Tubular heat exchanger with inert coating layer and application to titanium sponge production

A technology of tubular heat exchanger and cladding layer, which is applied in the field of rare metal metallurgy, can solve the problems of increasing the contact area between sponge titanium and metal panel iron, failing to expand the distillation area of titanium lump, and long production cycle of sponge titanium. Achieve the effect of avoiding spontaneous combustion, avoiding the problem of titanium lump hard core, and improving the efficiency of reduction reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

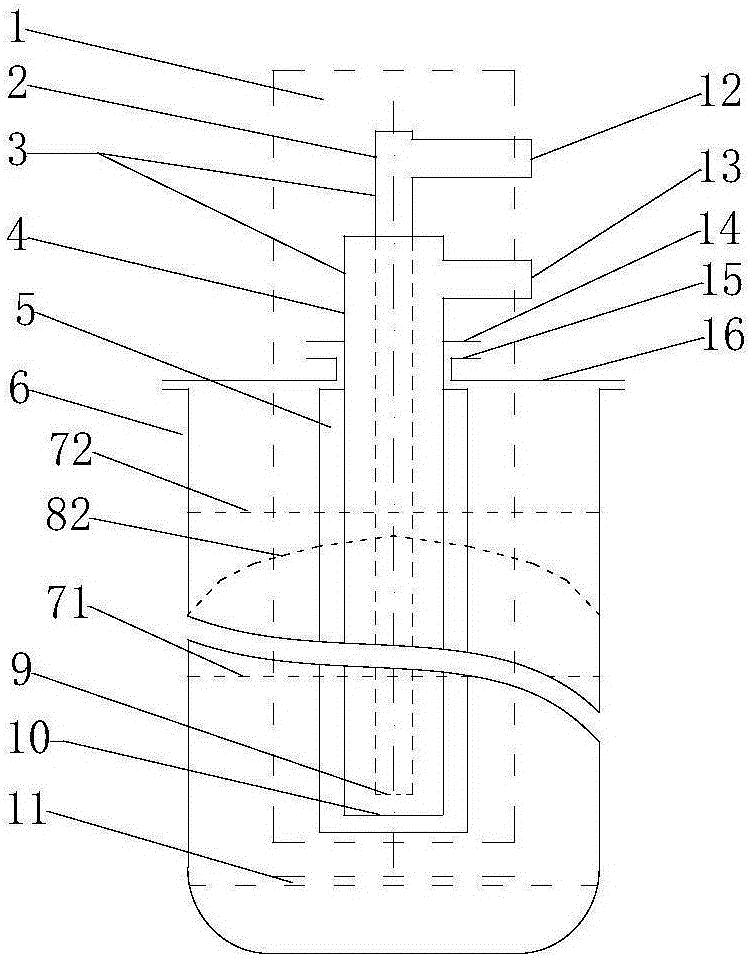

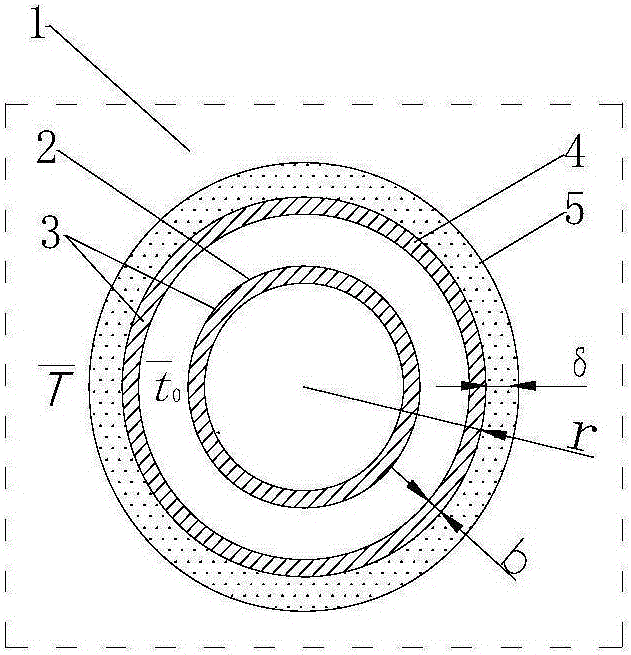

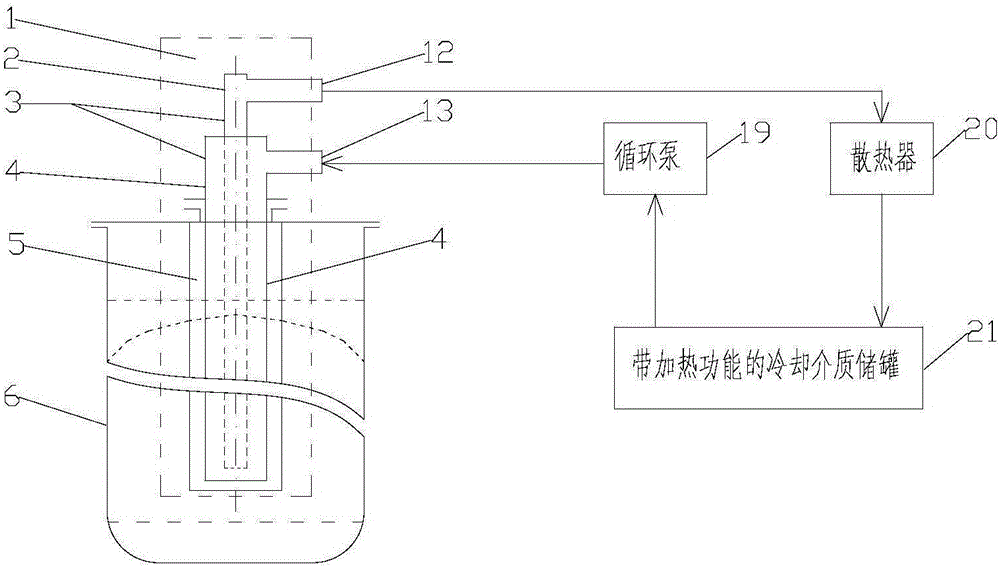

[0099] Such as figure 1 , figure 2 , image 3 As shown, in Example 1 of the present invention, the diameter of the reduction furnace reactor 6 is 1860mm, and the length is 4500mm; the tubular heat exchanger 3 and the reduction furnace reactor 6 are arranged concentrically, and the outer The outer diameter of the tube 4 is 200 mm, and the wall thickness of the outer tube is 10 mm. The outer diameter of the inner tube 2 of the tubular heat exchanger 3 is 140 mm, and the wall thickness of the inner tube 2 is 5 mm. The height of the inner tube lower end 9 from the inner side of the outer tube lower end 10 is 80mm. The lower end 10 of the outer tube is located on the upper part of the sieve plate 11, and the height from the sieve plate 11 is 800 mm.

[0100] The inert cladding layer of the inert cladding tube heat exchanger 1 in this embodiment adopts the method of mold casting to pre-coat the surface of the tube heat exchanger 3 with an inert substance, and the material of the...

Embodiment 2

[0104] Such as Figure 4 , Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that a layer of magnesium chloride inert material is pre-coated on a partial section of the outer surface of the tubular heat exchanger 3 . That is: such as Figure 4 As shown, the outer surface of the tubular heat exchanger 3 from the inner side of the reduction furnace reactor upper cover 16 to 200mm below the metal magnesium starting liquid level 7-1 is pre-coated with inert substance magnesium chloride to form an inert coating. Cladding 5-1; or as Figure 5 As shown, the exterior of the tubular heat exchanger 3 located at 200mm below the initial liquid level 7-1 of the reduction reaction of liquid metal magnesium in the reduction furnace reactor to 200mm above the liquid level 7-2 of the liquid metal magnesium reduction reaction The surface is pre-coated with inert substance magnesium chloride to form an inert coating layer 5-2; and the part of the lower surface of ...

Embodiment 3

[0107] Such as Figure 6 As shown, in this embodiment, the inert coating layer 5-4 on the outer surface of the tubular heat exchanger 3 located above the initial liquid level 7-1 of the reduction reaction of liquid metal magnesium in the reduction furnace reactor is added to the liquid state through the top. Magnesium metal is pre-formed in such a way that it forms condensation crusts on the outer surface of the tube heat exchanger.

[0108] That is, when the temperature of the reduction furnace reactor rises to 750-800°C, the liquid metal magnesium is added along the tube wall of the tube heat exchanger 3 by lifting the ladle, and the liquid metal magnesium flowing downwards in the tube heat exchange Under the action of the liquid cooling medium circulating in the device 3, it is solidified to form a pre-inert coating layer 5-4. The inert coating layer 5-4 reacts with titanium tetrachloride gas in the atmosphere inside the reactor after the magnesothermic reduction reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com