Energy-saving start method of oxygen generator

A start-up method and oxygen generator technology, applied in the direction of oxygen preparation, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of high cost, long time, low work efficiency, etc., to save electricity consumption costs, save electricity The effect of saving energy consumption and saving maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

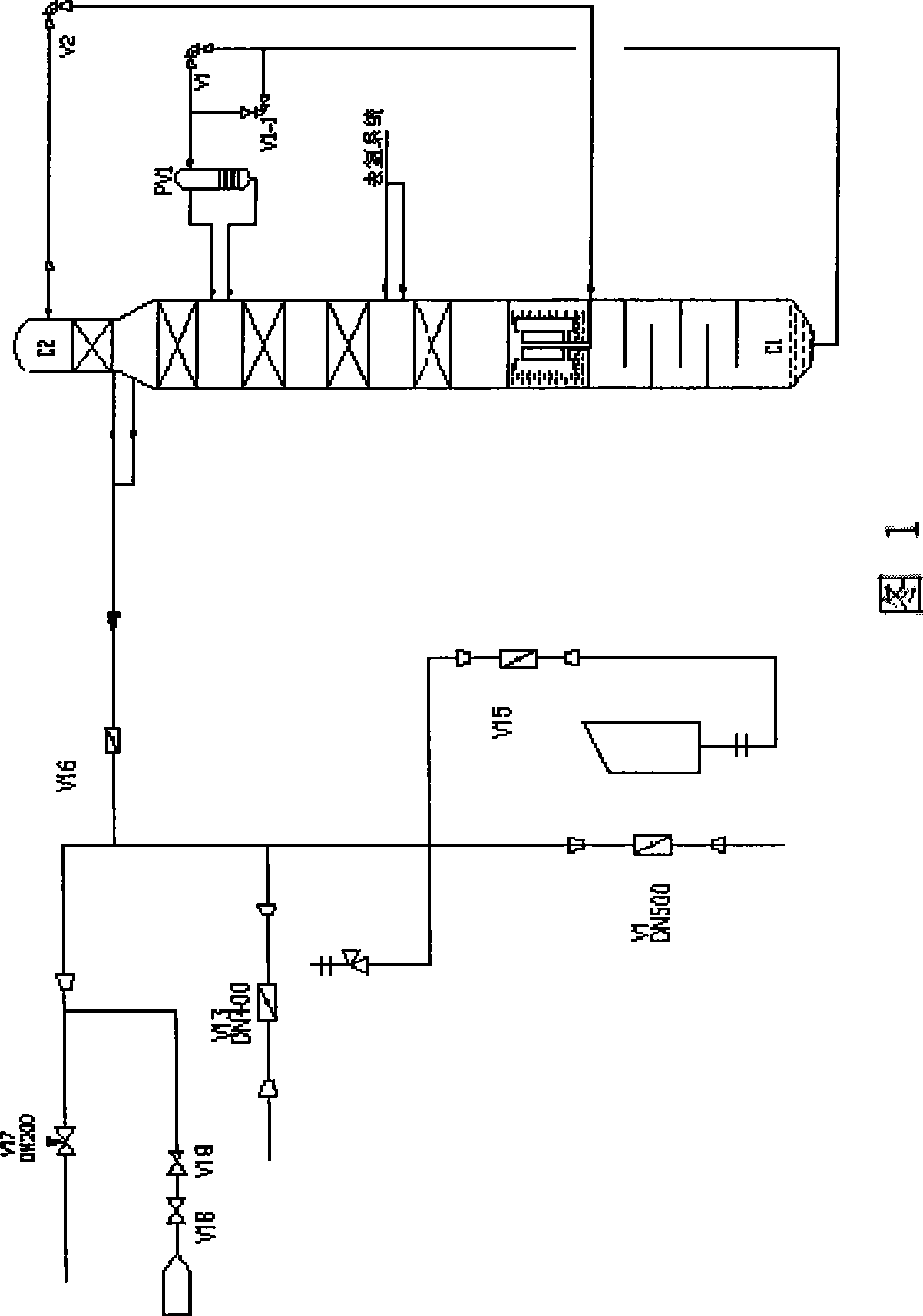

[0026] It can be seen from Figure 1 that the first use of low-pressure nitrogen in the pipe network to heat and purge the air separation system is equivalent to shortening the start-up time of the oxygen generator by about 36 hours.

[0027] The pressure of the low-pressure nitrogen pipe network is about 0.73MPa, and the 2#23500 oxygen generator starts to use low-pressure nitrogen to heat the air separation system.

[0028] Nitrogen in the low-pressure pipe network enters the molecular sieve flow path from the upper tower C2 to fill the upper tower C2. The specific flow path is: low-pressure nitrogen in the pipe network→low-pressure nitrogen into the sewage nitrogen system stop valve V18 and pressure reducing valve V19→V16 (contaminated nitrogen is removed Molecular sieve purification system) → upper tower C2 and argon system → V1 (lower tower C1 liquid air enters upper tower C2 regulating valve), V2 (lower tower C1 liquid nitrogen enters upper tower C2 regulating valve) → lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com