Emission control method of PM2.5 of fuel coal

An emission control and coal-fired technology, applied in the field of coal-fired flue gas treatment, can solve the problems of boiler superheater or reheater burst pipes, and the unsatisfactory dust removal effect of pulverized coal combustion. The effect of investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

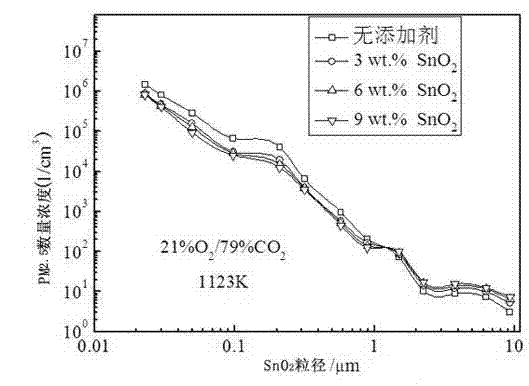

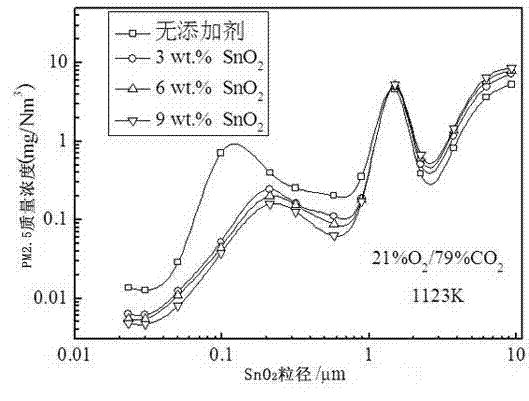

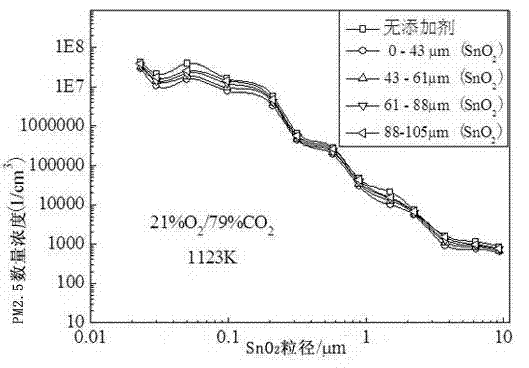

[0026] A method for controlling the emission of coal-fired PM2.5 of the present invention, the steps are:

[0027] Step 1. Grinding the Sn-based removal agent into a particle size of 54-105 The particles of the Sn-based scavenger are mixed with the coal, the addition of the Sn-based scavenger is 3-6wt% of the amount of coal burned, and the Sn-based scavenger is SnO 2 , Sn(OH) 2 or SnCO 3 , or SnO 2 , Sn(OH) 2 or SnCO 3 A mixture of any two or three of them, the amount of Sn-based removal agent added is adjusted according to the concentration of fly ash in the flue gas after the dust collector.

[0028] Step 2: send the coal to the coal mill for grinding, send the ground coal into the boiler furnace, and send the Sn-based removal agent into the boiler furnace along with the secondary air from the secondary air port of the boiler Combustion, the air required for combustion is sent into the boiler furnace by the blower;

[0029] Step 3: After combustion, the flue gas mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com