Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Reduce high temperature corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

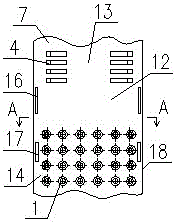

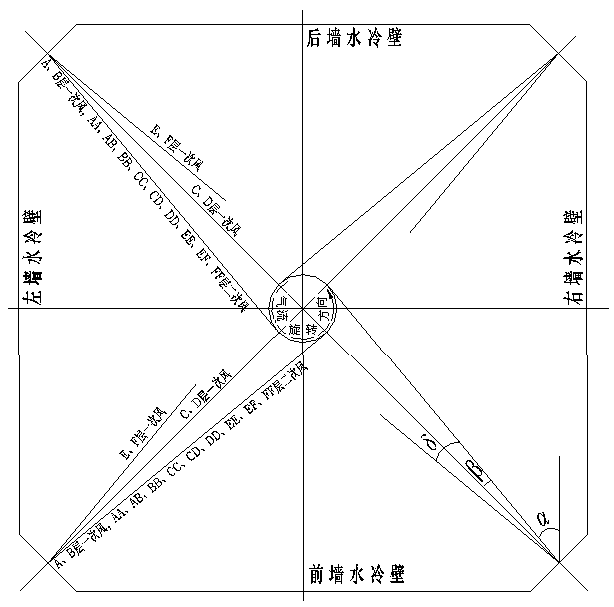

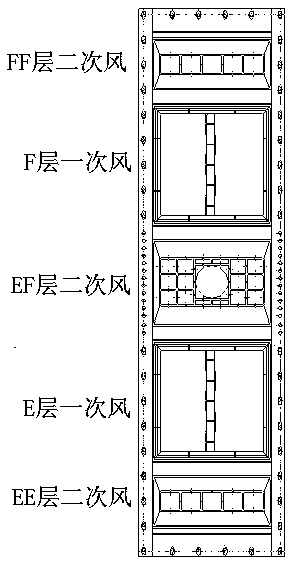

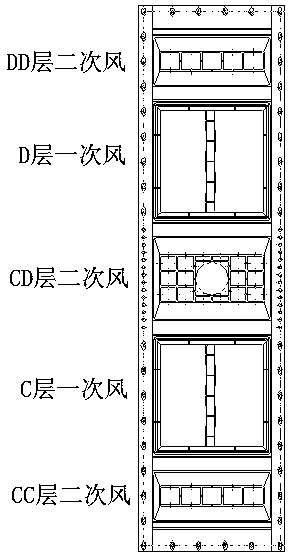

Face-fired boiler advanced denitration burning method

ActiveCN106247320AReduce concentrationLower emission valueCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelFlue gasHearth

The invention discloses a face-fired boiler advanced denitration burning method. The method comprises the following steps: fire coal is sent to a hearth through primary air in the primary air nozzles of a plurality of turbulent burners in each of layers of turbulent burners arranged on a front wall and a rear wall and is burnt, secondary air is introduced through secondary air nozzles of the turbulent burners, over fire air is introduced through one or more layers of over fire air nozzles on the front wall and the rear wall, the primary air and the secondary air on the front wall and the rear wall are oppositely introduced, the excess air coefficient range of the main burning area of the turbulent burners is 0.5-1.05, and the fire coal undergoes low oxygen burning; the excess air coefficient range of the over fire area of the over fire air nozzles is 1.05-1.3, and oxygen rich burning is carried out; and one or more layers of an amino reduction inhibitor are injected to the hearth under the uppermost over fire layer to reduce nitrogen oxides in flue gas in high temperature environment in the hearth and inhibit generation of new nitrogen oxides. The face-fired boiler advanced denitration burning method has the advantages of substantial reduction of the nitrogen oxide discharge value of the outlet of the hearth, realization of ultralow discharge, no strict temperature window or catalyst, great reduction of the denitration cost, and prevention of high temperature corrosion of water screens in the boiler.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP +1

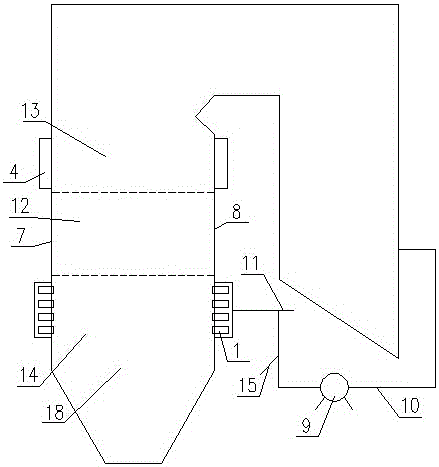

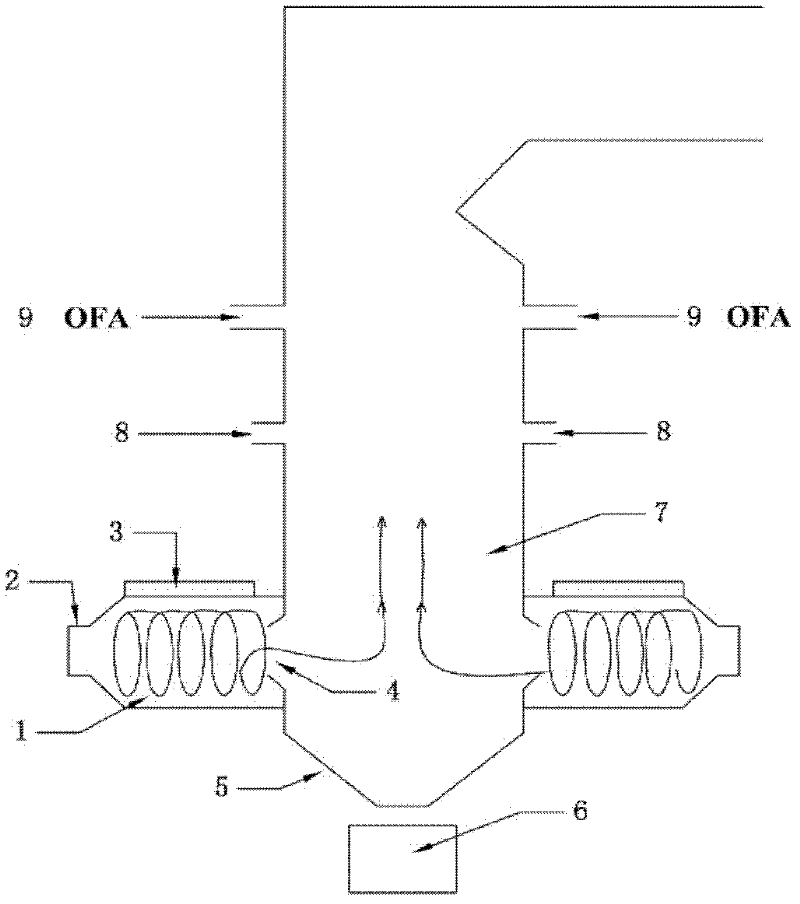

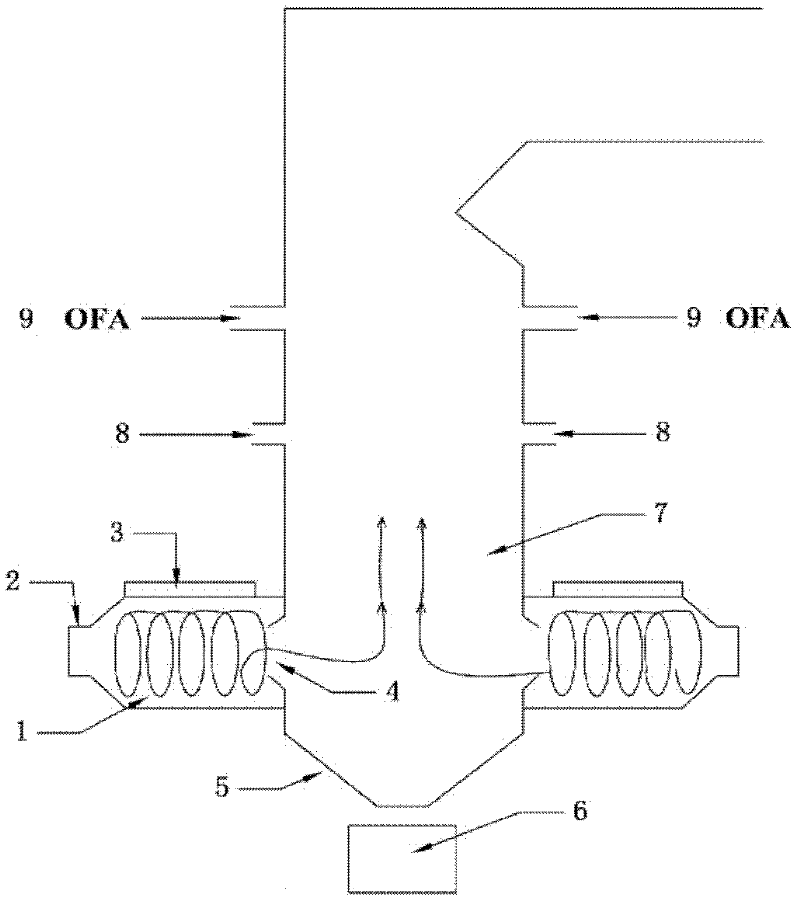

W-firing boiler advanced denitration combustion method

ActiveCN106247321AReduce concentrationLower emission valueFluegas recirculationIndirect carbon-dioxide mitigationHearthEngineering

The invention discloses a W-firing boiler advanced denitration combustion method. The method comprises the following steps: fire coal is sent to a hearth through primary air in the primary air nozzles of a plurality of main combustors on boiler arches of a front wall and a rear wall and is combusted, secondary air and under-arch secondary air are respectively introduced through secondary air nozzles and under-arch secondary air nozzles, exhaust gas wind is introduced through exhaust gas wind nozzles on the front wall and the rear wall, one or two layers of over-fire air are introduced through over-fire air nozzles, the excess air coefficient range of a main combustion area is 0.7-1.05, and the fire coal undergoes low oxygen combustion; the excess air coefficient range of an over-fire area is 1.05-1.3, and oxygen rich combustion is carried out; and one or more layers of an amino reduction inhibitor are injected to the hearth under the uppermost over-fire air layer to reduce nitrogen oxides in flue gas and inhibit generation of new nitrogen oxides. The W-firing boiler advanced denitration combustion method has the advantages of substantial reduction of the nitrogen oxide discharge value of the outlet of the hearth, realization of ultralow discharge, no strict temperature window or catalyst, great reduction of the denitration cost, and prevention of high temperature corrosion of water screens in the boiler.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP +1

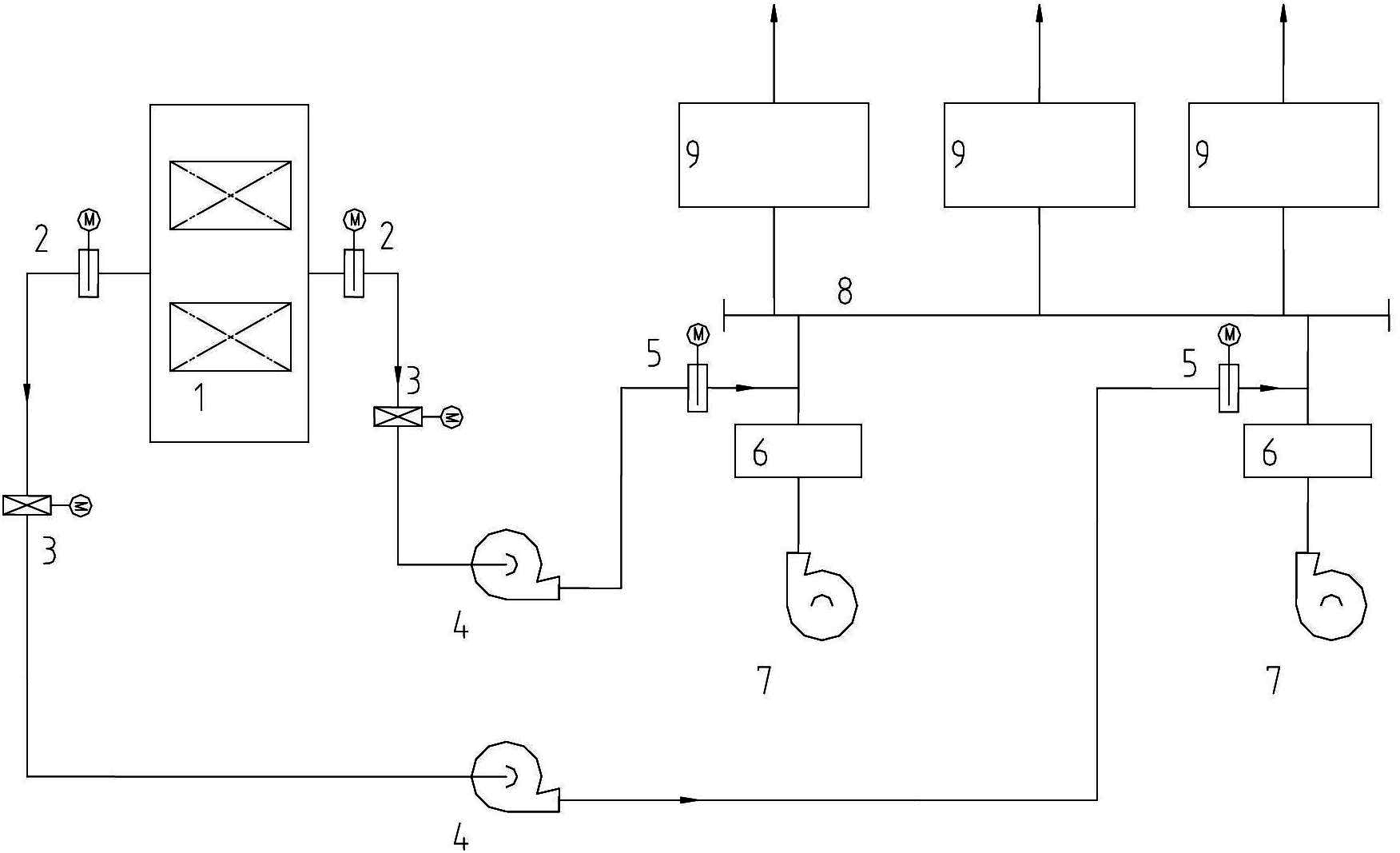

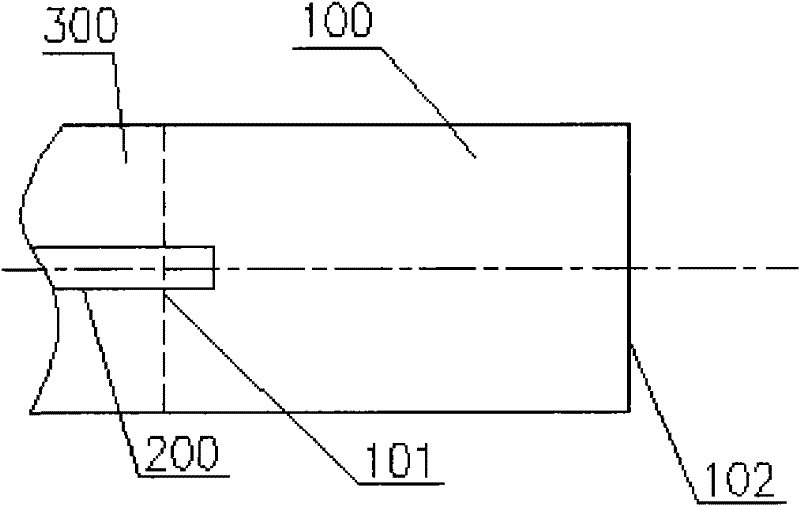

A boiler device using cyclone combustion method

InactiveCN102287813AReduce the power consumption of millingLow costFluidized bed combustionApparatus for fluidised bed combustionCycloneBoiler furnace

The invention discloses a boiler device adopting a cyclone combustion method, which comprises a cyclone tube, a boiler main furnace and a liquid slag granulation water tank. A primary air inlet is arranged at the front end of the cyclone tube, and a secondary air inlet is arranged in the middle of the cyclone tube. The tail of the cyclone is seamlessly connected with the main furnace of the boiler through a concave outlet; the lower tapered part of the main furnace of the boiler is a cold ash hopper, and the lower part of the cold ash hopper is arranged with a granulation water tank for granulating the boiler liquid slag discharge. The boiler device of the present invention has the following advantages: the fuel to be burned only needs to be simply crushed, which greatly saves the power consumption and cost of pulverizing; the combustion is stable; the heat intensity is high, and the boiler volume is small; the combustion efficiency is high and the economy is good; slag; ash and slag capture rate is high, fly ash content is greatly reduced; boiler size is compact; can burn a variety of fuels, fuel adaptability; boiler load adjustment capacity is large; ash slag is easy to comprehensive utilization; greatly reduce the occurrence of high temperature corrosion .

Owner:XI AN JIAOTONG UNIV

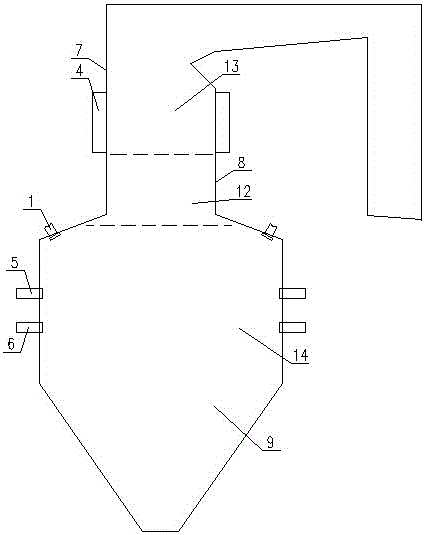

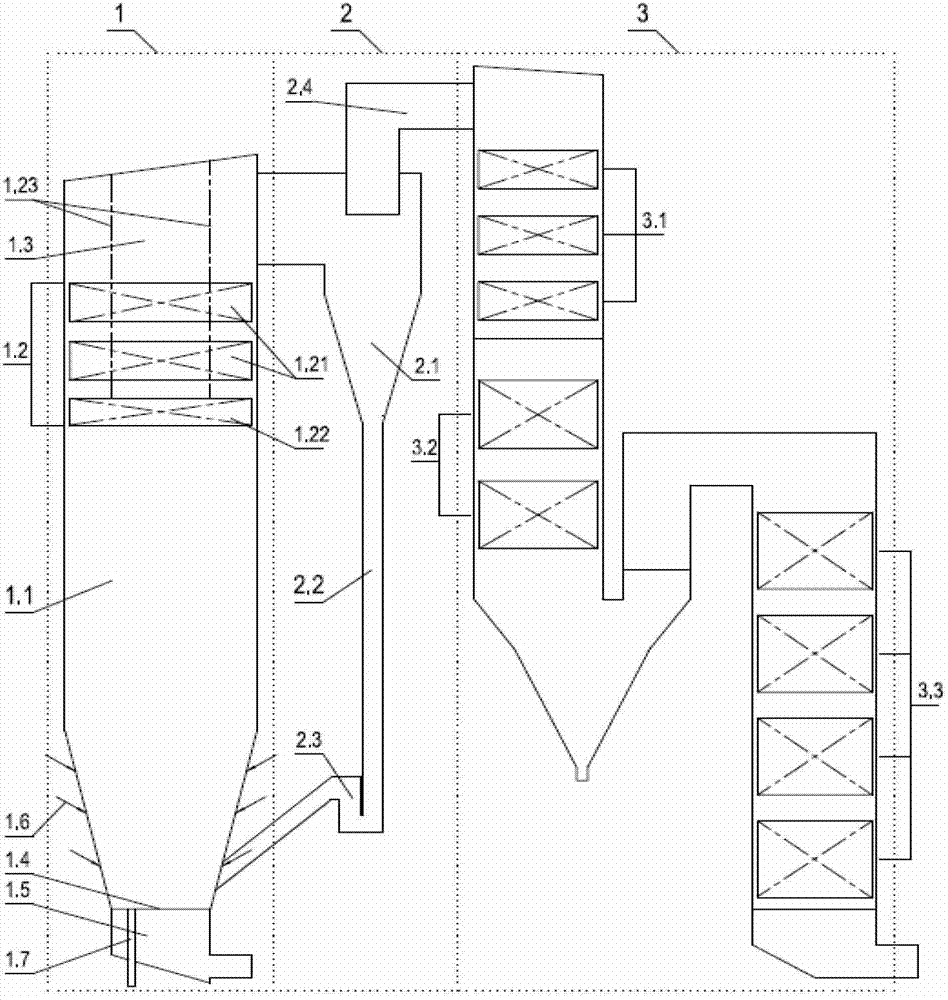

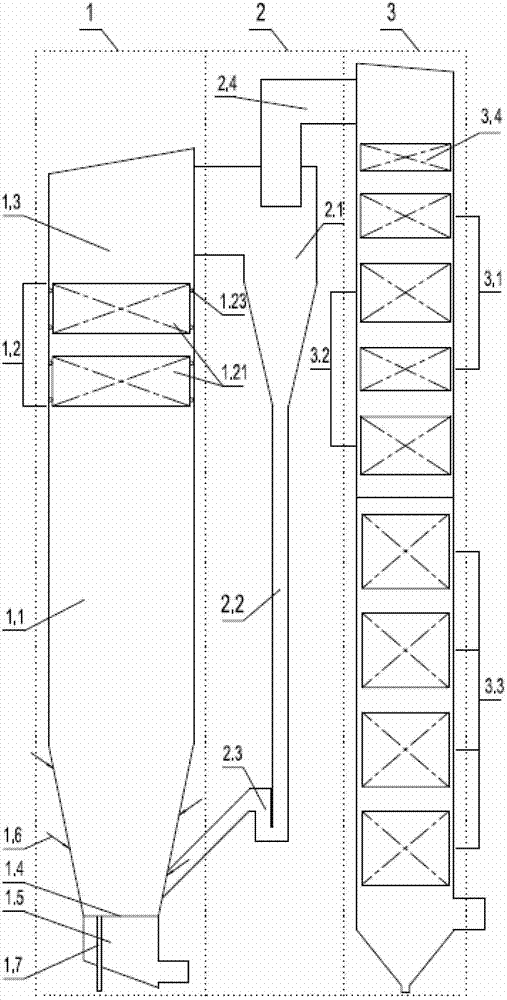

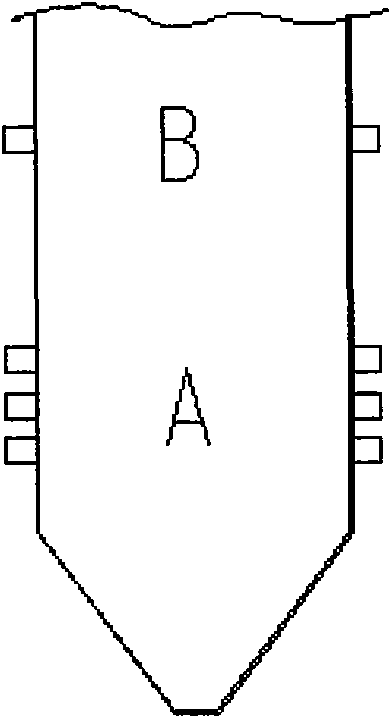

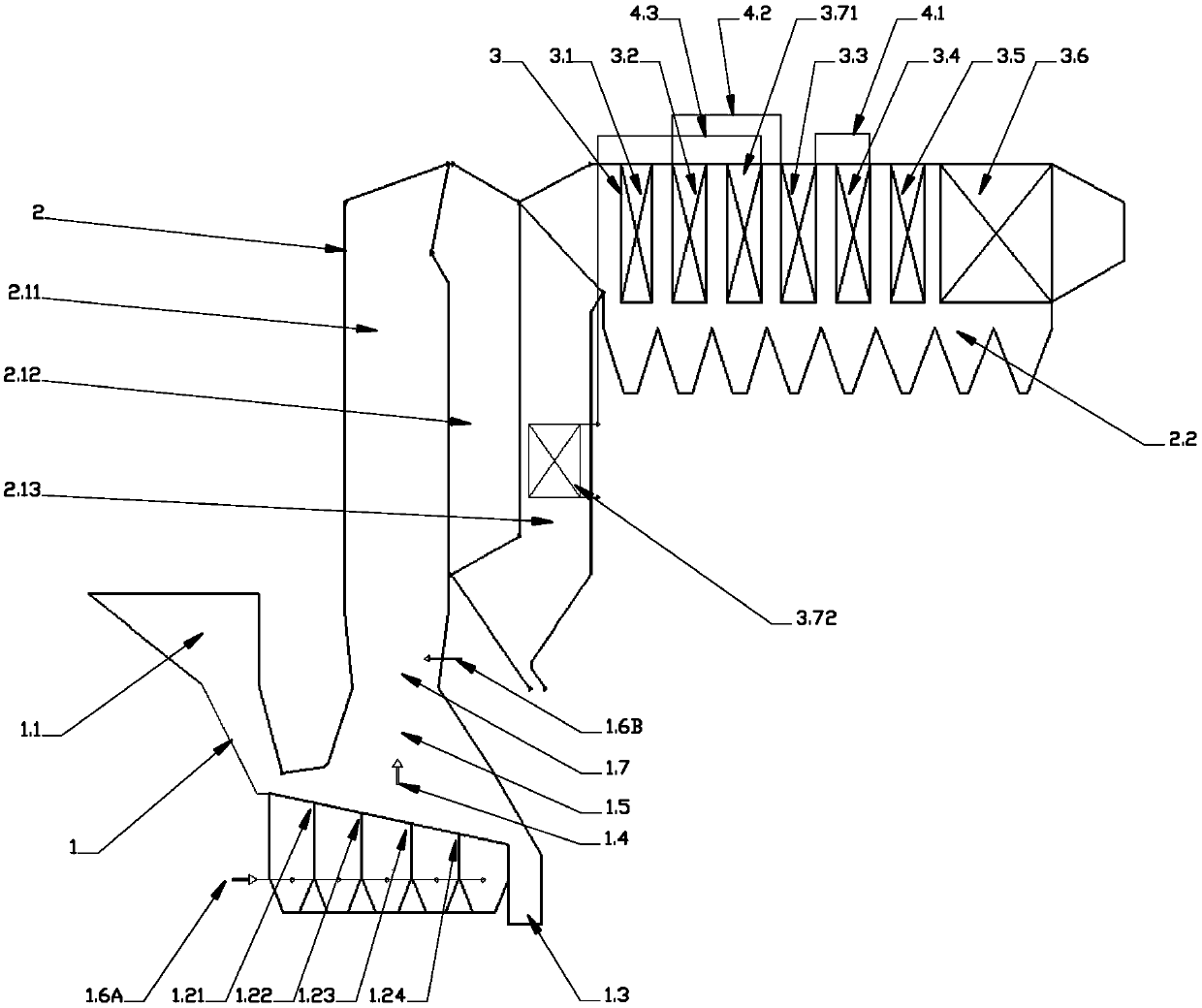

Semi-tower type medium-temperature separation biomass circulating fluidized bed boiler

ActiveCN102777895AAvoid low loadAvoid the problem of too low bed temperature under the condition of fuel changeFluidized bed combustionApparatus for fluidised bed combustionAir preheaterCombustion

The invention relates to a semi-tower type medium-temperature separation biomass circulating fluidized bed boiler, composed of a front shaft, a middle gas-solid separating and recycled material returning unit, and a tail flue, wherein the front vertical well comprises a hearth, a convection shaft and a smoke reversing chamber; the middle gas-solid separating and recycled material returning unit comprises a gas-solid separating device, a returning riser and a returning device; a super-heater, an economizer and an air pre-heater are arranged along a smoke flowing direction in the tail flue; a lower portion of the hearth is provided with 2 to 3 layers of secondary air along a height direction; an upper portion of the hearth is provided with a convection heated surface in the convection shaft; the hearth, the convection shaft, the smoke reversing chamber, the gas-solid separating device, the returning riser and the returning device compose a main circulation loop. According to the invention, adaptability of fuels is wide; combustion efficiency is high; abrasion and corrosion for the heated surface is poor; temperature of the smoke at an inlet of the gas-solid separating device is within a range of 400-750 degrees centigrade so as to effectively prevent slagging, slag hanging, dusts gathering, ashes blocking, bed materials blocking and returning device blocking in the boiler.

Owner:武汉和信益科技有限公司

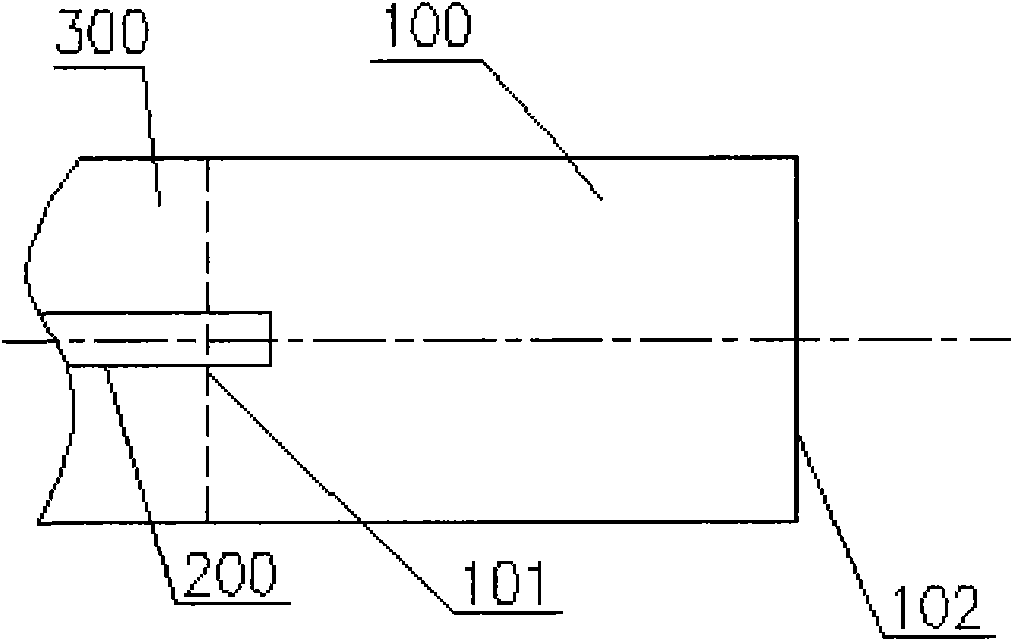

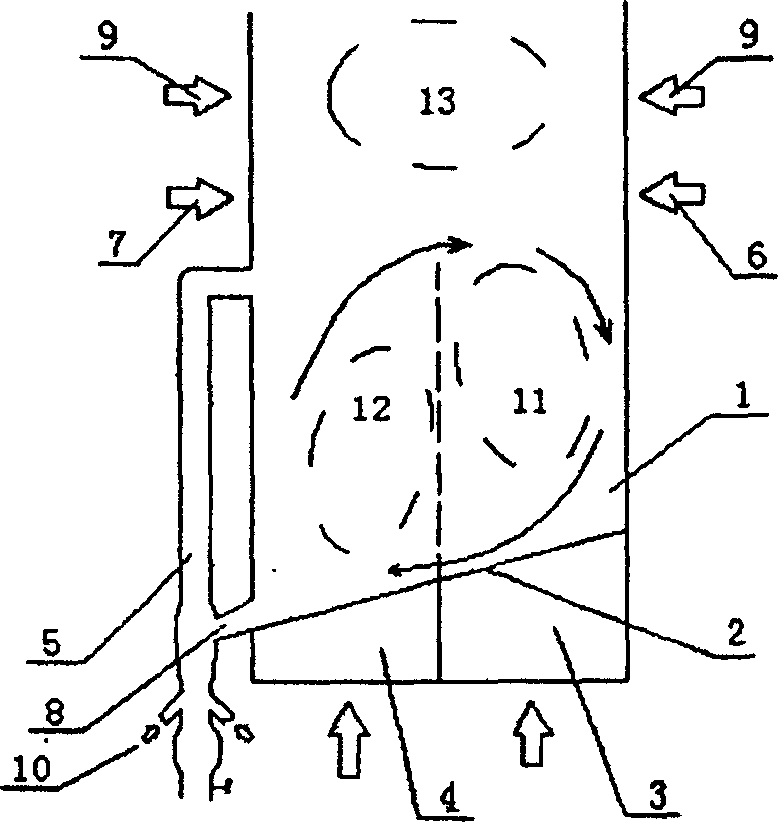

Pulverized coal burner and boiler with same

ActiveCN102032563AAchieve combustionOptimizationCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion chamberNitrogen

The invention discloses a pulverized coal burner and a boiler with the same. The disclosed pulverized coal burner comprises a heat source and an internal burning chamber, wherein the internal burning chamber ensures that an internal pulverized coal flow has a predetermined excess air coefficient; the heat source is positioned in the internal burning chamber; the internal burning chamber is provided with an inlet, a long cylindrical main burning chamber and an outlet; the heat source can ignite pulverized coal which passes through the internal burning chamber and ensures that the pulverized coal reducibly burns in the internal burning chamber; preferably, the internal burning chamber comprises the main burning chamber and a decelerating inlet section; and the sectional area of the decelerating inlet section is less than that of the main burning chamber. The internal burning chamber of the pulverized coal burner can maintain a smaller air coefficient, so reducing atmosphere is formed in the internal burning chamber; the pulverized coal reducibly burns in the internal burning chamber, so the pulverized coal flow enters a hearth in the form of high-temperature pulverized coal burning flame to improve the burning stability of the pulverized coal; meanwhile, the reducing burning can also convert a nitrogen element into a reducing intermediate product, so that fuel type nitrogen oxides are prevented from being produced.

Owner:YANTAI LONGYUAN POWER TECH

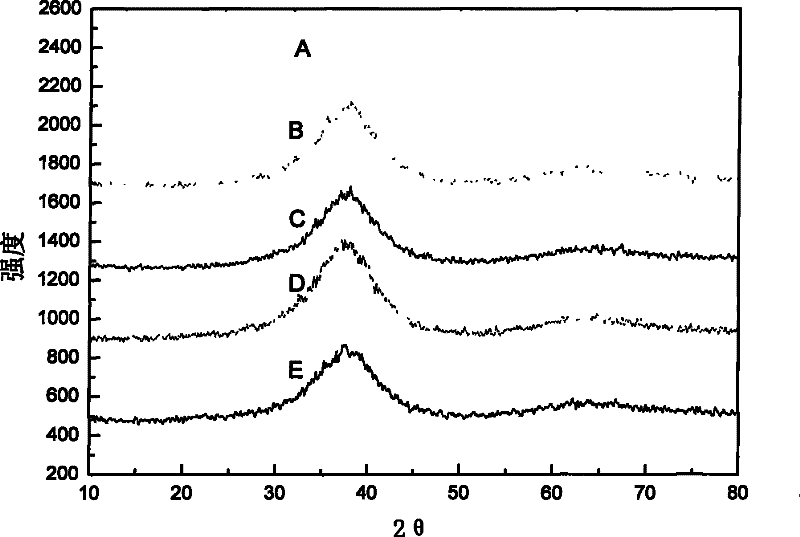

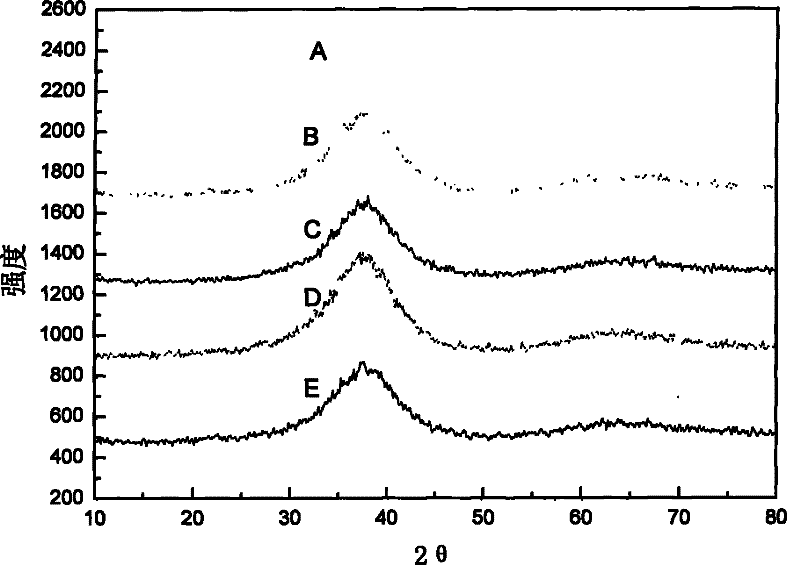

Recovery method of zirconium based amorphous alloy

ActiveCN101684522AImprove flexural strengthReduce oxygen contentProcess efficiency improvementRare-earth elementRecovery method

The invention relates to a recovery method of zirconium based amorphous alloy, comprising the following steps: a. rust removal, oxide removal and degreasing treatment are carried out to a zirconium based amorphous alloy scrap; b. the processed scrap and additives containing rare earth elements are mixed according to proportion, and the mixture is vacuum-melted; c. the temperature of the melted mixture is reduced to 100-200DEG C above the melting point of the mixture, and then the temperature is insulated; d. the mixture is vacuum-melted again, the melted mixture is injected into a copper moldand is cooled under the protective gas, thereby obtaining the amorphous alloy ingot. The recovery method of zirconium based amorphous alloy can effectively reduce the oxygen content in the amorphous alloy scrap; meanwhile, the bending strength of an amorphous alloy sample can be effectively improved, so as to increase the critical size of the amorphous alloy sample.

Owner:CHANGSHU YISHENG COMMODITY

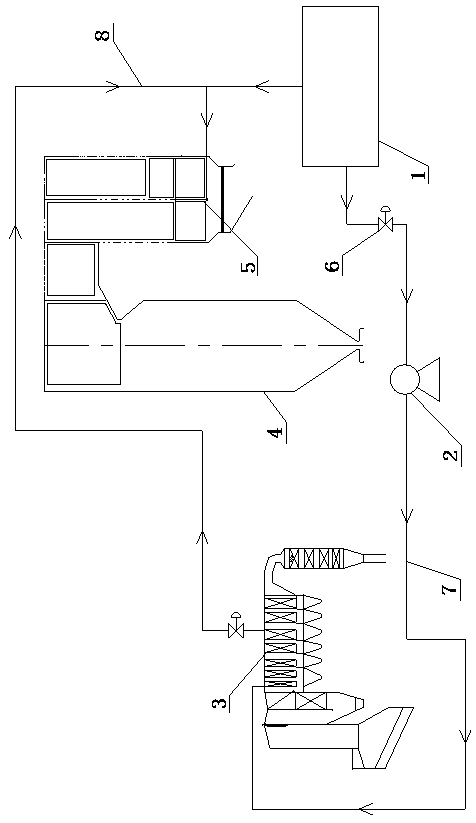

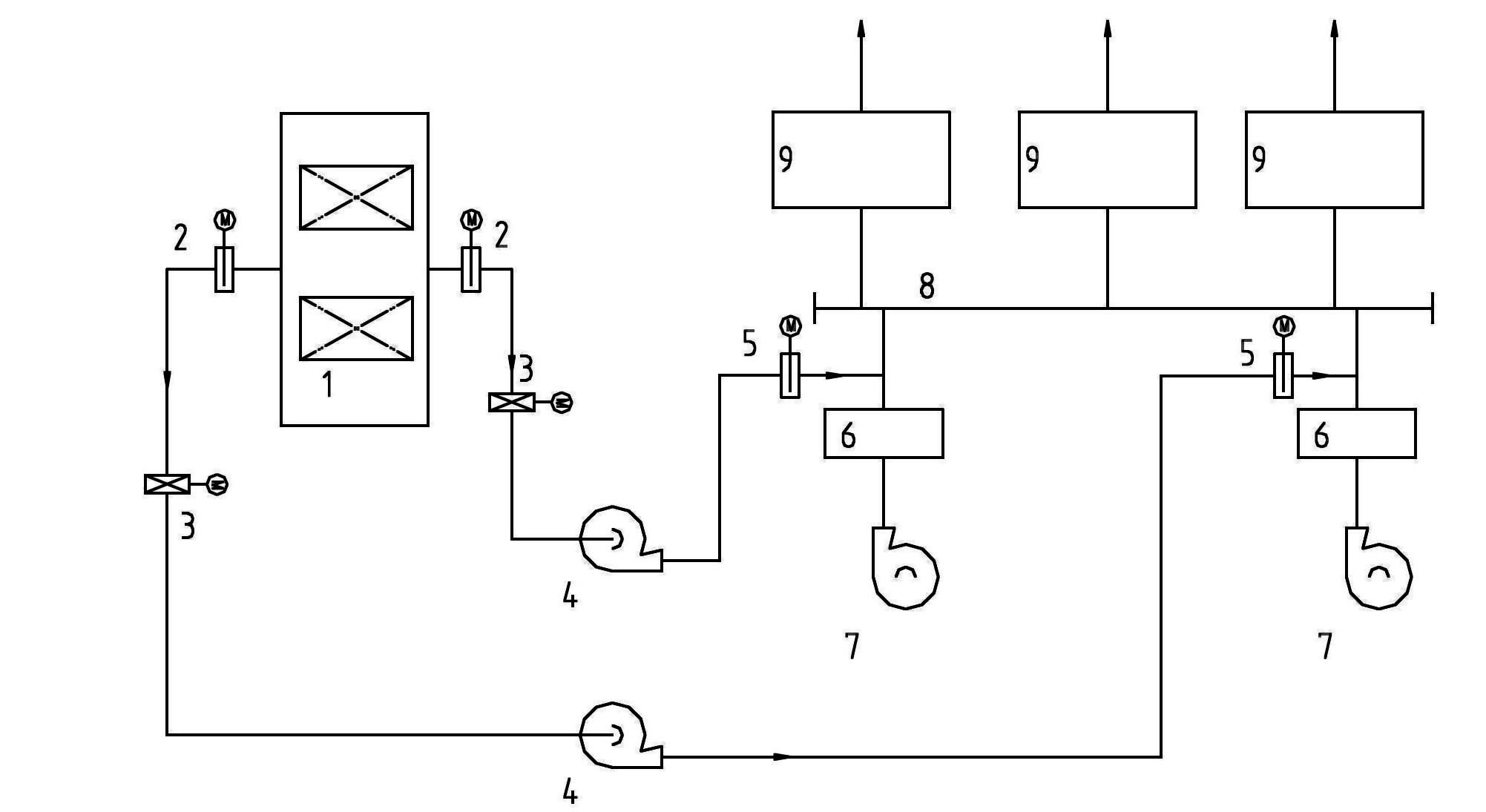

Garbage incineration furnace low-energy-level working medium and coal fired boiler coupled high-energy-level utilization system

PendingCN108266718ARaise the inlet water temperatureIncreased working fluidLiquid degasificationIncinerator apparatusSuperheaterHigh energy

The invention discloses a garbage incineration furnace low-energy-level working medium and coal fired boiler coupled high-energy-level utilization system. With garbage treatment as purpose, a garbageincineration furnace uses incineration heat in an afterheat boiler with a superheater inside, and is lower in power generation efficiency. The system comprises a high-pressure heater (1); a way of a water feeding pipeline (7) with a water feeding pump (2) of the high-pressure heater is connected with an afterheat furnace heated surface of a garbage incineration furnace (3); an outlet water pipe (8) of the garbage incineration furnace is connected with a tail coal economizer (5) of a coal fired boiler (4) after gathering with the other way of the water feeding pipeline of the high-pressure heater; and stop valves (6) are arranged on the water feeding pipeline connected with the afterheat furnace heated surface and the outlet water pipe of the garbage incineration furnace. The invention is applied to the garbage incineration furnace low-energy-level working medium and coal fired boiler coupled high-energy-level utilization system.

Owner:HARBIN BOILER

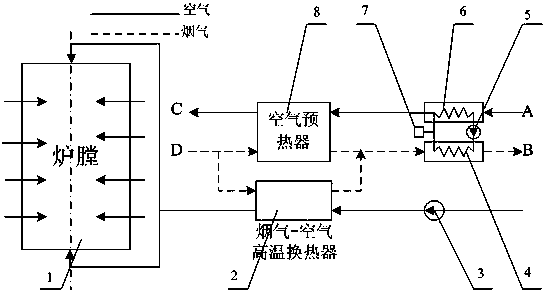

Device and method for reducing high-temperature corrosion of power station boiler by use of waste heat of flue gas

InactiveCN103776026ASimple processGuaranteed oxidizing atmosphereIndirect carbon-dioxide mitigationCombustion apparatusAir preheaterHigh-temperature corrosion

The invention discloses a device and a method for reducing high-temperature corrosion of a power station boiler by use of waste heat of flue gas. The device is additionally provided with a flue gas-air heat exchanger, an indirect-type air preheater, a Roots blower, a corresponding flue gas pipeline and a corresponding air pipeline. The method has the following flow path: one part of flue gas enters the flue gas-air heat exchanger before the flue gas enters the air preheater, the other part of the flue gas enters the air preheater to heat primary air and secondary air, the flue gas exhausted from the flue gas-air heat exchanger enters a gas flue at the outlet of the air preheater, and two flows of the flue gas are mixed and enter the indirect type air preheater; the indirect type air preheater is composed of a flue gas-air heat exchanger and an air-oil heat exchanger and utilizes conduction oil as a medium to achieve heat exchange of flue gas and air; the heated air in the flue gas-air heat exchanger, used as combustion air, enters a hearth from a side wall of a boiler burner so as to ensure that an oxidizing atmosphere is formed in a side wall combustion zone, and high temperature corrosion of a water cooled wall of the side wall is reduced or alleviated.

Owner:SOUTHEAST UNIV

Combustion method capable of effectively reducing slagging of boiler hearth

ActiveCN109028038ABurn down methodAvoid deflectionCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorSpray nozzle

The invention relates to a combustion method capable of effectively reducing slagging of a boiler hearth. Electrical energy is mainly obtained through thermal power generation of fire coal, power coalin China mostly is inferior coal, and slagging of a hearth during combustion is a problem plaguing the running of a power plant for a long time; and at present, a concentrated arrangement manner is adopted for combustors, the combustion temperature of pulverized coal is high, the slagging condition of a water-cooling wall of the boiler hearth is worsened, and the high-temperature corrosion of thewater-cooling wall is intensified. According to the combustion method, from composition, main combustors are comprised, each main combustor comprises a group of primary air nozzles and secondary airnozzles which are arranged at intervals, horizontal concentrated-dilute nozzles are selected as the primary air nozzles, the spiral directions of the secondary air nozzles are parallel to the centralaxes of the combustors, and the sprayed gas flow is parallel to the central axes of the combustor; and the main combustors are installed at the four corners of the boiler hearth, the central axes of the corner combustors and the water-cooling wall of the hearth form included angles alpha, and a small imaginary tangent circle is formed, so that the slagging and the high-temperature corrosion of thewater-cooling wall are effectively avoided. The invention relates to a combustion method capable of effectively reducing slagging of a boiler hearth.

Owner:HARBIN BOILER

Steam reheating system for waste incineration boiler

InactiveCN108036298AImprove heat transfer efficiencyLow investment costSuperheating controlIncinerator apparatusSuperheaterEngineering

The invention provides a reheater system for a waste incineration boiler. The reheater system aims at solving the problems. Due to the fact that a high-temperature reheater and a low-temperature reheater are additionally arranged and the high-temperature reheater and the low-temperature reheater are separately arranged, to improve the smoke environment where the high-temperature reheater is located and reduce high-temperature corrosion, the high-temperature reheater is arranged behind a horizontal flue third-stage superheater and in front of a second-stage superheater. To reduce the total length of the boiler, the low-temperature reheater is arranged in a third vertical flue, so that it can be guaranteed that the main steam temperature of the waste heat boiler is increased to 450 DEG C to480 DEG C, the reheating steam temperature reaches 400-450 DEG C, the safety and reliability of the reheaters can be improved, the heat exchange efficiency of the boiler is improved, no excess superheater area needs to be increased, the investment cost and the occupied area of the boiler are lowered, and the problems existing in the prior art can be solved effectively.

Owner:SHENZHEN ENERGY ENVIRONMENT ENG

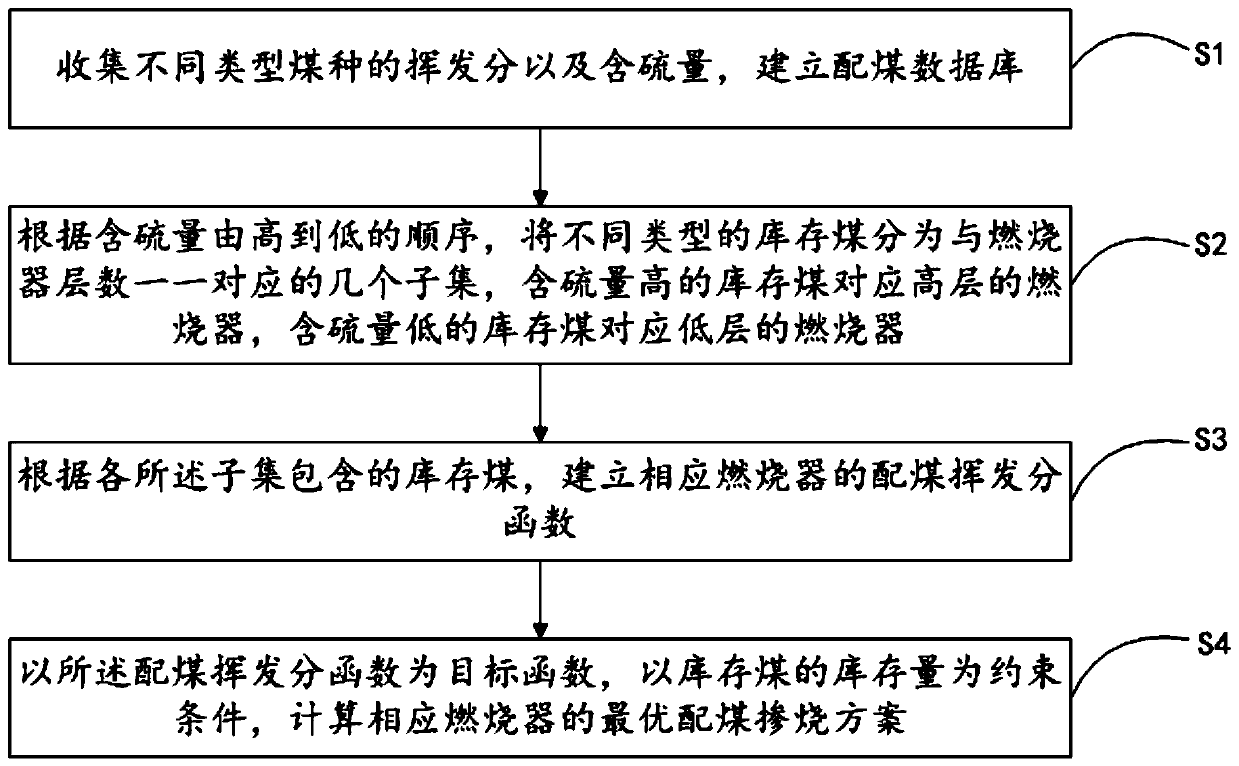

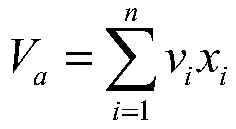

Coal blending combustion optimization method and device

ActiveCN111062534AExtended burn timeReduce high temperature corrosionForecastingResourcesThermodynamicsCombustor

The invention relates to the technical field of coal blending combustion, and discloses a coal blending combustion optimization method and device and a computer storage medium, and the method comprises the following steps: collecting volatile components and sulfur contents of different types of coal, and building a coal blending database; according to the sequence from high sulfur content to low sulfur content, dividing different types of stock coal into several subsets in one-to-one correspondence with the number of layers of the burners, enabling the stock coal with high sulfur content to correspond to the burners at a high layer, and enabling the stock coal with low sulfur content to correspond to the burners at a low layer; establishing a coal blending volatile component function of acorresponding combustor according to the stock coal contained in each subset; and calculating an optimal coal blending combustion scheme of the corresponding combustor by taking the coal blending volatile component function as a target function and taking the inventory of inventory coal as a constraint condition. The coal blending combustion method provided by the invention has the technical effect of less coking.

Owner:HUANENG YINGCHENG THERMAL POWER CO LTD

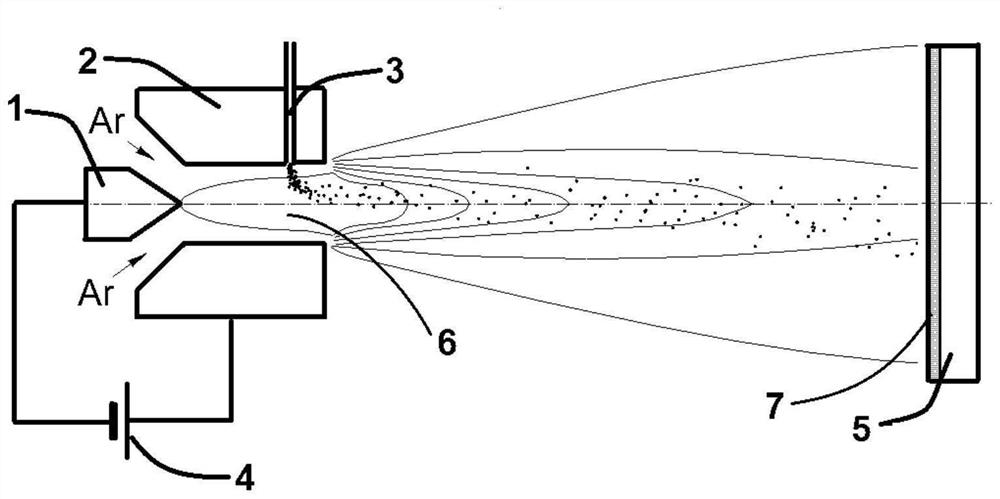

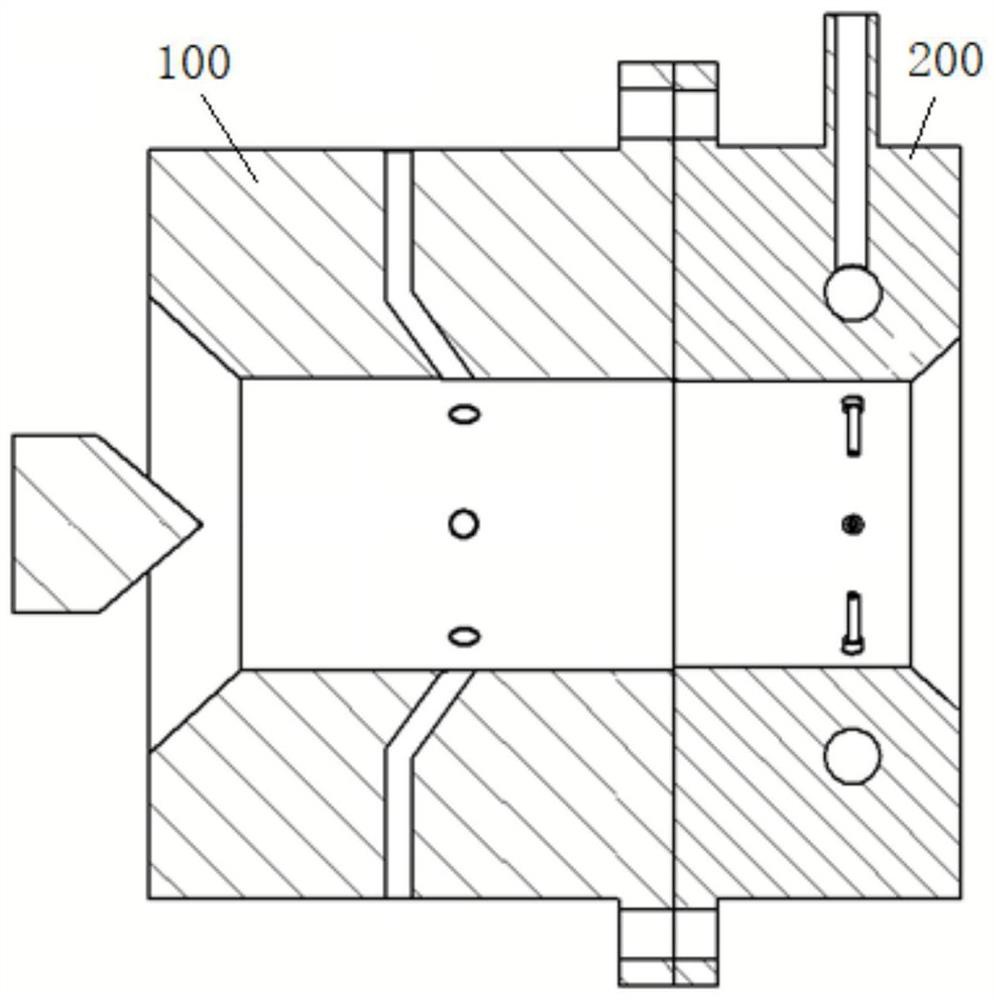

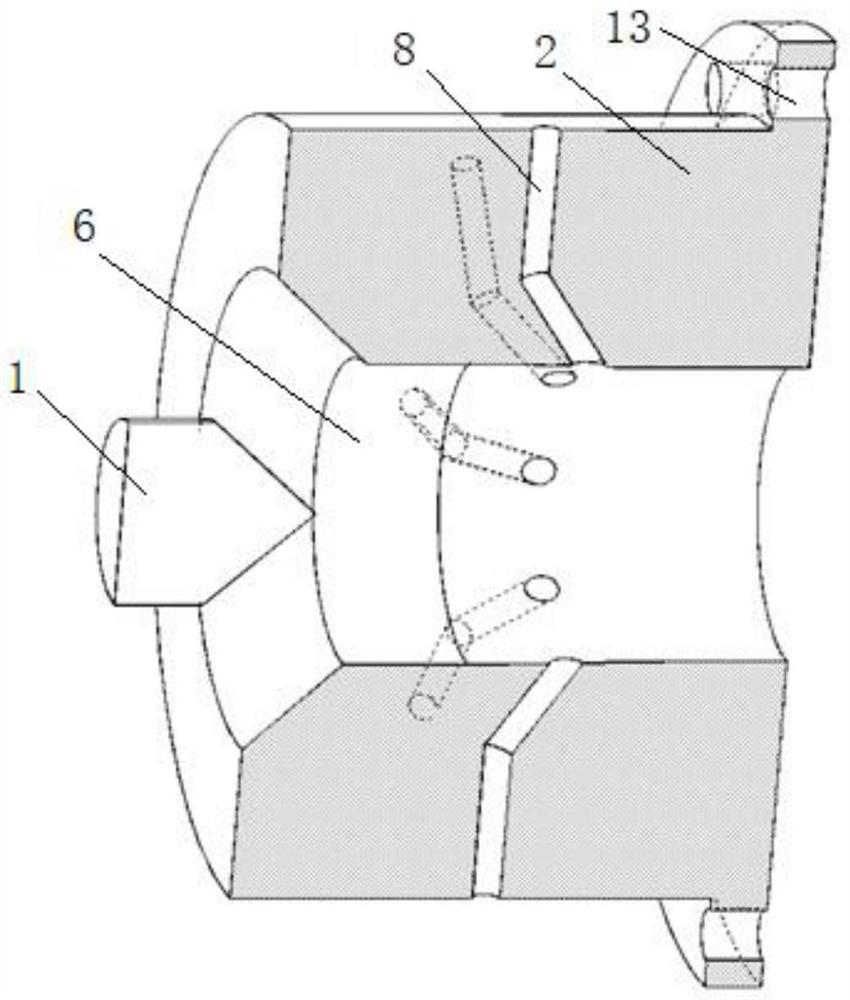

Hot cathode spray gun and nano plasma spraying device and method

PendingCN114481003AExtended service lifeReduce high temperature corrosionMaterial nanotechnologyMolten spray coatingJet flowNanoparticle

The hot cathode spray gun comprises a cathode with a conical emission structure and an annular anode, and bent channels which are evenly distributed and used for communicating the outside with an inner cavity of the anode are formed in the anode in the circumferential direction of the anode; the invention further discloses a nano plasma spraying device which comprises the hot cathode spray gun and a loader which is detachably connected with the hot cathode spray gun and used for providing nano particle suspension liquid. The loader is provided with an injection channel which is communicated with the inner cavity and is coaxial with the inner cavity; the invention further discloses a spraying method adopting the nano plasma spraying device. The device is simple, the loader is attached to one side of the anode of the spray gun, and a plurality of suspension nozzles are distributed around the jet flow, so that the nanoparticle suspension can be efficiently injected into the high-temperature plasma, and the loader can be prevented from being frequently replaced due to damage of the anode. The spray gun anode is protected from being ablated by high-temperature plasma through a flow control method introducing the Coanda effect.

Owner:ZHEJIANG UNIV

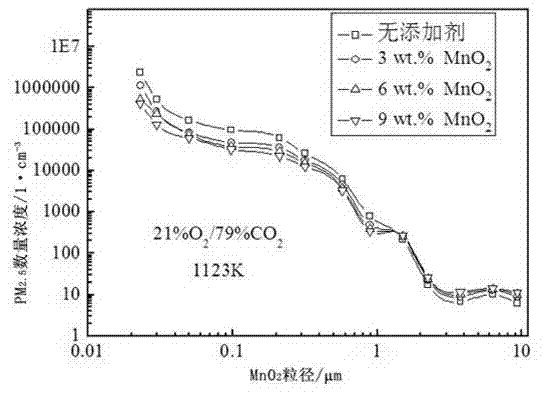

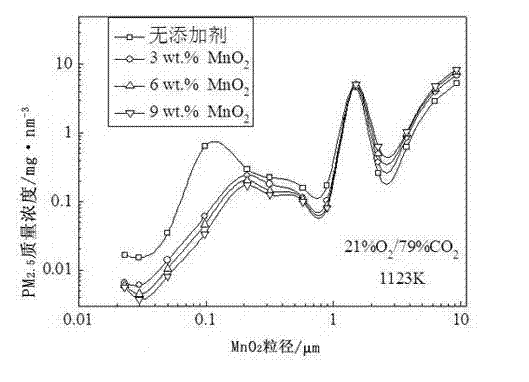

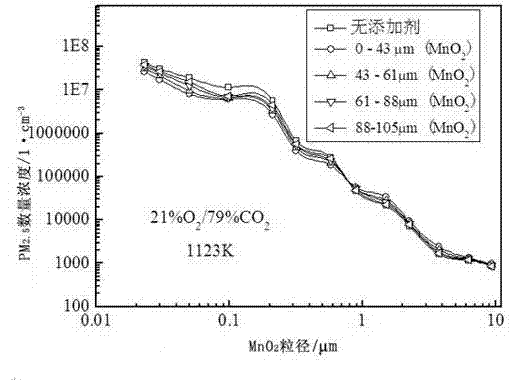

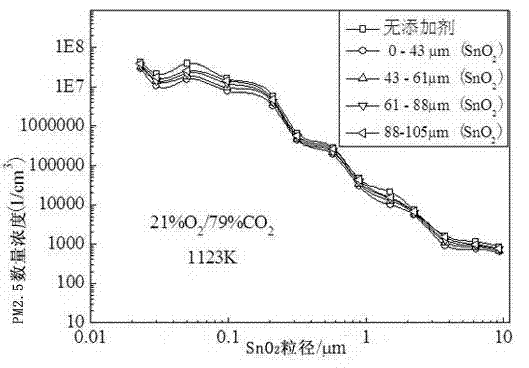

Method for controlling discharge of superfine particulate matters of fire coal

InactiveCN102921265AEmission controlLarge particlesAuxillary pretreatmentLighting and heating apparatusParticulatesDesorption

The invention relates to a method for controlling the discharge of superfine particulate matters of fire coal. The method comprises the following steps of: grinding a Mn-base desorption agent into granules of which the grain diameters are 54 to 105 micrometers, and mixing the Mn-base desorption agent with the fire coal, wherein the addition amount of the Mn-base desorption agent is 3 to 6 weight percent of the fire coal amount, and the Mn-base desorption agent is a mixture of MnO2, Mn3O4 and Mn(OH)2 or MnCO3 or MnO2, Mn3O4 and Mn(OH)2 or MnCO3; grinding the fire coal in a coal grinding machine, conveying the ground fire coal into a boiler hearth, conveying the Mn-base desorption agent into the boiler hearth with secondary air from a secondary tuyere of a boiler for combusting, and conveying air required by combustion into the boiler hearth by a forced draught blower; and allowing smoke which is formed after combustion and is mixed with the Mn-base desorption agent to enter a deduster, filtering and discharging. By the method, the high-temperature corrosion of alkali metal sodium and potassium on a boiler superheater or a boiler reheater can be reduced effectively; and harmful heavy metal elements can be removed from the smoke while particulate matters (PM) 2.5 are removed.

Owner:HENAN UNIV OF SCI & TECH

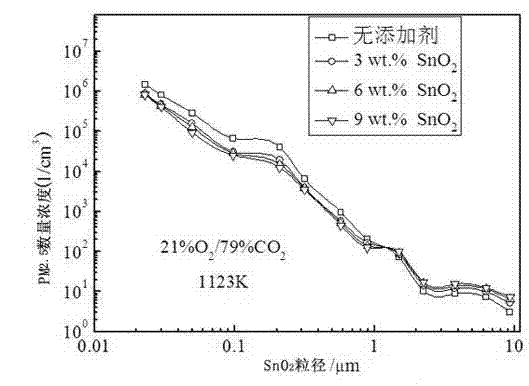

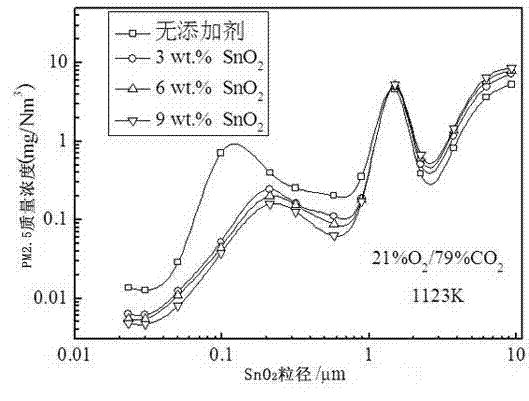

Emission control method of PM2.5 of fuel coal

The invention relates to an emission control method of PM2.5 of fuel coal. The emission control method comprises the following steps of: grinding an Sn-based removing agent into particles with the particle diameter of 54-105 mu m, and mixing the Sn-based removing agent with the fuel coal, wherein the addition amount of the Sn-based removing agent is 3-6 wt% that of the fuel coal; and the Sn-based removing agent is a mixture of SnO2, Sn(OH)2 or SnCO3 or SnO2, Sn(OH)2 or SnCO3; feeding the fuel coal into a coal mill, feeding the fuel coal into the hearth of the boiler after grinding, feeding the Sn-based removing agent into the hearth of the boiler from a secondary air hole of the boiler along secondary air to be burned, and feeding air required for combustion into the hearth of the boiler by an air feeder; discharging smoke mixed with the Sn-based removing agent after combustion after filtering by entering a dust remover. The method disclosed by the invention is capable of effectively reducing high-temperature corrosion of an over-heater or a reheater of the boiler by alkali metal sodium and potassium; and harmful heavy metal elements in smoke can also be removed while PM2.5 is removed.

Owner:HENAN UNIV OF SCI & TECH

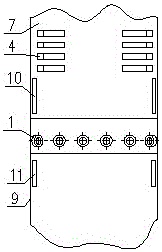

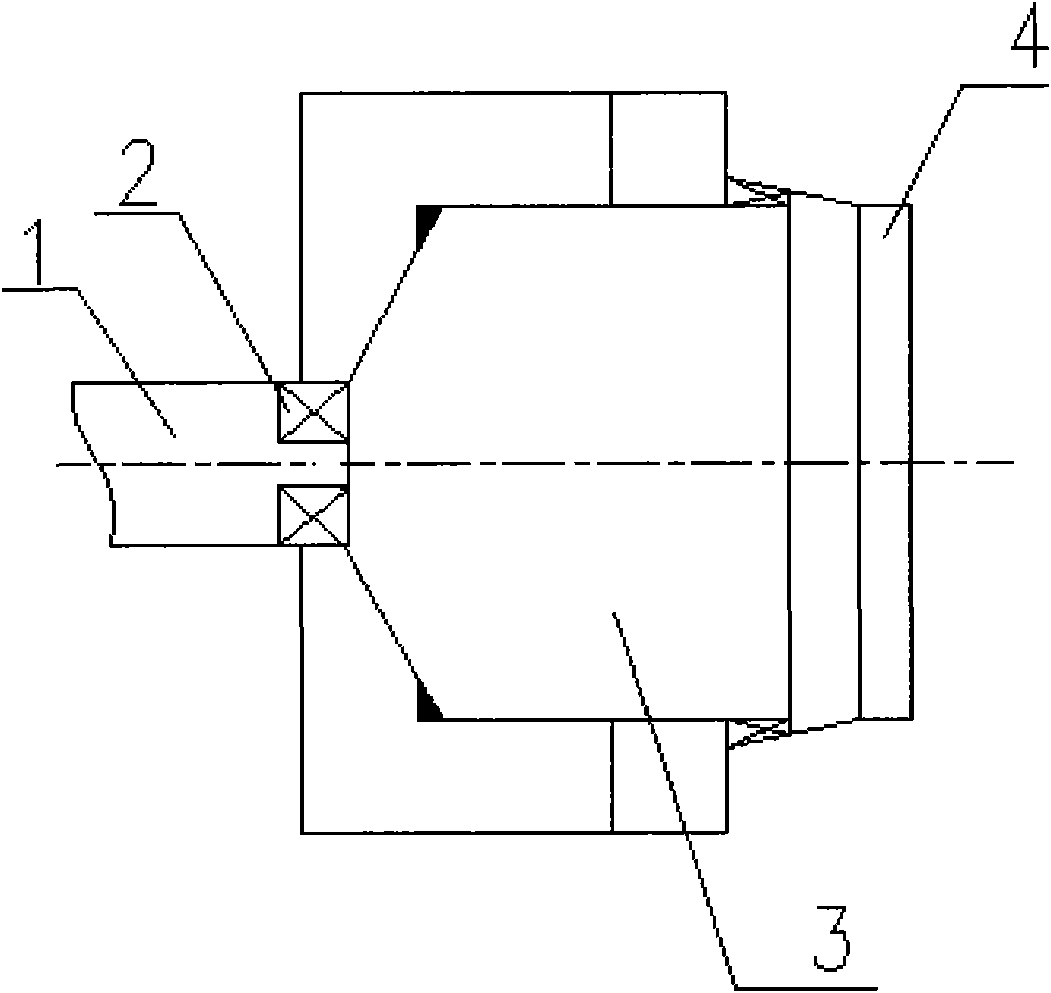

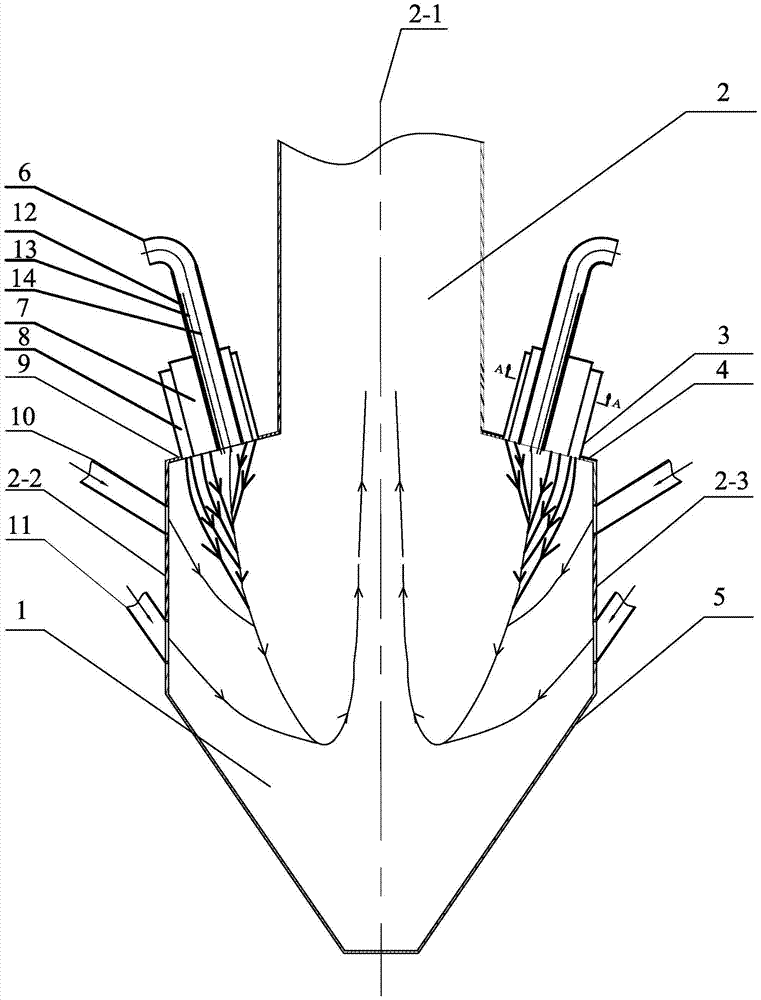

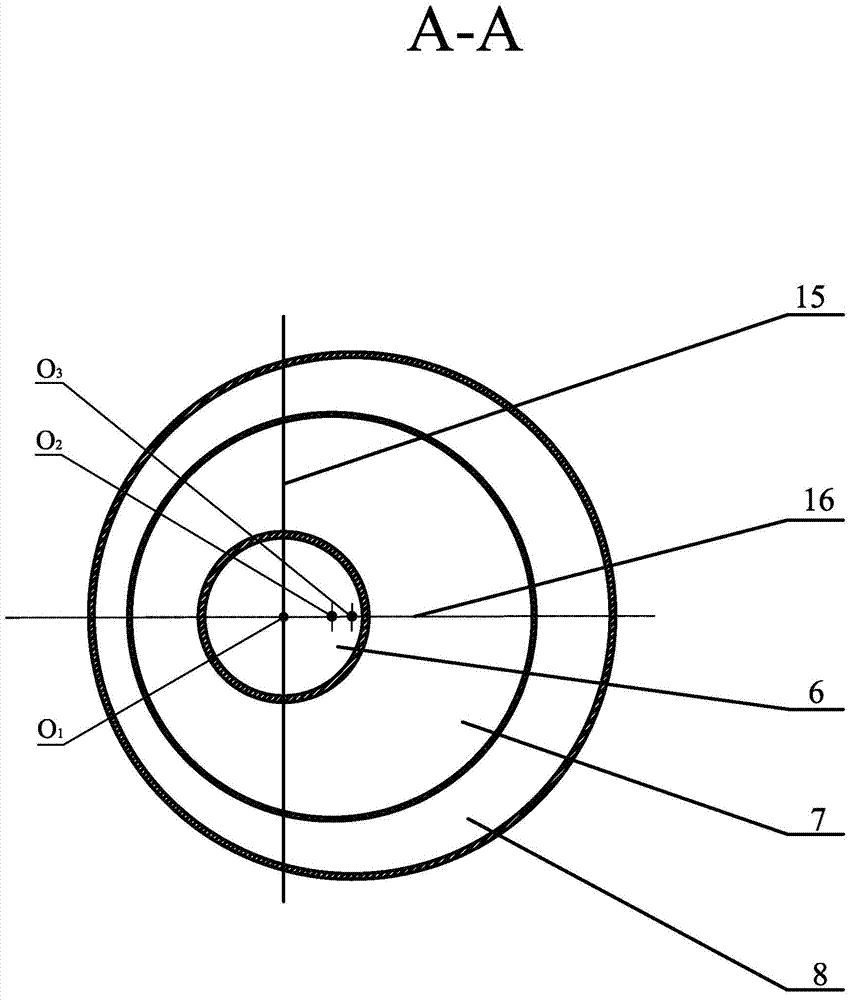

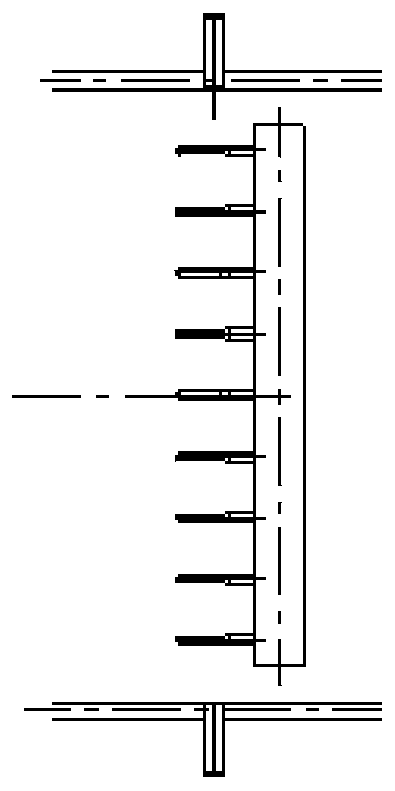

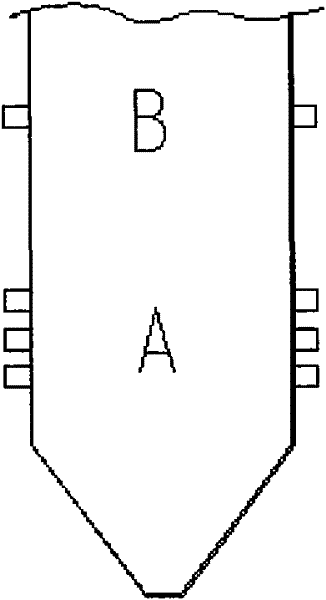

W flame boiler with swirl pulverized coal burner primary and secondary air eccentrically arranged

ActiveCN105546521BImprove flame stabilityFire aheadCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustionNitrogen oxide

The invention belongs to the technical field of low-nitric oxide combustion of W-flame boilers, and relates to a W-flame boiler, in particular to a W-flame boiler with rotational flow pulverized coal burners with primary air and secondary air eccentrically arranged to solve the problems that a W-flame boiler with rotational flow pulverized coal burners arranged on an arch is large in NOx discharge and high in fly ash combustible matter content, scorification occurs on a front wall water wall and a rear wall water wall of a lower hearth, and high-temperature abrasion happens. The W-flame boiler comprises a boiler body, the multiple rotational flow pulverized coal burners, a plurality of exhausting steam nozzles and a plurality of classification wind nozzles. The boiler body is composed of a lower hearth and an upper hearth. The multiple rotational flow pulverized coal burners are evenly distributed on a front arch and a rear arch of the upper hearth. An inner secondary air pipe and an outer secondary air pipe in each rotational flow pulverized coal burner are arranged in the direction far away from the center line of the hearths in an offset manner relative to primary air pipes.

Owner:HARBIN INST OF TECH

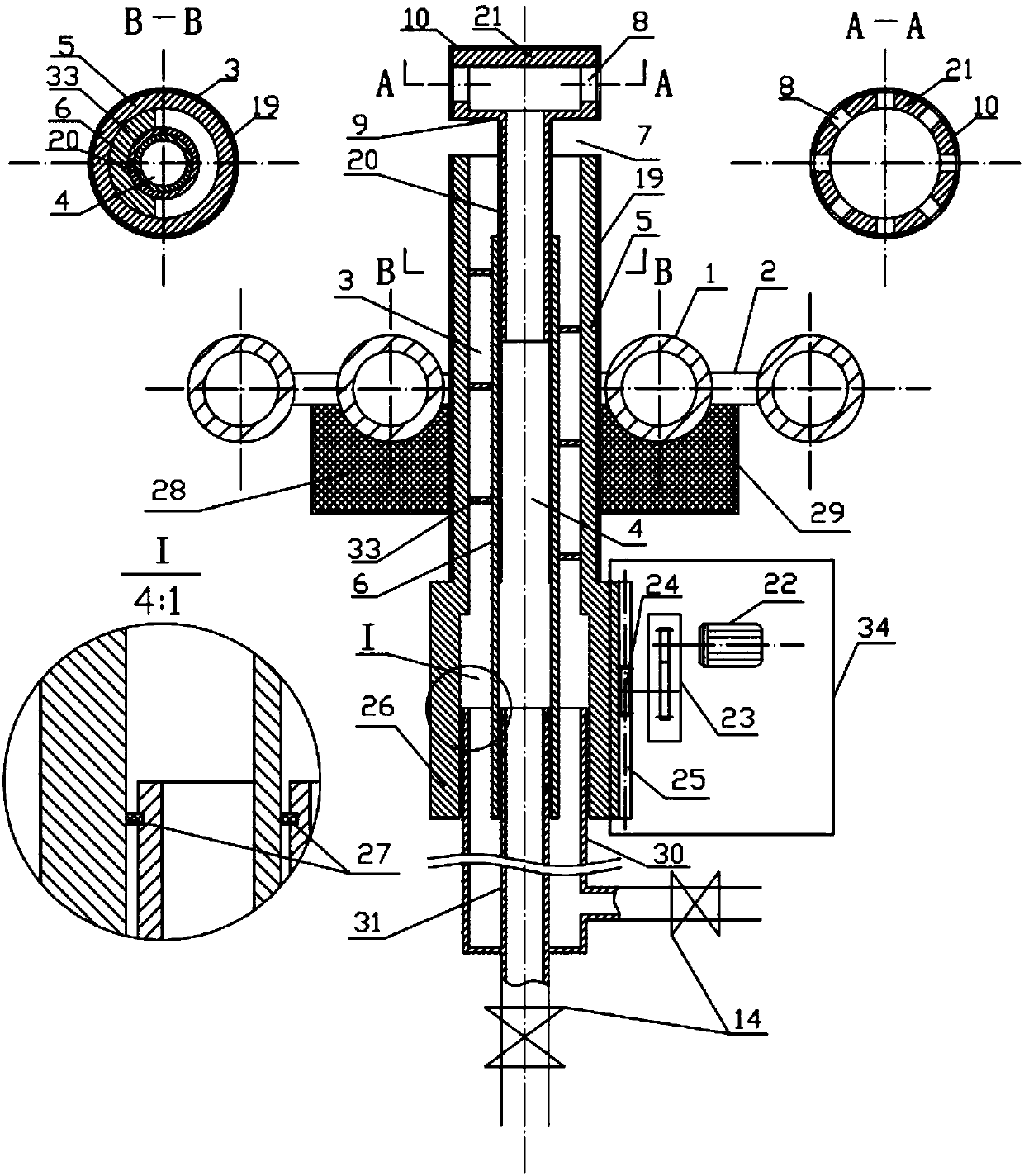

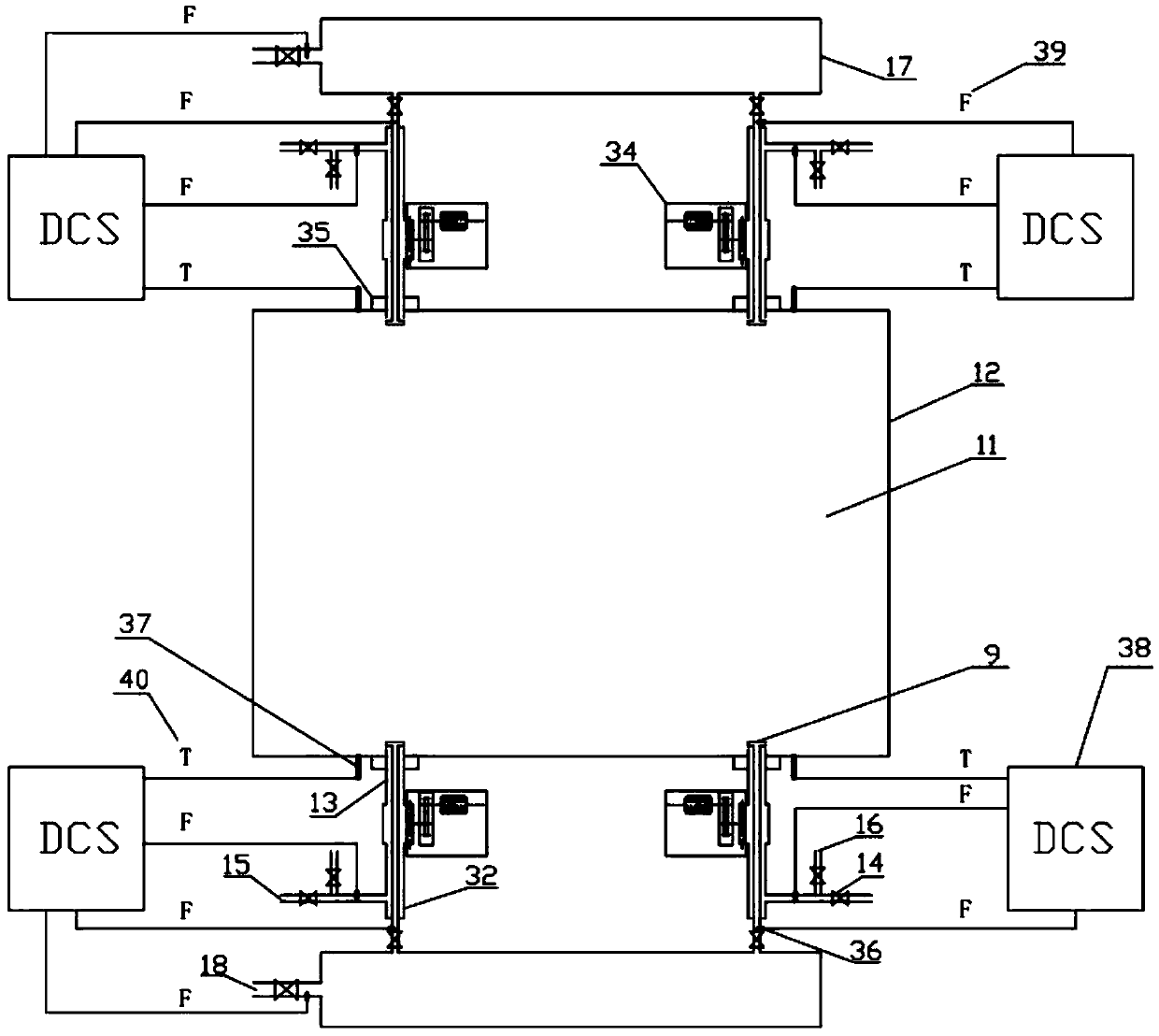

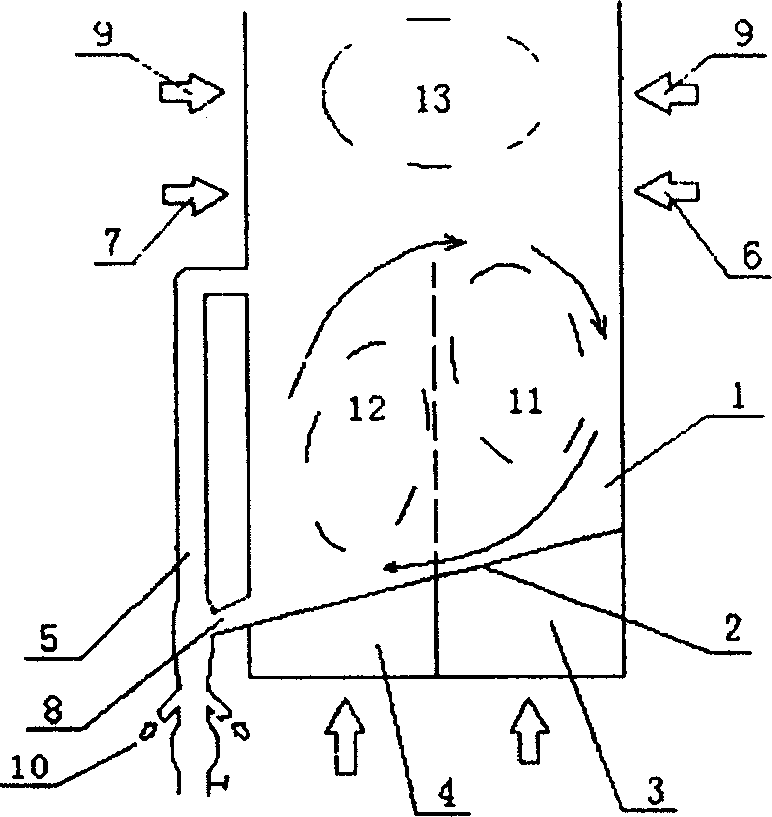

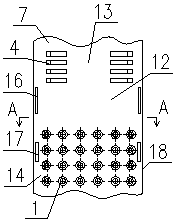

Near-wall attaching method and near-wall attaching apparatus for preventing high temperature corrosion of water cooling wall of boiler

ActiveCN107747731AReduce high temperature corrosionReduce pipe wall temperatureCasings/liningsNon-combustible gases/liquids supplyEngineeringNozzle

A near-wall attaching apparatus is composed of: patent unit apparatuses, a linking wind pipe and a measurement and control system. The patent unit apparatus is composed of a ventilating sleeve tube, alinking sleeve tube, a spiral baffle plate, a sealing device, a secondary wind spray nozzle, a zirconia ceramic heat insulation disk, a zirconia ceramic heat insulation pipe, an adjustment valve, anaxial adjustment device, etc. A connection pipe and a bottom disk of the secondary wind spray nozzle are respectively in threaded connection with the ventilating sleeve tube and the zirconia ceramic heat insulation bottom disk. A plurality of secondary wind mouths are formed in the circumference of the bottom disk. The zirconia ceramic heat insulation pipe sleeves the outer pipe of the ventilatingsleeve tube, wherein the outlet of the zirconia ceramic heat insulation pipe and the bottom disk of the secondary wind spray nozzle form a compressed air nozzle. The air nozzle sprays a double-layerair film which separates furnace gas and the water wall, so that the water wall has the function of preventing high temperature corrosion. By means of pre-adjustment of the secondary wind spray nozzle, adjustment of the adjustment valve and axial adjustment of the patent unit apparatuses, the near-wall wind apparatus has good parameter adjustable performance and adaptability. Due to the heat insulation disk and the heat insulation pipe, the secondary wind and compressed air achieve double cooling, wherein the secondary wind spray nozzle is detachable, so that anti-burning and replaceable features of the parts in the boiler are achieved. The number of the patent unit apparatuses can be changed according to volume of the boiler.

Owner:XIANGTAN UNIV

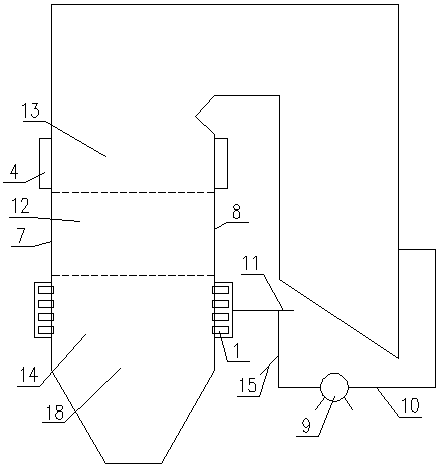

Internal circulation fluidized bed garbage combustion device having melt sticking dechlorination function

The present invention relates to an internal recycling fluidized bed refuse incineration equipment with viscous melt-phase dechlorination which is used in the field of environment protection. Said equipment includes internal recycling fluidized bed furnace cavity, inclined non-uniformly air-distributing plate, low-speed first ai chamber, high-speed first air chamber, life pipe, refuse fuel inlet, dechlorination agent inlet, slag discharge outlet, secondary air inlet, separation air inlet, thermal decomposition zone, combustion zone and burning zone, etc.

Owner:SHANGHAI JIAOTONG UNIV

Mixed firing boiler of industrial waste and domestic waste

InactiveCN106705065AAdaptable to changeSolve incomplete combustionIndirect carbon-dioxide mitigationCasings/liningsCombustion chamberFlue gas

The invention discloses a mixed firing boiler of industrial waste and domestic waste. The mixed firing boiler comprises a steel frame, combined combustion equipment, a furnace chamber, a tail flue gas duct, an ash falling device and a deslagging device, wherein the combined combustion equipment comprises a rotary kiln and a grate; the industrial waste and the domestic waste enter from a feeding port of the head of the rotary kiln; the tail of the rotary kiln is connected with an inlet of the furnace chamber; an outlet of the furnace chamber is connected with the tail flue gas duct; the furnace chamber and the tail flue gas duct are mounted on the steel frame; the ash falling device is arranged below the tail flue gas duct; the grate is arranged below the furnace chamber; the deslagging device is mounted below the grate; and the furnace chamber comprises a combustion chamber, a reburning chamber and a triple-pass. According to the structure disclosed by the invention, the industrial waste and the domestic waste can be efficiently treated and the problem of co-firing of various kinds and components of industrial waste and domestic waste can be solved. Besides, the problem of small space of the deslagging chamber is solved, so that continuous and efficient operation of the boiler is guaranteed.

Owner:ZHEJIANG WEIMING ENVIRONMENT PROTECTION

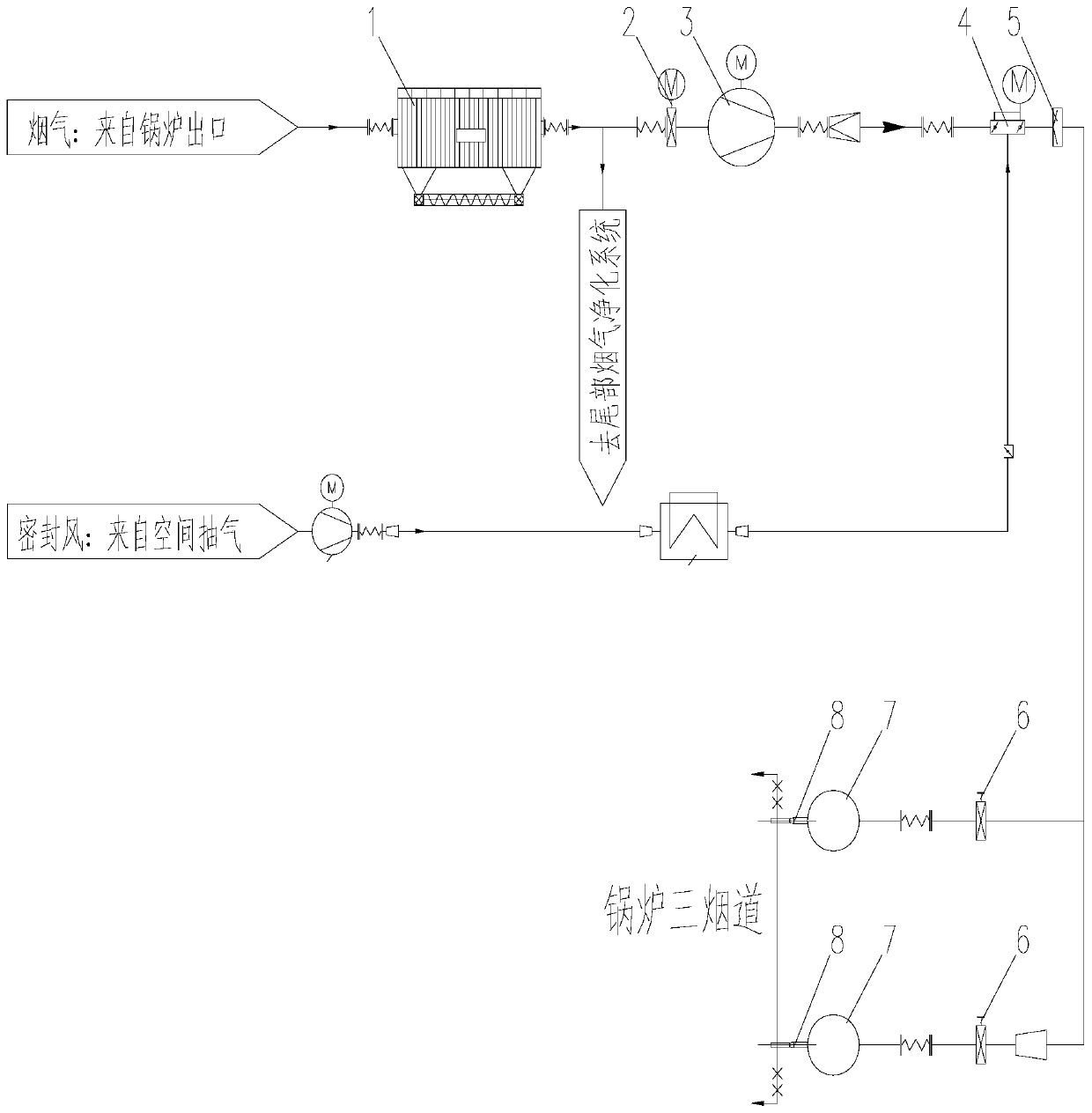

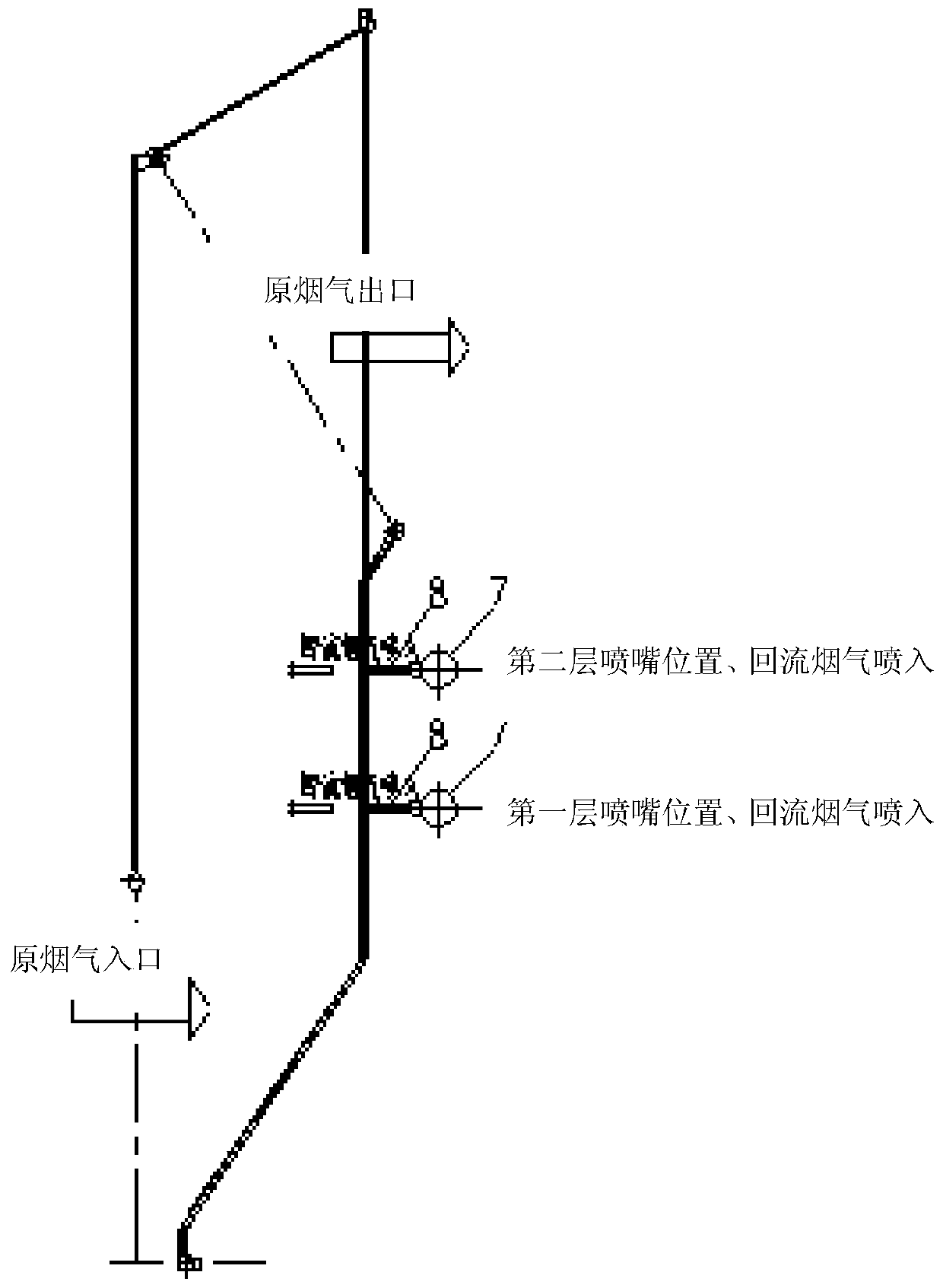

Garbage incineration waste heat boiler flue gas backflow system

PendingCN110793039AUniform speedUniform temperatureIncinerator apparatusCombined combustion mitigationSuperheaterCheck valve

The invention provides a garbage incineration waste heat boiler flue gas backflow system. The system comprises an electrostatic dust remover, an electric inlet adjusting air door, a backflow fan, an outlet electric closing baffle door, a flue gas check valve, a manual shut-off valve, a flue gas pipe box and injection nozzles which are sequentially connected from a garbage incineration boiler fluegas outlet. The injection nozzles are arranged on the flue gas pipe box on a rear side wall of a boiler third flue. After flue gas on the tail portion of a boiler passes through the electrostatic dustremover, part of the clean flue gas is extracted by the backflow fan and enters the pipe box on the rear side walls of three flues of the boiler, and the flue gas is sprayed into the three flues at positive pressure at high speed to be mixed with high-temperature flue gas in the flues turbulently. The backflow flue gas is ejected into the flues in the middle of the third flue and is fully and turbulently mixed with the high-temperature flue gas, and the problems that the temperature field and the speed field of the third flue are not uniform are effectively relieved. The measured service lifeof a superheater can reach 10 years or longer, and meanwhile, the heat efficiency of the boiler is also improved.

Owner:SHANGHAI SUS ENVIRONMENT

RDF garbage incinerator of circulating fluidized bed

InactiveCN111503644AImprove combustion efficiencyImprove stabilityFluidized bed combustionIncinerator apparatusFluidized bedCooling chamber

The invention discloses an RDF garbage incinerator of a circulating fluidized bed, and relates to the field of circulating fluidized bed boilers. The RDF garbage incinerator of the circulating fluidized bed comprises an inclined air distribution device, a layered air supply water cooling wall hearth, a high-temperature water cooling cyclone separator, a cooling chamber and an external heat exchanger. The inclined air distribution device is arranged at the bottom of the layered air supply water cooling wall hearth. Multiple upper secondary air ports and multiple lower secondary air ports are arranged on the layered air supply water cooling wall hearth. A discharging opening of the layered air supply water cooling wall hearth communicates with a feeding opening of the high-temperature watercooling cyclone separator. A gas outlet of the high-temperature water cooling cyclone separator communicates with a gas inlet of the cooling chamber. A material falling leg of the high-temperature water cooling cyclone separator communicates with a feeding opening of the external heat exchanger. A discharging opening of the external heat exchanger communicates with a material return port of the layered air supply water cooling wall hearth. By means of the RDF garbage incinerator of the circulating fluidized bed, the combustion efficiency, running stability and economic performance of a circulating fluidized bed boiler are improved.

Owner:BEIJING ENVIRONMENT ENG TECH CO LTD

Smoke recirculation device for separating primary air and secondary air

PendingCN110657439AReduce unit consumptionReduce the amount of fly ashAir supply regulationIndirect carbon-dioxide mitigationCombustionEnvironmental engineering

The invention provides a smoke recirculation device for separating primary air and secondary air. The smoke recirculation device comprises an incinerator, a smoke purification device, a primary fan and a secondary fan. The incinerator is configured to incinerate biomass to generate smoke. The smoke purification device is configured to purify the smoke, and one part of purified smoke discharged bythe smoke purification device serves as recirculation smoke. The primary fan is configured to drain air, so that the air serves as primary air of the incinerator. The secondary fan is configured to drain air and the recirculation smoke, and the air and the recirculation smoke serve as secondary air of the incinerator. According to the provided smoke recirculation device for separating the primaryair and the secondary air, the primary fan drains the air as the primary air, the secondary fan drains the air and the recirculation smoke as the secondary air, thus the flying ash quantity and the flying ash carbon content are lowered, fuel unit consumption is lowered, high-temperature corrosion is reduced, and the combustion condition is optimized.

Owner:光大绿色环保管理(深圳)有限公司

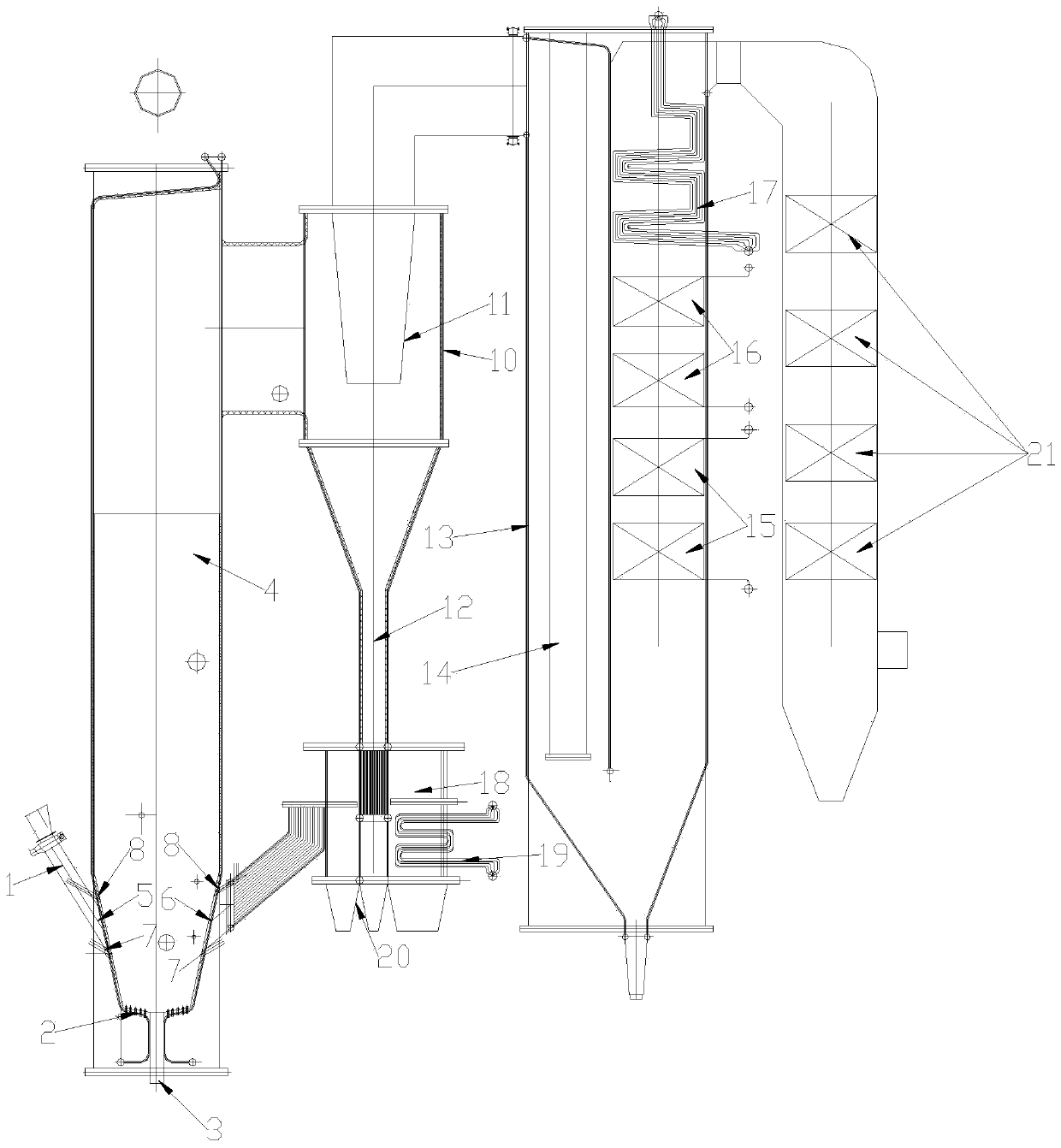

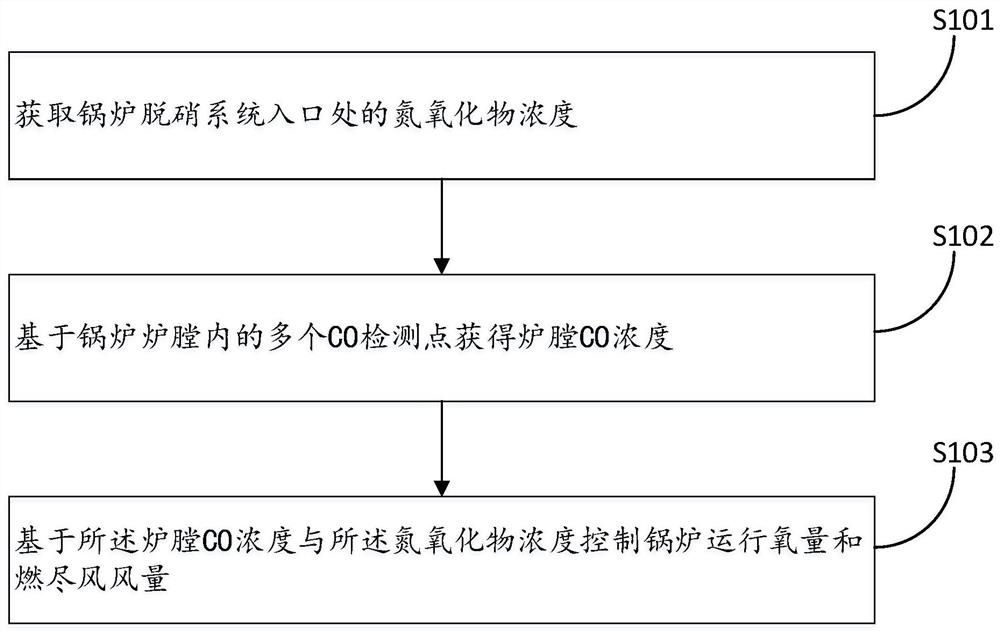

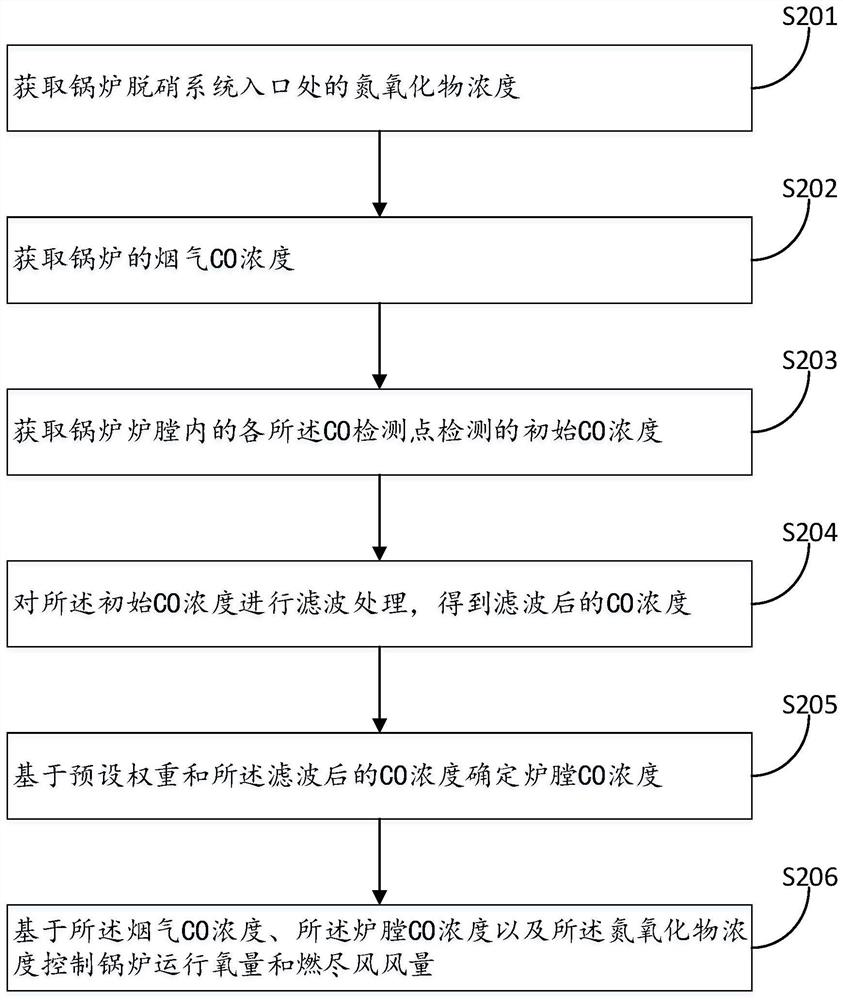

Combustion optimization method based on CO online monitoring

ActiveCN112797439AExtended service lifeControl high temperature corrosionAir supply regulationChemistryBoiler furnace

The invention discloses a combustion optimization method based on CO online monitoring. The method comprises the steps that the concentration of nitrogen oxides at an inlet of a denitration system of a boiler is obtained, the CO concentration of a hearth based on a plurality of CO detection points in the hearth of the boiler is obtained, the operation oxygen amount and the over fire air amount of the boiler are obtained based on the CO concentration of the hearth and the concentration of the nitrogen oxides, therefore, under the condition that the cost is not increased, serious high-temperature corrosion of the boiler is avoided, the treatment pressure of the denitration system of the boiler is reduced, and the service life of the boiler is prolonged.

Owner:HUANENG POWER INT CO LTD DEZHOU POWER PLANT +1

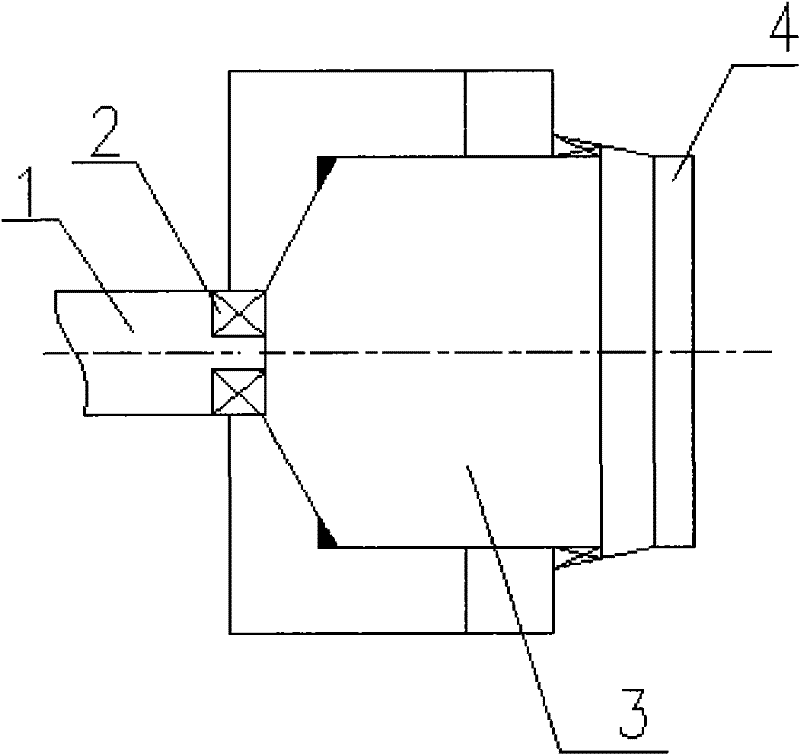

Furnace smoke extraction lignite drying system of direct-blowing pulverizing system of double-inlet and double-outlet steel ball coal mill

The invention relates to a furnace smoke extraction lignite drying system of a direct-blowing pulverizing system of a double-inlet and double-outlet steel ball coal mill. The furnace smoke extraction lignite drying system is simple in structure, low in investment cost, capable of improving the applicability of the pulverizing system to coal types, free of influence to the safety of a boiler, favorable for relieving high-temperature corrosion of a water-cooled wall and reducing NOx emission and the like and capable of increasing the lignite blending ratio to 0.4. The furnace smoke extraction lignite drying system comprises two recirculating pipelines which are connected with an economizer inlet flue of a tail shaft of the boiler, wherein each recirculating pipeline comprises a recirculating fan; an electric side plate gate I and an electric air damper are arranged at the junction of the recirculating fan and the economizer inlet flue; and an electric side plate gate II is arranged at the junction of the recirculating fan and a primary hot air pipeline.

Owner:SHANDONG ELECTRIC POWER ENG CONSULTING INST CORP

Internal circulation fluidized bed garbage incineration method having melt sticking dechlorination function

Owner:SHANGHAI JIAOTONG UNIV

Pulverized coal burner and boiler with same

ActiveCN102032563BAchieve combustionOptimizationCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion chamberNitrogen

The invention discloses a pulverized coal burner and a boiler with the same. The disclosed pulverized coal burner comprises a heat source and an internal burning chamber, wherein the internal burning chamber ensures that an internal pulverized coal flow has a predetermined excess air coefficient; the heat source is positioned in the internal burning chamber; the internal burning chamber is provided with an inlet, a long cylindrical main burning chamber and an outlet; the heat source can ignite pulverized coal which passes through the internal burning chamber and ensures that the pulverized coal reducibly burns in the internal burning chamber; preferably, the internal burning chamber comprises the main burning chamber and a decelerating inlet section; and the sectional area of the decelerating inlet section is less than that of the main burning chamber. The internal burning chamber of the pulverized coal burner can maintain a smaller air coefficient, so reducing atmosphere is formed inthe internal burning chamber; the pulverized coal reducibly burns in the internal burning chamber, so the pulverized coal flow enters a hearth in the form of high-temperature pulverized coal burning flame to improve the burning stability of the pulverized coal; meanwhile, the reducing burning can also convert a nitrogen element into a reducing intermediate product, so that fuel type nitrogen oxides are prevented from being produced.

Owner:YANTAI LONGYUAN POWER TECH

A kind of deep denitration combustion method of hedging boiler

ActiveCN106247320BReduce concentrationLower emission valueCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustionFlue gas

The invention discloses a face-fired boiler advanced denitration burning method. The method comprises the following steps: fire coal is sent to a hearth through primary air in the primary air nozzles of a plurality of turbulent burners in each of layers of turbulent burners arranged on a front wall and a rear wall and is burnt, secondary air is introduced through secondary air nozzles of the turbulent burners, over fire air is introduced through one or more layers of over fire air nozzles on the front wall and the rear wall, the primary air and the secondary air on the front wall and the rear wall are oppositely introduced, the excess air coefficient range of the main burning area of the turbulent burners is 0.5-1.05, and the fire coal undergoes low oxygen burning; the excess air coefficient range of the over fire area of the over fire air nozzles is 1.05-1.3, and oxygen rich burning is carried out; and one or more layers of an amino reduction inhibitor are injected to the hearth under the uppermost over fire layer to reduce nitrogen oxides in flue gas in high temperature environment in the hearth and inhibit generation of new nitrogen oxides. The face-fired boiler advanced denitration burning method has the advantages of substantial reduction of the nitrogen oxide discharge value of the outlet of the hearth, realization of ultralow discharge, no strict temperature window or catalyst, great reduction of the denitration cost, and prevention of high temperature corrosion of water screens in the boiler.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP +1

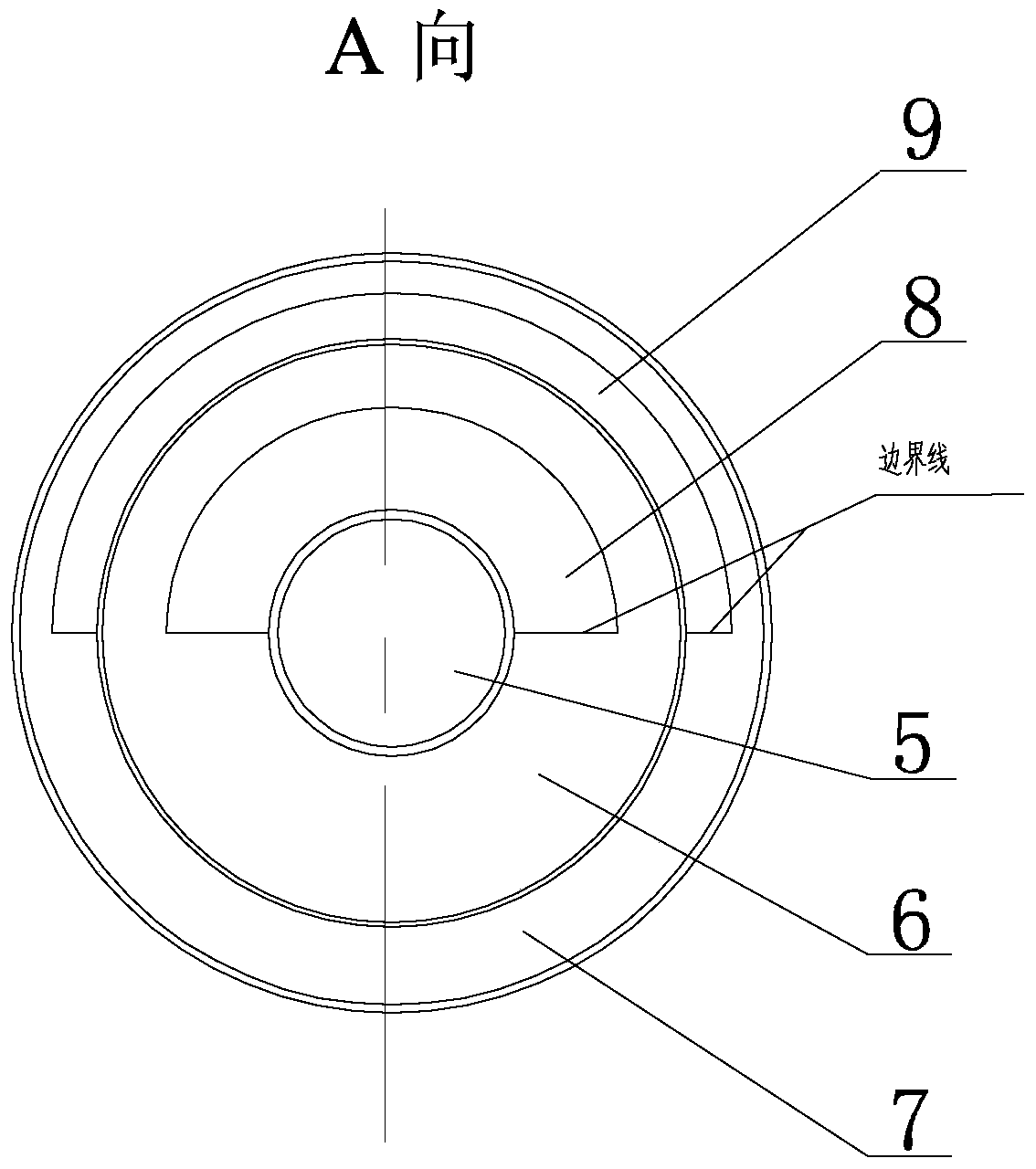

A swirl pulverized coal burner with secondary air offset for w-flame boiler

ActiveCN105423294BGood for early ignitionImprove flame stabilityPulverulent fuel combustion burnersCombustion apparatusCombustion chamberSlag

Disclosed is a secondary air offset whirl pulverized coal burner for a W flame boiler. The problems of high NOx discharge amount, high fly ash combustible matter content, slag-bonding to water walls of front and back walls of a lower combustion chamber and high temperature corrosion of the W flame boiler which is provided with an existing whirl pulverized coal burner on an arch are solved. A circular ring inner secondary air stop block in the circumferential direction is added in inner secondary air on a dividing cylinder of primary air and inner secondary air of the whirl pulverized coal burner; the angle of the circular ring inner secondary air stop block in the circumferential direction is 180 degrees; a circular ring outer secondary air stop block in the circumferential direction is added in outer secondary air on a dividing cylinder of the inner secondary air and the outer secondary air; the angle of the circular ring outer secondary air stop block in the circumferential direction is 180 degrees; the boundary line in the diameter direction of the circular ring inner secondary air stop block and the circular ring outer secondary air stop block is parallel to the front and back walls of the boiler; the circular ring inner secondary air stop block and the circular ring outer secondary air stop block are mounted on one side close to the center of a combustion chamber. The secondary air offset whirl pulverized coal burner is used for the W flame boiler.

Owner:HARBIN INST OF TECH

Recovery method of zirconium based amorphous alloy

ActiveCN101684522BImprove flexural strengthReduce oxygen contentProcess efficiency improvementRare-earth elementRecovery method

The invention relates to a recovery method of zirconium based amorphous alloy, comprising the following steps: a. rust removal, oxide removal and degreasing treatment are carried out to a zirconium based amorphous alloy scrap; b. the processed scrap and additives containing rare earth elements are mixed according to proportion, and the mixture is vacuum-melted; c. the temperature of the melted mixture is reduced to 100-200DEG C above the melting point of the mixture, and then the temperature is insulated; d. the mixture is vacuum-melted again, the melted mixture is injected into a copper moldand is cooled under the protective gas, thereby obtaining the amorphous alloy ingot. The recovery method of zirconium based amorphous alloy can effectively reduce the oxygen content in the amorphous alloy scrap; meanwhile, the bending strength of an amorphous alloy sample can be effectively improved, so as to increase the critical size of the amorphous alloy sample.

Owner:CHANGSHU YISHENG COMMODITY

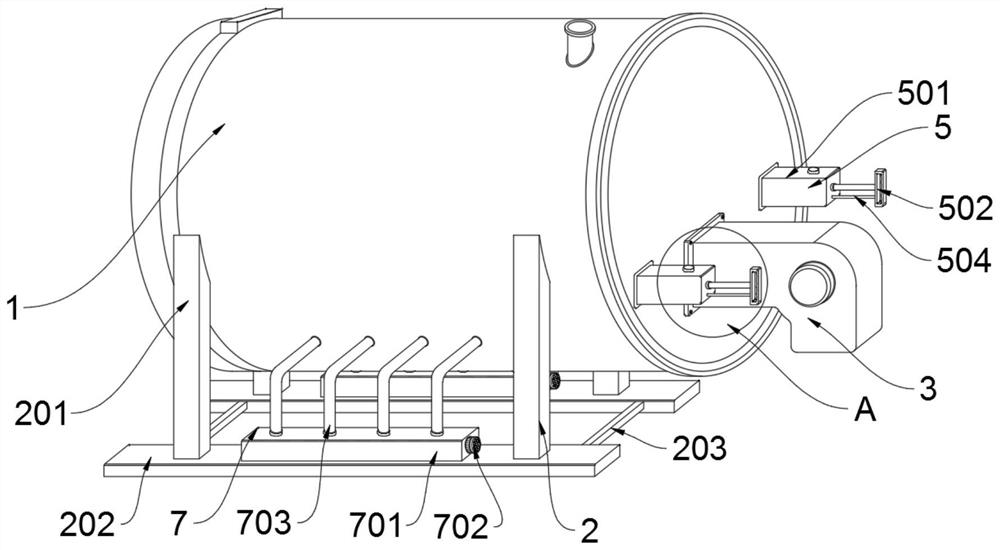

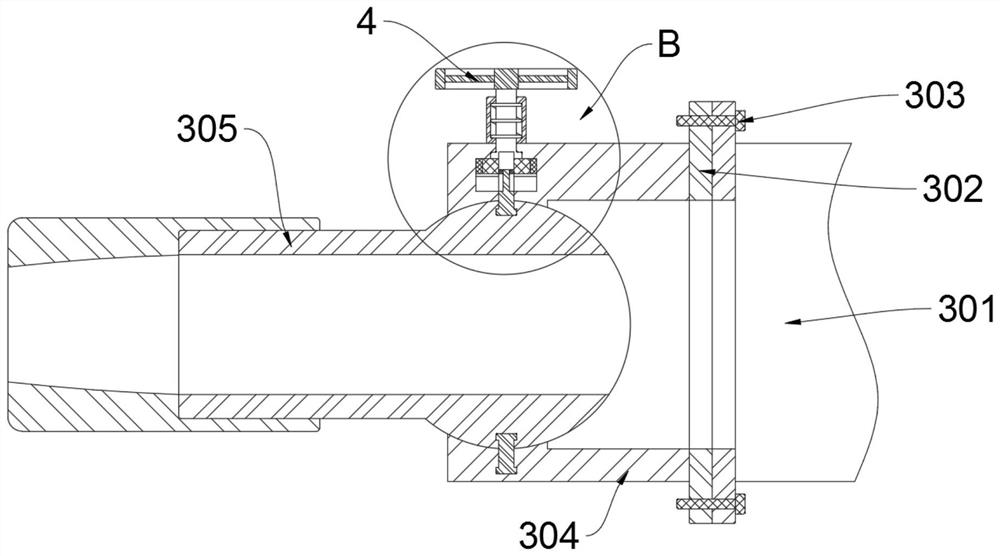

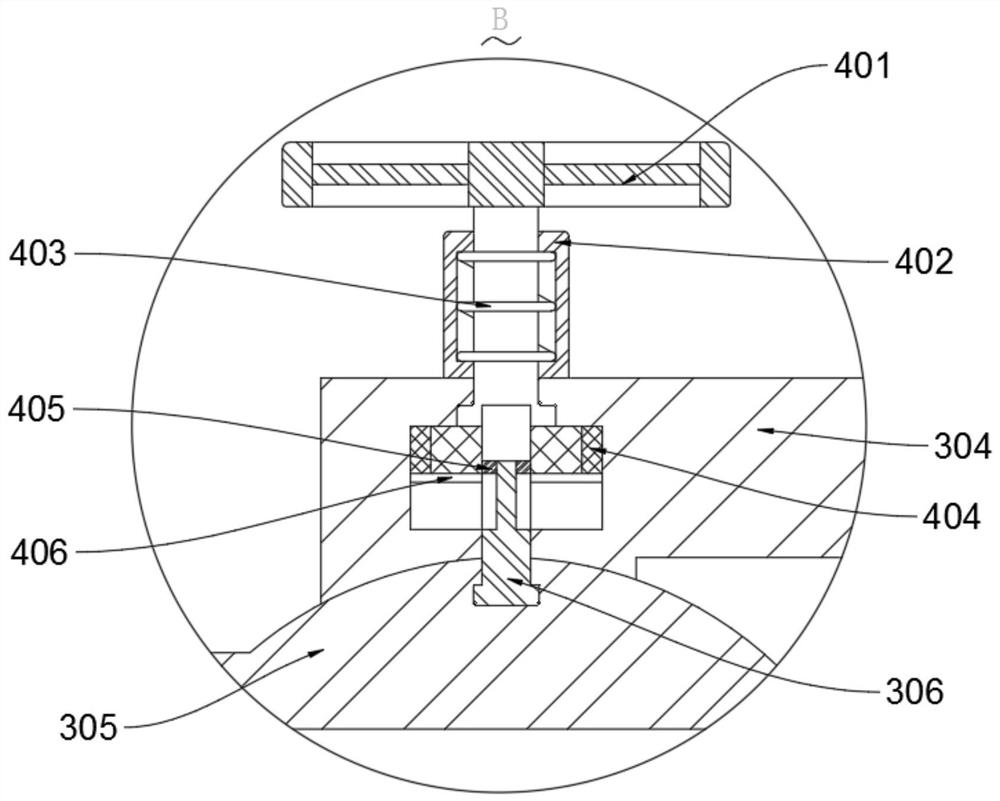

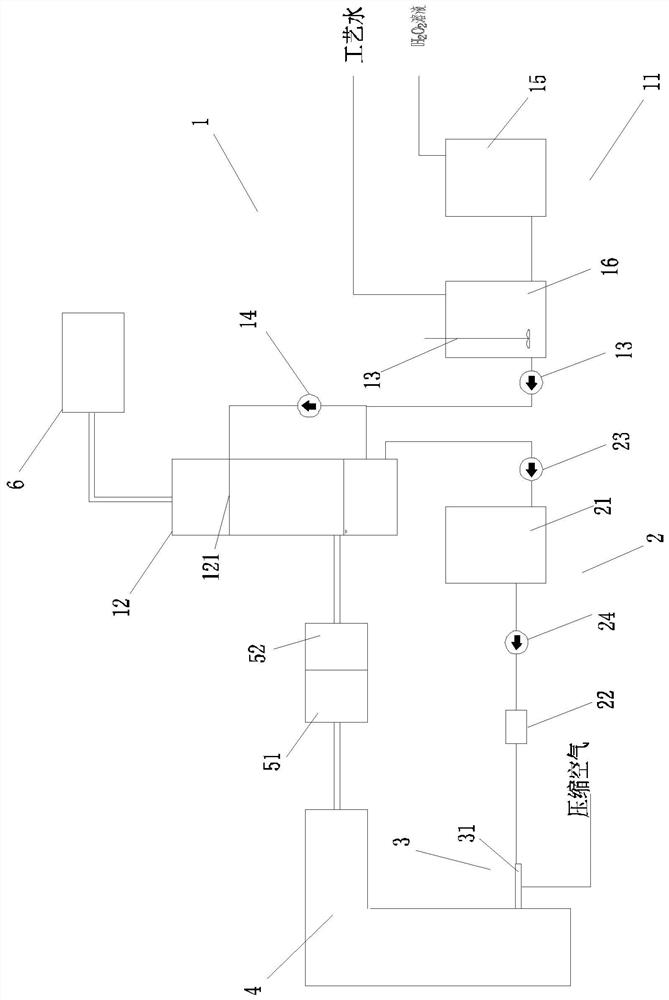

Once-through boiler capable of preventing high-temperature corrosion of water cooling wall

PendingCN114198771AReduce high temperature corrosionReduces impact and corrosionCombustion using liquid and pulverulent fuelCasings/liningsProcess engineeringFuel oil

The invention relates to the technical field of boilers, in particular to a once-through boiler capable of preventing high-temperature corrosion of a water cooling wall, which comprises a boiler body, a supporting mechanism, a combustion mechanism, a combustion-supporting mechanism and an air distribution mechanism are arranged on the boiler body, an adjusting mechanism is arranged on the combustion mechanism, a sealing mechanism is arranged on the combustion-supporting mechanism, and the adjusting mechanism is arranged on the combustion mechanism. The fuel injection direction of the combustion mechanism can be adjusted in advance, flame smoke generated by fuel is prevented from directly impacting the water cooling wall, and high-temperature corrosion to the water cooling wall is reduced. Through cooperation of the combustion-supporting mechanism and the sealing mechanism, fuel oil can be conveniently added into a hearth of the boiler body for supporting combustion under the condition that the coal quality is poor, more smoke generated by insufficient combustion is avoided, and then impact and corrosion to a water cooling wall tube are reduced; a layer of parallel air film can be formed on the surface of the water-cooled wall through the arranged air distribution mechanism, impact of smoke flow perpendicular to the surface of the water-cooled wall is reduced, and high-temperature corrosion to the water-cooled wall is further reduced.

Owner:HUANENG WUHAN POWER GENERATION CO LTD

Waste incineration power plant sulfur recycling device and anti-corrosion method thereof

InactiveCN111888912AMeet the purpose of ultra-low emissionLow costGas treatmentDispersed particle separationFlue gasWater chlorination

The invention discloses a waste incineration power plant sulfur recycling device, and relates to the field of high-temperature corrosion protection. The device comprises a hydrogen peroxide deacidification system, a sulfuric acid storage and conveying system, an injection system and an incinerator, the hydrogen peroxide deacidification system comprises a hydrogen peroxide preparation and supply system and a wet tower system; the sulfuric acid storage and conveying system comprises a sulfuric acid buffer tank; the injection system comprises a spray gun. Sulfuric acid generated in the deacidification process is sprayed into the incinerator through the double-fluid nozzle, the concentration of alkali metal in flue gas fly ash can be reduced, meanwhile, the chlorine-sulfur ratio of an alkali metal compound is reduced, then the high-temperature corrosion effect of chlorate on a metal heating surface is reduced, the service life of the heating surface is prolonged, and the operation time ofa power plant is prolonged. The invention further relates to an anti-corrosion method of the waste incineration power plant sulfur recycling device.

Owner:龙净能源发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com