Furnace smoke extraction lignite drying system of direct-blowing pulverizing system of double-inlet and double-outlet steel ball coal mill

A steel ball coal mill and pulverizing system technology, applied in the direction of drying gas arrangement, drying, drying machine, etc., can solve the problems of unit shutdown, failure to implement, and increase in power consumption of the plant, so as to achieve little impact on the flow field, Easy-to-implement, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the drawings and embodiments.

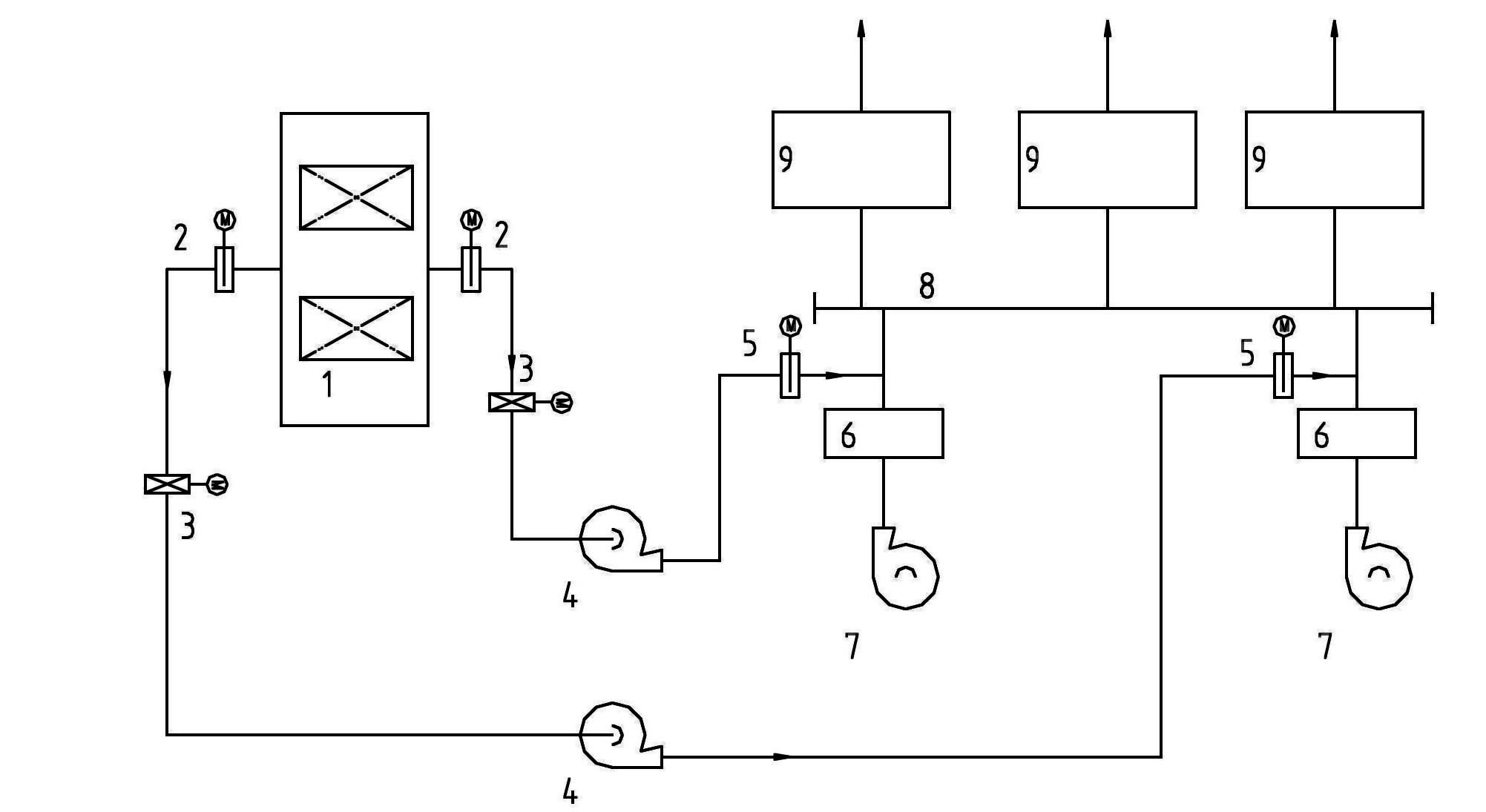

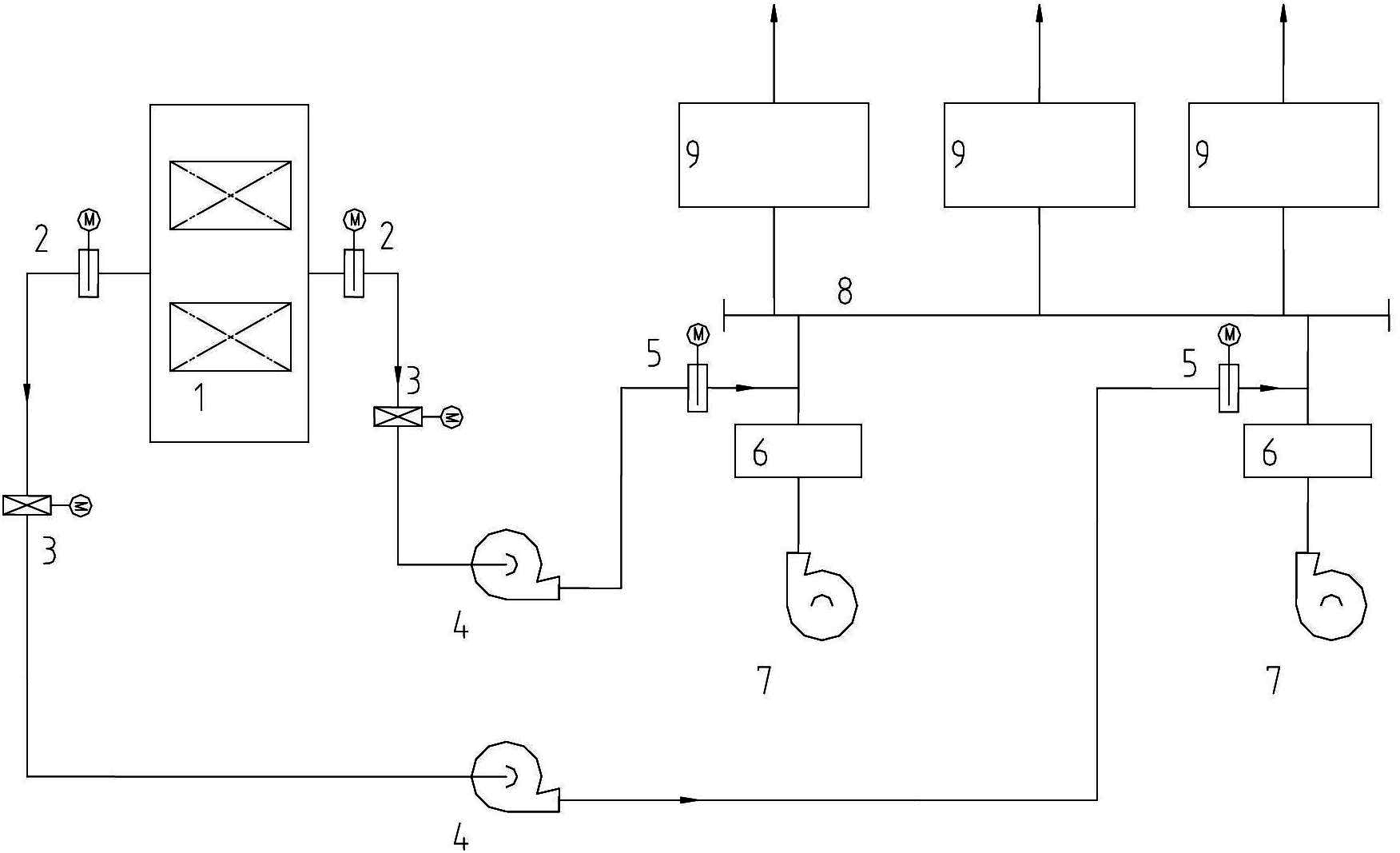

[0023] Such as figure 1 As shown, it includes two recirculation pipelines connected to the inlet flue of the economizer 1 in the shaft at the tail of the boiler. Each recirculation pipeline includes a recirculation fan 4, the recirculation fan 4 and the economizer 1 inlet An electric flapper door I2 and an electric damper 3 are arranged at the flue connection; an electric flapper door II5 is arranged at the connection of the recirculation fan 4 and the hot primary air duct 8.

[0024] The medium-temperature furnace smoke is extracted from the inlet flue of the economizer 1 on the left and right sides of the boiler tail shaft, pressurized by the recirculation fan 4 arranged on the floor of the boiler house, and then added to the pulverizing system through the hot primary air duct 8. The pulverizing system after the access point of the hot primary air duct 8 remains uncha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com