Waste incineration power plant sulfur recycling device and anti-corrosion method thereof

A technology of waste incineration and recycling, which is applied to the anticorrosion of sulfur recycling devices in waste incineration power plants and the field of sulfur recycling devices in waste incineration power plants. Corrosion effect, avoid adverse effects, increase operating time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand through the description.

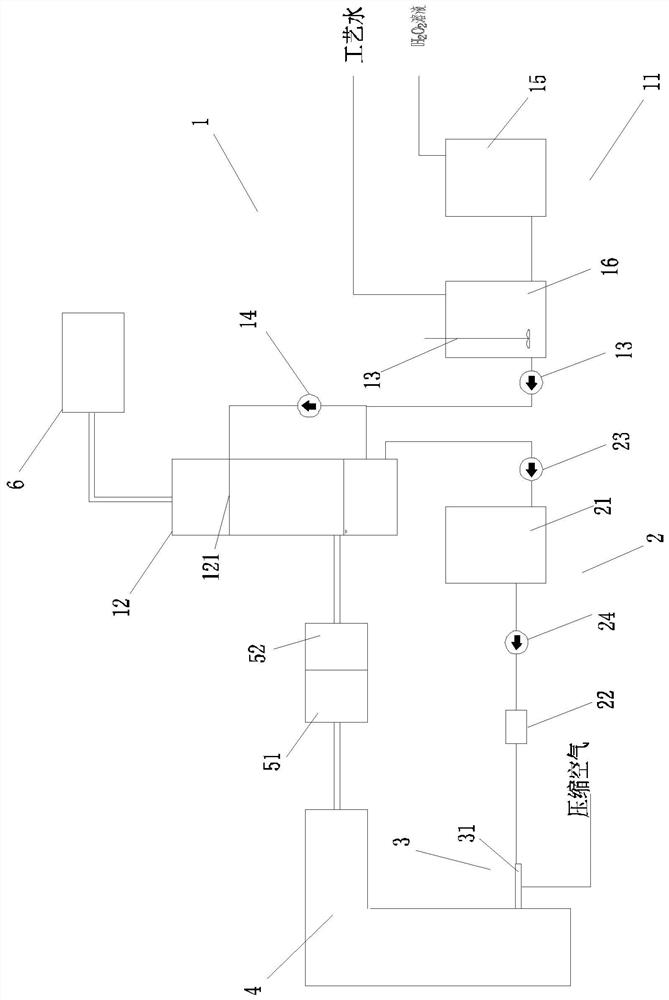

[0035] Referring to the accompanying drawings, it can be seen that the sulfur recycling device of the waste incineration power plant is characterized in that it includes a hydrogen peroxide deacidification system 1, a sulfuric acid storage and delivery system 2, an injection system 3 and an incinerator 4;

[0036] The hydrogen peroxide deacidification system 1 includes a hydrogen peroxide preparation supply system 11 and a wet tower system 12; the hydrogen peroxide preparation supply system 11 is connected to the lower side of the wet tower system 12 through a hydrogen peroxide supply pump 13, and the lower side of the wet tower syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com