Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

163results about How to "Reduce electricity consumption costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Titanium alloy TC4 hot-rolled tube and production method thereof

The invention relates to a titanium alloy, in particular to a titanium alloy TC4 hot-rolled tube and a production method thereof. By weight, the composition of the alloy is as follows: the balance of Ti, 5.5 percent to 6.75 percent of Al, 3.5 percent to 4.5 percent of V, less than or equal to 0.1 percent of Fe, less than or equal to 0.1 percent of C, less than or equal to 0.03 percent of N, less than or equal to 0.015 percent of H and less than or equal to 0.15 percent of O. A tube blank is heated and rolled on line, the on-line heating temperature is 600 DEG C to 1200 DEG C, and is kept for 1 to 45 minutes, the deformation at each pass is 15 percent to 85 percent, the rolling speed is 20 to 90 times / min, a finished product is produced after 1 to 10 times of rolling, the rolled finished product is annealed in oxygen or vacuum, the annealed finished product is washed by alkali and acid or acid and then by water, and thereby the product is obtained. The tensile strength of the titanium alloy tube is 895MPa to 1300MPa, the elongation of the titanium alloy tube is 8 percent to 25 percent, the metallographic structure is uniform, and a stress-relief annealed metallographic structure and a fully recrystalization annealed metallographic structure can be obtained.

Owner:忠世高新材料股份有限公司

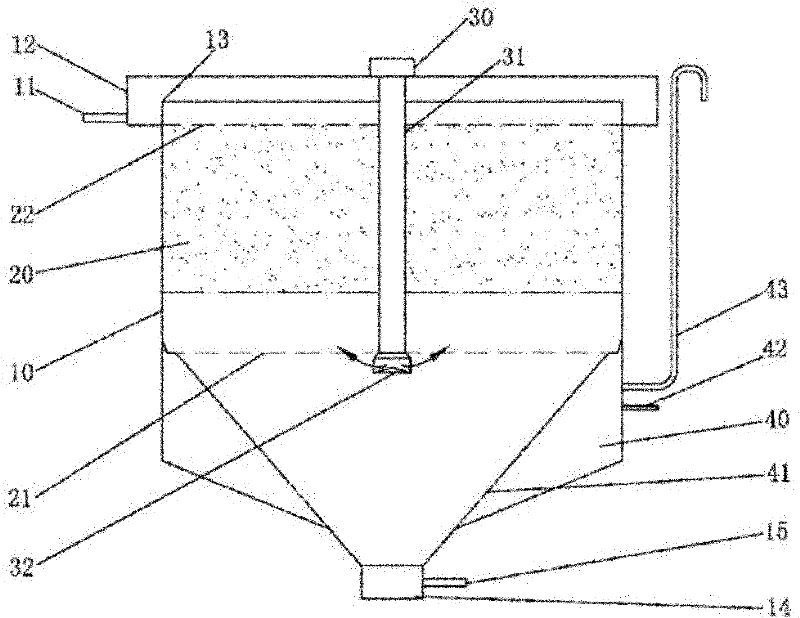

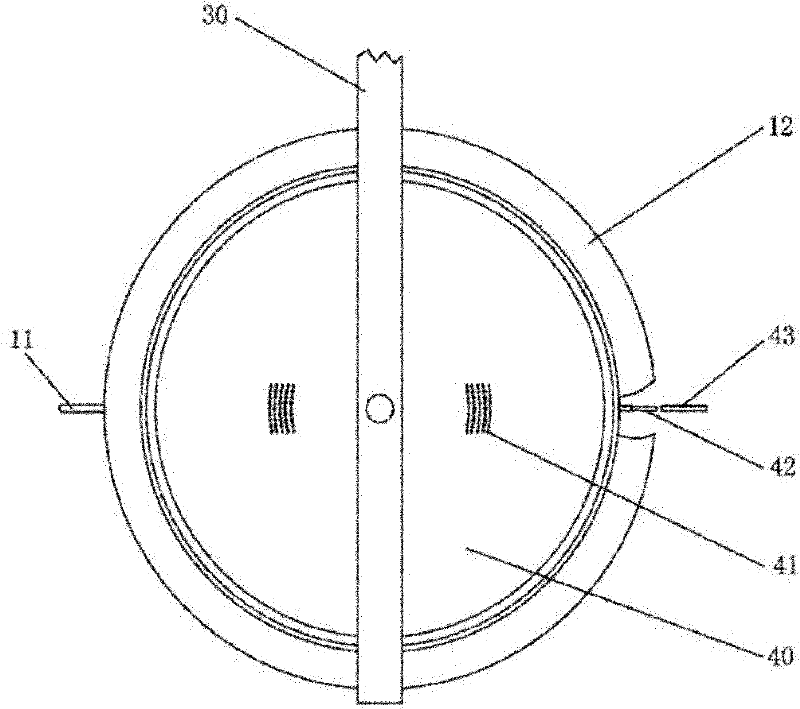

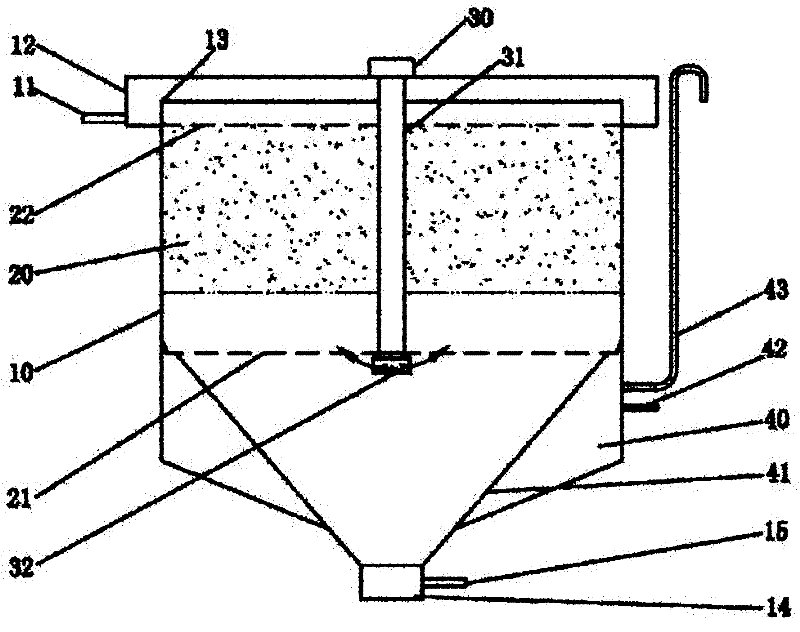

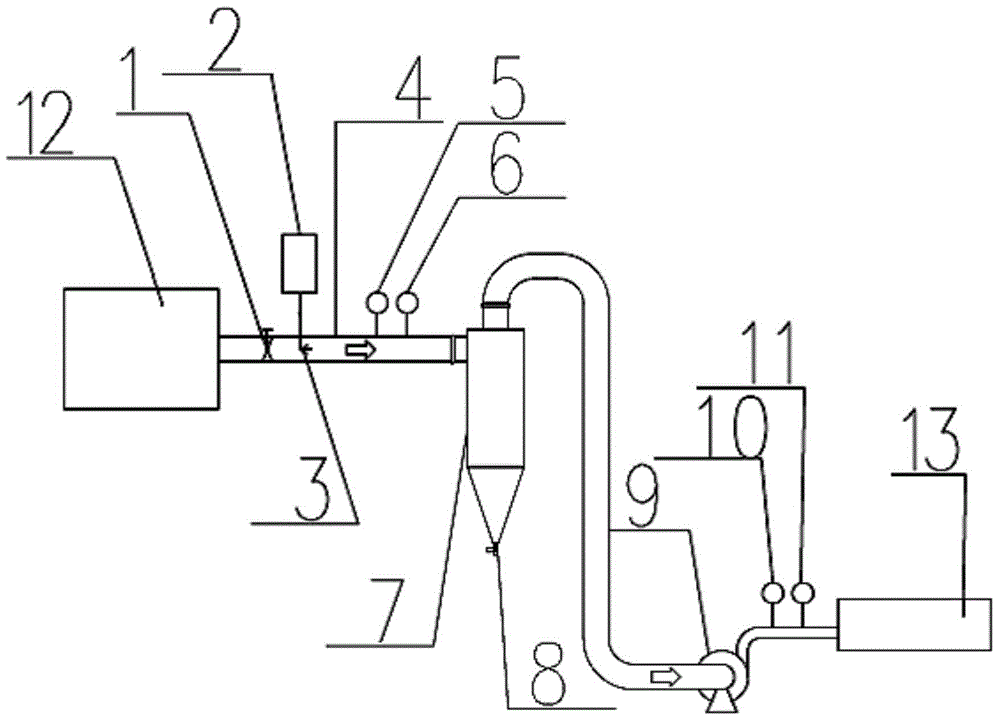

Aquiculture integrated water processing unit and flushing method thereof

InactiveCN102218236ALarge specific surface areaSmall particle sizeLoose filtering material filtersGravity filtersProduct gasWater processing

The invention relates to the technical field of aquiculture water processing and discloses an aquiculture integrated water processing unit, which comprises a hopper-shaped pool body (10); a hole plate (22) is arranged at the upper part of the pool body (10); a filter material (20) for light weight foaming grains is arranged on the lower part of the hole plate (22); a communicating hole (41) and aback-flushing air chamber (40) are arranged at the lower part of the conical surface of the pool body (10); an intake pipe (42) and an exhaust pipe (43) are respectively arranged above the pool body;and a screen (21) is arranged at the lower part of the cylinder of the pool body (10). A flushing method for the aquiculture integrated water processing unit is as follows: a discharge pipe (15) is opened and then is closed; the intake pipe (42) is opened for charging air; the water in the back-flushing air chamber (40) is pressed into the pool body (10); when the back-flushing air chamber (40) is filled with air, the intake pipe (42) is closed and the exhaust pipe (43) is opened instantly; then the air is exhausted and the water in the pool body (10) quickly enters the back-flushing air chamber (40); then the filter material (20) downwards expands and looses; and the intercepted suspension solids and aged biomembrane fall into the water and the filter material (20) is flushed. The filtermaterial has high water processing efficiency, good back-flushing effect and low energy consumption.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

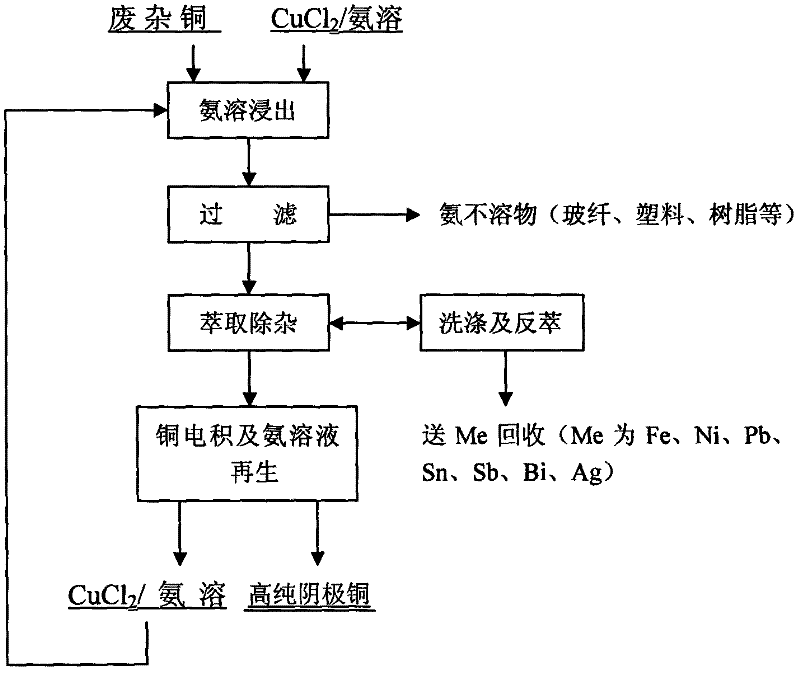

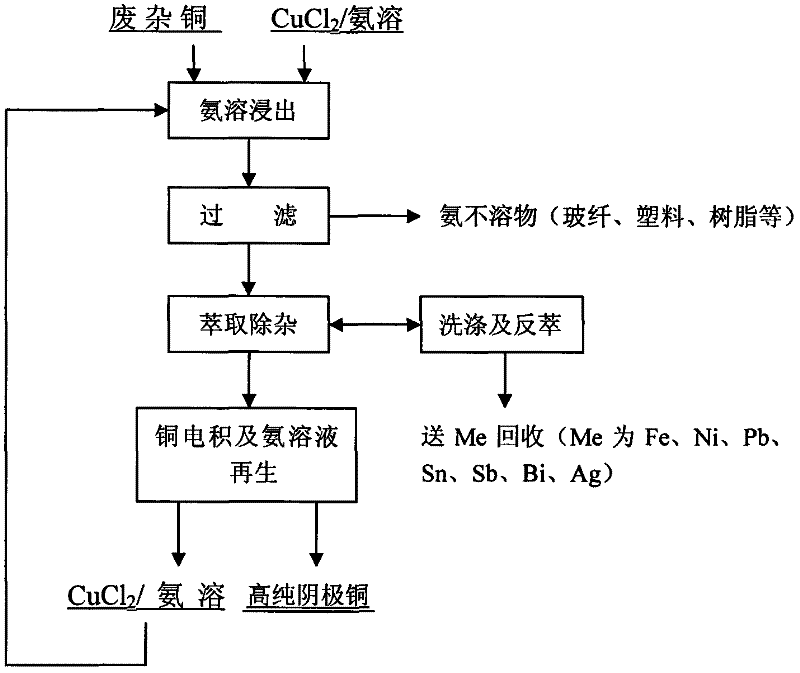

Method for extracting copper from scrap copper through wet process

InactiveCN102443703ALower specific resistanceReduce concentration overpotentialPhotography auxillary processesProcess efficiency improvementEnvironmental resistanceElectrolysis

The invention relates to a method for extracting copper from scrap copper through a wet process. The method comprises the steps of: A) ammonia dissolving leaching: putting scrap copper in a multicomponent solution of ammonia, an ammonia salt, a monovalent chloride, and a divalent copper chloride to form an appropriate electric potential, and reacting the scrap copper with ammonia complex ions so as to be dissolved in the multicomponent solution and generate stable monovalent copper complex ions, filtering out most of metal element impurities Fe, Ni, Al, Sn and Pb from the scrap copper, leaving a small amount of impurities to undergo an oxidation reaction and react with ammonia molecules to generate complex ions of different coordination numbers and exist in the solution; B) extraction for impurity removing: extracting impurities Ag, Fe, Ni, Zn, Bi, Cr, Mn, Sb, Pb, and Sn into an organic phase, and keeping the monovalent copper complex ions in the solution; C) diaphragm electrolytic deposition for preparing high-purity cathode copper: carrying out electrolytic deposition of copper in the cathode chamber of a negative ion membrane electrolyzer, thus obtaining a well crystallized negative copper plate. The method of the invention is characterized by environmental protection and low energy consumption, and can generate high-purity copper directly.

Owner:周毅舟

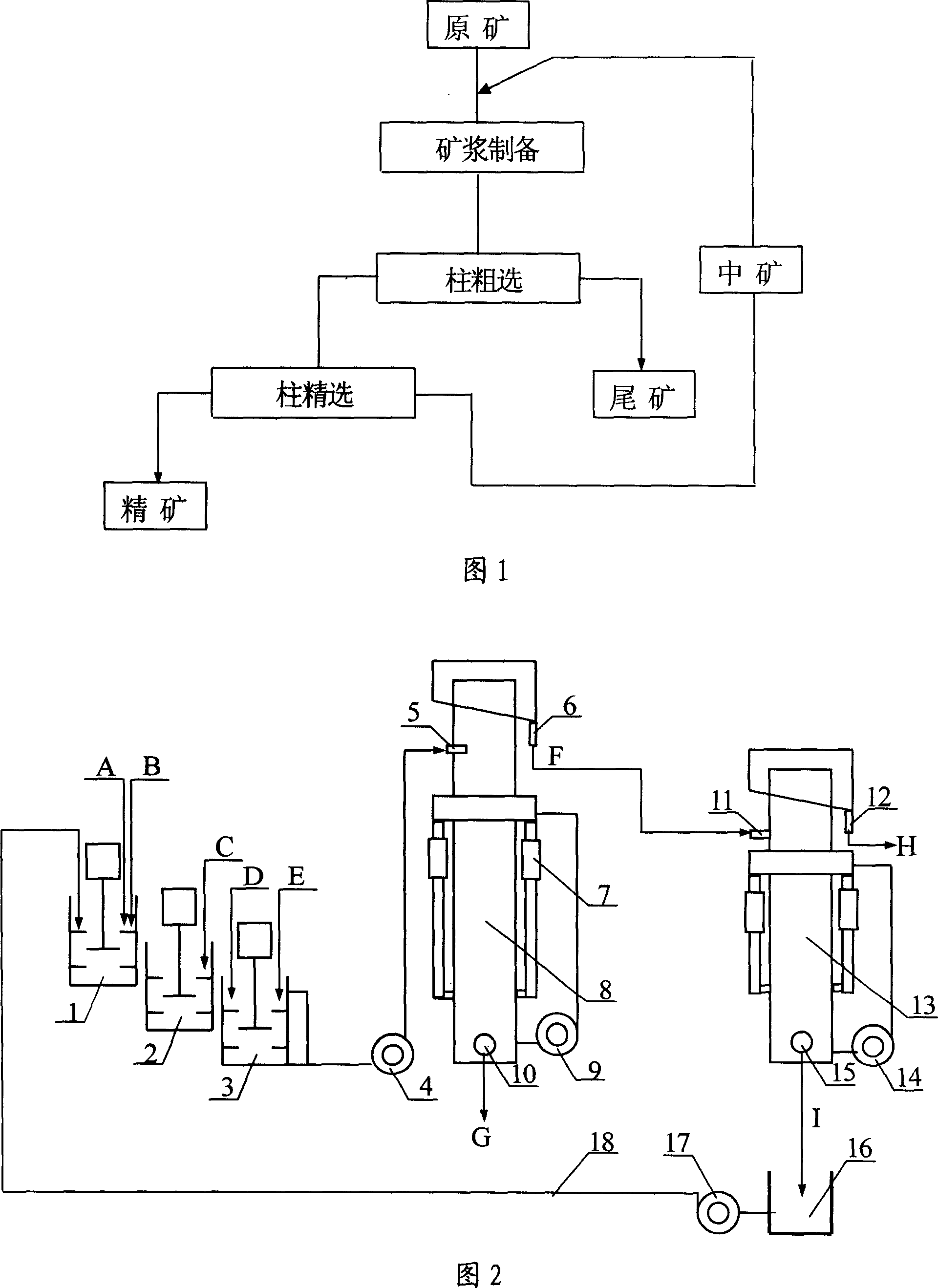

Column type short-stage tungseten crude grading process and equipment

The invention relates to a post-type tungsten selecting method, wherein it uses two cyclone-static foam float selecting posts as selecting devices, with three slurry barrels, liquid level controller and mine circulator. It first feeds the mine into slurry barrel, adds float select agent to mix the slurry; feeds the slurry via feeding pump to the rough float selecting post to be separated and selected; then the rough selected and fine selected mines flow into the fine selecting float selecting post, and the rough selected mine is discharge at the bottom of rough selecting float selecting post, to be selected in the fine selecting post; and the fine selected mine is discharged at the upper fine mine outlet, and the tail mine is discharge at the bottom outlet into mine buffer pool, to be fed back to the slurry barrel. The invention has low cost and high efficiency.

Owner:CHINA UNIV OF MINING & TECH

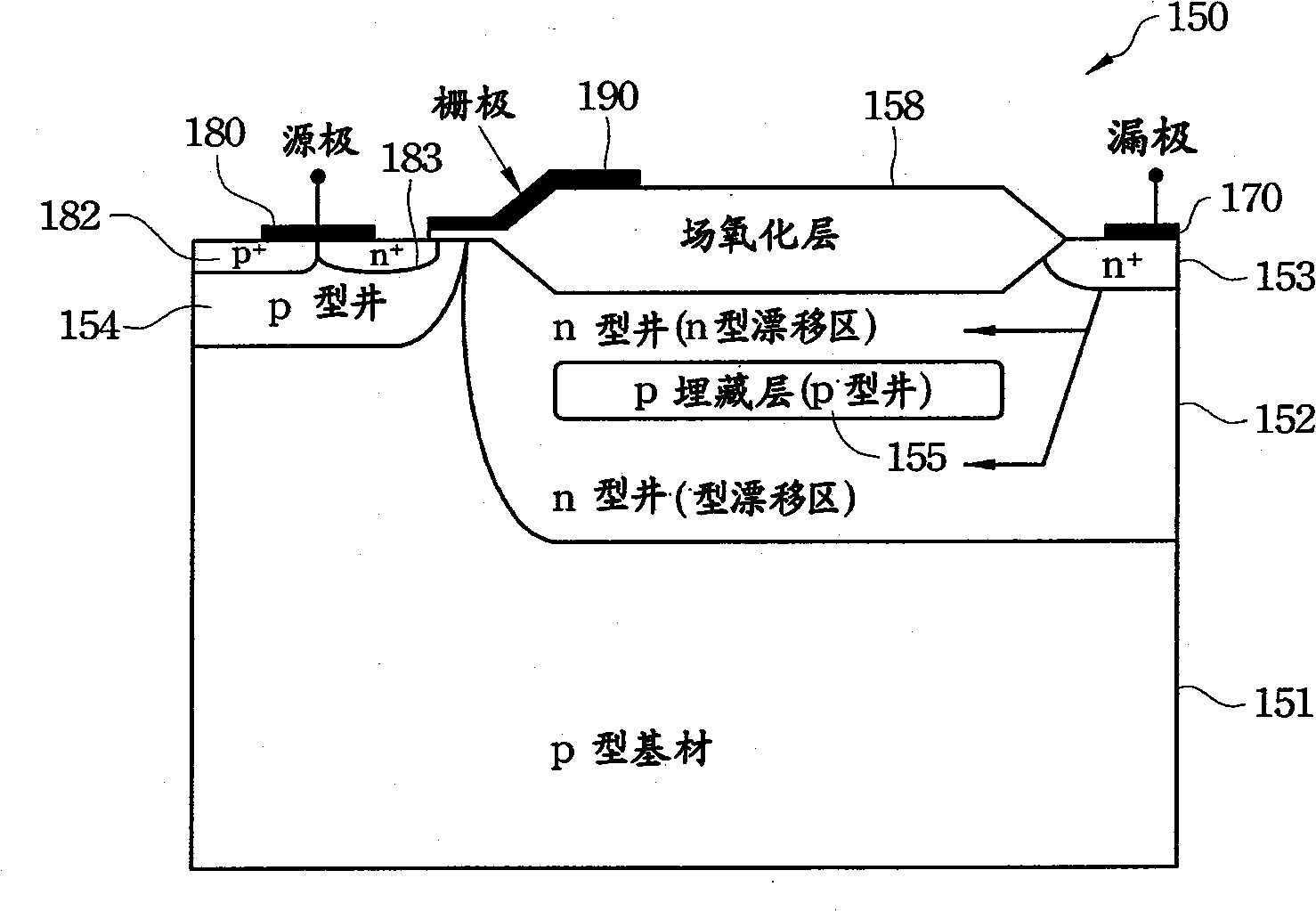

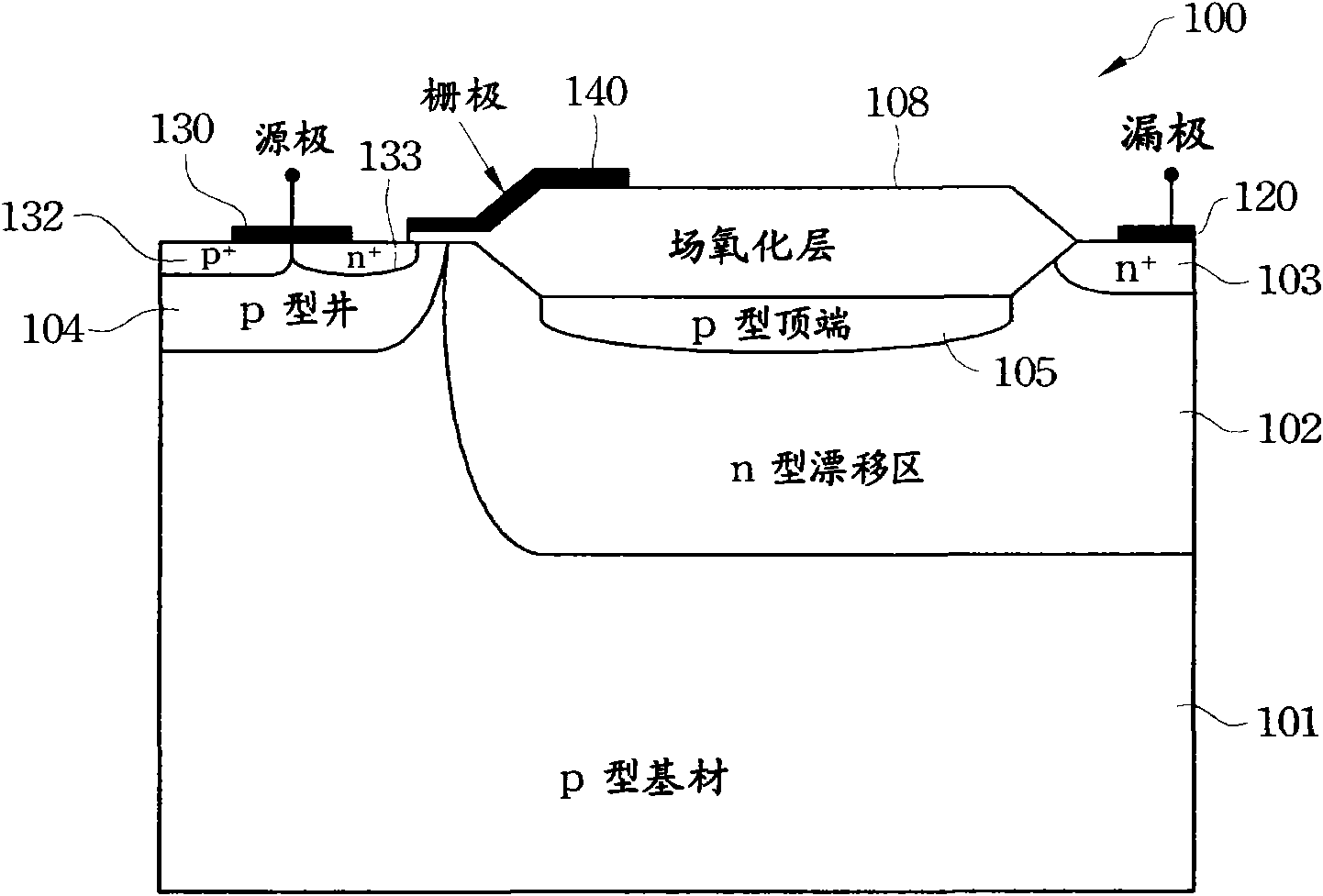

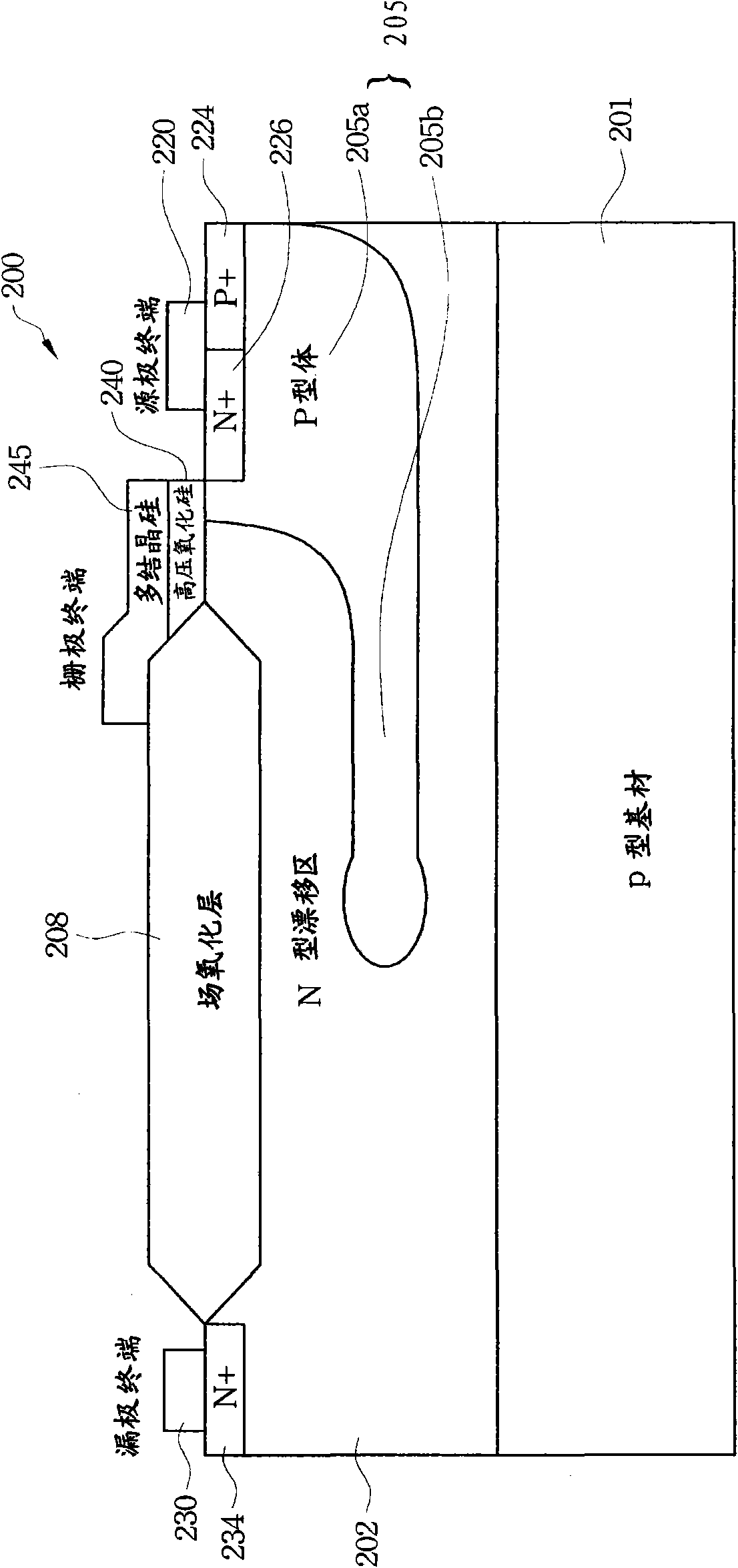

High voltage semiconductor transistor and method of manufacturing same

ActiveCN102214692AImprove performanceReduce the on-resistance RonSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringHigh pressure

The invention relates to a high voltage semiconductor transistor and a method of manufacturing the same. The transistor includes a semiconductor substrate, a gate strucutre formed on the semiconductor substrate, a source and a drain formed in the substrate on either side of the gate structure, a first doped well formed in the substrate, and a second doped well formed in the first well. One portion of the second well surrounds the source and the other portion of the second well extends laterally from the first portion in the first well. Through arranging a double-well structure in the semiconductor substrate (an extending p-type well area is located in an n-type well area), the BV value is increased and the transistor performance is enhanced. Additionally, the arrangement of the p-type doped extending area reduces the conductive resistance Ron in operation of the transistor so as to save the power cost of the transistor.

Owner:TAIWAN SEMICON MFG CO LTD

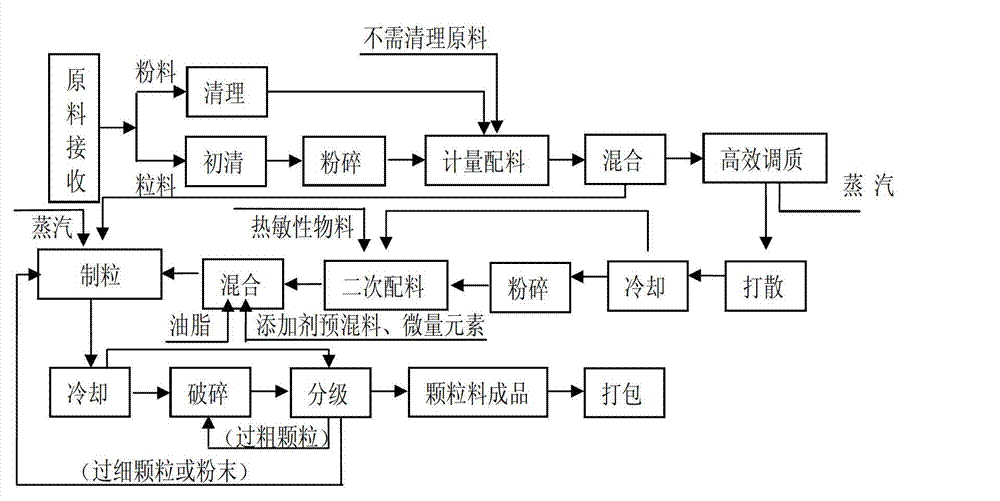

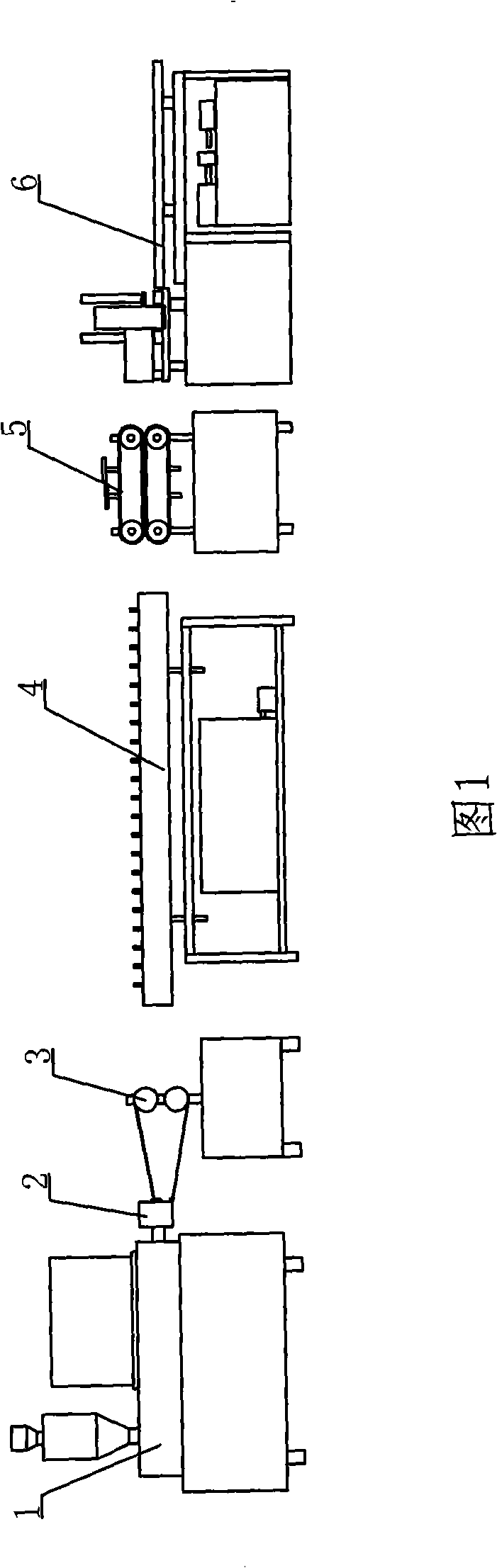

Livestock and poultry feed production technology for granulating powder at low temperature after conditioning and baking process of powder

ActiveCN103110172AIncrease conditioning and agingIncrease the secondary ingredient mixing processFeeding-stuffFood shapingCooking & bakingPrill

The invention discloses a livestock and poultry feed production technology for granulating powder at a low temperature after a conditioning and baking process of the powder. According to the livestock and poultry feed production technology, firstly, mixed feed in which no heat-sensitive ingredient or feed additive is added is subjected to an efficient conditioning and baking process and made into a cooked powered material; secondly, the cooked powered material is cooled, and then heat-sensitive ingredients and feed additives are added into the cooked powered material; and lastly, the cooked powdered material with the sensitive ingredients and the feed additives is granulated at the low temperature to form granulated feed. Through the livestock and poultry feed production technology, not only is power of arranged equipment relatively low, but also the activity of the heat-sensitive ingredients in the feed can be reserved to the greatest extent while the cooked powdered material is made into granules.

Owner:FEED RESEARCH INSTITUTE CHINESE ACADEMY OF AGRICULTURAL SCIENCES

Titanium alloy (TC11) rolled tube and preparation method thereof

The invention relates to a titanium alloy and particularly relates to a titanium alloy (TC11) finished tube and a preparation method thereof. According to the TC11 finished tube, the alloy contains the following ingredients in percentage by weight: the balance of Ti, 5.8-7.0% of Al, 0.2-0.35% of Si, 0.8-2.0% of Zr, 2.8-3.8% of Mo, not higher than 0.1% of Fe, not higher than 0.05% of C, not higher than 0.04% of N, not higher than 0.0125% of H and not higher than 0.15% of O. The TC11 tube prepared by the preparation method has the properties that the tensile strength is 800-1,300MPa, the elongation percentage is 8-25%, and the metallographic structure is uniform and comprises metallographic structures of stress annealing and complete-recrystallization annealing.

Owner:忠世高新材料股份有限公司

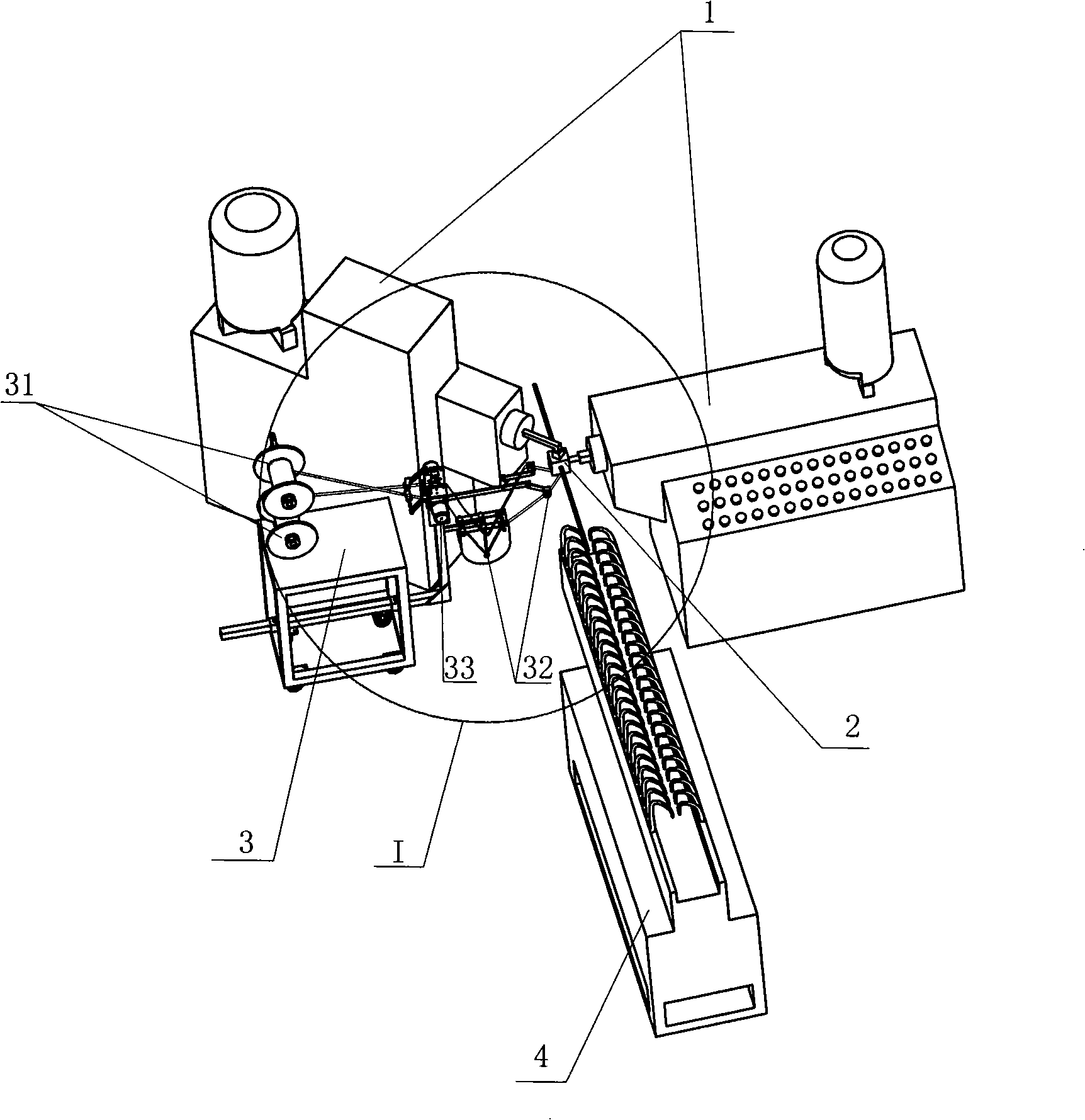

Suede plastering method for decorative strip of vehicle

InactiveCN101318487AImprove the quality of pastingEasy to cleanLiquid surface applicatorsVehicle componentsWorking environmentEngineering

The invention relates to a velvet sticking method for a decorative strip of a vehicle which conducts flocking after coating glue on a film surface which can carry out thermal bonding with the body of the decorative strip; then the flocked film is cut into the flocked glue belts with needed width; after leading one end of the flocked glue belts to pass through a channel on an extruding die, the one end of the flocked glue belts is exposed out of the extruding opening of the extruding die and the back surfaces of the back ends of the flocked glue belts are caused to be just corresponding to the part needed to be stuck with the velvet of the body of the decorative strip extruded from the extruding opening; with the body of the decorative strip extruded from the extruding opening of the extruding die, the back parts of the flocked glue belts are thermally bonded on the part needed to be stuck with the velvet of the body of the decorative strip. After the scheme is adopted, not only can the device investment and the operation personnel be obviously reduced, the production period is shortened, the production cost and the risk of batch production are reduced, but also the flocking efficiency and the flocking quality of the film can be greatly improved; besides, the working environment is amended, the health of the operation personnel is protected and the machine is avoided from being polluted by the velvet.

Owner:NINGBO XINTAI MACHINERY

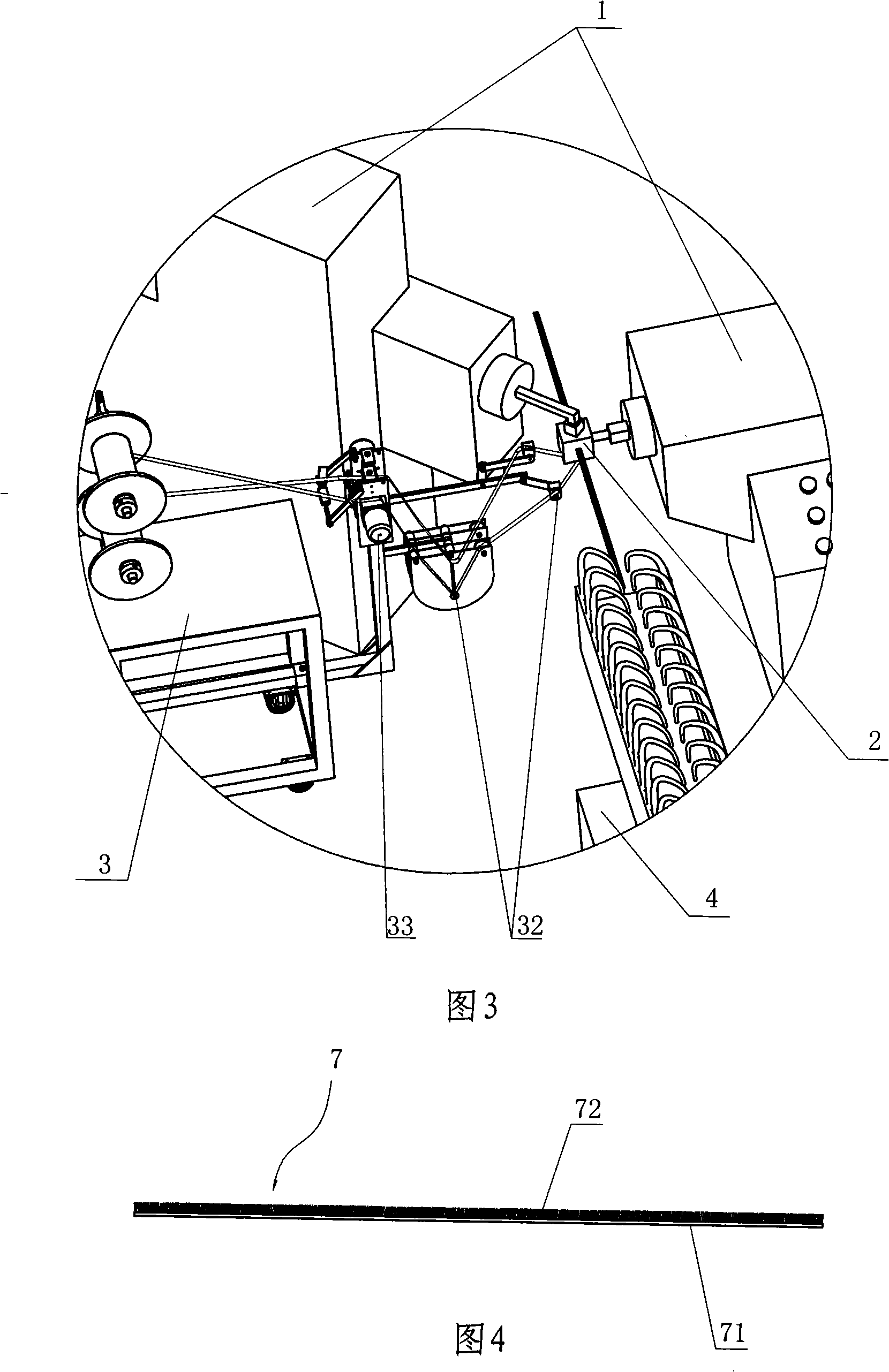

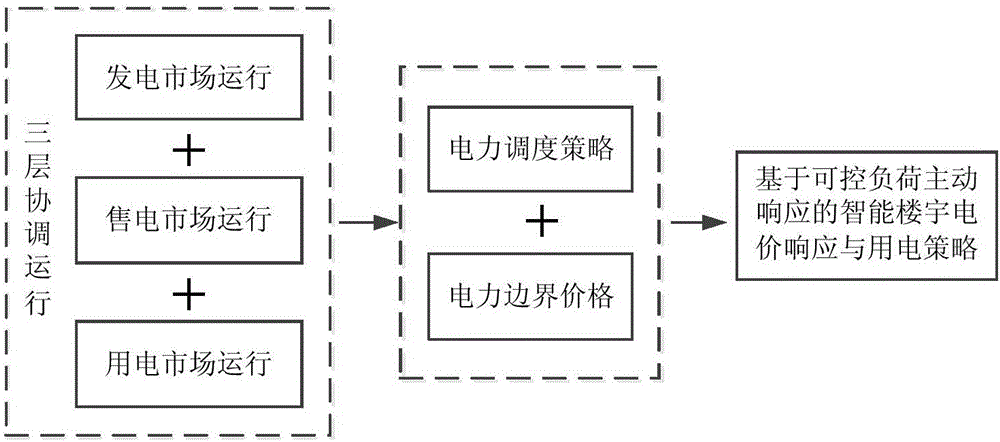

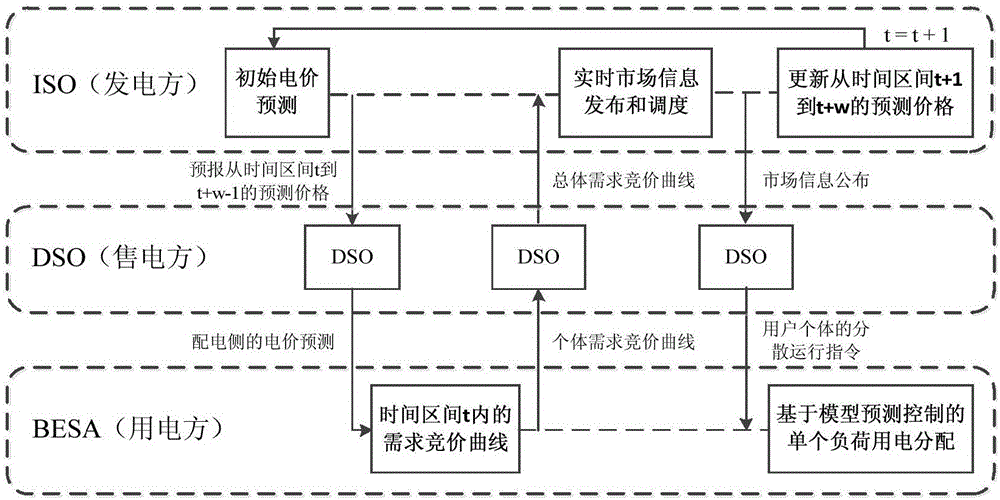

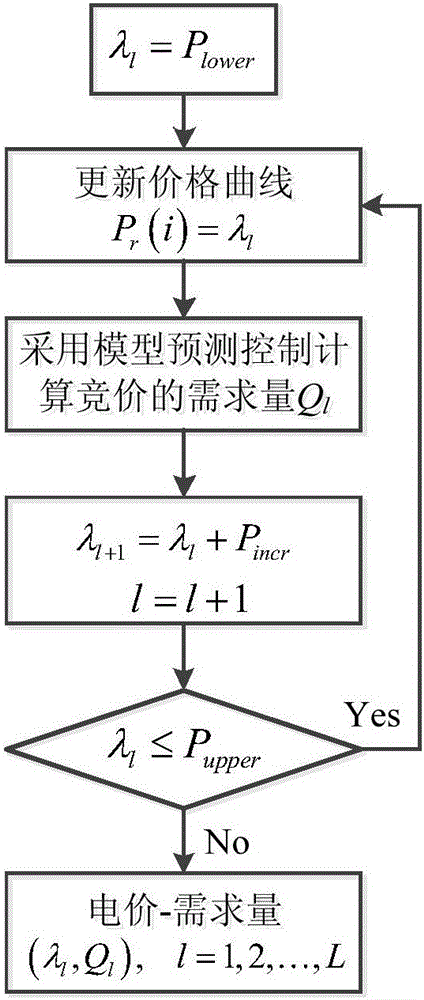

Intelligent building electricity price response electricity utilization method based on controllable load active response

InactiveCN105760969AReduce electricity consumption costsMarket predictionsForecastingElectricity priceCoordinate control

The invention relates to an intelligent building electricity price response electricity utilization method based on controllable load active response, comprising: (1) establishing a three-layered electric power market structure under controllable load active response, and generating strategies of electricity price formation according to user load active response; and (2) based on a controllable load active response mode, establishing an intelligent building electricity utilization method and a sensitive load electricity price bidding method. The invention provides a method of actively participating in an electric power market for buildings / users, performs coordinative control and optimal adjustment on each load through interaction between loads and the market, and reduces user electric power consumption costs.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO ELECTRIC POWER RES INST +2

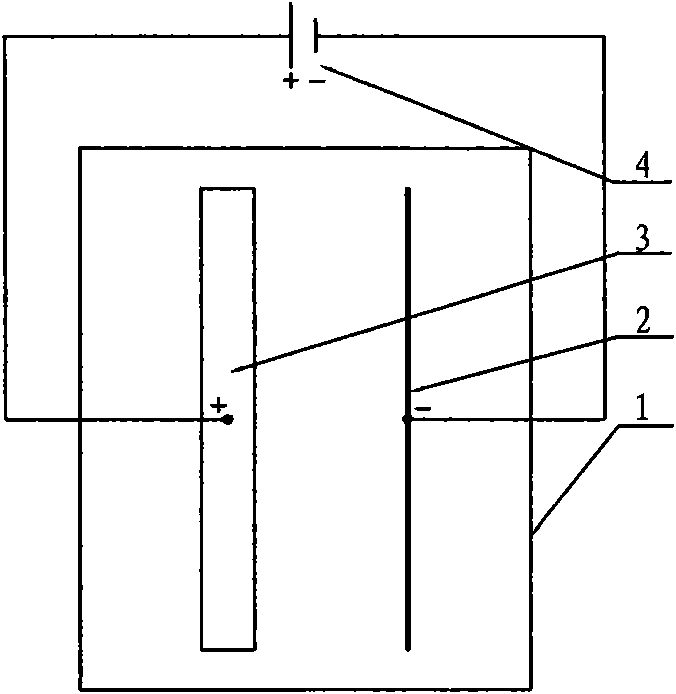

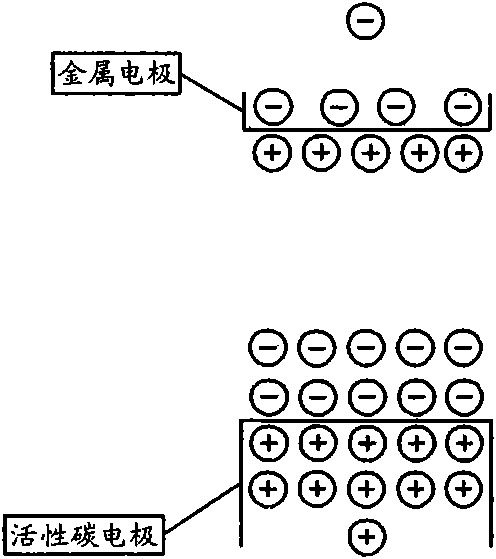

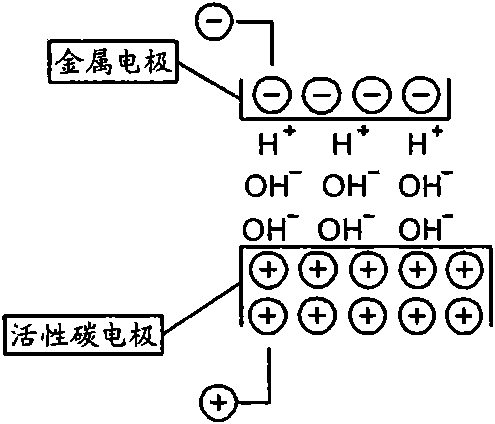

Reductive water non-diaphragm electrolysis device

InactiveCN102020341ARealize popularization of commercializationReduce consumptionWater/sewage treatmentActivated carbonStable state

The invention relates to a reductive water non-diaphragm electrolysis device belonging to the technical field of electrolysis of water and comprising an electrolyzer, a pair of negative electrode and positive electrode arranged in the electrolyzer, and a power supply electrically connected with the negative electrode and the positive electrode; one of the negative electrode and the positive electrode is an activated carbon electrode mainly made of activated carbon, and the other electrode is a metal electrode made of metal; the distance delta between the negative electrode and the positive electrode is not greater than 5m but is greater than 0. The device can adapt to various kinds of raw water and can prepare reductive water with wide pH range and a stable state without adding any substance directly by electrifying; moreover, compared with various water electrolysis devices, the reductive water non-diaphragm electrolysis device has lower power consumption and manufacturing cost, and thereby, the commercial popularization of the non-diaphragm electrolysis device can be implemented.

Owner:李国梅 +2

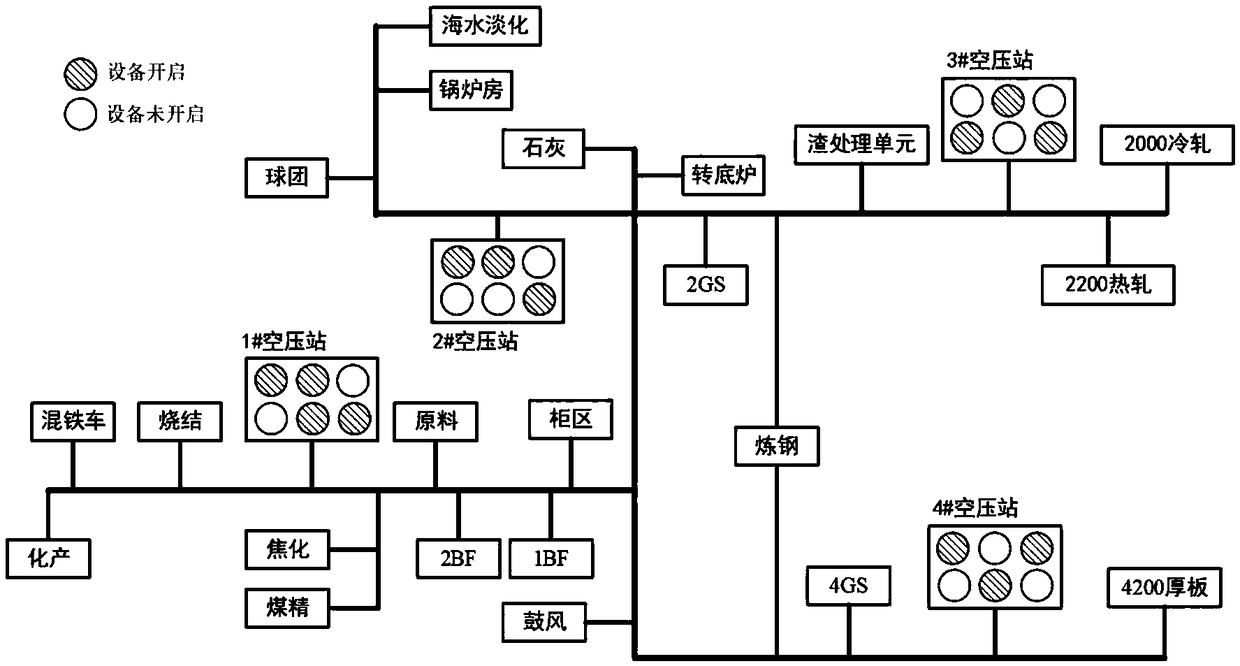

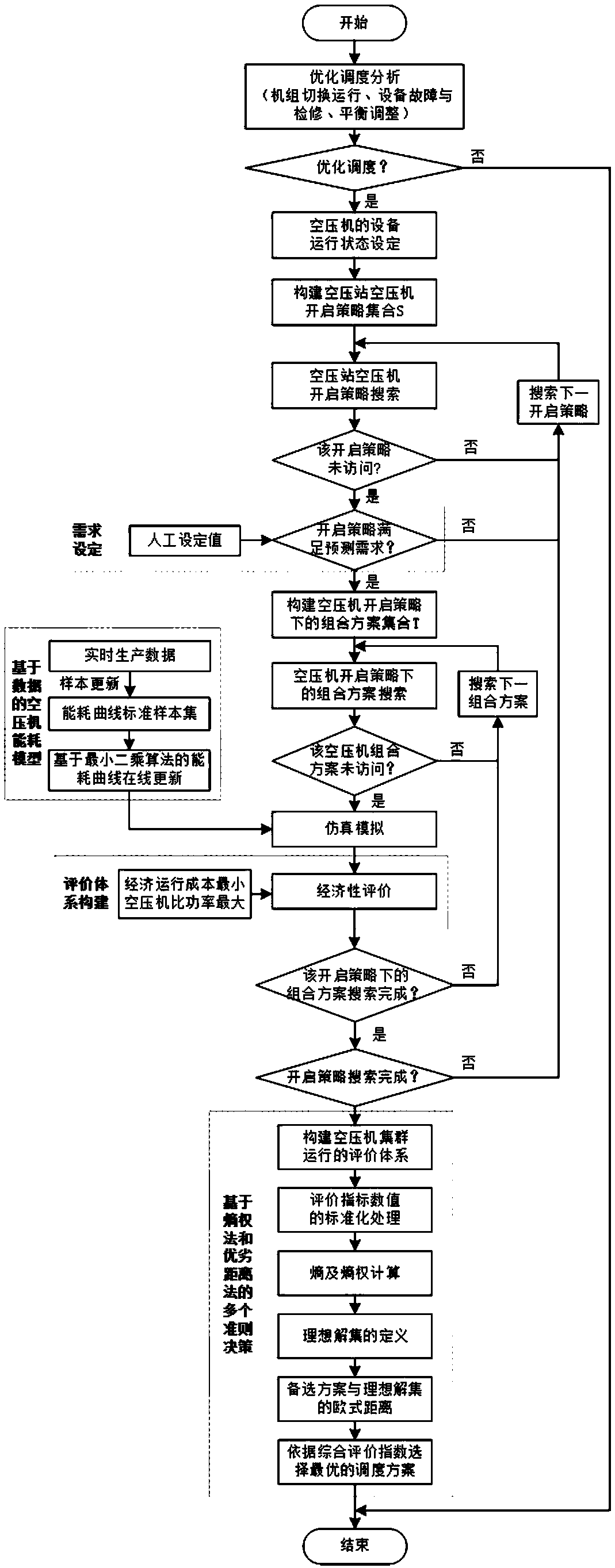

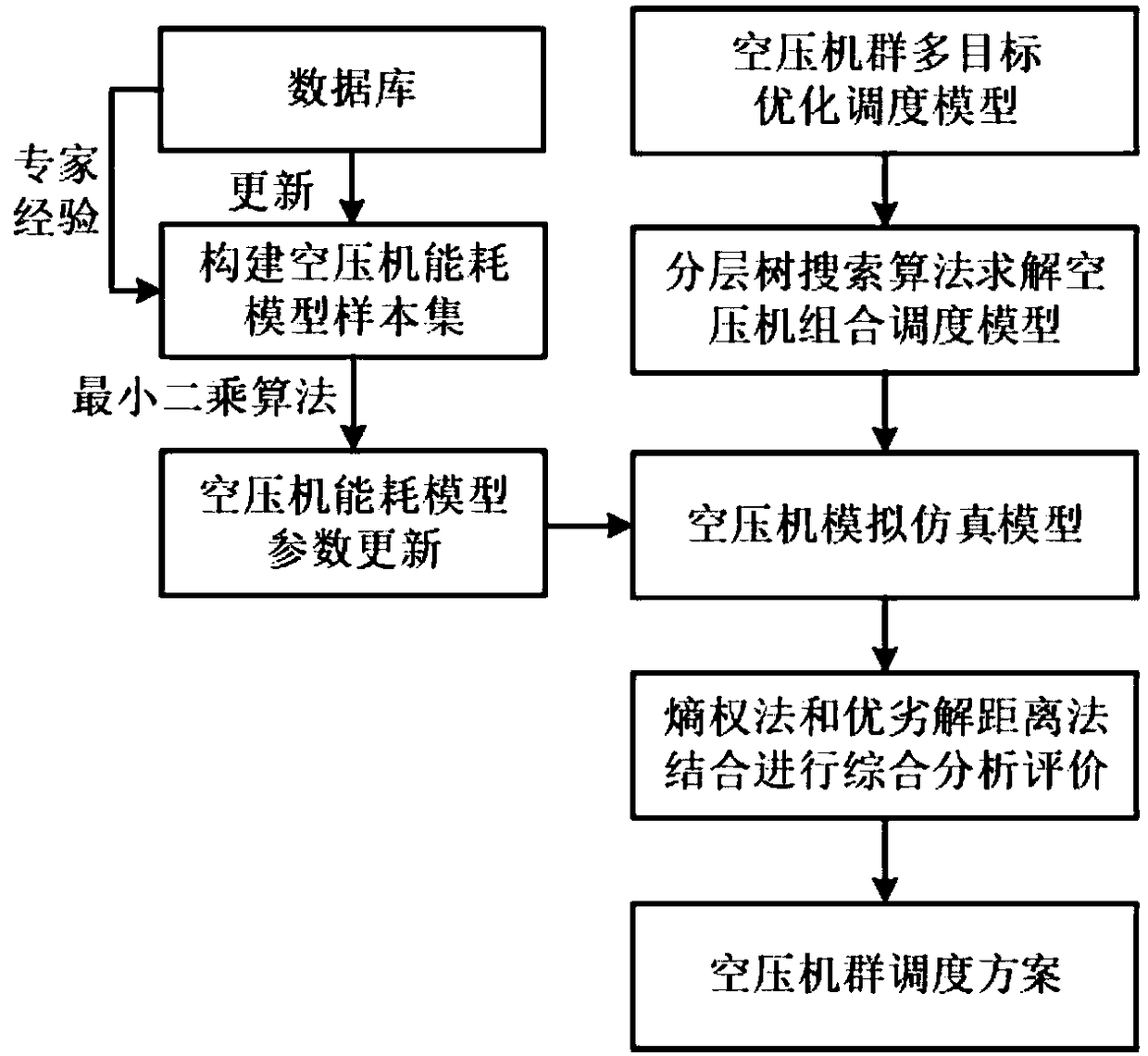

Air compressor group optimization scheduling method based on hybrid model

ActiveCN109164704AQuick solveShorten development timeAdaptive controlModel sampleEntropy weight method

The invention relates to an air compressor group optimization scheduling method based on a hybrid model, belonging to the field of information technology. In order to solve the blindness in present air compressor group scheduling, a hybrid model combining a simulation technology and a combined scheduling optimization decision is established. The method comprises the steps of dynamically updating an air compressor energy consumption model sample set constructed by expert experience by using an industrial field real-time sample, then performing on-line learning on relevant parameters of an air compressor energy consumption model by using a least squares algorithm, solving an air compressor group multi-objective optimization scheduling model by using a simulation technology and a hierarchicaltree search algorithm, and finally, comprehensively evaluating the acquired scheduling plan by using an entropy weight method and a TOPSIS method, thereby assisting on-site dispatchers in making a safe, energy-saving, environment-friendly and economic scheduling plan. The method also has wide application value in different industrial fields.

Owner:DALIAN UNIV OF TECH

Reduction and carbonization method for titanium-containing raw material

The invention relates to a reduction carbonization method of the titanium-bearing material, which belongs to the metallurgy field. The invention solves the technology difficult problem that the bottom of a furnace rises and the generated foamed slag is excessive during the reduction carbonization process of the titanium-bearing material. The reduction carbonization method of the titanium-bearing material in the invention has various power distribution systems in the various implementation stages of material melting, reduction carbonization, and discharging; during the material melting stage, the transformer capacity is fully exerted, to ensure that the material is melted quickly; during the reduction carbonization stage, the electric furnace power is controlled to ensure that the depth of a steady foamed slag layer does not exceed 50 percent of the depth of a material melting tank; during the discharging stage, the electric furnace power is enhanced, to ensure that the melted and carbonized slag flow out of an electric furnace steadily, and the power cannot be shut off during the discharging. The reduction carbonization method of the titanium-bearing material of the invention can realize continuous production, the production operation is secure, the reduction carbonization power consumption and the production cost are reduced, the production efficiency is enhanced, and the invention has broad application prospect.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

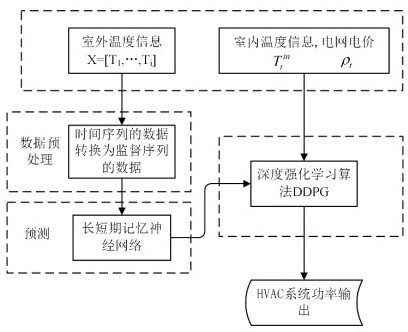

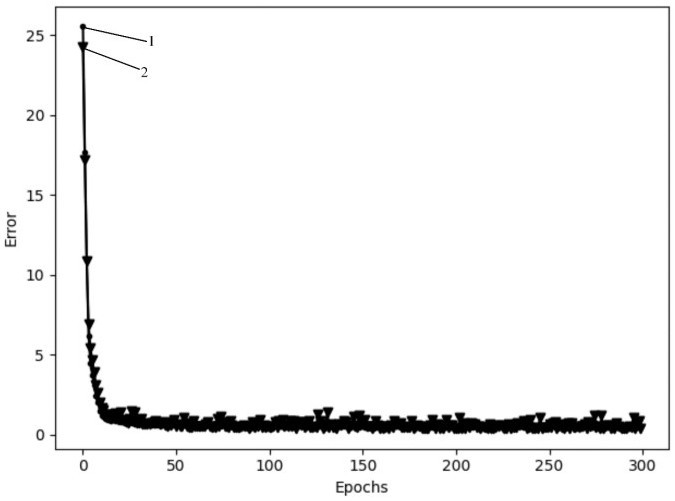

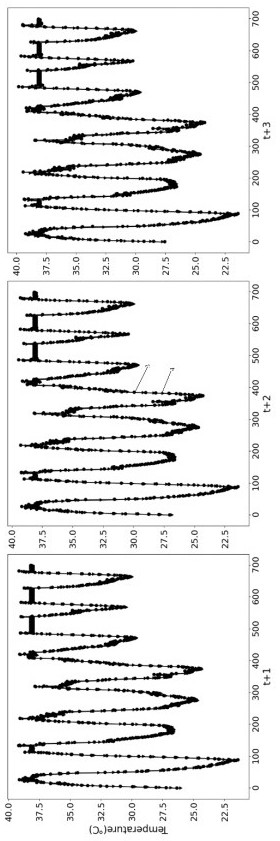

HVAC control system based on multi-step prediction deep reinforcement learning algorithm

ActiveCN113112077AImprove comfortGuaranteed comfortForecastingNeural architecturesAlgorithmReinforcement learning algorithm

The invention relates to an intelligent control method of a control system of an HVAC (Heating, Ventilation, Air-conditioning and Cooling) control system, in particular to an HVAC control system based on an LSTM (Long Short Term Memory) neural network of a GC (generalized correntropy) loss function and a DRL (deep reinforcement learning) algorithm. The method comprises the following steps: acquiring outdoor environment temperature, indoor environment temperature and electricity price information of a power grid, preprocessing the acquired data, and predicting the outdoor environment temperature of multiple steps in the future by using historical data of the outdoor environment temperature; on the basis of the future outdoor temperature value, the indoor environment temperature and the power grid electricity price information, controlling the power output of the HVAC system by utilizing a DDPG (Deep Deterministic Policy Gradient) algorithm of the DRL. According to the invention, the HVAC system can be intelligently controlled in real time, so that the user cost is reduced, the satisfaction degree of the user is ensured, and the method has high practical engineering application value.

Owner:TAIYUAN UNIV OF TECH

Underground mine water treatment system and method

InactiveCN103570179AReduce dosageSave power consumptionMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationWater treatment systemWater quality

The invention relates to the field of drainage and purification treatment in coal mines, and in particular relates to an underground mine water treatment system. The underground mine water treatment system comprises a preliminary sedimentation tank, a mixed reaction tank, a super magnetic separator and a filter which are connected in sequence, wherein the super magnetic separator is connected with an underground sump; the underground sump is connected with the filter through a drainage pump; the filter is connected with a clean water tank; the preliminary sedimentation tank, the mixed reaction tank, the super magnetic separator, the underground sump and the drainage pump are arranged in an underground water treatment chamber; the filter and the clean water tank are arranged on the ground. According to the mine water treatment system, based on the characteristics of short solid-liquid separation time, high efficiency, small equipment and the like of the super magnetic separation equipment, the mine water treatment system is constructed in an underground roadway; compared with the conventional mine water treatment station, the underground mine water treatment system has the advantages that the system is not influenced by seasonal temperature changes, the quality of the treated water is stable, pump lifting is not required, a little amount of chemicals is consumed, the operation cost is saved, and the system is constructed underground to save the floor area.

Owner:COAL IND JINAN DESIGN & RES

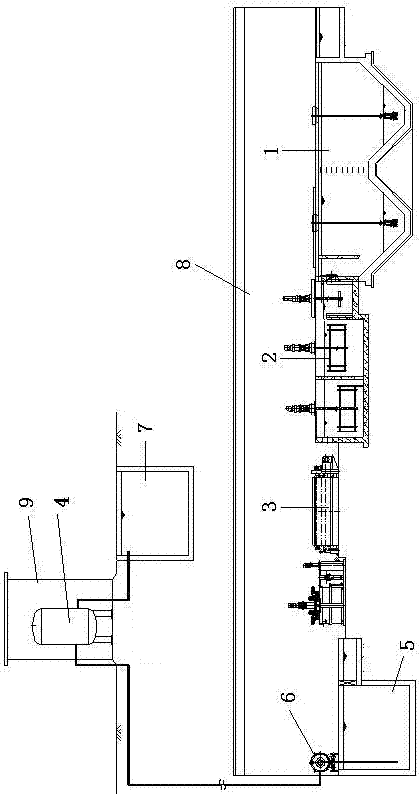

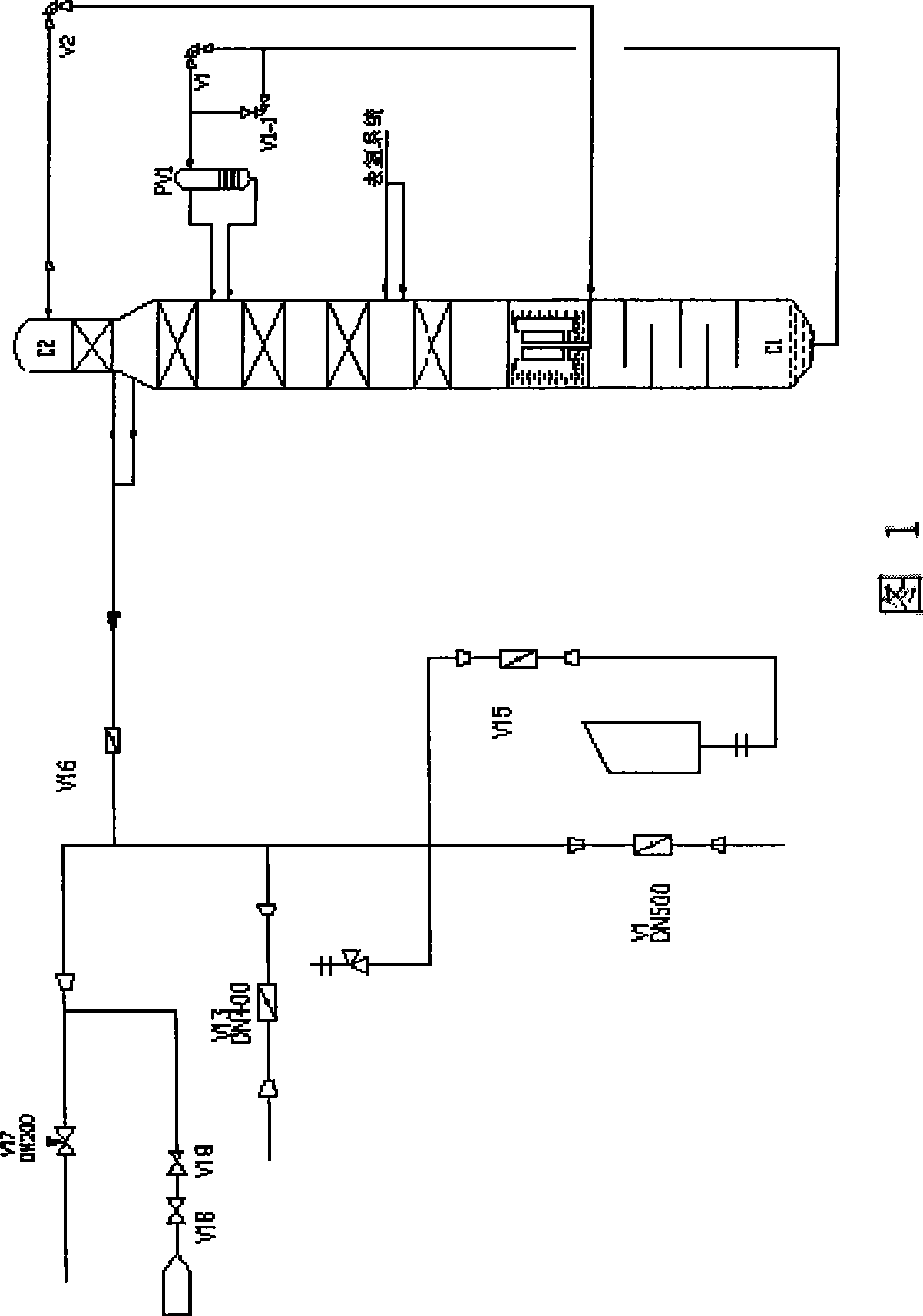

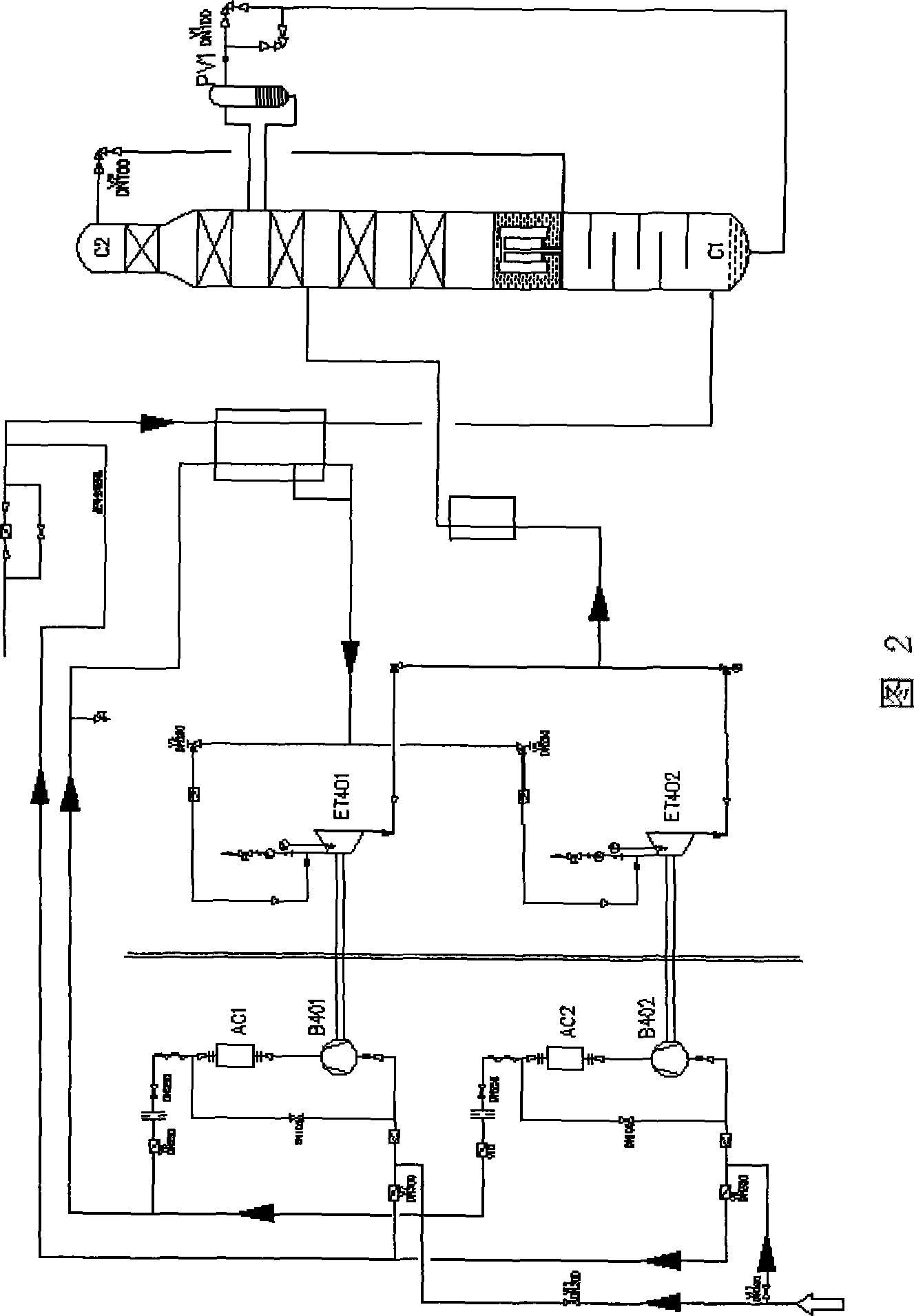

Device for producing ammonia gas through pyrolysis of urea by using high-temperature flue gas as heat source

InactiveCN104548931AReduce electricity consumption costsLow running costChemical industryDispersed particle separationSuperheaterRotational flow

The invention relates to the field of processes for producing ammonia gas through urea, and aims to provide a device for producing ammonia gas through pyrolysis of urea by using high-temperature flue gas as a heat source. The device for producing ammonia gas through pyrolysis of urea by using high-temperature flue gas as the heat source comprises a rotational flow pyrolysis furnace, a bypass flue duct, a flue gas baffle, a mechanical atomizing spraying gun, a flue gas flow sensor, a flue gas temperature sensor, a booster fan, an ash discharging bucket, a pressure sensor and a temperature sensor. The device adopts a small amount of high-temperature flue gas close to a high-temperature superheater as the heat source for urea pyrolysis, adopts a cheap low-grade energy source to replace a high-grade energy source, and reduces the consumption of power required by urea pyrolysis and running cost; the device adopts the rotational flow pyrolysis furnace, so that the content of dust in flue gas is effectively reduced, the abrasion of dust against the booster fan is reduced, the work environment of the booster fan is improved, the service life of the booster fan is prolonged, meanwhile, uniform mixing of the urea and the high-temperature flue gas is ensured, and the pyrolysis efficiency of the urea is improved.

Owner:浙江百能科技有限公司

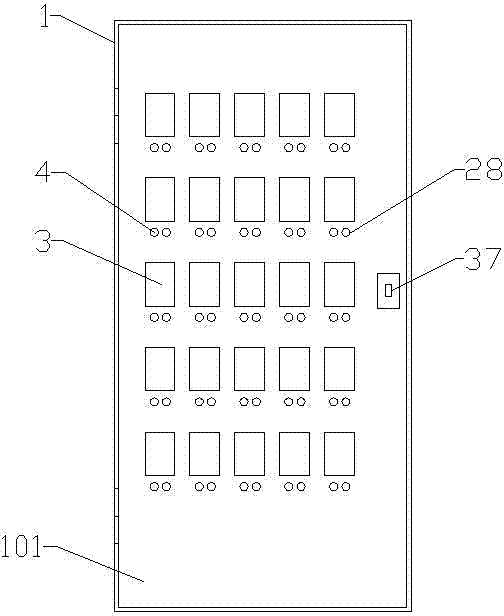

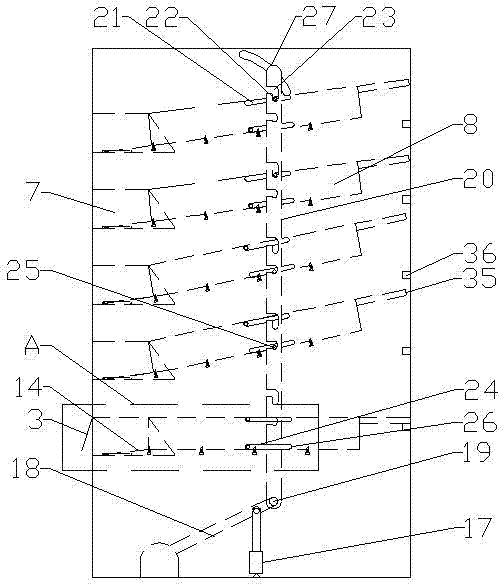

Vending machine with adjustable storage chamber inclination

InactiveCN103942884AIncrease varietyAdd variety typeCoin-freed apparatus detailsApparatus for dispensing discrete articlesEngineeringElectric control

The invention relates to a vending machine, in particular to a vending machine with the adjustable storage chamber inclination. According to the vending machine with the adjustable storage chamber inclination, a plurality of electric control doors arranged longitudinally and horizontally are arranged on a panel, a commodity exhibition and sale chamber is arranged behind the electric control doors, a channel which can have two inclinations through adjustment is hinged to the rear surface of the commodity exhibition and sale chamber, the interior of the channel is divided into a plurality of commodity storage chambers through partition boards, and the partition boards can be attached to the top surface of the channel under the action of rotary shaft springs and be fixed through positioning slots and electromagnetic tongue pins after the partition boards drop down. According to the vending machine with the adjustable storage chamber inclination, the variety types of commodities which can be sold through the vending machine are increased, the requirement for limiting the appearance, the size, the weight and the frangibility degree of the commodities is lowered, the varieties of the commodities which can be sold through the vending machine can be enriched greatly, the number of the commodities stored in the whole machine is increased, and the space utilization rate is effectively increased; meanwhile, the structure is simple, the whole vending machine is low in manufacturing cost, and due to the fact that the electromagnetic tongue pin instant power consumption technique, the partition board spring automatic restoring technique, the commodity self-weight downward sliding technique and other techniques are adopted, power consumption cost is reduced, and the return on investment of the vending machine is effectively increased.

Owner:韩云飞

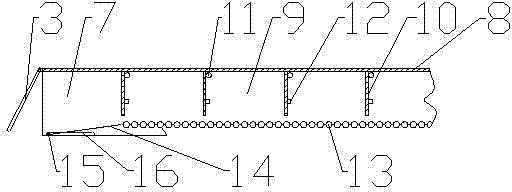

Special lithium iron phosphate accumulator for new energy hybrid electric vehicle

InactiveCN104617331AReduced oxidation capacityImprove thermal stabilityElectrode carriers/collectorsSecondary cellsNew energyElectrical battery

The invention discloses a special lithium iron phosphate accumulator for a new energy hybrid electric vehicle. The lithium iron phosphate accumulator comprises a plurality of single batteries which are combined in series-parallel connection, wherein each single battery comprises a positive plate, a negative plate, a diaphragm and electrolyte, wherein the positive plate and the negative plate respectively comprise positive and negative current collectors and active substances; the positive and negative current collectors are same in size, and the active substances are coated on the positive and negative current collectors; the positive plate comprises lithium iron phosphate, a conductive agent and a positive current collector, wherein lithium iron phosphate has an olivine structure; an inclined aluminum mesh is adopted as the positive current collector, and the thickness of the aluminum mesh is 0.10-0.15 mm; the positive active substance of the each single battery comprises the following components in percentage by weight: LiFePO4:SP:KS-6:PVDF:NMP=(90-92):(1-2):(2-1):(5-6):(120-140). The special lithium iron phosphate accumulator disclosed by the invention has the advantages of high heat stability in a charging state, low oxidizing capacity on electrolyte and preferable overcharge resistant property through the structure and a preparation method by adopting lithium iron phosphate, has excellent temperature characteristics, can achieve the ambient operating temperature of -20-60 DEG C, and can be used for reducing the equipment purchase cost and the power consumption cost.

Owner:深圳市索阳新能源科技有限公司

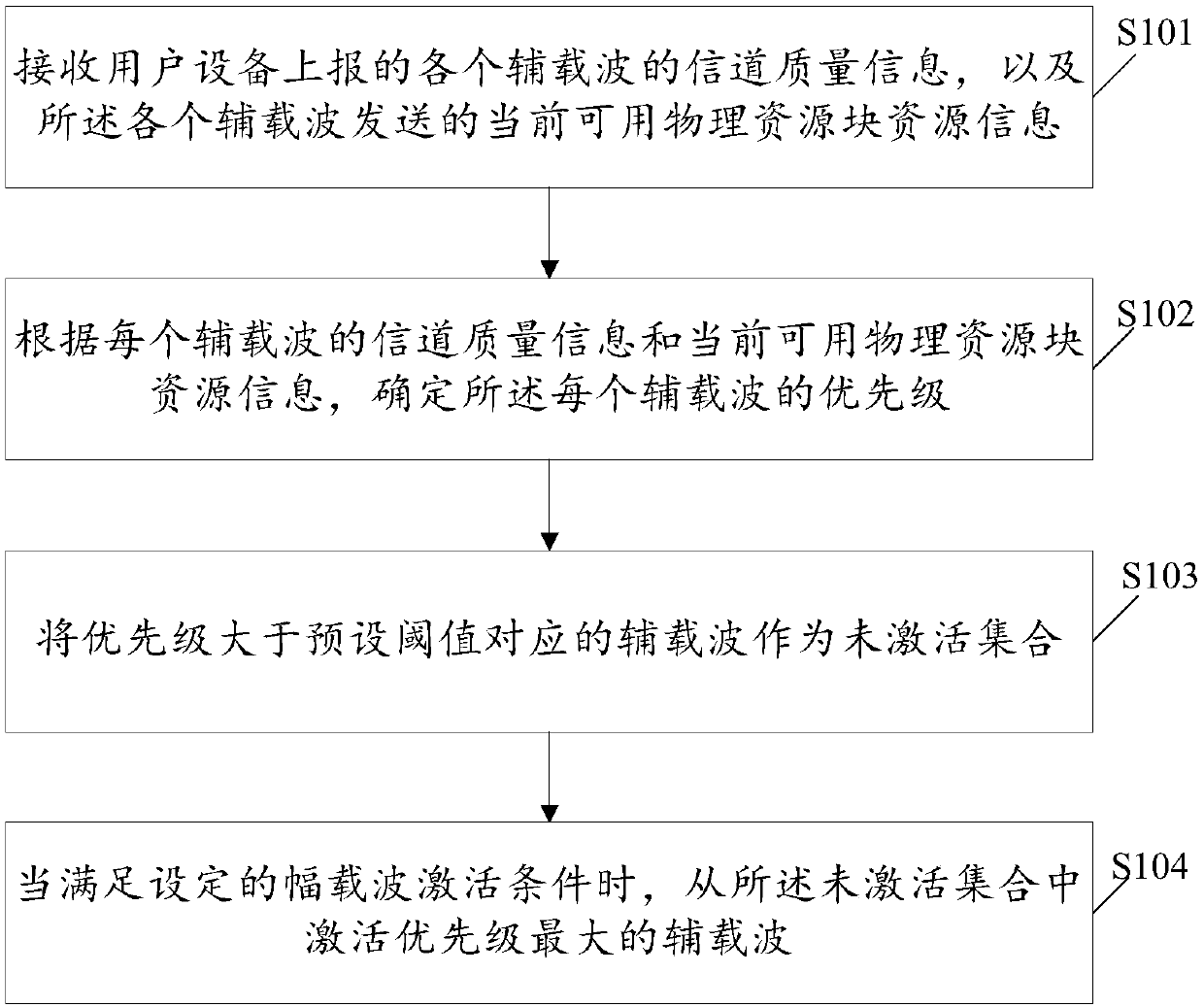

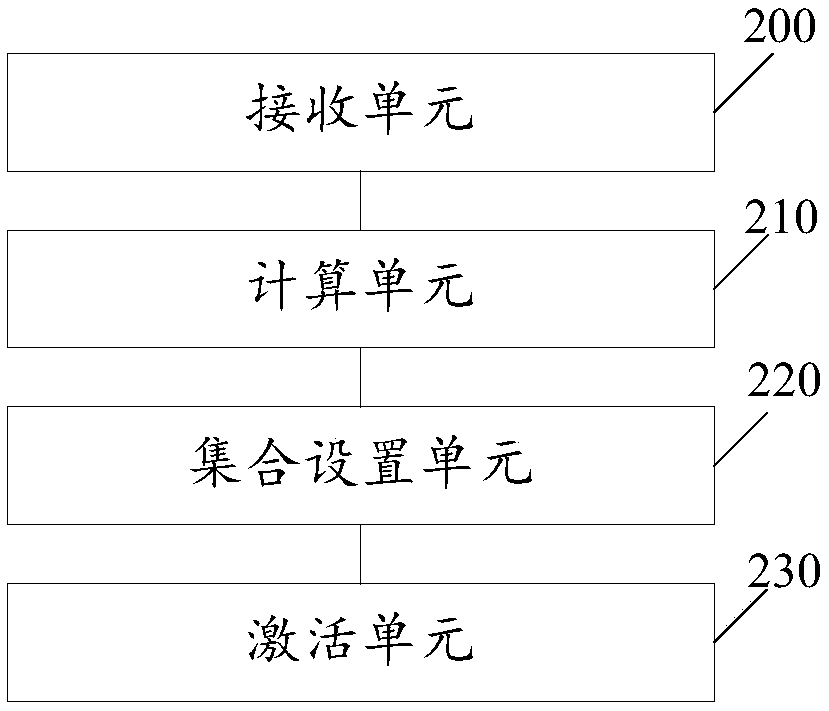

Multi-carrier aggregated auxiliary carrier management method and base station

ActiveCN108024357AReduce electricity consumption costsAvoid wastingHigh level techniquesWireless communicationResource informationResource block

The invention discloses a multi-carrier aggregated auxiliary carrier management method and base station. The problem that the UE saves the wireless resource under multi-carrier is solved. The method comprises the following steps: receiving channel quality information of each auxiliary carrier reported by the UE, and the current available physical resource block resource information sent by each auxiliary carrier; determining the priority of each auxiliary carrier according to the channel quality information and the current available physical resource block resource information; taking the corresponding auxiliary carrier with the priority greater than the preset threshold value as the inactivated set; when a set amplitude carrier activation condition is satisfied, activating the auxiliary carrier with the maximum priority from the inactivated set.

Owner:ZTE CORP

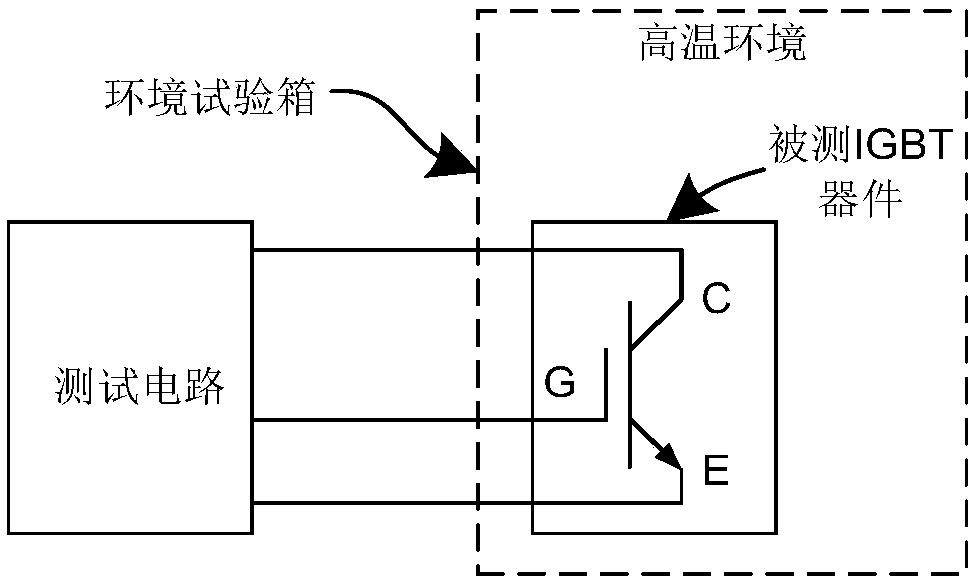

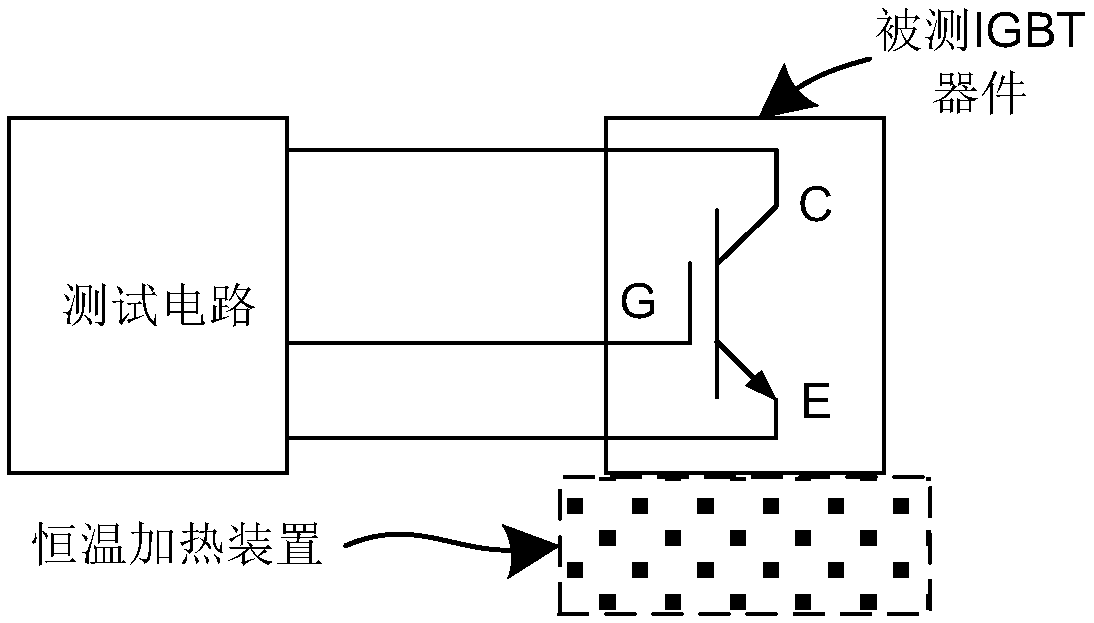

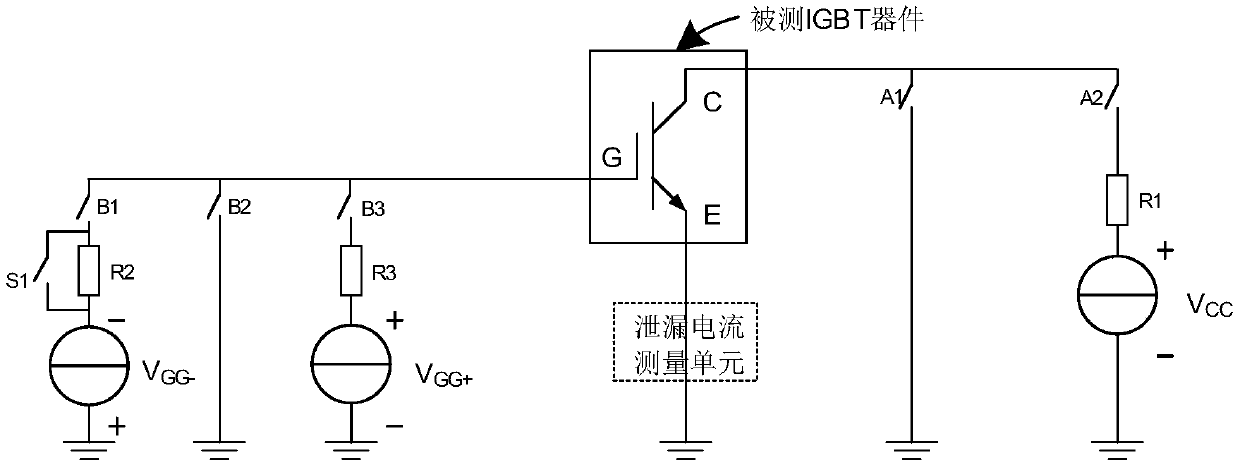

Method and system capable of being compatible with various environmental aging tests

ActiveCN109596964AIncrease profitReduce procurement costsIndividual semiconductor device testingTest powerHigh humidity

The invention relates to a method and a system capable of being compatible with various environmental aging tests. The system comprises a test environment device and a test circuit; the test environment device can be used to provide a test environment required by a to-be-tested power device in the environmental aging test; the test circuit can be used to provide electrical conditions needed by theto-be-tested power device in the environmental aging test, so that a required reverse bias test or grid bias test can be carried out on the to-be-tested power device; the test environment which can be provided by the test environment device includes a low-temperature environment, a high-temperature environment and a high-temperature and high-humidity environment; through cooperation of the test environment provided by the test environment device and / or the electrical conditions loaded by the test circuit, the required environmental aging test can be carried out on the to-be-tested power device; and the various environmental aging tests can be realized at the same time by utilizing the same device, so that the comprehensive utilization rate of the test is improved, and the installation space, the purchasing cost and the follow-up operation and maintenance cost are reduced.

Owner:山东阅芯电子科技有限公司

Energy-saving start method of oxygen generator

InactiveCN101428764AReduce electricity consumption costsShorten start timeChemical industryOxygen preparationStart timeEngineering

The invention discloses an energy-saving starting method for an oxygen producing machine, wherein the method comprises the following steps: a, sweeping of a space division system; b, accumulation of liquid air of the space division system; and c, starting of an oxygen producing machine, wherein during the sweeping of a space division system in step a, the heating and the sweeping of the space division system are performed by adopting low pressure nitrogen in a pipe network; during the accumulation of liquid air of the space division system in step B, the expansion and the refrigeration of the space division system are performed by adopting the low pressure nitrogen in the pipe network; the starting of the oxygen producing machine in step c includes the starting of an air compression system, an air precooling system and a molecular sieve system; in step b, after a main condenser of a space division column reaches air liquefaction temperature, loxygen discharged by the main condenser is reversely charged into the main condenser before stoppage, so that the liquid level of the main condenser reaches a liquid level required at the step of adjusting purify; and in step b, the expanded nitrogen entering the space division system is repeatedly pumped, pressed and recycled. An air compressor does not start, and the sweeping of the space division system is performed by utilizing the nitrogen in the pipe network; the time and the energy consumption of the sweeping of the space division system are saved; the starting time of space division is greatly shortened; the power consumption is saved; and the commissioning time is shortened.

Owner:ANYANG IRON & STEEL

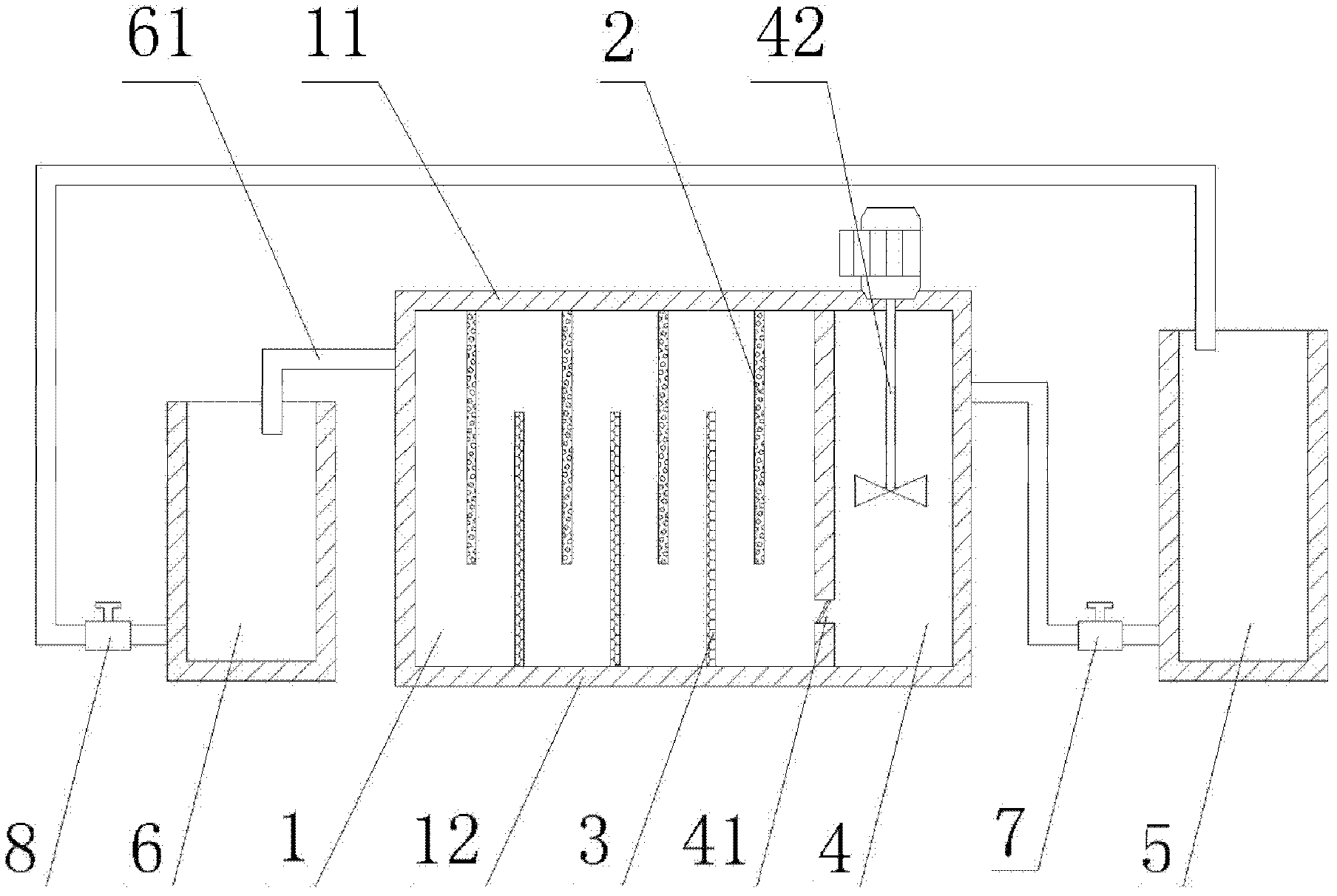

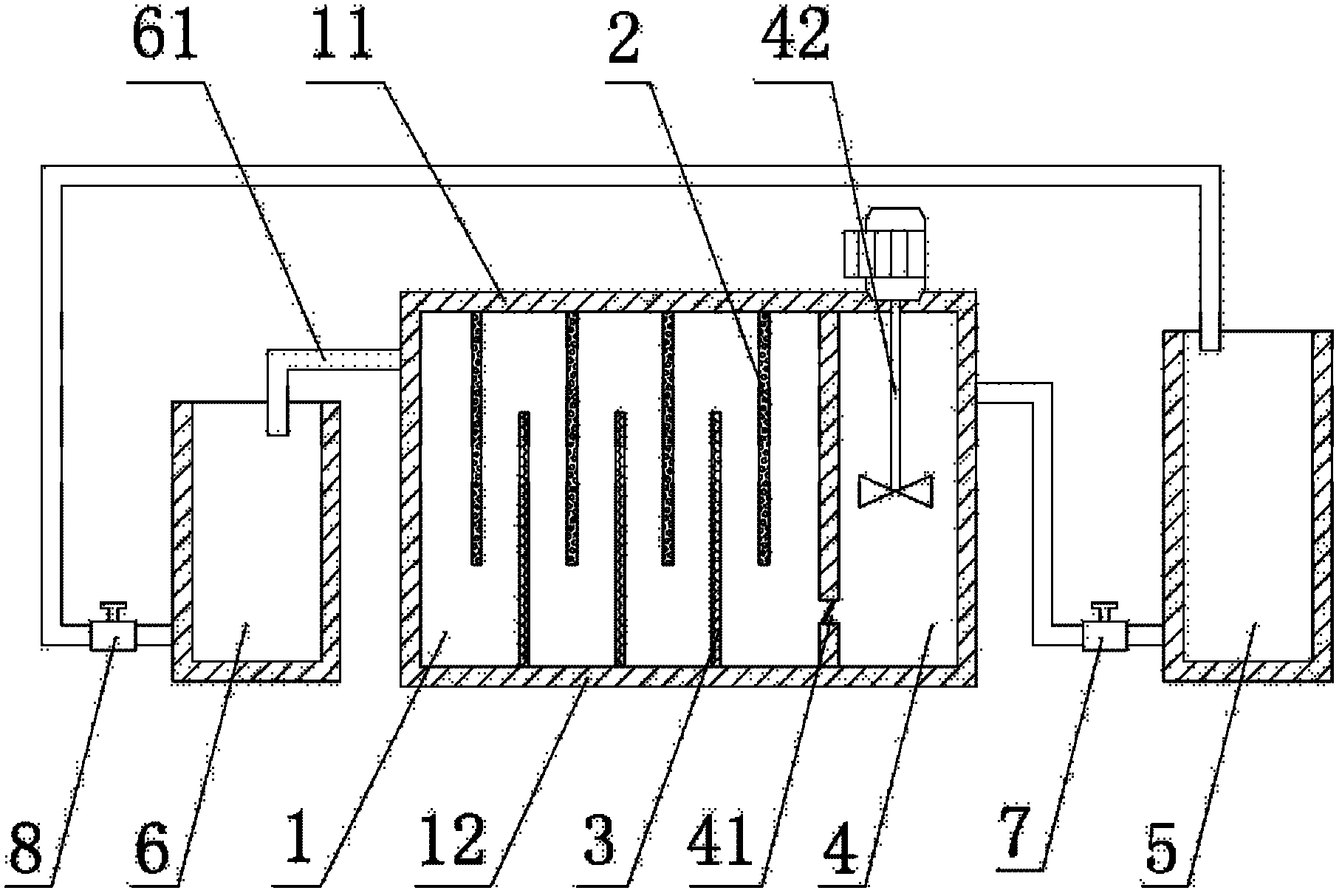

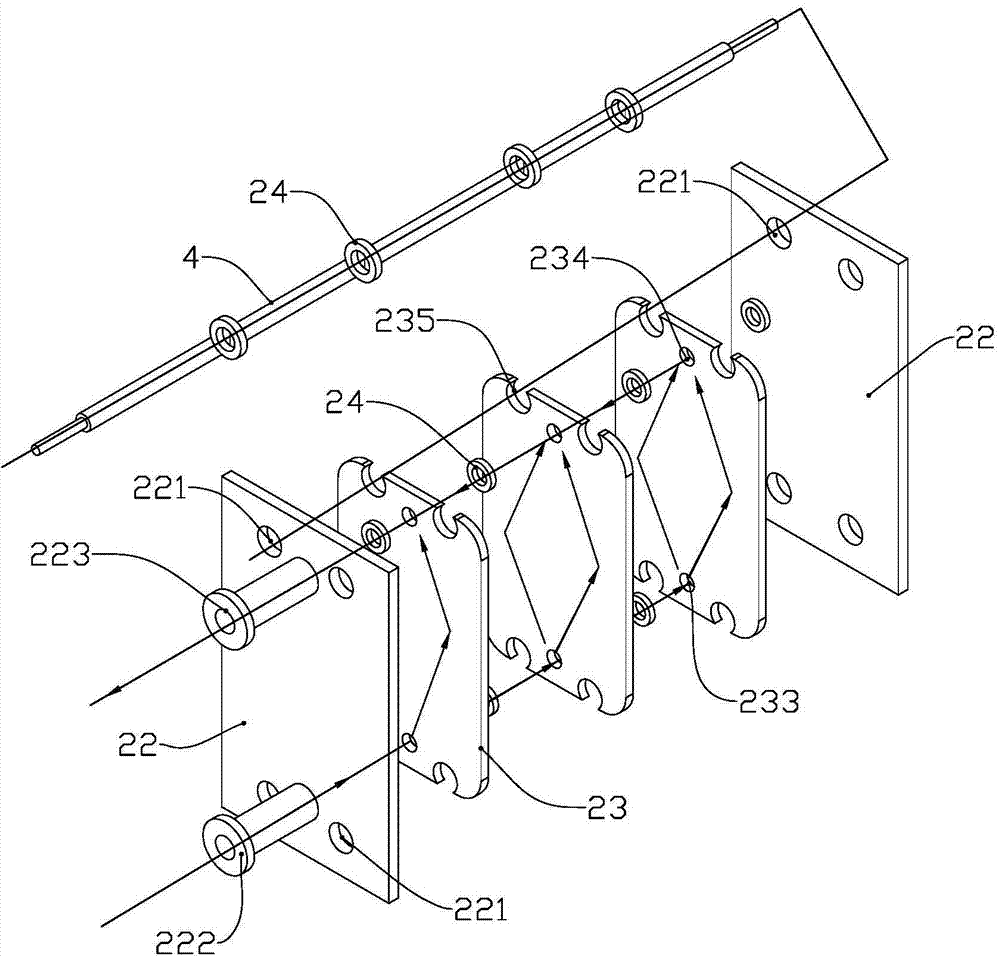

Treating system for industrial wastewater containing heavy metal and treating method thereof

ActiveCN102424457AImprove stress toleranceAvoid short circuit problemsWater/sewage treatmentElectrolysisBiochemical engineering

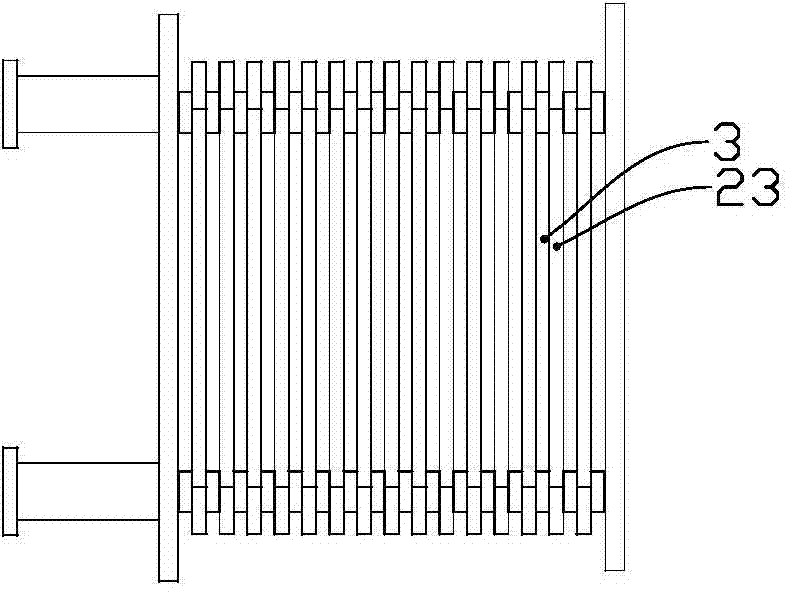

The invention provides a treating system for industrial wastewater containing heavy metal. The system comprises an electrolytic tank (1); the electrolytic tank (1) comprises a first trough wall (11) and a second trough wall (12), which are arranged to be opposite; positive plates (2) and negative plates (3) are staggerly arranged in the electrolytic tank (1), the first ends of the positive plates(2) are fixed on the first trough wall (11), the first ends of the negative plates (3) are fixed on the second trough wall (12), and each negative plate (3) is a starting sheet of a tri-dimensional network structure. According to the invention, because of utilization of the tri-dimensional network structure in the treating system, the negative starting sheets have substantially improved capacity in bearing stress, and the problem of short circuit of cathodes and anodes caused by cracking of the negative plates is avoided; the operation of plate stripping is omitted. The invention also provides a treating method for industrial wastewater containing heavy metal by using the treating system.

Owner:HUNAN VARY TECH

Preparation method of titanium alloy seamless pipe

The invention provides a preparation method of a titanium alloy seamless pipe. The preparation method comprises the following steps: step 1, smelting titanium sponge and intermediate alloy for multiple times to obtain a titanium alloy cast ingot; step 2, heating the titanium alloy cast ingot obtained by smelting, carrying out drawing forging, and carrying out multi-heating-number upsetting and drawing above the transformation temperature of the titanium alloy and below the transformation temperature of the titanium alloy in a staggered manner to obtain a titanium alloy bar blank; step 3, punching a through hole in a titanium alloy bar, and performing boring to obtain a titanium alloy hollow bar blank; step 4, coating the inner surface and the outer surface of the heated titanium alloy hollow rod blank with lubricating agent, and then extruding the titanium alloy hollow rod blank to obtain a titanium alloy extruded pipe blank; step 5, performing one-time forming precision forging on thetitanium alloy extruded pipe blank to obtain a precision forging finished pipe blank; and step 6, conducting straightening and machining after overall heat treatment to obtain the titanium alloy seamless pipe. The titanium alloy seamless pipe manufactured by the preparation method has the advantages of being adjustable in pipe outer diameter and shape, high in size precision, high in structural uniformity and the like.

Owner:湖南湘投金天科技集团有限责任公司 +1

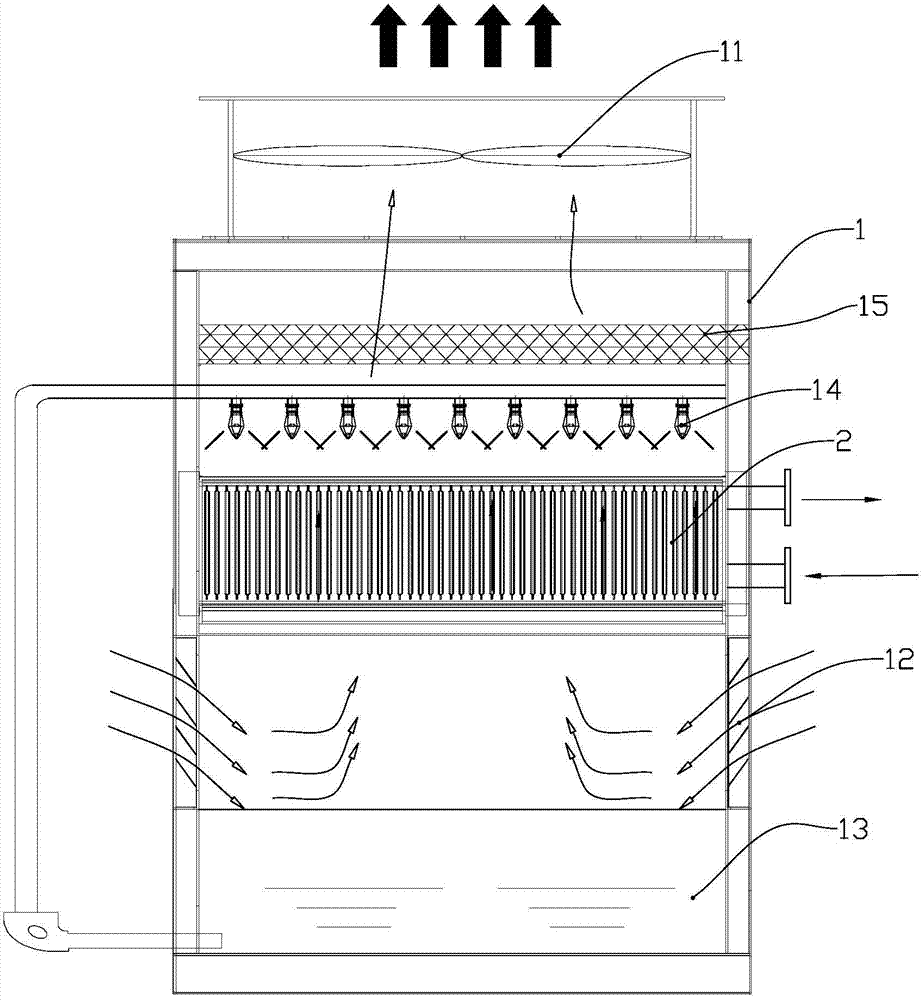

Sealed cooling tower

InactiveCN104776729ASolve the installation of polyvinyl chloride fillerSolve efficiency problemsTrickle coolersLiquid mediumCooling tower

The invention discloses a sealed cooling tower and solves the problems that an existing cooling tower is filled with polyvinyl chloride packing and the heat exchange efficiency is low. The sealed tower comprises a tower body, a spraying system, a heat exchange part and a fan, wherein the heat exchange part is a cooler; multiple shell type heat exchange units are vertically arranged in the cooler at intervals; a spraying and air flow channel is formed between the outer walls of two adjacent heat exchange units; at least one inlet and at least one outlet are formed in each heat exchange unit; at least one set of to-be-cooled medium channel penetrating through the inlet and the outlet of each heat exchange unit is formed in the heat exchange unit; the inlets of the heat exchange units are communicated with one another and are converged to form a to-be-cooled liquid medium inlet; the outlets of the heat exchange units are communicated with one another and are converged to form a to-be-cooled liquid medium outlet. The inside structure of the sealed cooling tower is simplified and the cooling efficiency is improved.

Owner:济南秦泰热工技术有限公司

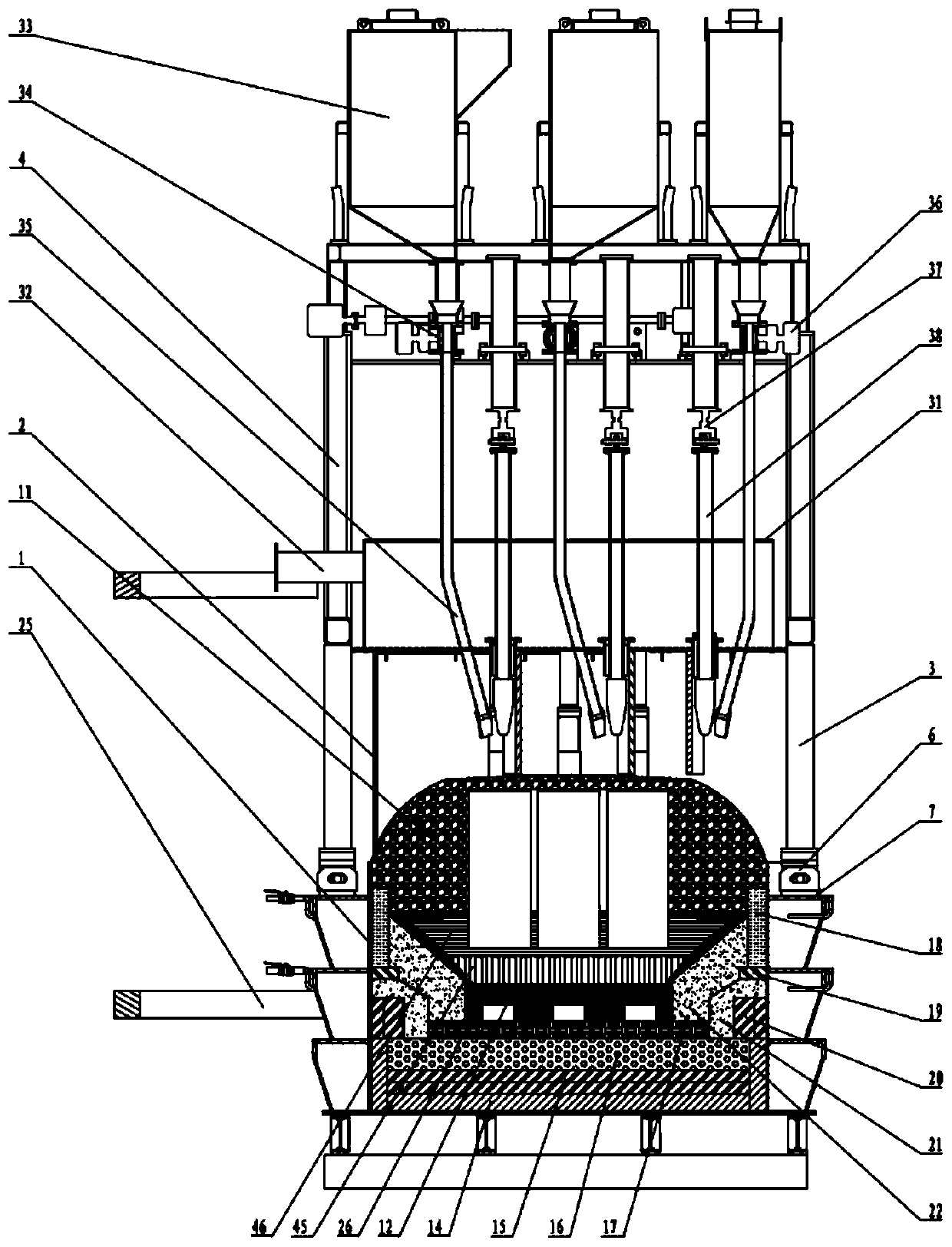

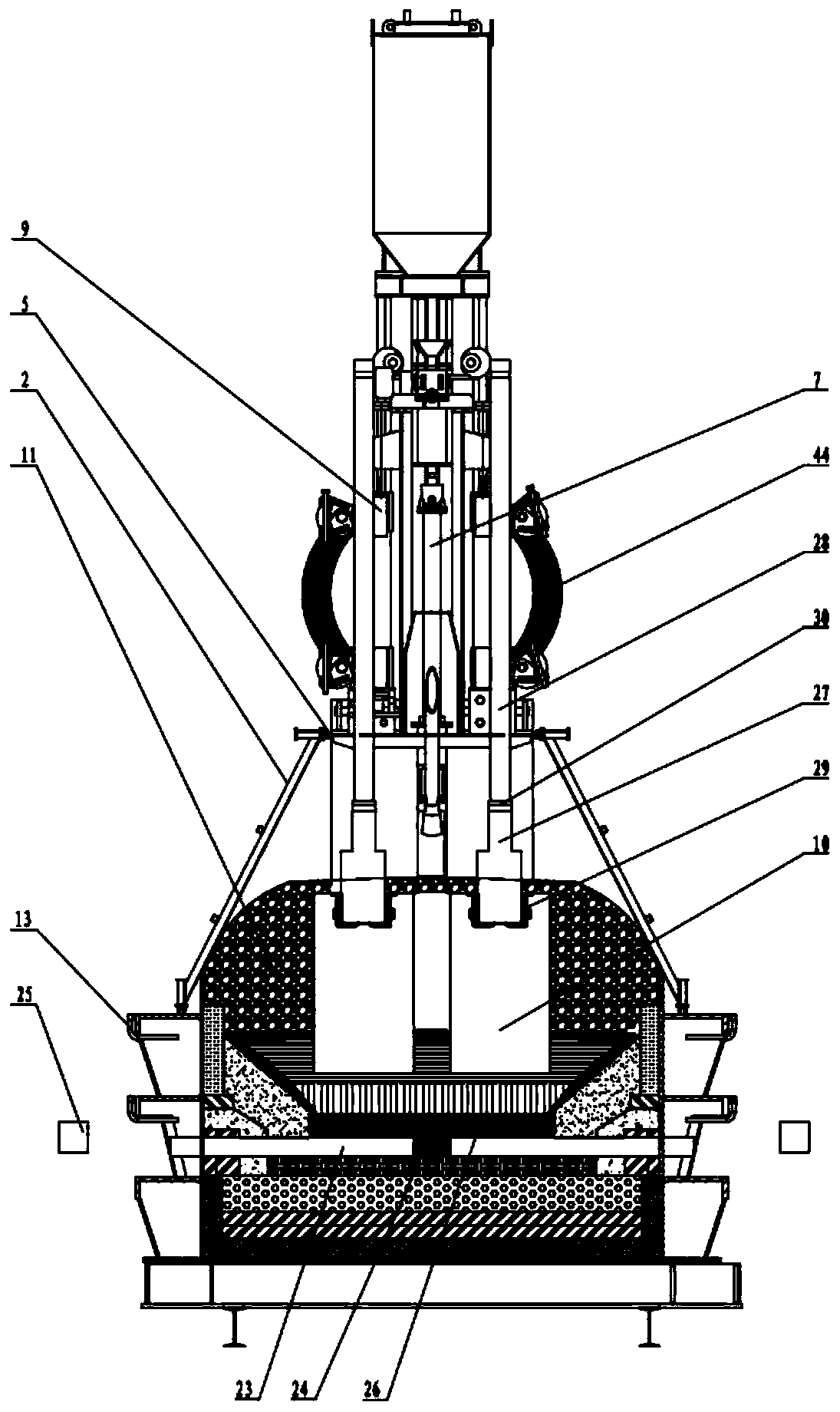

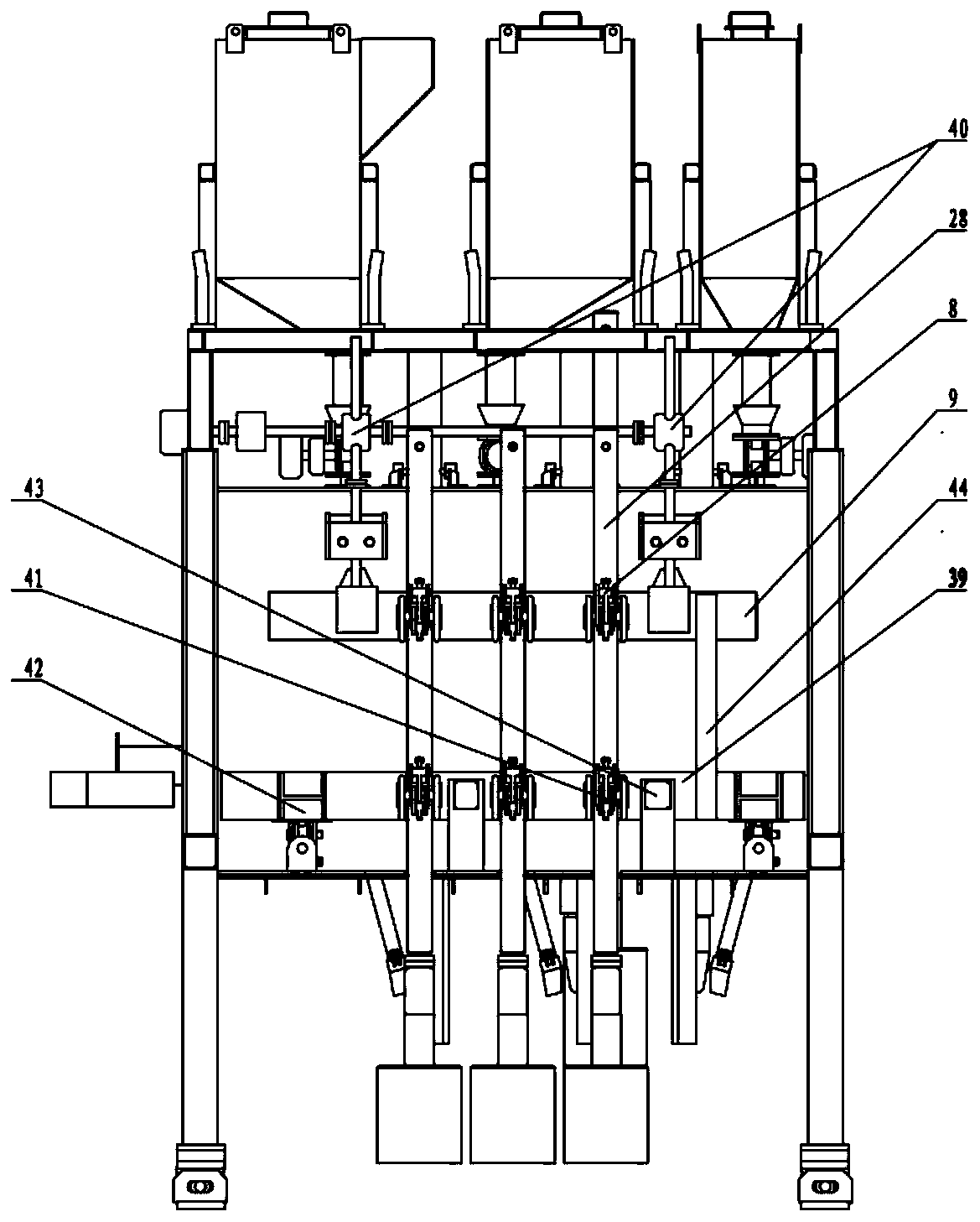

Rare earth electrolytic tank for producing rare earth and alloys thereof

The invention discloses a rare earth electrolytic tank for producing rare earth and alloys thereof. The rare earth electrolytic tank comprises an electrolytic tank body, a cathode group structure, ananode group structure and a tank upper portion structure, wherein the electrolytic tank body comprises a tank shell and a tank lining, the tank upper portion structure comprises a vertical column girder frame, a material feeding system, a shell ramming system, an anode lifting and busbar switching system and a tank hood plate, the upper end of the anode group structure is connected with the anodelifting and busbar switching system, anode blocks at the lower end are vertically inserted in electrolyte inside the tank body, the parts, exposed outside the electrolyte level face, of the anode blocks are covered by an anode covering material, the anode lifting and busbar switching system is used for adjusting the polar distance between the anode blocks and the cathode group structure, the material feeding system, the shell ramming system and the anode lifting and busbar switching system are integrated into an intelligent tank control system, the upper edge of the tank hood plate is connected with the edge of the side portion of a horizontal hood plate, and the lower edge of the tank hood plate is connected with the upper surface of the tank shell to realize closeness of the electrolytictank. By means of the rare earth electrolytic tank for producing the rare earth and the alloys thereof, rare earth electrolytic tank automatic continuous, high-efficiency, low-energy-consumption, low-cost and clean production is realized.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Purification method for silica ore through chlorination roasting-leaching

The invention relates to an extraction process for silica (quartz), in particular to a purification method for a silica ore through chlorination roasting-leaching. The purification method overcomes technical problems in selective removal of harmful elements like Fe, Cu, Al and Ti in the silica ore. The method comprises the following steps: crushing the silica ore and subjecting the crushed silica ore to water quenching at a high temperature; carrying out drying and grinding to obtain silica powder; mixing the silica powder with a chlorinating agent and placing an obtained mixture into an enclosed kiln for roasting; leaching out calcine with a mixed acid; and carrying out washing, neutralization and drying. According to the method, a variety of metal oxides are used to react with the chlorinating agent so as to remove impurities on the surface of the silica powder; thus, the method provided by the invention is superior to a flotation acid leaching process for purification of the silica ore, can replace a flotation method for purification of the silica powder and is more applicable to treatment of silicon oxide with a poor grade. Production process of the method accords with requirements of environmental production.

Owner:庄翔昊

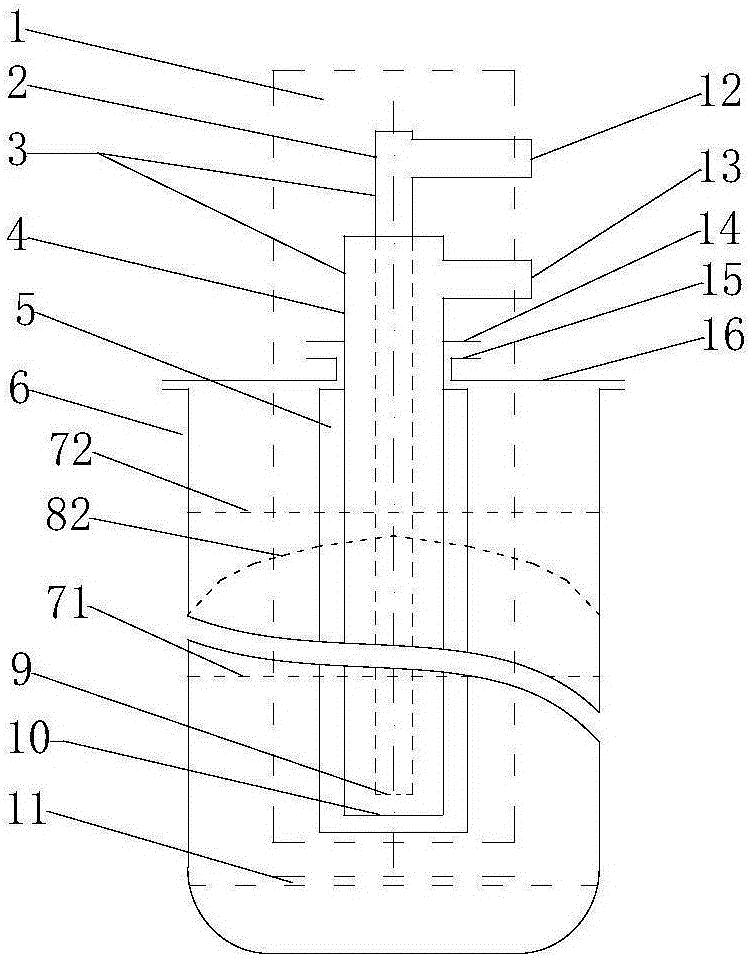

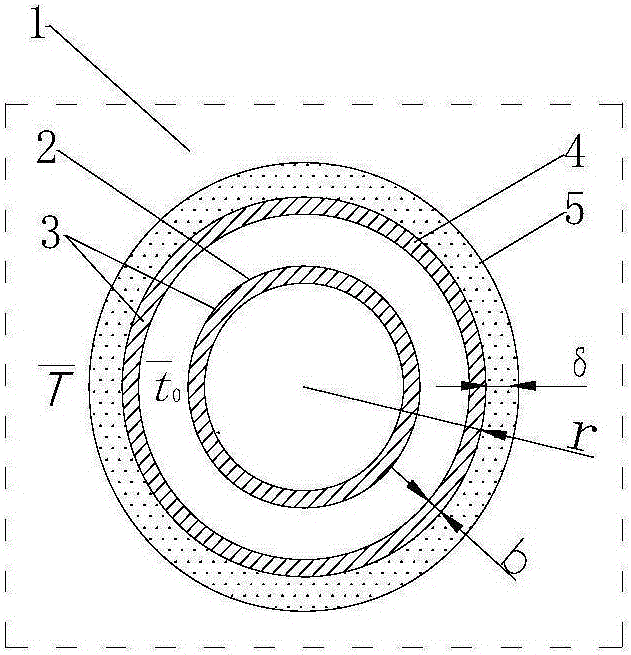

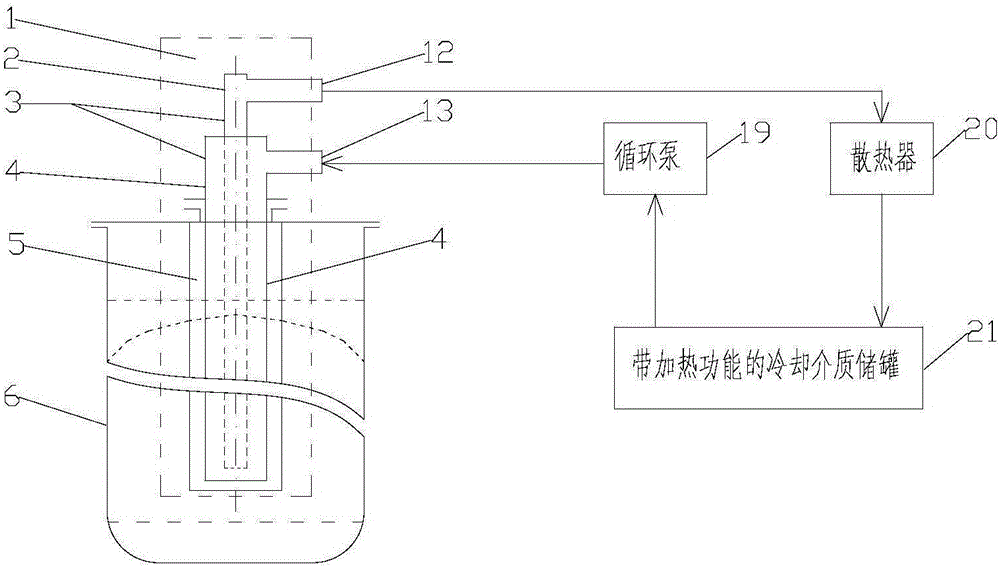

Tubular heat exchanger with inert coating layer and application to titanium sponge production

ActiveCN105925820AIncrease productivityImprove reduction efficiencyStationary tubular conduit assembliesTitanium tetrachlorideMagnesium

The invention discloses a tubular heat exchanger with an inert coating layer and application to titanium sponge production. The tubular heat exchanger can be used for quickly rejecting heat generated from a magnesiothermic reduction reaction and gathered in a liquid magnesium central area, so that the titanium tetrachloride feeding amount can be multiplied; meanwhile, the inert coating layer on the surface of the tubular heat exchanger always remains in a solidification state, thereby preventing formation, deposition and attachment of a titanium crystal on the metal surface of the tubular heat exchanger, and preventing bonding of a titanium lump and the metal surface of the tubular heat exchanger; and after the reduction is finished, the coating layer is melted and drops off, and a cavity is formed in the axis position of the titanium lump, so that the titanium sponge distillation period can be shortened by half or above. By adoption of the tubular heat exchanger provided by the invention, the titanium sponge production efficiency is multiplied, the power consumption cost is greatly reduced, and a prerequisite is provided for further enlargement of a furnace profile.

Owner:王进民

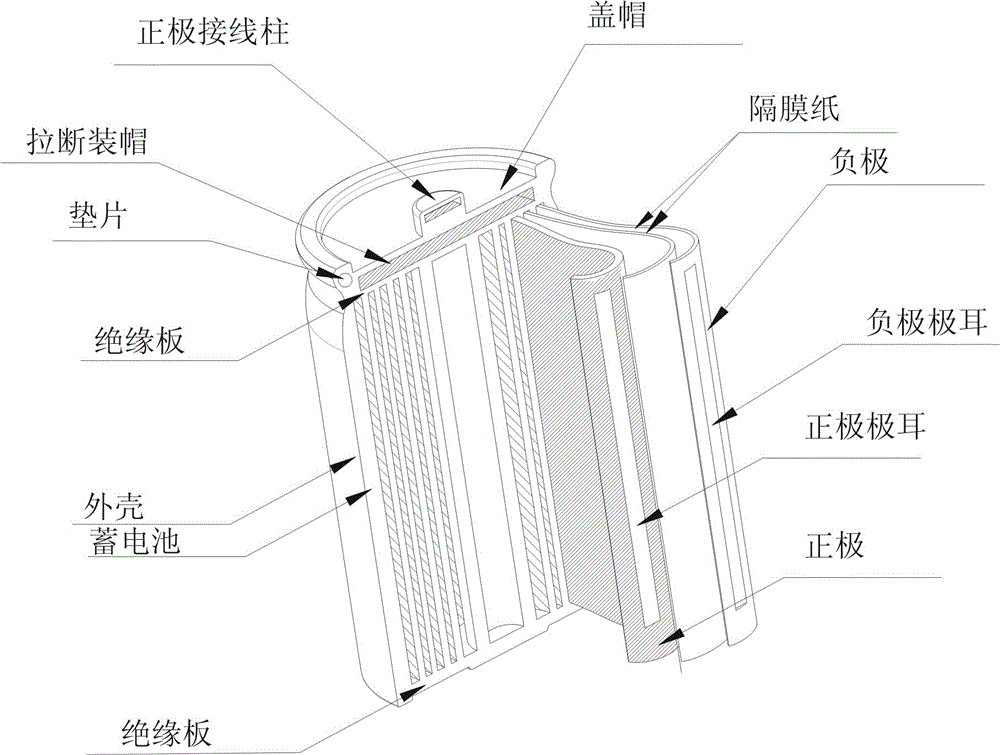

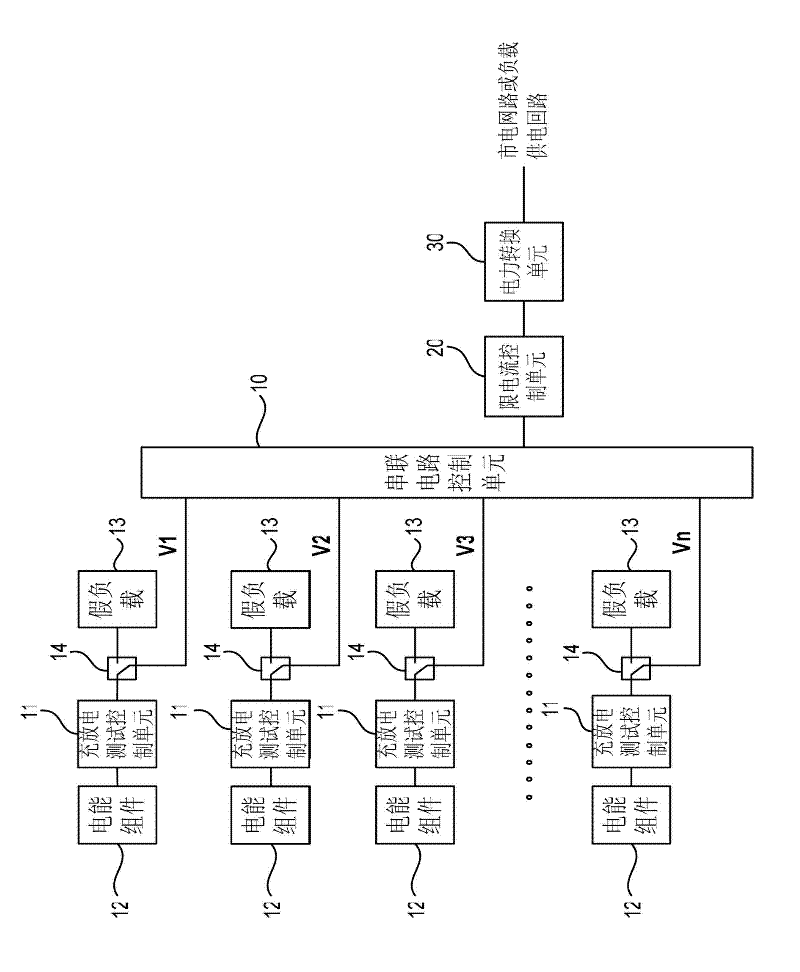

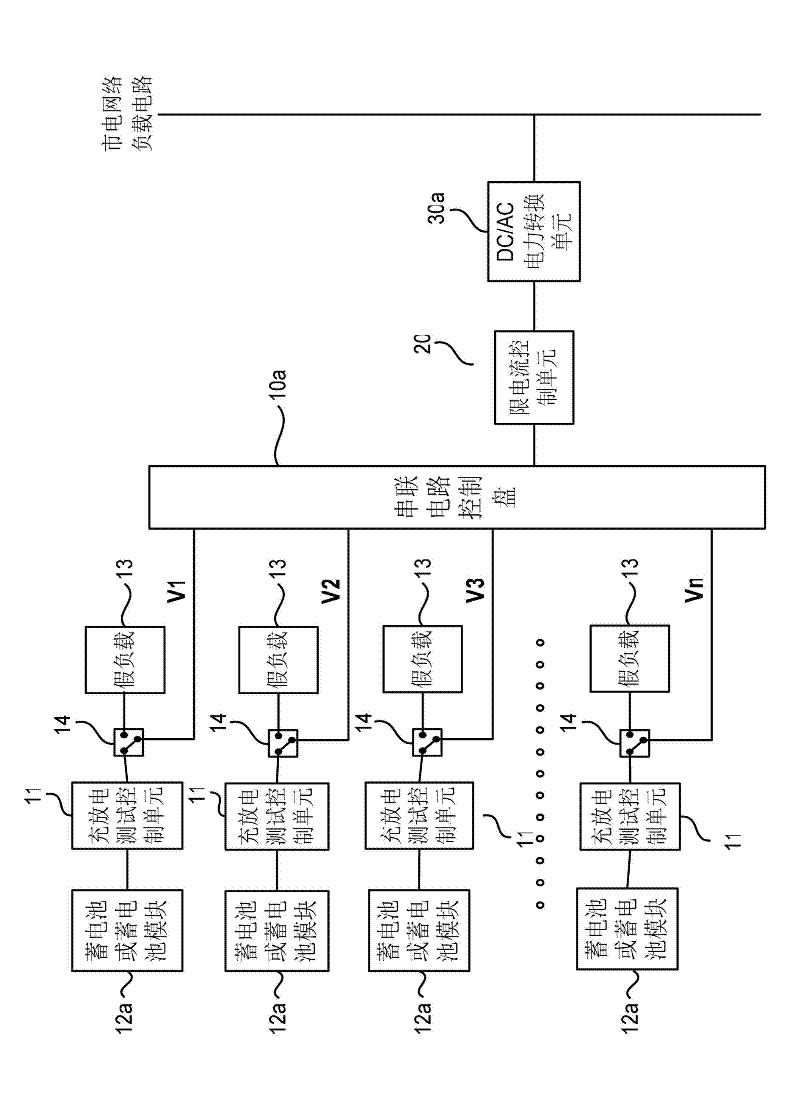

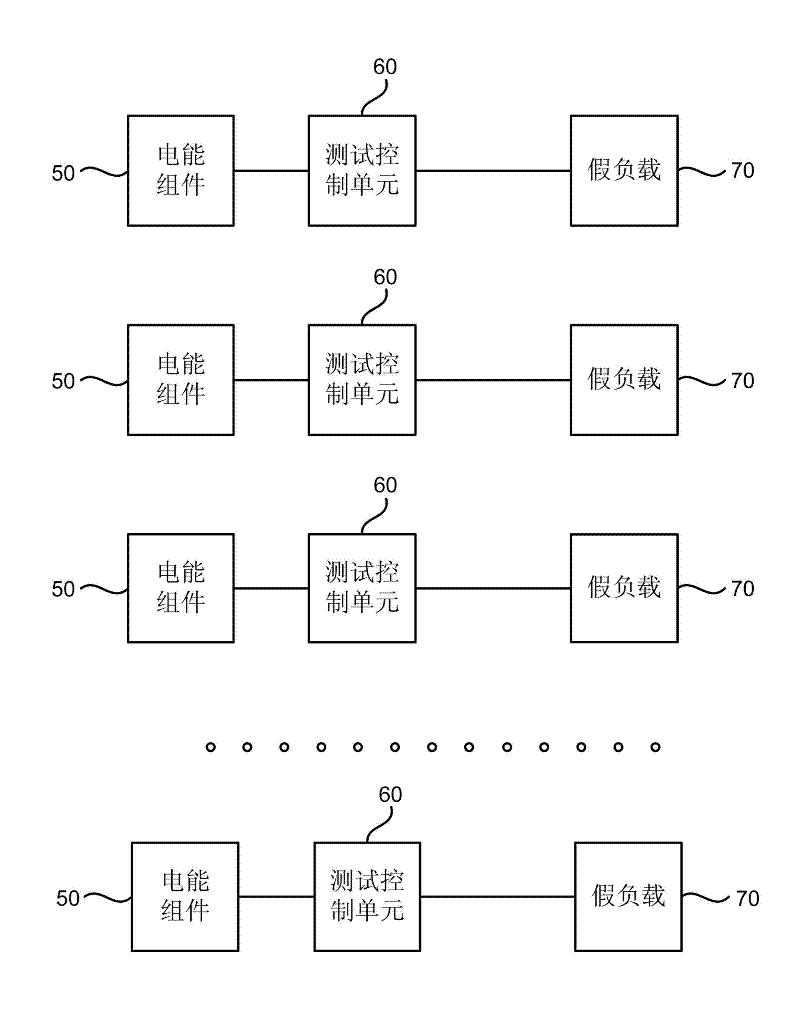

Waste electric energy recycling device

InactiveCN102545294AReduce electricity consumption costsImprove process energy savingBatteries circuit arrangementsElectric powerCurrent limitingPower grid

The invention discloses a waste electric energy recycling device which is used for recycling waste electric energy generated in a discharging process, but has no influence to the original aim of a burn-in test. The waste electric energy recycling device comprises a series circuit control unit, a current limiting control unit and an electric power converting unit, wherein the series circuit control unit capable of serially connecting a plurality of groups of electric energy modules to form a proper voltage condition and also disconnecting a single or the plurality of groups of electric energy modules from a series loop; the current limiting control unit is connected with the series circuit control unit and used for setting and limiting the current output of the electric energy modules; and the electric power converting unit is connected with the current limiting control unit and used for converting direct current electric energy into alternating current electric power and providing the alternating current electric power for an actual load. Therefore, the waste electric energy consumed by the original dummy load is recycled and then converted into effective electric power to be fed to an electric power network system to be established so as to be recycled; the electric energy consumption cost in the packaging process of the electric energy modules is reduced; and double benefits of energy saving and high efficiency for a process are achieved.

Owner:黄绪耀

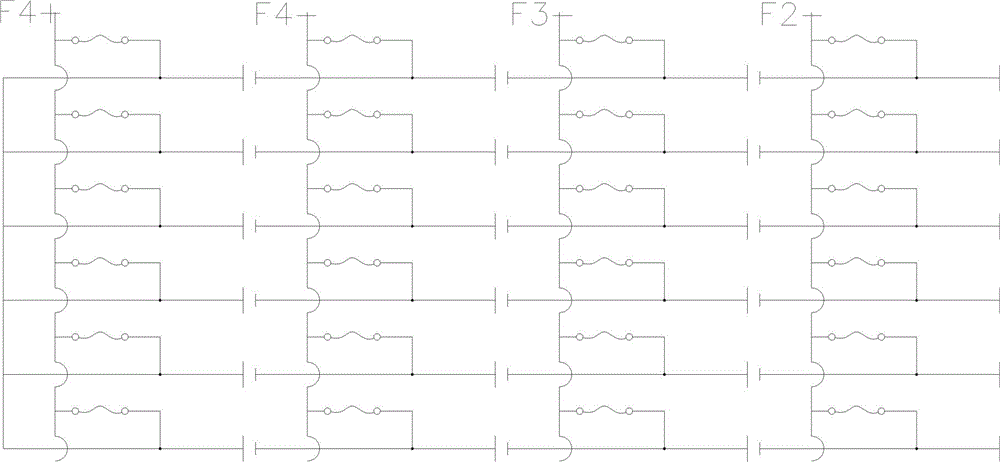

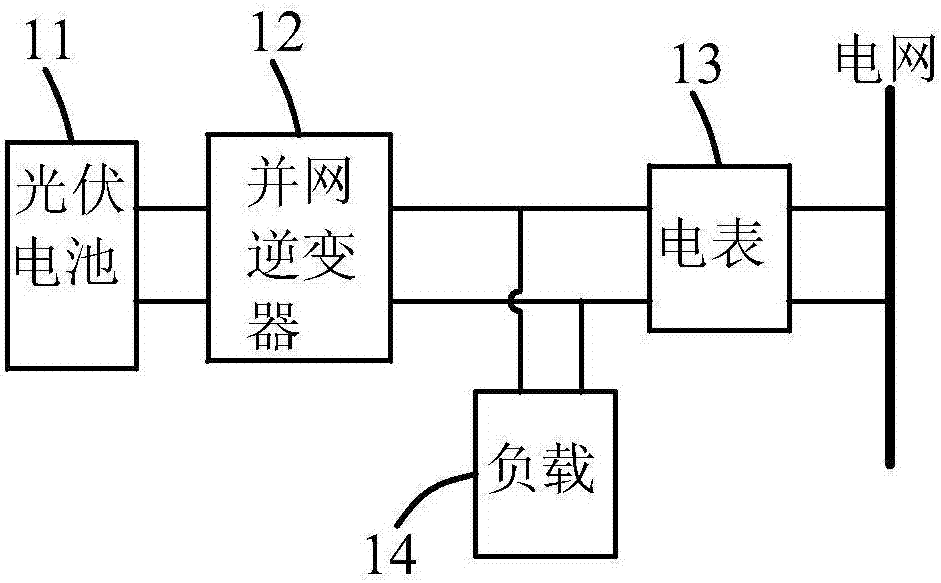

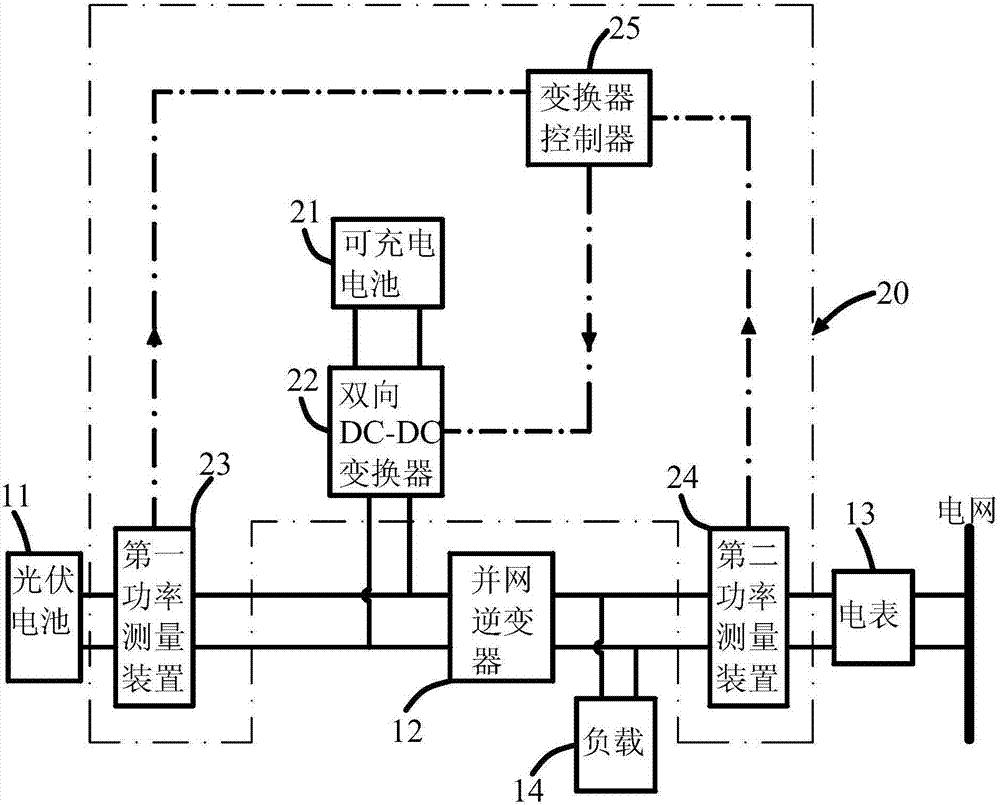

Energy management device for photovoltaic grid-connected power generation system

ActiveCN107332270AReduce purchase of electricityReduce electricity consumption costsBatteries circuit arrangementsPower network operation systems integrationDc dc converterGrid connected inverter

The invention provides an energy management device for a photovoltaic grid-connected power generation system. The photovoltaic grid-connected power generation system comprises a photovoltaic battery and a grid-connected inverter. The photovoltaic battery is connected with a power grid through the grid-connected inverter. The energy management device comprises a rechargeable battery and a bidirectional DC-DC converter, wherein the rechargeable battery is connected with the input end of the grid-connected inverter through the bidirectional DC-DC converter; a first power measuring device which is used for measuring the output power of the photovoltaic battery; a second power measuring device which is used for measuring the power consumption power or grid-connected power of the photovoltaic grid-connected power generation system; and a converter controller which is used for controlling the bidirectional DC-DC converter for managing the capacity of the rechargeable battery. The energy management device provided by the invention reduces power consumption cost of the user.

Owner:EATON PHOENIXTEC MMPL CO LTD

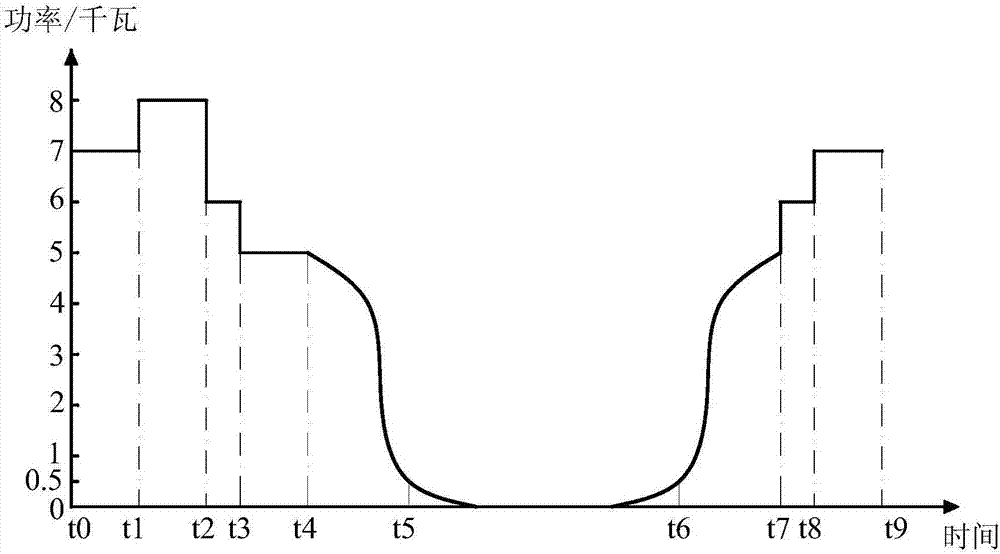

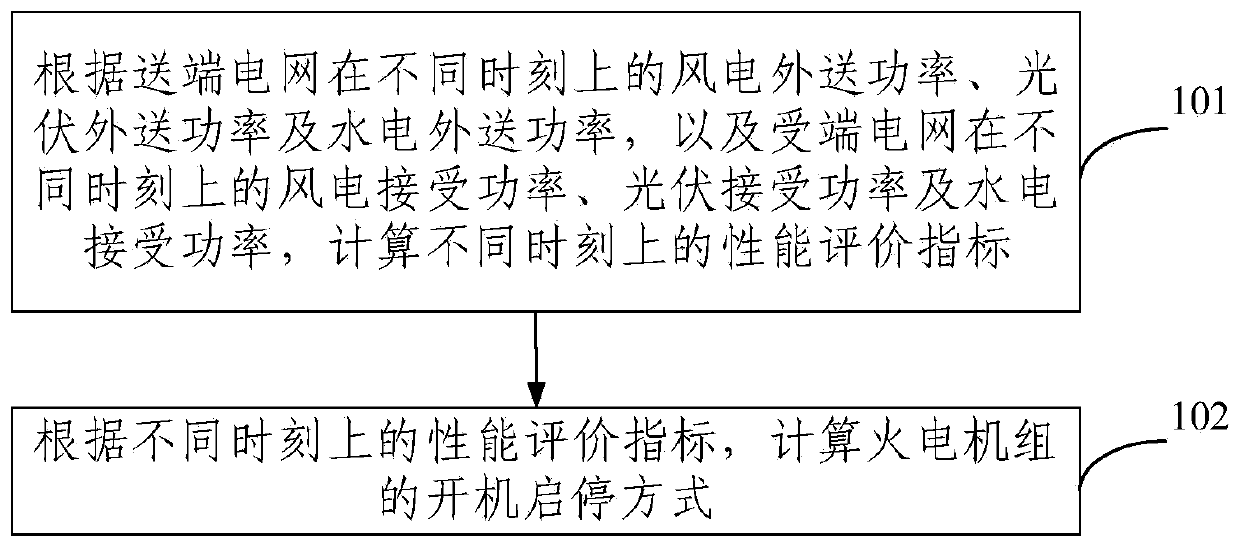

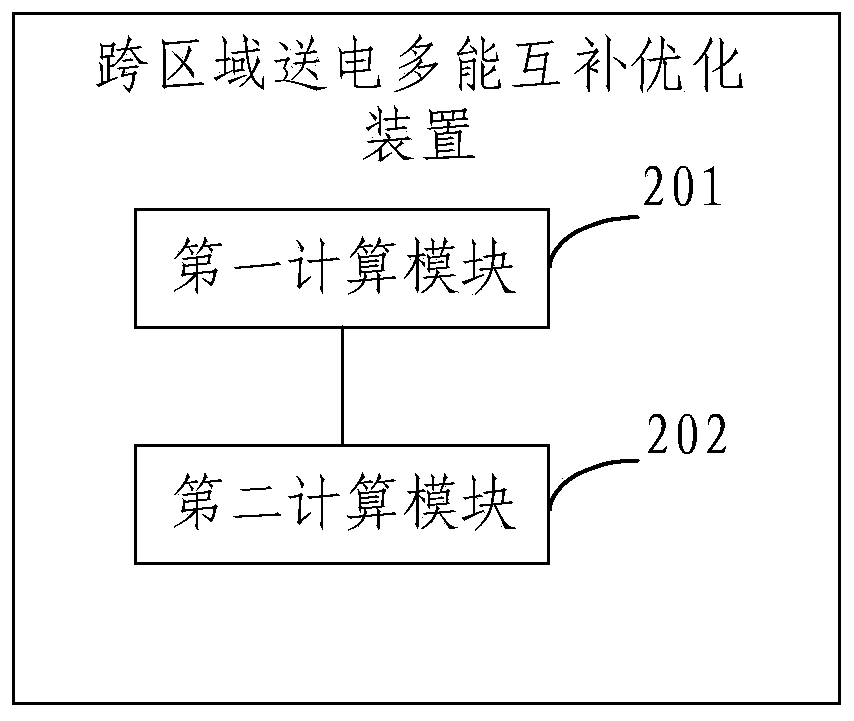

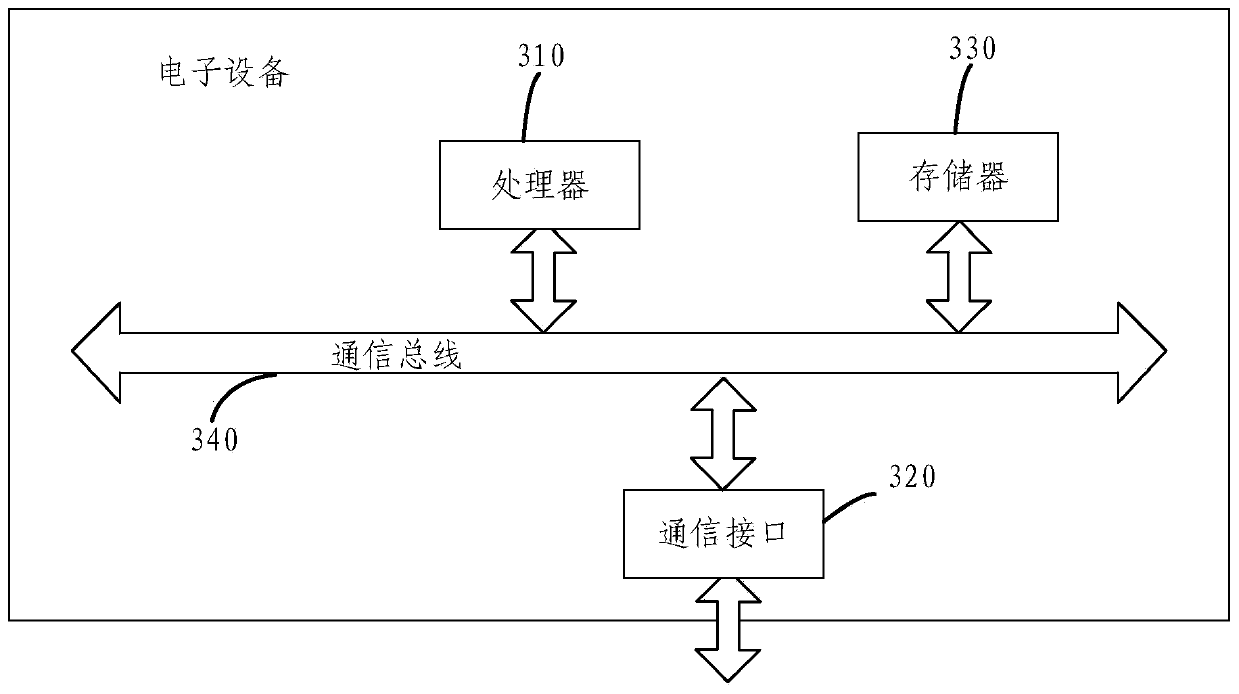

Cross-regional power delivery multi-energy complementary optimization method and device

ActiveCN109980688AReduce electricity consumption costsEnergy industryForecastingElectricityOptimal scheduling

The embodiment of the invention provides a cross-regional power delivery multi-energy complementary optimization method and device, and belongs to the field of power technology. The cross-regional power delivery multi-energy completement optimizing method comprises the following steps: calculating performance evaluation indexes at different moments according to wind power delivery power, photovoltaic delivery power and hydropower delivery power of a delivery end power grid at different moments, as well as wind power acceptable power, photovoltaic acceptable power and hydropower acceptable power of a receiving end power grid at different moments; and calculating the power-on start / stop manner of a thermal power generating unit according to the performance evaluation indexes at different moments. The power demand of the receiving end power grid is taken into consideration, and optimal scheduling of cross-regional wind power, hydropower, photovoltaic and thermal power is realized, so thatan optimization scheme is provided for the delivery consumption of cross-regional clean energy, and the power consumption cost of power grid enterprises is lowered.

Owner:CENT CHINA BRANCH OF STATE GRID CORP OF CHINA

Method for refrigerating and preserving Chunhua plums

InactiveCN102524367ARefrigeration temperature increasedReduce electricity consumption costsCultivating equipmentsFruits/vegetable preservation by freezing/coolingCool storageEngineering

The invention relates to a method for refrigerating and preserving Chunhua plums. The method comprises the following steps of: picking; precooling; selecting; performing ozone treatment before packaging; packaging; and refrigerating, wherein in the precooling step, cold water is adopted for precooling, the temperature of the cold water is controlled to be 3-4DEG C, and the cooling time is 25 to 35 minutes, so that the core temperature of fruit bodies is reduced to be 4-6DEG C; in the refrigerating step, the temperature of a refrigeration house or a refrigerating chamber is kept to be 6-8DEG C, and the relative humidity is controlled to be 80-90 percent; meanwhile, an air interchanger is arranged in the refrigeration house or the refrigerating chamber. The invention has the advantages that: compared with the prior art, the method ensures that the refrigerating temperature is greatly improved, and power consumption cost of storage is saved; and moreover, after various quality indexes of the fruits are compared, the descent speeds of hardness and total soluble solid (TSS) content of the fruits under the cooling storage condition are lower than those of a control group, the rising speeds of the rotting rate of the fruits and the browning index of the pulp are slow, and the method is suitable to be promoted and applied in a large area.

Owner:张延

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com