Coal blending combustion optimization method and device

An optimization method and technology for coal blending, applied in the field of coal blending and blending, can solve problems such as boiler coking, and achieve the effects of reducing high temperature corrosion, reducing coking and avoiding coking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

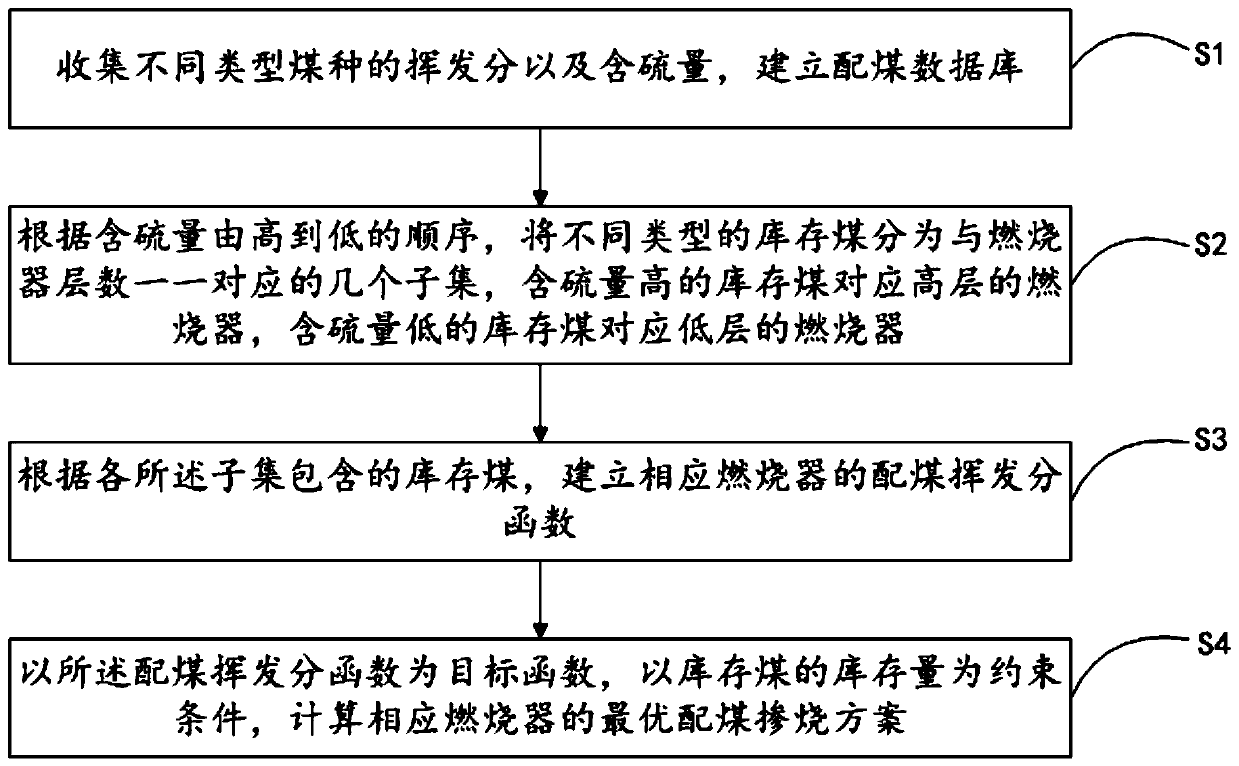

[0015] like figure 1 As shown, Embodiment 1 of the present invention provides a coal blending and blending optimization method, comprising the following steps:

[0016] S1. Collect the volatile matter and sulfur content of different types of coal, and establish a coal blending database;

[0017] S2. According to the order of sulfur content from high to low, different types of stock coal are divided into several subsets corresponding to the number of burner layers. The stock coal with high sulfur content corresponds to the burner of the high layer. Low inventory coal corresponds to low-level burners;

[0018] S3. According to the stock coal included in each subset, establish a coal blending volatile function of the corresponding burner;

[0019] S4. Taking the volatile content function of the coal blending as an objective function and taking the inventory of coal as a constraint condition, calculate an optimal coal blending and burning scheme for the corresponding burner.

...

Embodiment 2

[0056] Embodiment 2 of the present invention provides a coal blending and blending optimization device, including a processor and a memory, and a computer program is stored in the memory. When the computer program is executed by the processor, the coal blending provided by the above embodiment is realized. Blending optimization method.

[0057] The coal blending and blending firing optimization device provided in this embodiment is used to realize the coal blending and blending firing optimization method. Therefore, the technical effects of the coal blending and blending firing optimization method are also provided by the coal blending and blending firing optimization device, which will not be repeated here.

Embodiment 3

[0059] Embodiment 3 of the present invention provides a computer storage medium on which a computer program is stored. When the computer program is executed by a processor, the method for optimizing coal blending and blending combustion provided by the above embodiment is realized.

[0060] The computer storage medium provided in this embodiment is used to implement the coal blending and blending firing optimization method, so the technical effects of the coal blending and blending firing optimization method are also provided by the computer storage medium, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com