Pulse feeder

A feeder and pulsation generator technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of increased loss, large uniformity of feeding speed, large contact surface between powder and hot air flow, etc. The effect of reducing the contact area, protecting the feeding hopper, and reducing the flying loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

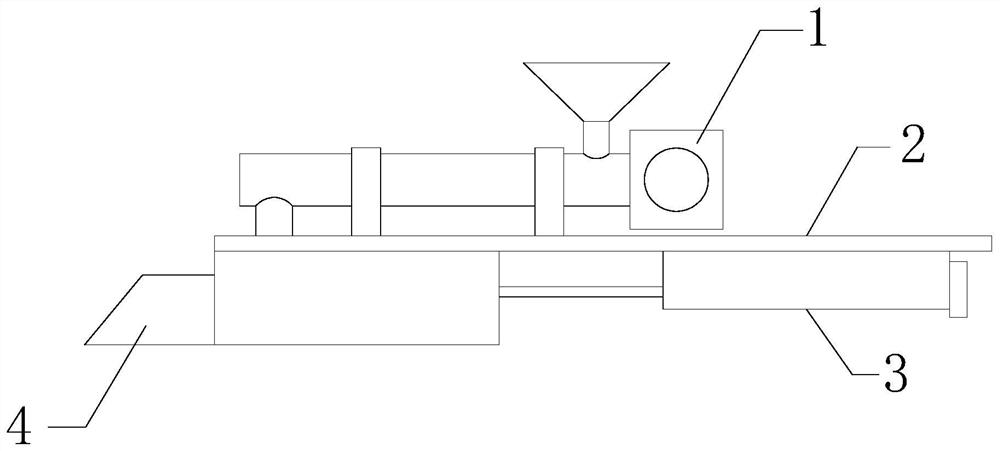

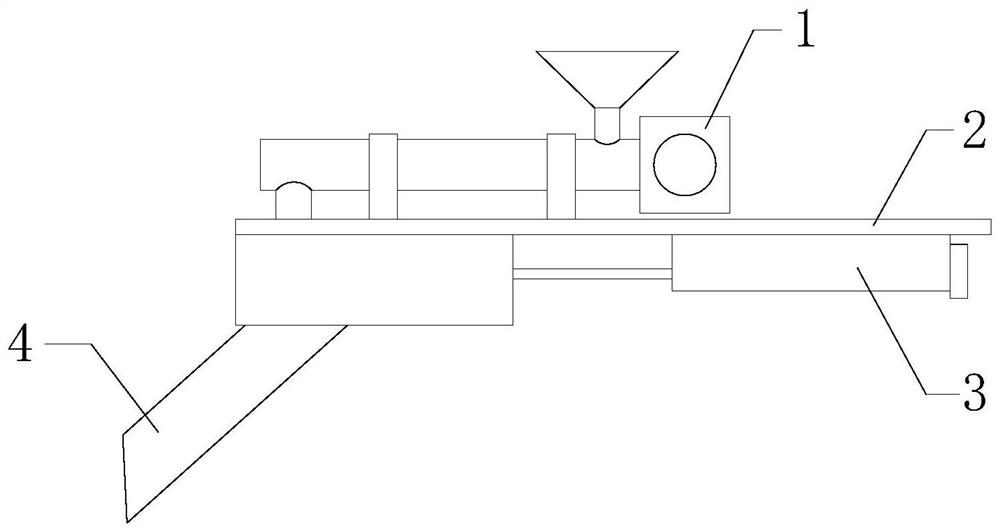

[0026] see Figure 1-Figure 2 , a pulsating feeder, including an installation platform 2, a screw feeding mechanism 1, a pulsation generator 3 and a hopper, the screw feeding mechanism 1 is arranged on the top of the installation platform 2, and the pulsation generator 3 is arranged on the installation platform 2 At the bottom, the feeding hopper 4 is used to receive the material conveyed by the screw feeding mechanism 1 and transfer it into the molten pool of the electrolytic furnace, and the feeding hopper is driven by the pulse generator 3 to move.

[0027] As an improved solution of the above solution, the screw conveying mechanism 1 can adopt one of belt conveyor, bucket conveyor, buried scraper conveyor, vibrating conveyor or pneumatic conveyor.

[0028] As an improvement on the above scheme, see image 3 The screw conveying mechanism 1 includes a hopper 103, a rotating shaft blade 105 and a first motor 101, and the top of the chute 103 is provided with an upper hopper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com