058443AGood quality and stabilityAppearance color is pureAluminium fluoridesAluminum fluorideHeating time

The invention relates to a method for preparing high-purity anhydrous aluminum chloride. The method is characterized by comprising the preparing process that analytically pure aluminum fluoride trihydrate and ammonium bifluoride are used as raw materials, and the steps of the preparing process include that firstly, AlF3H2O and NH4HF2 are evenly mixed in the proportion of 70:30, are loaded into a compact sintered alundum crucible and are put into a dry boiler; secondly, the temperature in the dry boiler is raised to be 150 DEG C to 180 DEG C, and the heating time is 2-3 h; thirdly, the temperature in the dry boiler is raised to be 250 DEG C to 280 DEG C, and the heating time is 2-3 h; fourthly, the temperature in the dry boiler is raised to be 500 DEG C to 550 DEG C, and the heating time is 3-4 h. The method for preparing the high-quality anhydrous aluminum chloride has the advantages that the quality stability is good, the color of the appearance is pure, cost is low, flying losses are few, the purity of products is high, and the requirement of fundamental experiment study can be met.

Owner:ANHUI JINYANG FLUORINE CHEM

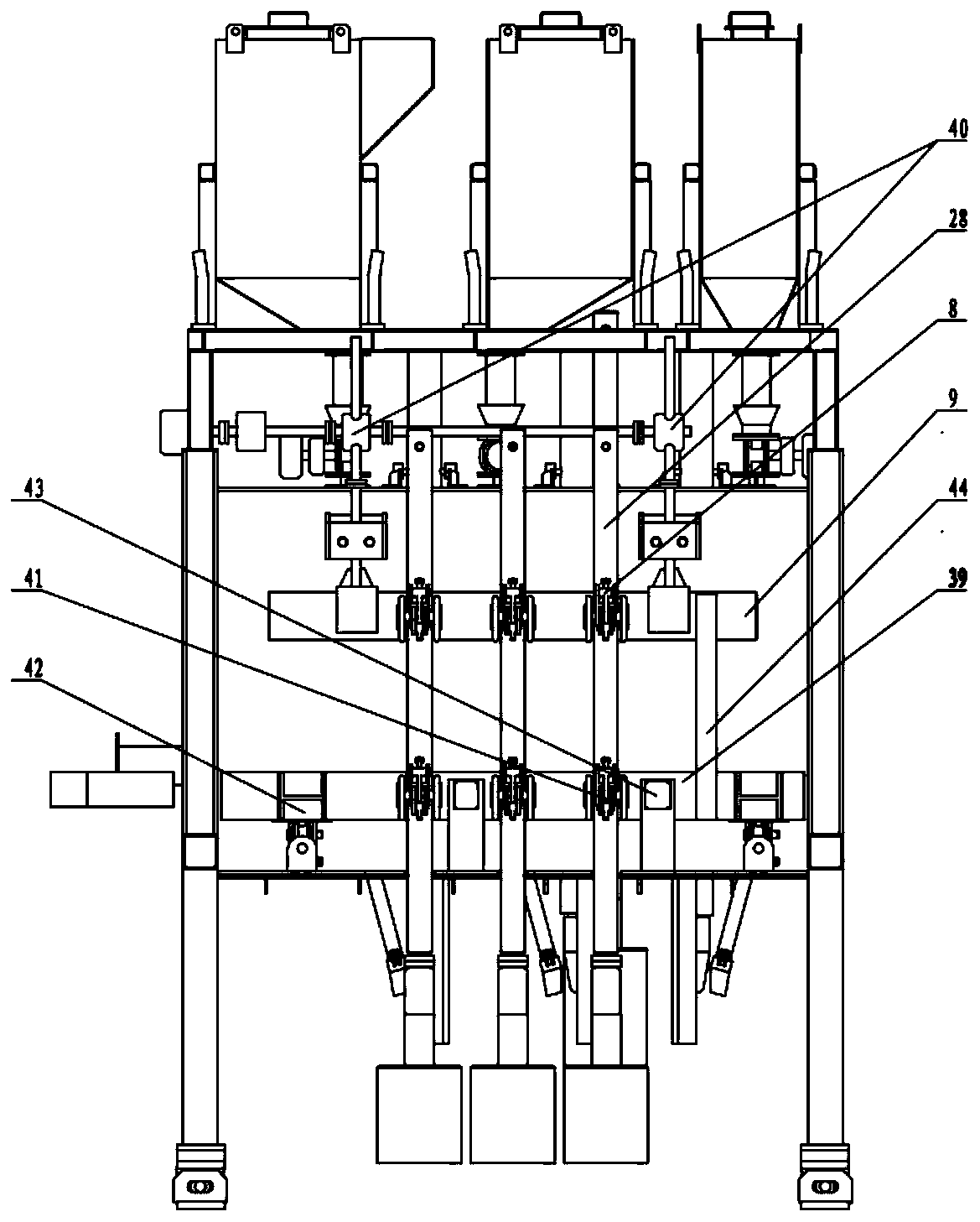

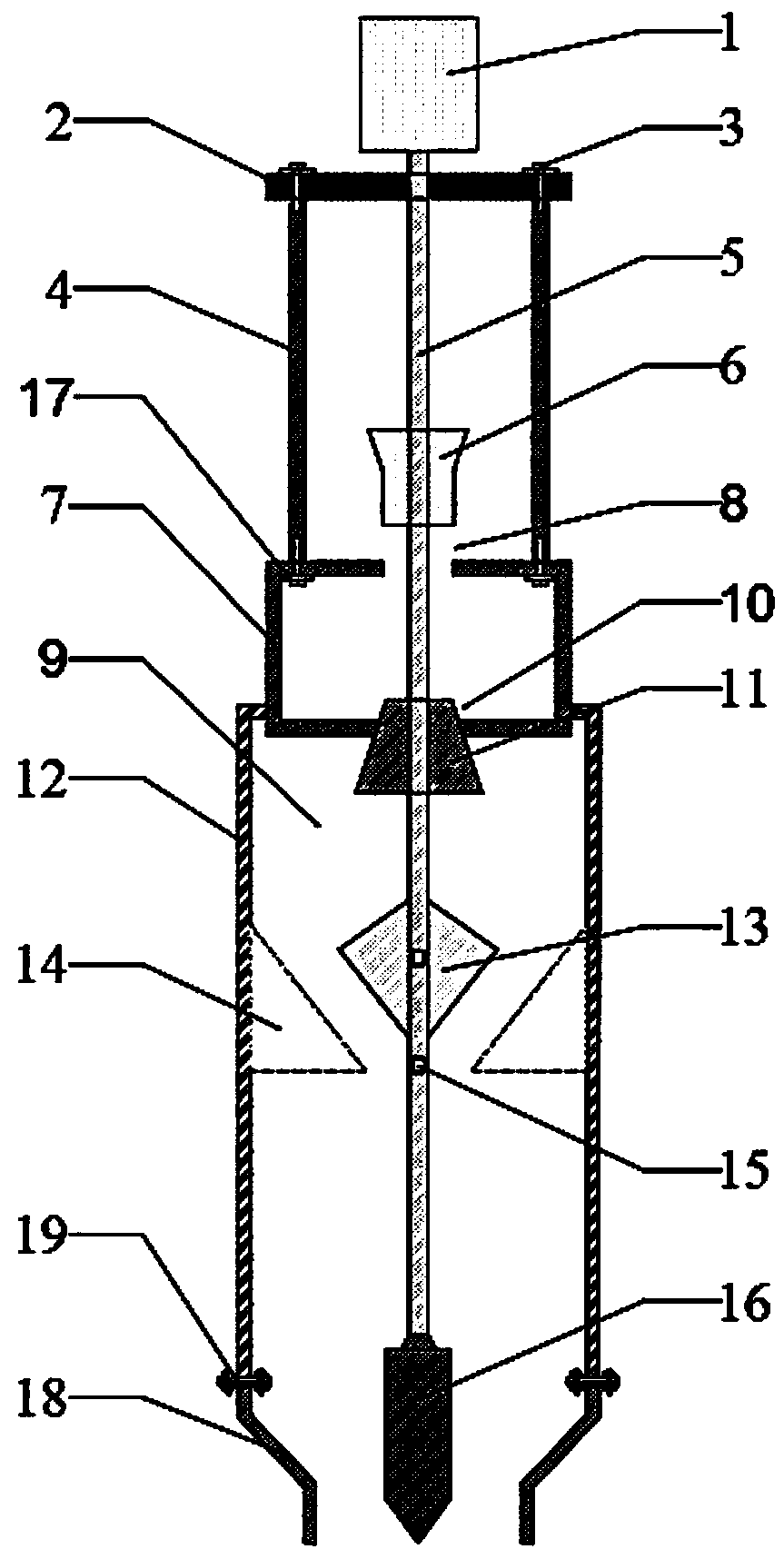

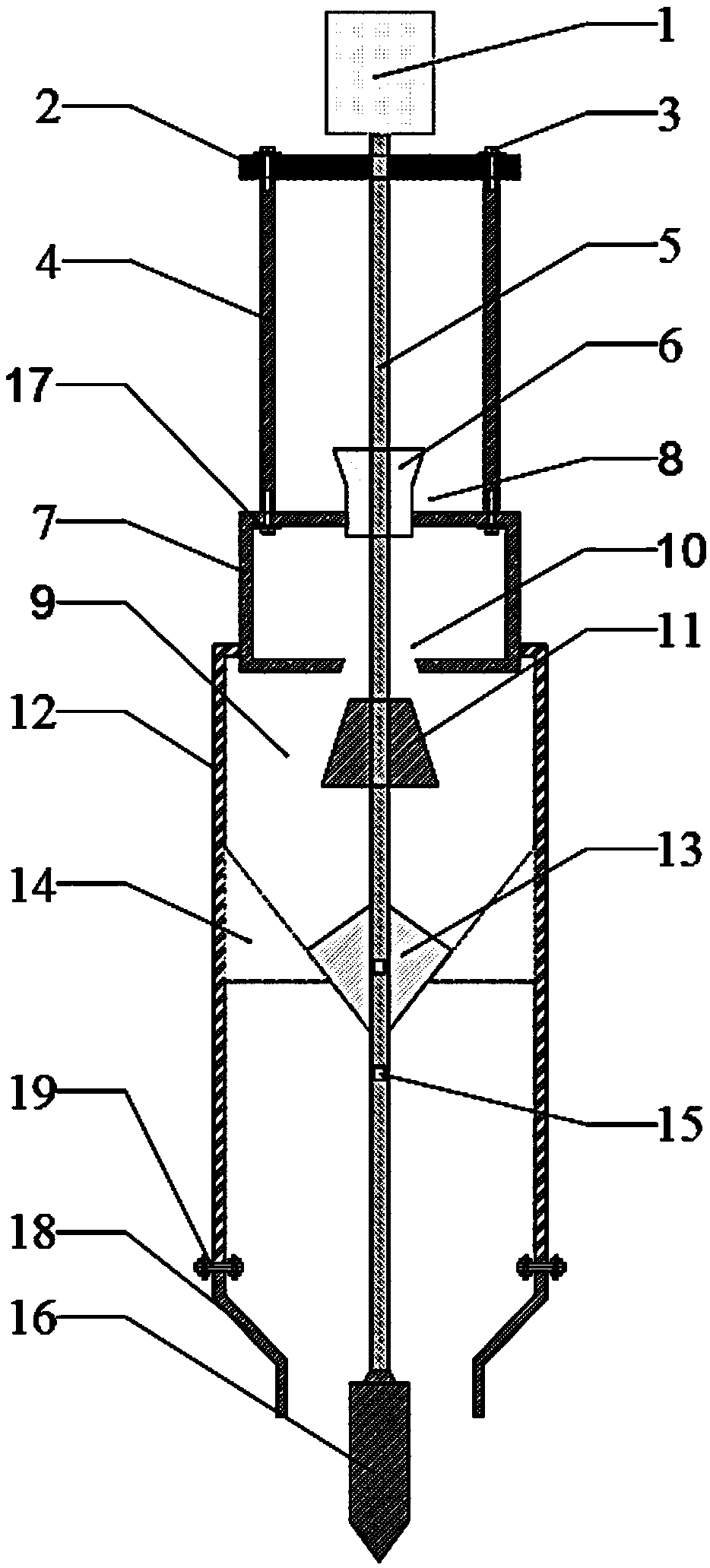

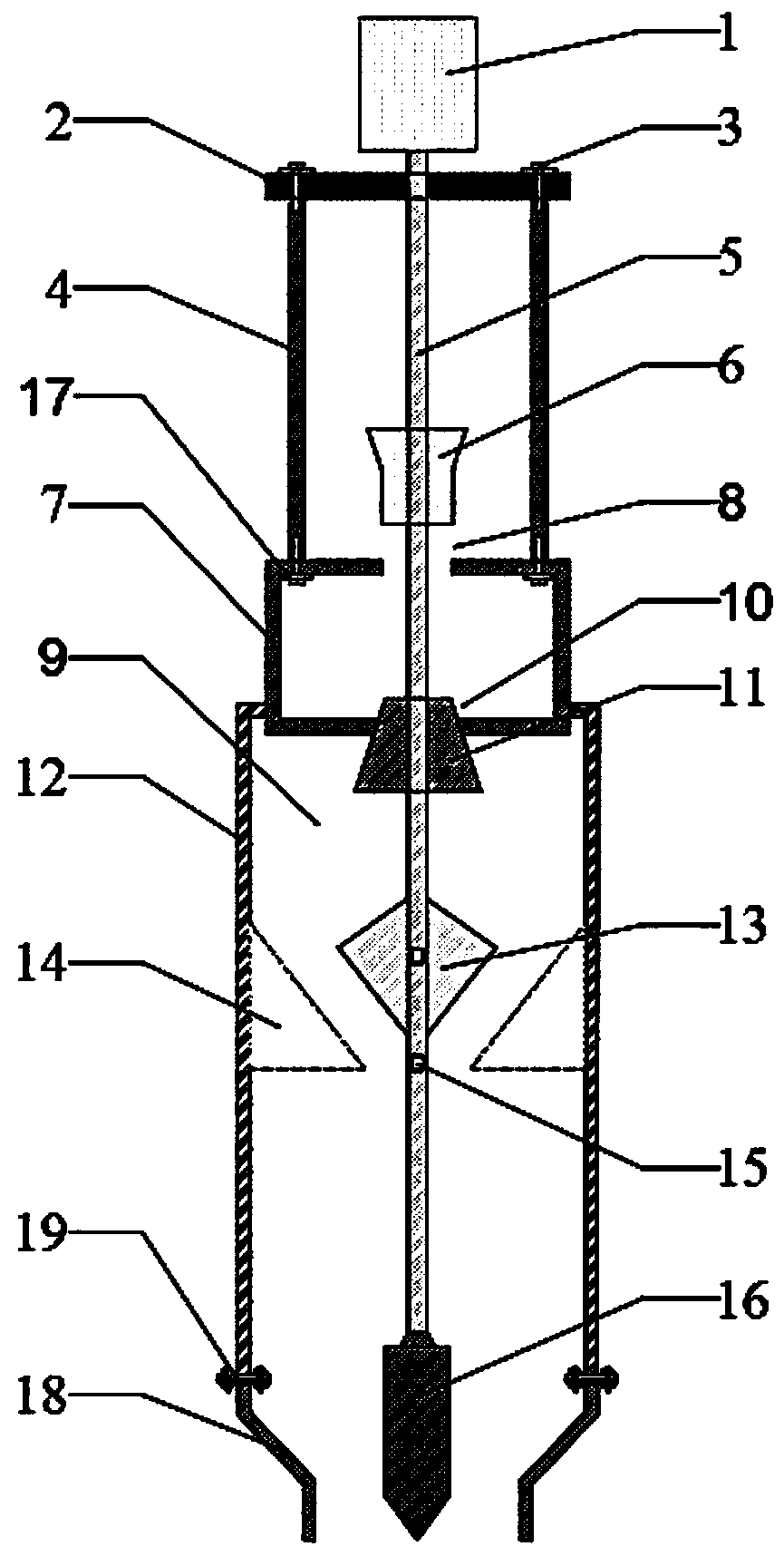

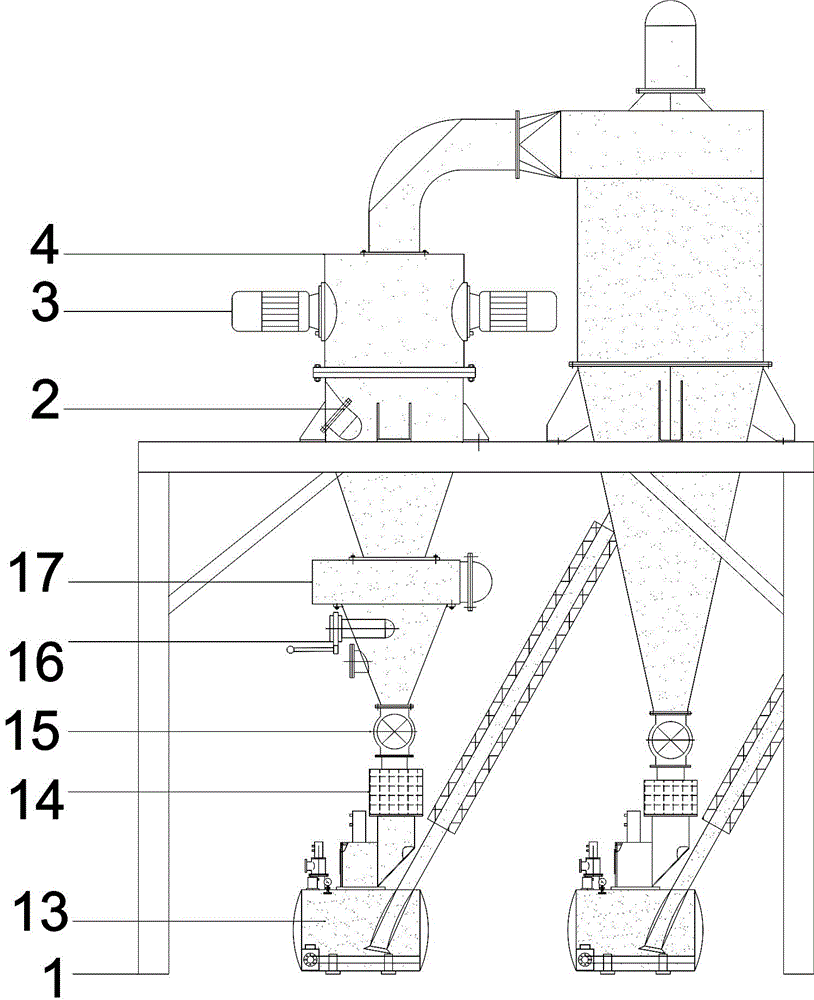

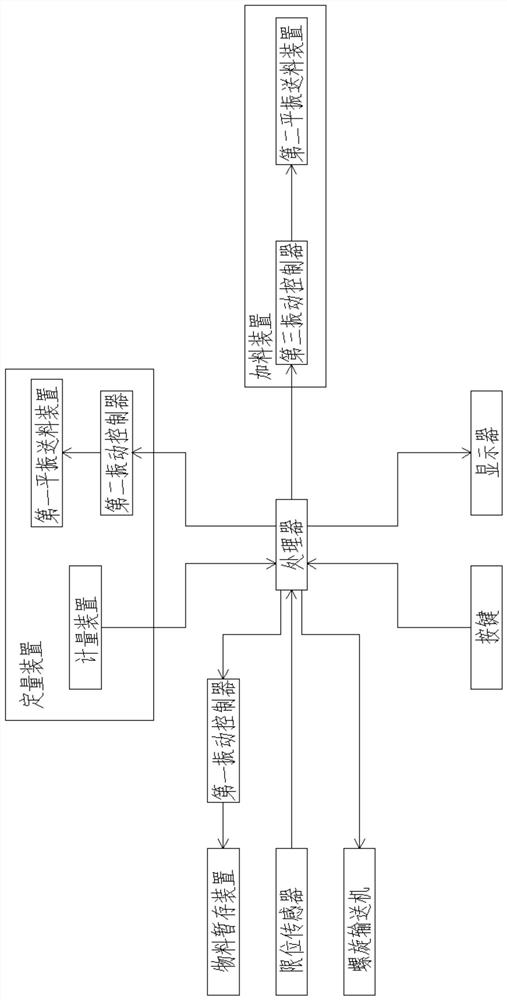

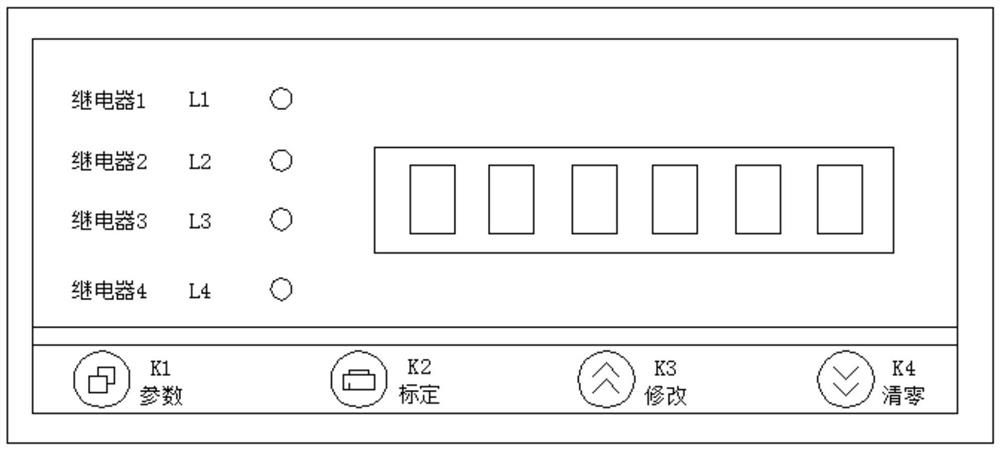

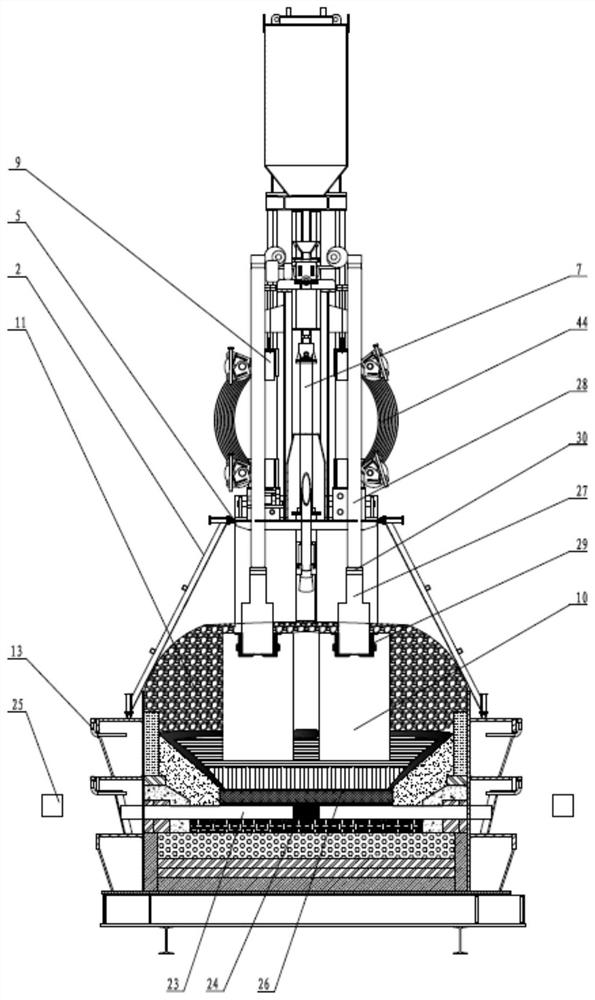

An automatic feeding device for rare earth electrolysis and its operating method

ActiveCN110129833BReduce flying lossFull electrolysisElectrolysis componentsProcess engineeringIndustrial engineering

The invention provides automatic feeding equipment for rare earth electrolysis and an operation method thereof, and relates to the technical field of feeding devices. The automatic feeding equipment comprises a material temporary storage device used for controlling the total feeding amount, a quantitative device used for controlling single feeding amount and a feeding device used for uniformly feeding materials, wherein the material temporary storage device, the quantitative device and the feeding device communicate with one another through a material channel in sequence so as to enable the materials to flow therethrough in sequence, and a discharging port of the feeding device extends to the position above a rare-earth electrolytic cell and is used for feeding the materials to the rare-earth electrolytic cell. The equipment is reasonable in design, the timing, quantitative and uniform feeding is realized through a three-stage feeding mode formed by arranging the material temporary storage device, the quantitative device and the feeding device, so that rare earth oxide in an electrolyte is sufficiently electrolyzed, the production efficiency is improved, and the stability of the process is ensured; and meanwhile, the labor intensity of workers and the flying loss of the materials can be reduced, and the environment of a production workshop is improved.

Owner:LESHAN YOUYAN RARE EARTH NEW MATERIAL CO LTD +1

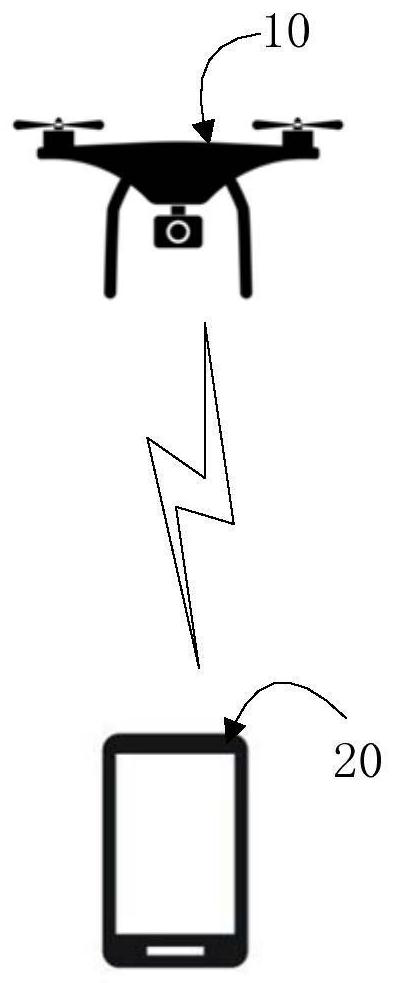

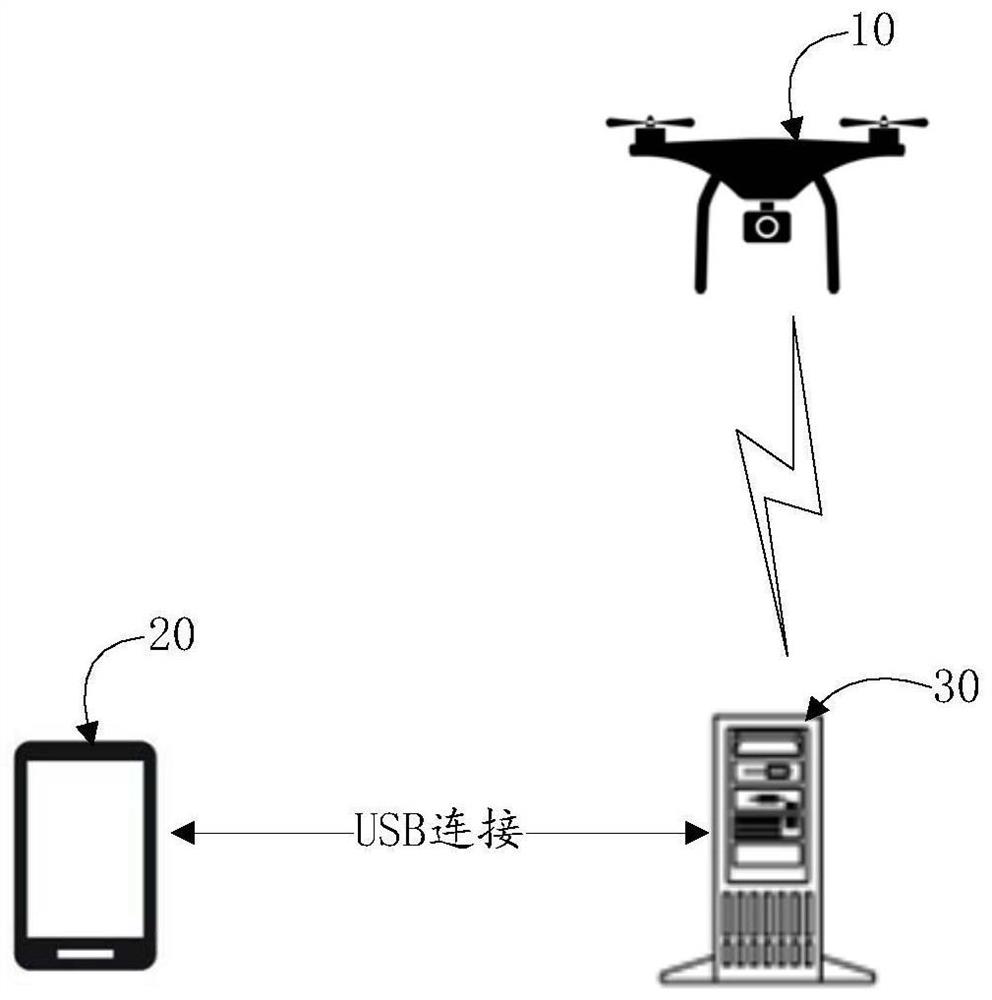

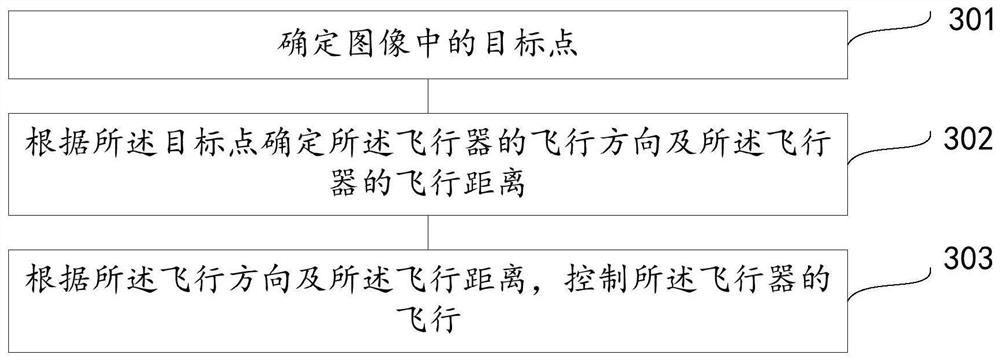

Flight control method, device, terminal equipment and flight control system of aircraft

ActiveCN109032184BReduce flying lossEasy to operatePosition/course control in three dimensionsFlight directionFlight vehicle

The embodiment of the invention relates to the technical field of aircraft, and discloses a flight control method, device, terminal equipment and flight control system of an aircraft. Wherein, the method is applied to the terminal equipment, and the terminal equipment is connected to the aircraft in communication. The aircraft includes a gimbal and a photographing device mounted on the gimbal. The method includes: determining the target point in the image, and the image is the current position The image captured by the photographing device; according to the target point, the flight direction and the flight distance of the aircraft are determined; and the flight of the aircraft is controlled according to the flight direction and the flight distance. This method can accurately control the aircraft to fly to the target point input by the user, and control the aircraft to stop flying immediately after the aircraft flies to the target point, so as to realize the flight control effect of pointing to where to fly, so that the user does not have to fly the aircraft to the desired point. It can be manually stopped after the location, which effectively improves the user experience.

Owner:SHENZHEN AUTEL INTELLIGENT AVIATION TECH CO LTD

A rare earth electrolytic cell for producing rare earth and its alloys

ActiveCN110484937BReduce anode costReduce electricity consumption costsElectrodesMetallurgyControl system

The invention discloses a rare earth electrolytic tank for producing rare earth and alloys thereof. The rare earth electrolytic tank comprises an electrolytic tank body, a cathode group structure, ananode group structure and a tank upper portion structure, wherein the electrolytic tank body comprises a tank shell and a tank lining, the tank upper portion structure comprises a vertical column girder frame, a material feeding system, a shell ramming system, an anode lifting and busbar switching system and a tank hood plate, the upper end of the anode group structure is connected with the anodelifting and busbar switching system, anode blocks at the lower end are vertically inserted in electrolyte inside the tank body, the parts, exposed outside the electrolyte level face, of the anode blocks are covered by an anode covering material, the anode lifting and busbar switching system is used for adjusting the polar distance between the anode blocks and the cathode group structure, the material feeding system, the shell ramming system and the anode lifting and busbar switching system are integrated into an intelligent tank control system, the upper edge of the tank hood plate is connected with the edge of the side portion of a horizontal hood plate, and the lower edge of the tank hood plate is connected with the upper surface of the tank shell to realize closeness of the electrolytictank. By means of the rare earth electrolytic tank for producing the rare earth and the alloys thereof, rare earth electrolytic tank automatic continuous, high-efficiency, low-energy-consumption, low-cost and clean production is realized.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

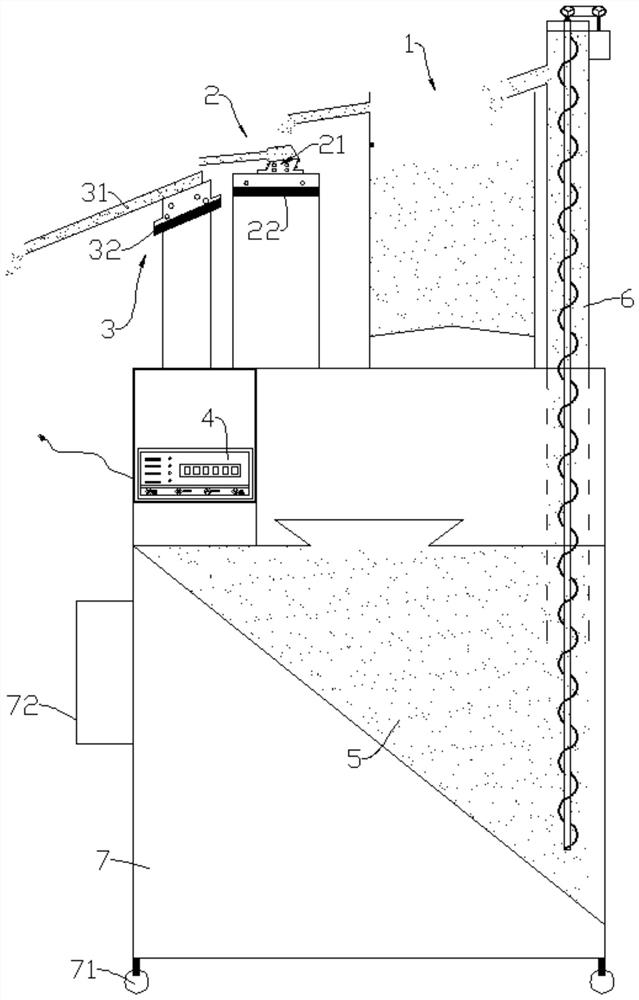

A feeder for ultra-fine or low bulk density powder in an aluminum electrolytic cell and a feeder method thereof

The invention belongs to the technical field of metallurgical industry, and in particular relates to an aluminum electrolytic cell ultra-fine or low bulk density powder feeder, comprising a shell, a first compression device, a second compression device and a discharge pot; the inner cavity of the shell is opened There is a cavity communicating with the outside, a feed port is opened on the side wall of the housing, the top of the first piston is fixedly connected to the other end of the first driving rod; the second piston is connected to the second A compression chamber is formed between the piston rods, the side wall of the compression chamber is provided with a compressed air inlet, and the bottom of the discharge pot is provided with a diversion groove connected thereto. Compress the volume of the material, and use compressed air to discharge the material from the diversion tank to the electrolytic cell at a certain initial speed, which can effectively reduce the flying loss of ultra-fine powder and materials with low bulk density, and improve the effectiveness of feeding. Simple and reliable, good sealing, easy maintenance, can adapt to long hours of work.

Owner:NORTHEASTERN UNIV LIAONING

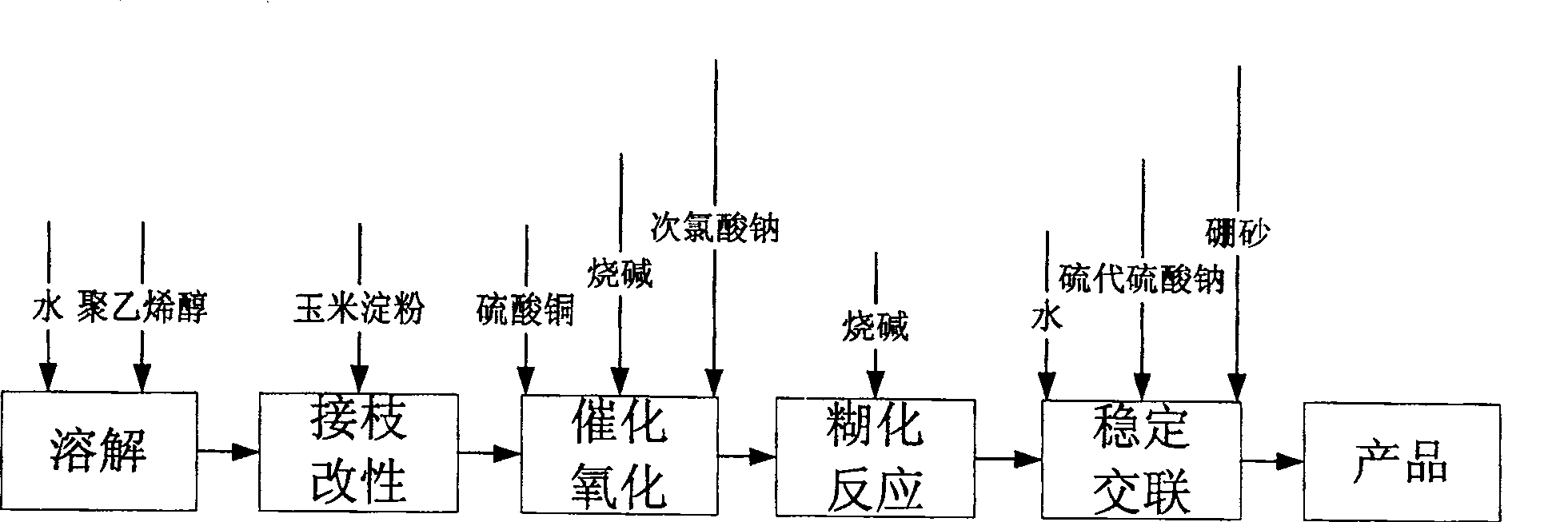

Ecological briquette surface curing agent and its preparing method

InactiveCN100500791CReduce flying lossReduce pollutionOther chemical processesTransportation itemsCross-linkSocial benefits

The invention relates to ecotype coal surface curing agent and the preparing method. It includes the following steps: using polyvinyl alcohol, corn starch as basic material, and water as solvent; grafting modification for the polyvinyl alcohol, corn starch; adding catalyst and oxidant to produce oxidized starch; adding caustic soda to gelatinize; adding water to dilute; adding stabilizer and cross-linking agent to prepare other component. It has the features of nontoxic, tasteless, satisfying environmental protection demand, strong coal cohesive force, wide material sources, economic, practical, and huge economic and social benefits for coal railway transportation.

Owner:BEIJING JIAOTONG UNIV

A method for increasing carbon and desulfurizing phosphorus pig iron

ActiveCN106868246BGood effect of carbon increase and desulfurizationImprove absorption rateSolid carbonIntermediate frequency

The invention relates to the field of aluminum electrolysis production, in particular to an environment-friendly phosphorous pig iron additive, a preparation method of the environment-friendly phosphorous pig iron additive and a phosphorous pig iron recarburization and desulphurization method. The environment-friendly phosphorous pig iron additive is prepared by pressing 95.5%-98.5% of a carbon material, 1.0%-3.5% of a binder and 0.5%-1% of carbonate by mass percent into a pellet. The carbon material is solid carbon obtained by carrying out vacuum metallurgy treatment on waste cathode carbon blocks. The preparation method is simple, the prepared additive is low in cost, and the recarburization and desulphurization effect on phosphorous pig iron is good. The phosphorous pig iron recarburization and desulphurization method comprises the steps that the additive and a phosphorous pig iron raw material are added into an intermediate frequency furnace in a layered manner, and then smelting is carried out. The method is high in carbon absorptivity and good in desulphurization effect, meanwhile, material flying losses in the phosphorous pig iron recarburization and desulphurization process can be effectively reduced, and the workshop environment can be improved; and the flowability phosphorous pig iron liquid is good, and the obtained phosphorous pig iron meets the requirement of phosphorous pig iron for prebaked anode casting.

Owner:SHANDONG NANSHAN ALUMINUM +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com