Multifunctional self-oscillation flow jet flow drill

A self-excited oscillating jet, multi-functional technology, applied in vibration drilling, liquid/gas jet drilling, etc., can solve the problems of short service life, shallow drilling depth, low work efficiency, etc., and achieve long drilling depth, Increased porosity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

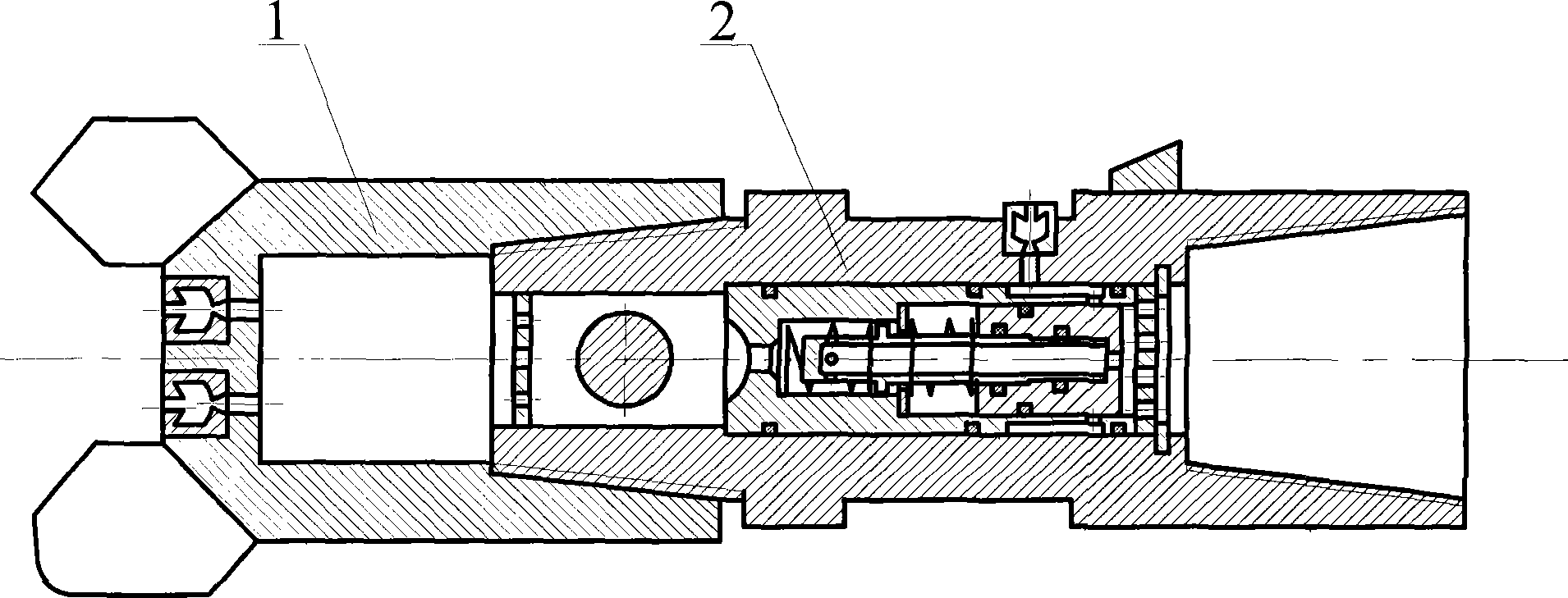

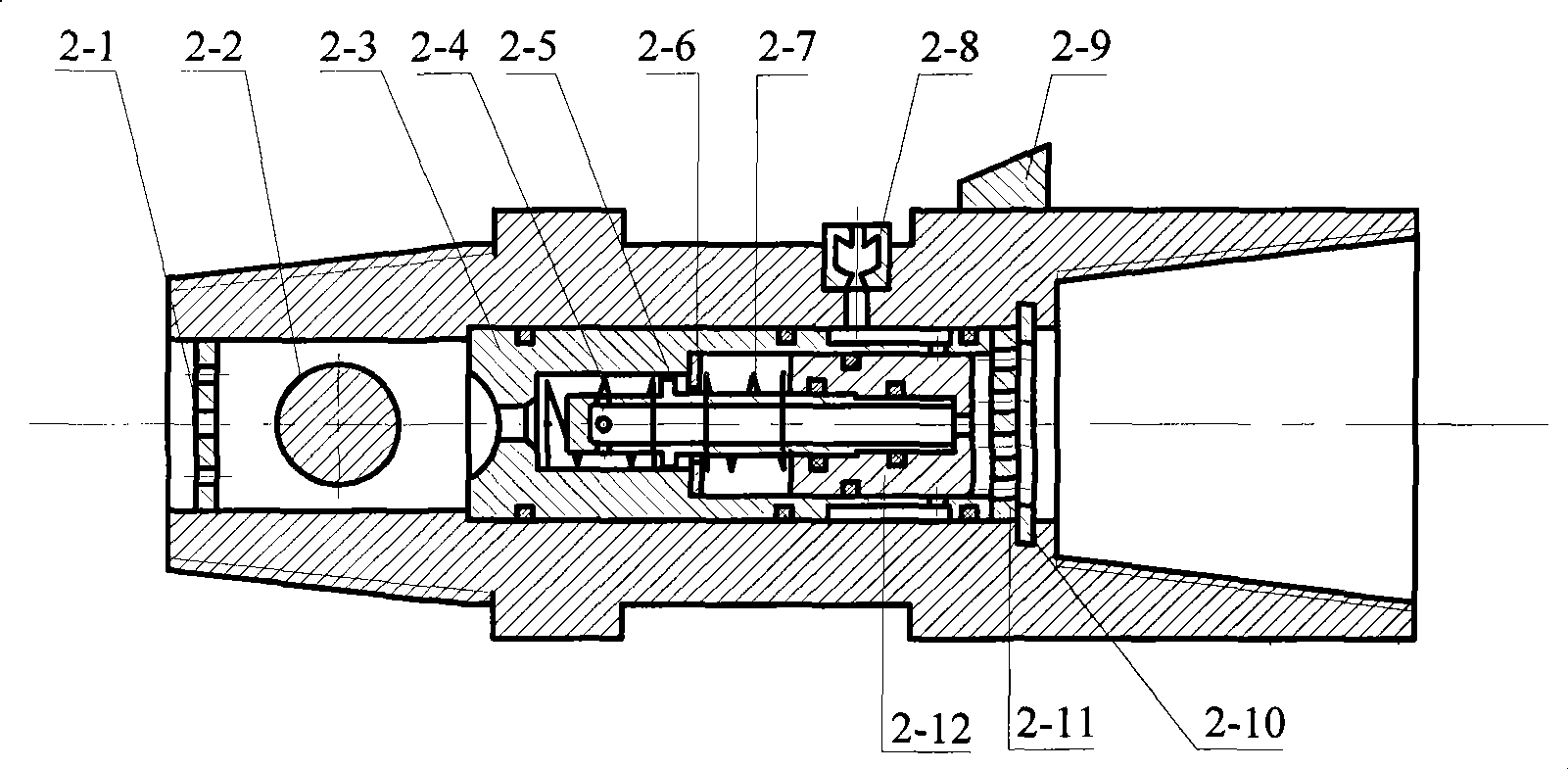

[0034] combine Figure 1 to Figure 12 , the implementation of the multifunctional self-excited oscillating jet drill bit is now described:

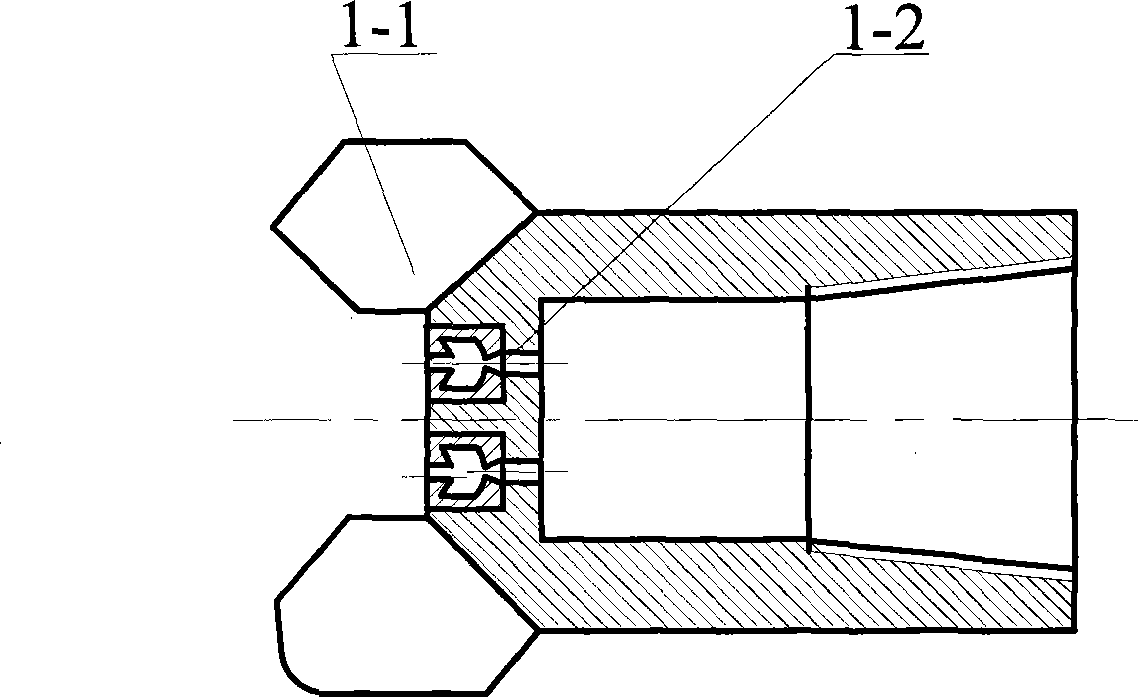

[0035] The multifunctional self-excited oscillating jet drill includes a front end drill 1 with an axial nozzle 1-1 and a cutting head 2 with a radial nozzle 2-8.

[0036] combine image 3 and Figure 4 It can be seen that the cutting head 2 is a hollow structure that runs through front and back, and there are crushing blades 2-9 on the outer periphery of the tail of the cutting head. Both ends of the cavity are provided with a front-end filter sheet 2-1 and a rear-end filter sheet 2-11, see Figure 5 and Figure 11 , to prevent cinders around the multifunctional self-excited oscillating jet drill bit from entering the inside of the drill bit during the working process, and the front part is provided with a pressure-holding check valve core 2-2, see Figure 6 , to prevent the pressure water ejected from the axial nozzle 1-1 from flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com