Waste electric energy recycling device

An electric energy recovery and electric energy technology, applied in circuit devices, battery circuit devices, current collectors, etc., can solve the problems of wasted energy consumption and inability to meet the needs of users, and achieve the effect of reducing the cost of electric energy consumption and improving process energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

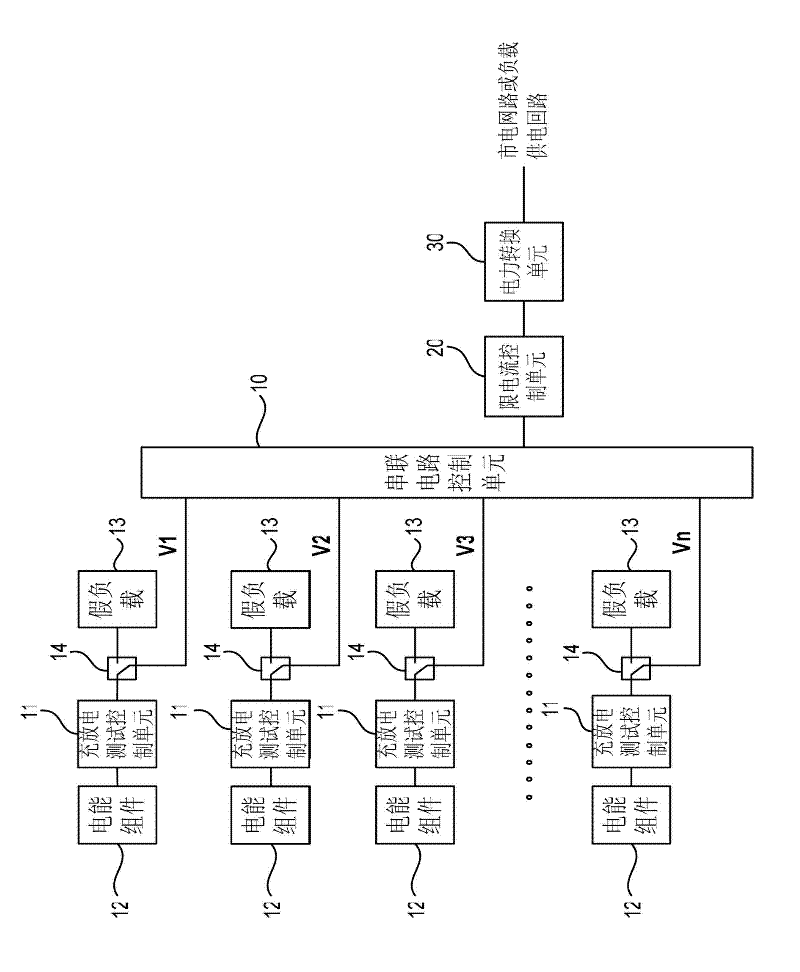

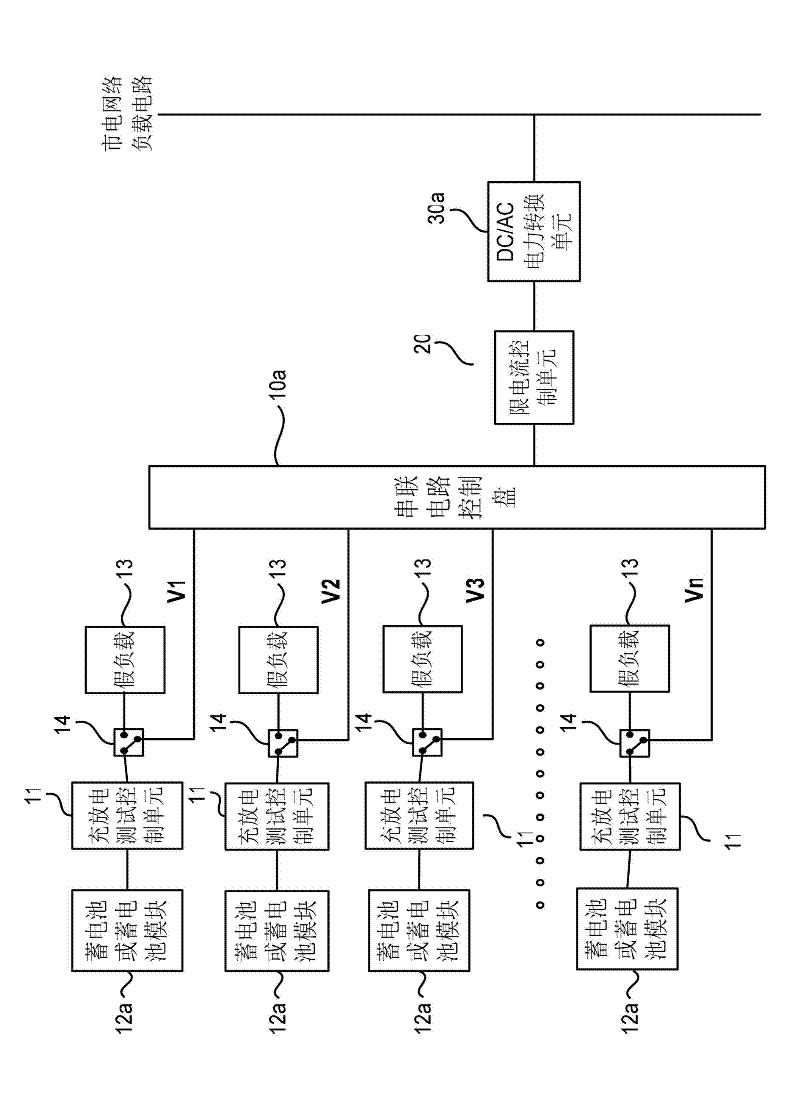

[0039] Please refer to FIG. 1 , which is a schematic diagram of the basic structure of the present invention. As shown in the figure: the present invention is a waste electric energy recovery and reuse device, which consists of a series circuit control unit 10, a current limiting control unit 20 and a power conversion unit 30, which are used to recover waste electric energy during the discharge test process. , and does not affect the original burning machine test purpose.

[0040] The above-mentioned series circuit control unit 10 can connect multiple sets of independent electric energy components 12 in the charge and discharge test control unit 11 in series to form an appropriate voltage condition, and can also disconnect single or multiple sets of electric energy components 12 from the series circuit. The series circuit control unit 10 includes switch components 14 for multiple groups of independent dummy loads 13 .

[0041] The current limiting control unit 20 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com