Internal circulation fluidized bed garbage combustion device having melt sticking dechlorination function

A waste incineration and internal circulation technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of increased investment costs, operational difficulties, large and complex systems, etc., and achieve the effect of reducing dioxin pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

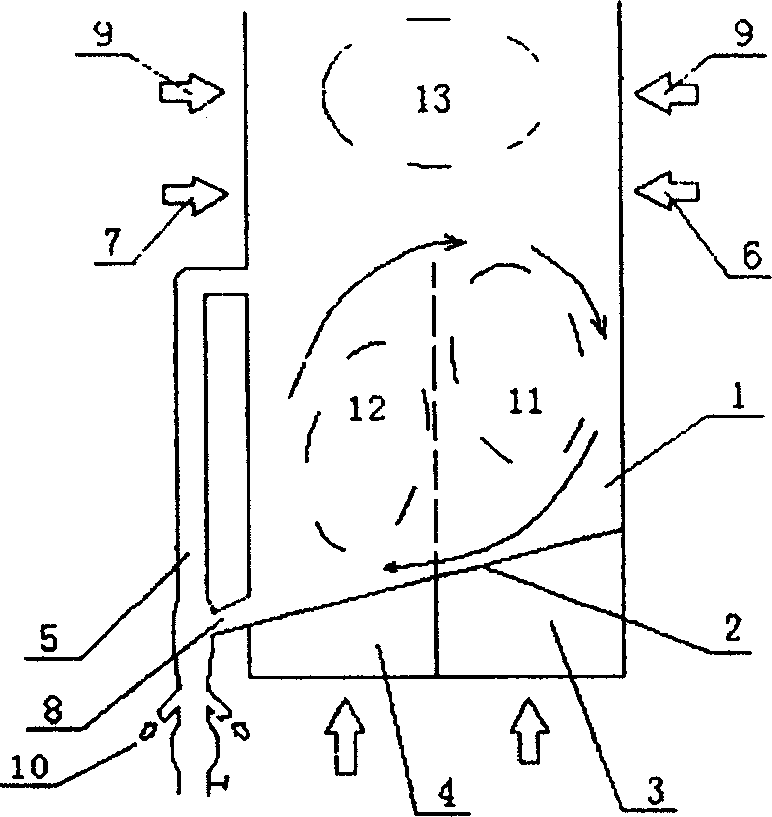

[0009] Such as figure 1 As shown, the present invention includes: an internal circulating fluidized bed furnace 1, an inclined non-uniform air distribution plate 2, a low-speed primary air chamber 3, a high-speed primary air chamber 4, a riser 5, a waste fuel feed port 6, and a dechlorination agent supply Material port 7, slag discharge port 8, secondary air inlet 9, sorting air inlet 10, pyrolysis zone 11, combustion zone 12, burnout zone 13. The connection relationship is as follows: the bottom of the inner circulating fluidized bed furnace 1 is an inclined non-uniform air distribution plate 2; the lower part of the inclined non-uniform air distribution plate 2 is provided with a low-speed primary air chamber 3 and a high-speed primary air chamber 4; according to the air distribution plate 2 Depending on the wind speed, the inner circulating fluidized bed furnace 1 is divided into a low-speed wind area and a high-speed wind area. In the hot state, it is the pyrolysis area 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com