Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

737results about How to "Improve the breeding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low cost, high-wearability hypereutectic high chromium cast iron and its production method

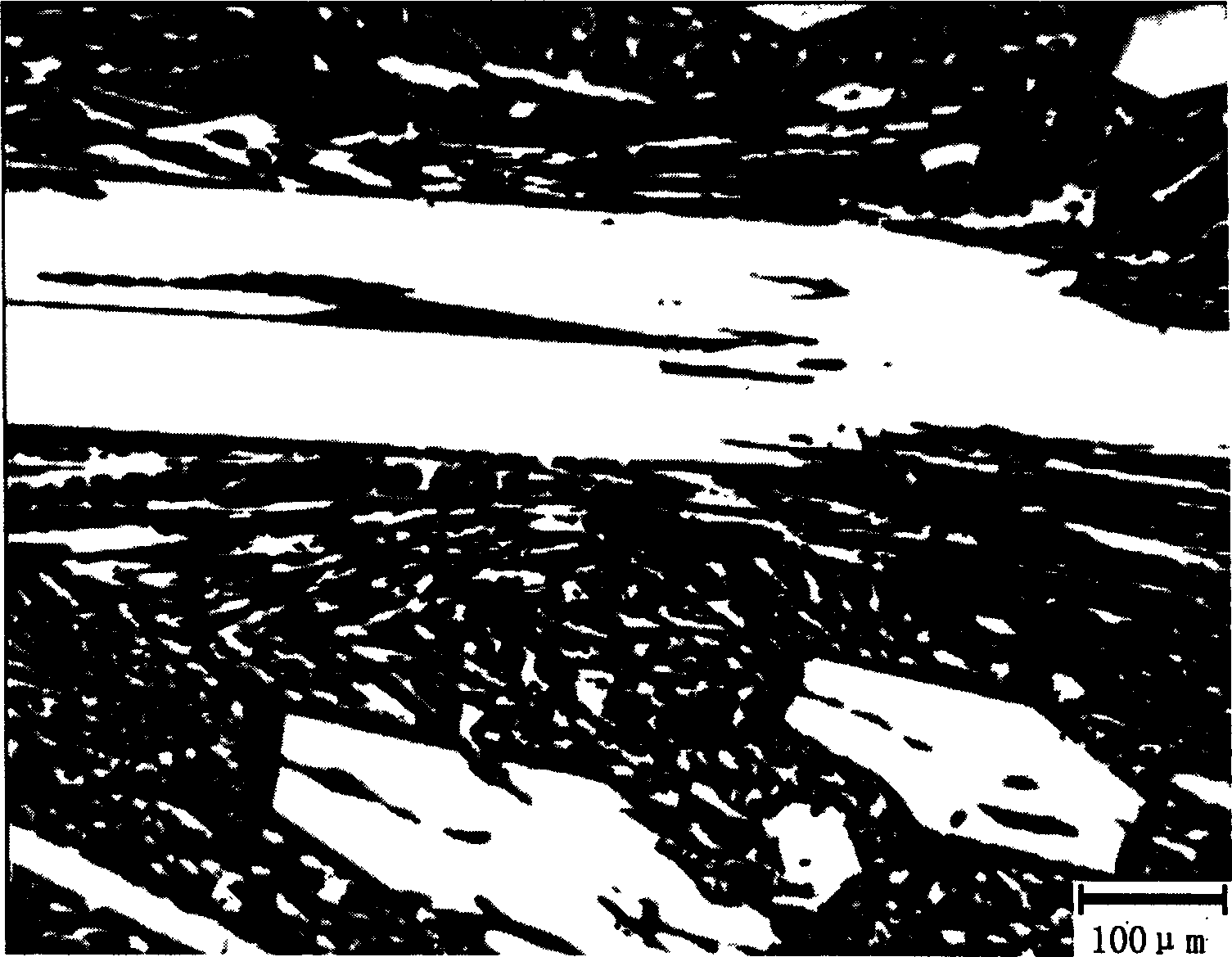

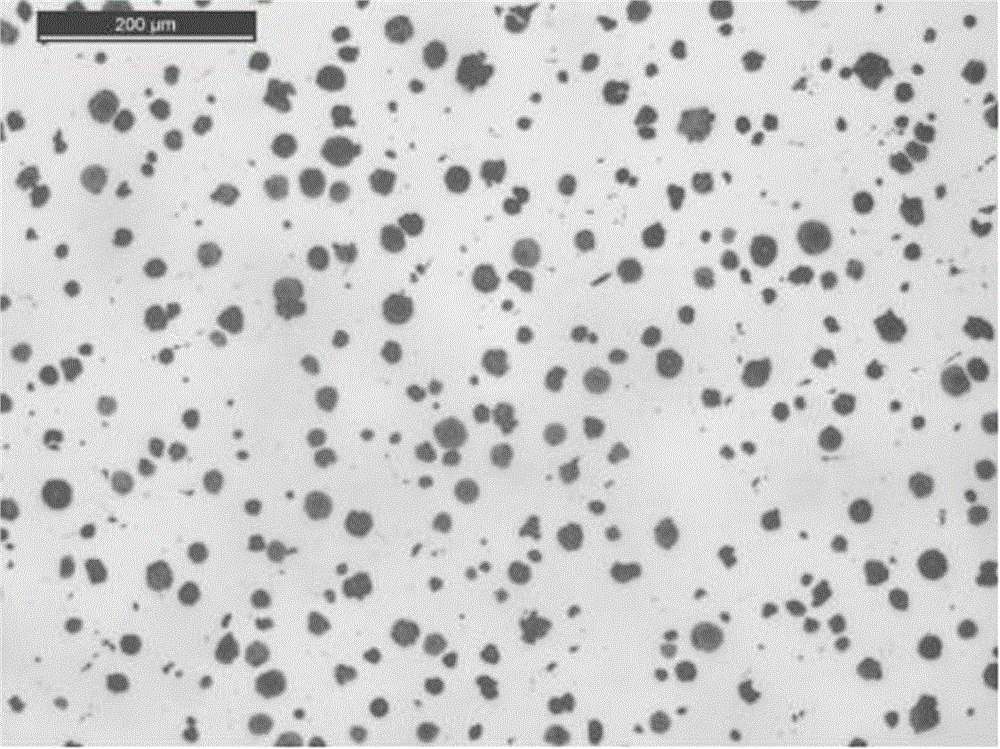

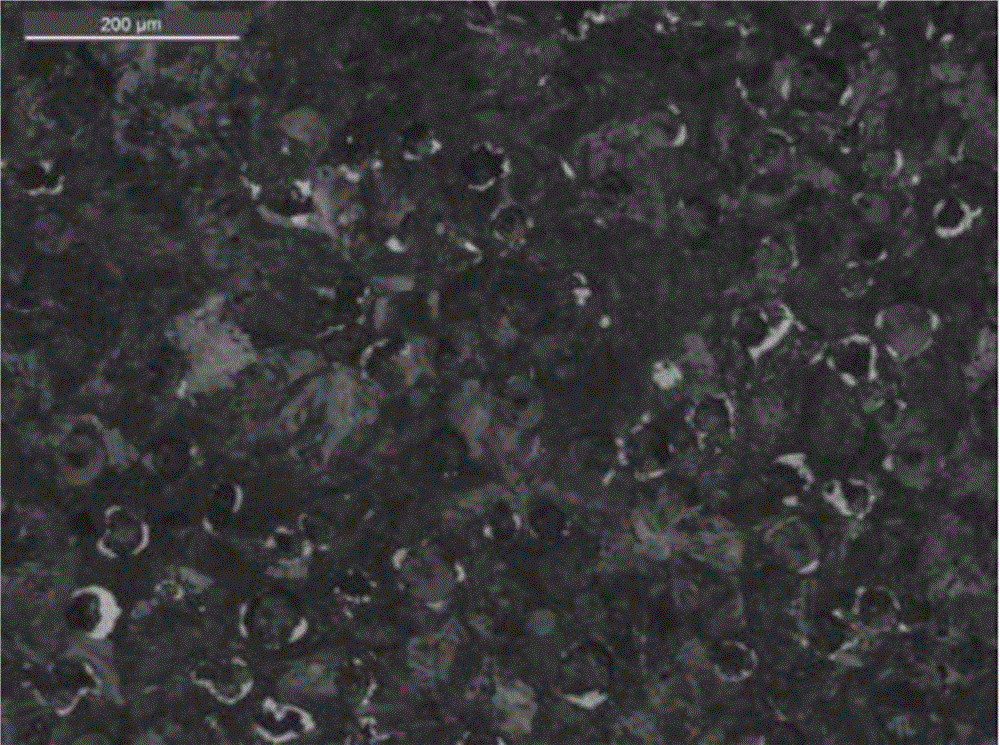

This invention provides a hypereutectic high chromium cast iron cast iron and its making method, the main components of the cast iron as follows: Cú‘3.5í½4.5úÑú¼Mnú‘1.0í½3.0úÑú¼Crú‘17í½30úÑú¼Siú‘0.5í½1.5 úÑú¼Cuú‘1.0í½2.0úÑú¼Pú‘íœ0.06úÑú¼Sú‘íœ0.06úÑú¼Niú‘íœ1úÑú¼the rest is iron. The making method is to use twice gestation transformation dealing method to thin the early produced calcium carbide, wherein the grain such as TiN and NbNin in the alloy of the inoculant can increase the uncleus quantum of the early produced calcium carbide. The rare earth, magnesium and kallium congregate on the surface of the early produced calcium carbide to make them thin and spheric. The inoculant can speed the solidification of the alloy to prohibit the early produced calcium carbide from growing to reach the aim of thinning the early produced calcium carbide. Wherein, the sediment pump overcurrent piece made by the hypereutectic high chromium cast iron cast iron has a better casting charater, resistance, and high using longevity.

Owner:XI AN JIAOTONG UNIV

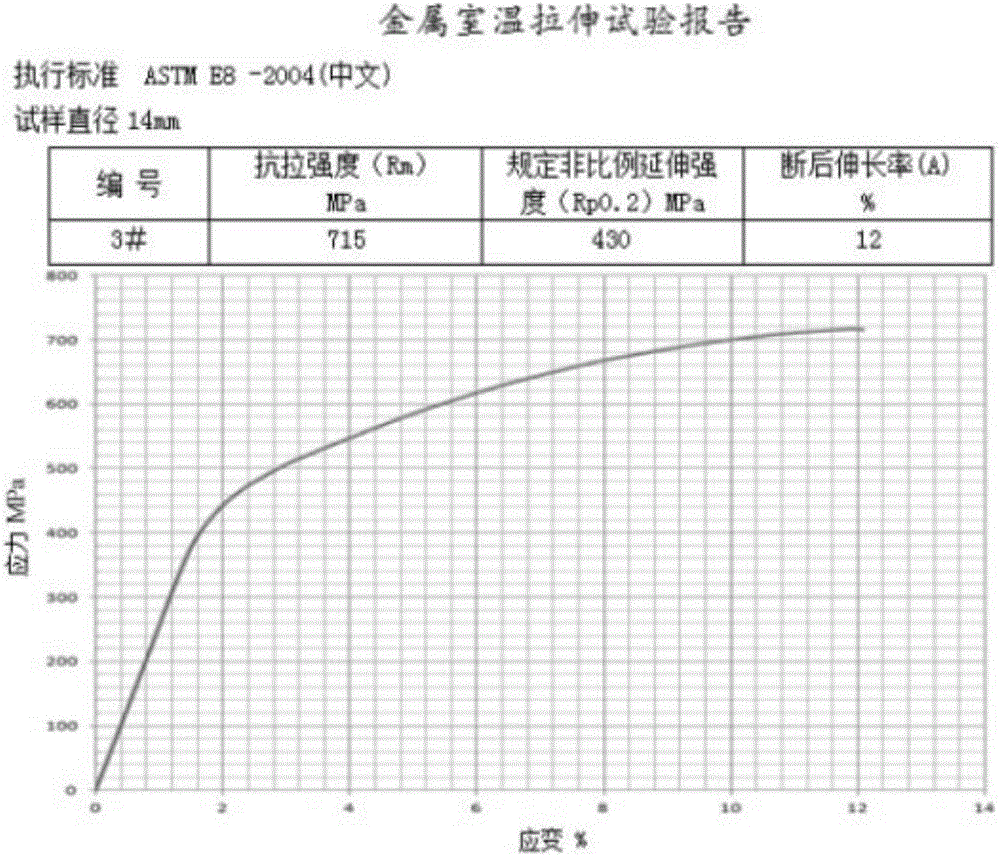

High-strength high-tenacity cast-state QT700-10 and production method thereof

ActiveCN106811676AIncrease the number ofReduce oxidation burnProcess efficiency improvementHigh intensityDuctile iron

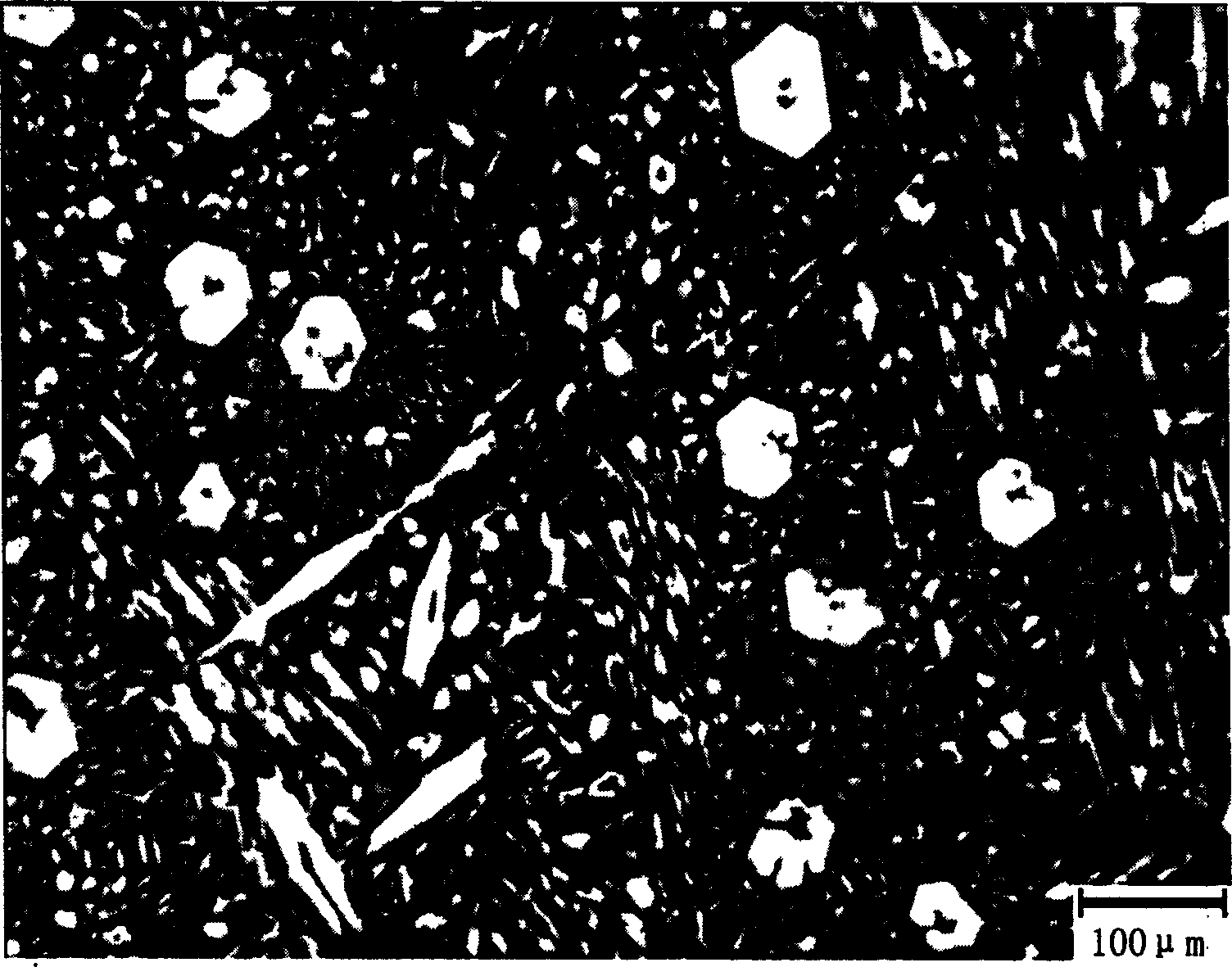

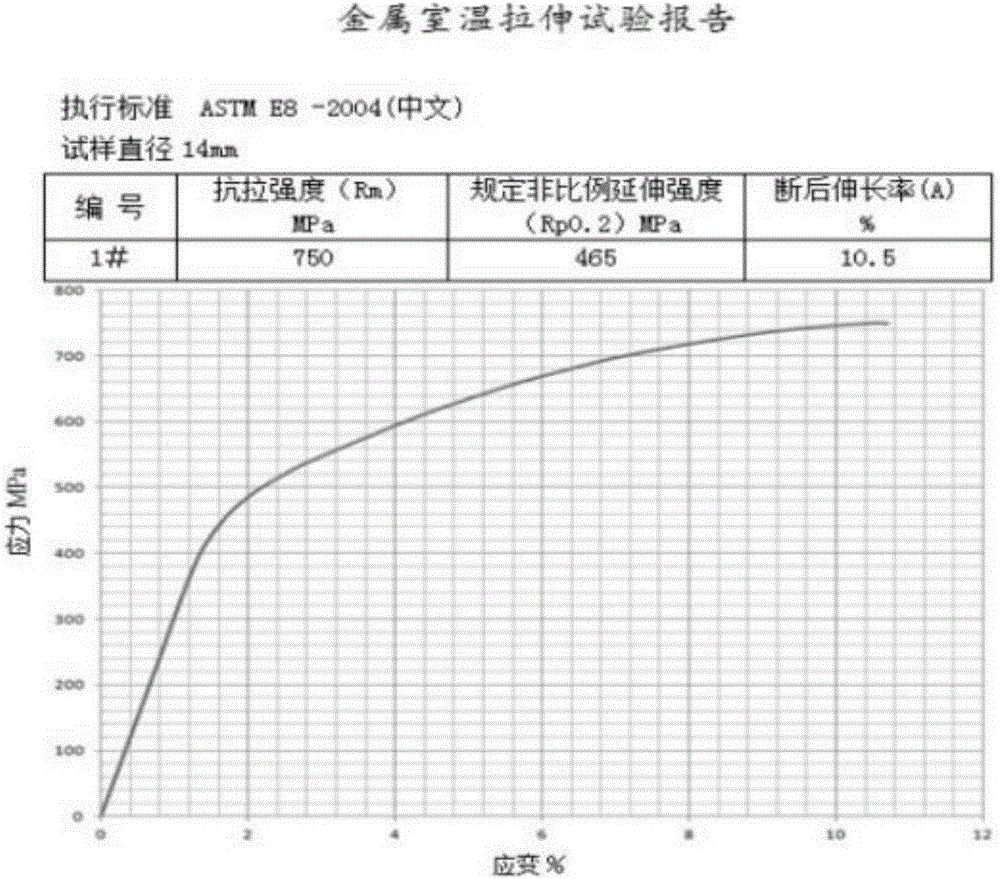

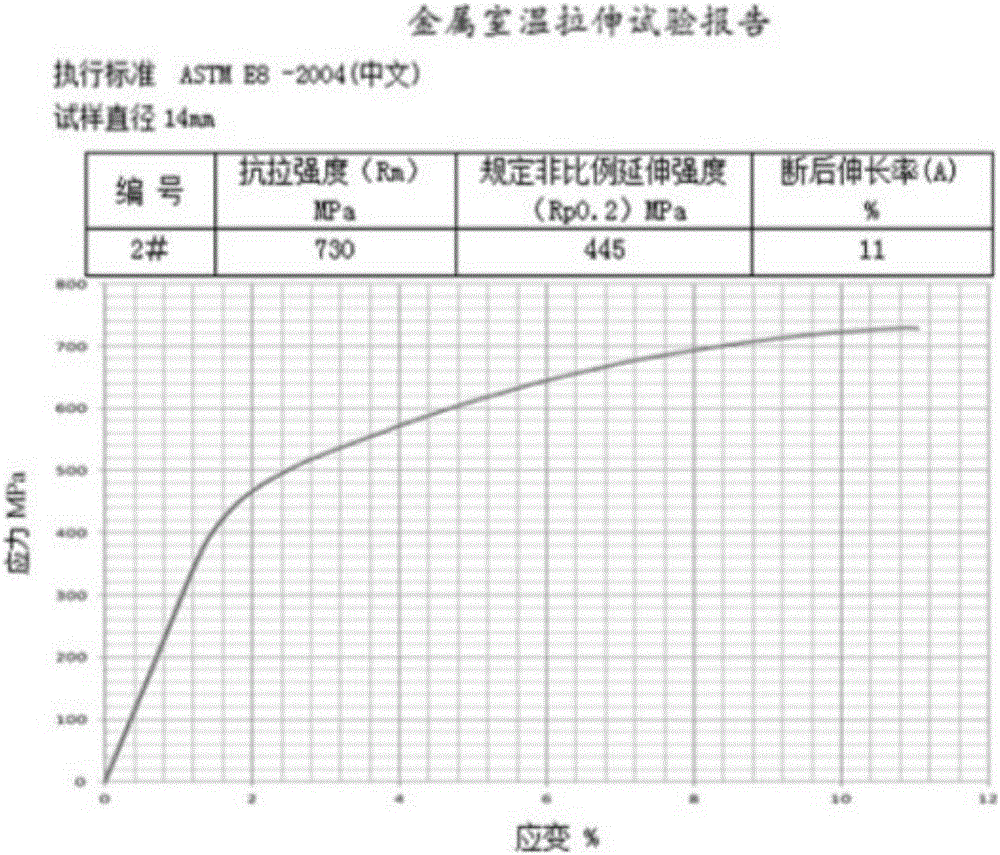

The invention belongs to the field of casting technologies and new materials and particularly relates to a high-strength high-tenacity cast-state QT700-10 and a production method thereof. Compared with ductile iron produced in the prior art, the high-strength high-tenacity cast-state QT700-10 has high strength and a high elongation rate, heat treatment is not needed, heavy metal, such as, Ni and Mo are not added in production, the tensile strength Rm in the cast state is larger than or equal to 700 MPa, the elongation rate A is larger than or equal to 10%, compared with the standard brand QT 450-10, the lowest tensile strength is improved by 55% under the same elongation rate; and compared with the standard brand QT 700-2, the lowest elongation rate is improved by four times under the same tensile strength. The high-strength high-tenacity cast-state QT700-10 can meet requirements of automobile ductile iron castings with high requirements for safety and comprehensive mechanical properties.

Owner:山东汇金股份有限公司

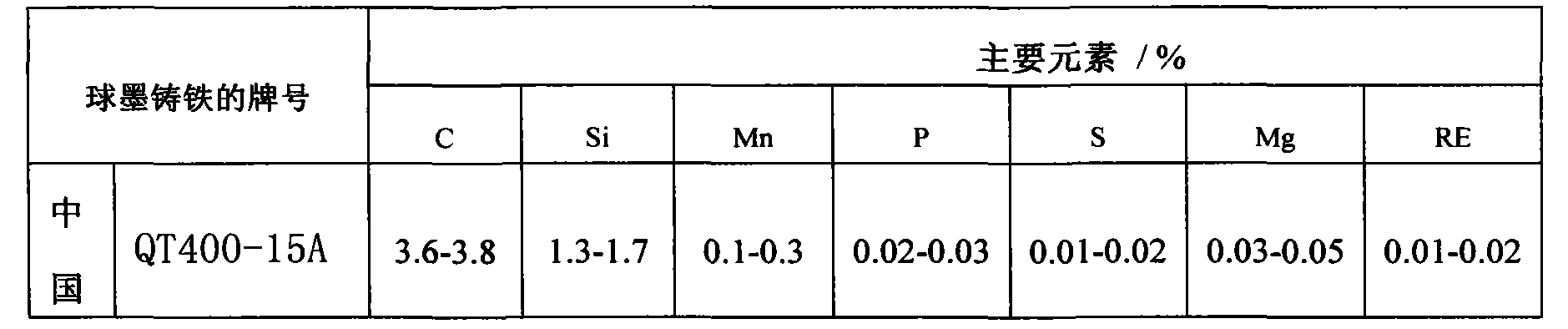

High-strength low-temperature-resisting spheroidal graphite cast iron and preparing method thereof

The invention relates to the field of spheroidal graphite cast iron, in particular to high-strength low-temperature-resisting spheroidal graphite cast iron and a preparing method thereof. The spheroidal graphite cast iron comprises, by mass percent, 3.2% to 3.5% of carbon, 2.1% to 2.3% of silicon, 0.4% to 0.5% of manganese, 0.4% to 0.6% of copper, 0.2% to 0.4% of nickel, 0.2% to 0.4% of molybdenum, 0.04% to 0.06% of magnesium, 0.05% to 0.08% of chromium, 0.005% to 0.008% of titanium, 0.002% to 0.003% of vanadium, not larger than 0.04% of phosphorus, not larger than 0.02% of sulphur and the balance iron. The preparing method of the high-strength low-temperature-resisting spheroidal graphite cast iron comprises following steps: firstly, raw materials are smelted; secondly, spheroidizing treatment and inoculation are carried out; and thirdly, heat treatment is carried out. Through reasonable arrangement of all element components, the tensile strength of the spheroidal graphite cast iron is improved, a proper nucleating agent is prepared, internal inoculation matched with inoculation in a ladle is adopted, the inoculation effect is reinforced, meanwhile, during heat treatment, the heating temperature, the heat preservation time, the cooling rate and the manner are reasonably arranged, the strength and low temperature resistance of the iron are effectively improved, the spheroidal graphite cast iron is high in strength and excellent in low temperature resistance, and the preparing method is simple and efficient.

Owner:HANSHAN COUNTY XINGDA DUCTILE IRON FACTORY

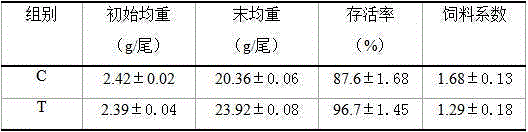

Grouper environmentally-friendly soft granulated feed and preparation method thereof

InactiveCN102178105ANutritional full priceBalanced nutritionFood processingClimate change adaptationEnvironmental resistanceEcological environment

The invention provides a grouper environmentally-friendly soft granulated feed and a preparation method thereof. The grouper environmentally-friendly soft granulated feed comprises the following nutritional components in percentage by weight: 40 to 50 percent of crude protein, 6 to 12 percent of crude fat, 8 to 15 percent of crude ash, 22 to 28 percent of carbohydrate, and 6 to 10 percent of moisture. According to the invention, the high-quality grouper environmentally-friendly soft granulated feed is studied, popularized and applied, so that the nutrition of the launched feed goes to be complete and balanced, and the palatability of the feed is good, not only can the feed digestive absorption rate of grouper be improved, but also the survival rate and growing speed of the grouper are improved, and the fish quality is improved. Therefore, non-polluted fish products are produced, and the cultivation economical benefit is improved; and the feed has active and profound significance in reducing the usage of small trash fish, lightening the sea area pollution, protecting the marine eco-environment, and promoting the sustained stable and health development of the marine fish culture industry.

Owner:福建省淡水水产研究所

Construction method of superior strains of rapid-growing crassostrea gigas

InactiveCN102742531ASpeed up the breeding processReduce breeding labor costsClimate change adaptationPisciculture and aquariaAccessory gonadOyster

The invention discloses a construction method of superior strains of rapid-growing crassostrea gigas. The construction method is characterized by comprising the following steps: A. building a breeding base population, using the shell height and the total weight as a seed selection goal, and keeping and collecting parent shellfish according to high-selective intensity as the basic parent shellfish population; B. by adopting the population continuous progeny selection, selecting a certain number of gonadal matured individuals from the preceding generation of parent shellfish population to form a succeeding generation parent shellfish population, conducting artificial insemination by adopting a post-mortem method; at the pre-maturation period, keeping and collecting the individuals with high shellfish height and high total weight according to the high selective intensity as the parent shellfish for breeding; C, conducting the quantitative character detection and the genetic parameter estimation on the succeeding generation parent shellfish population in step B; D, repeating steps B and C while performing the genetic diversity analysis on three generations of the continuous progeny selection systems, and conducting the evaluation of the breeding effect. With the adoption of the construction method of the superior strains of the rapid-growing crassostrea gigas, the breeding progress is largely speeded up, the labor cost of breeding is reduced, the breeding effect is obvious, and the economic benefit of breeding the crassostrea gigas is improved.

Owner:OCEAN UNIV OF CHINA

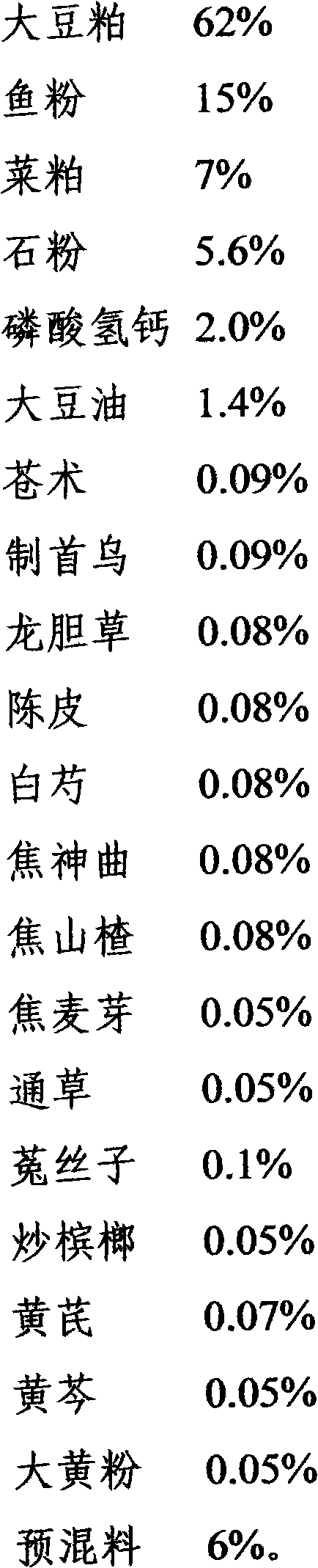

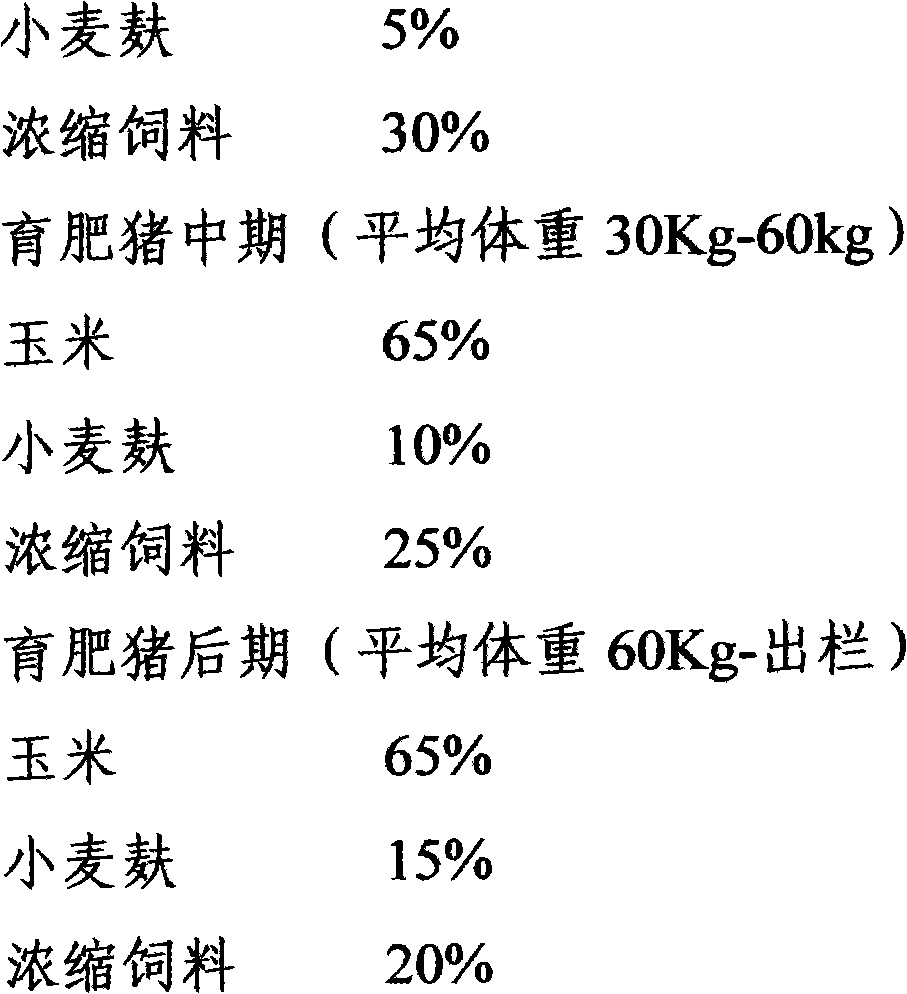

Concentrated feed containing Chinese herbal medicine for growing-finishing pig

ActiveCN102084940AImprove disease resistanceImprove immunityFood processingAnimal feeding stuffDiseaseMiddle medulla

The invention discloses a concentrated feed containing Chinese herbal medicine for growing-finishing pig. The concentrated feed comprises soybean meal, fish meal, rapeseed meal, stone powder, calcium hydrogen phosphate, soybean oil, and premix; the following Chinese herbal medicine components are added into the concentrated feed: rhizoma atractylodis, processed fleece-flower root, gentian, tangerine peel, white peony root, parched medicated leaven, parched hawthorn, parched malt, medulla tetrapanacis, semen cuscutae, stir-fried betelnut, radix astragali, scutellaria, rhubarb powder, etc. The feed can improve the immunity, disease resistance, and stress resistance of growing-finishing pigs; the feed has improved quality, can enhance the appetite of the animals, and promote the digestion and the absorption; and the utilization rate of the feed is increased, and the breeding cost is reduced. The feed also has blood circulation invigorating, stomach-strengthening, parasite-expelling, and rapid fattening functions.

Owner:HENAN MUHE GROUP FEED

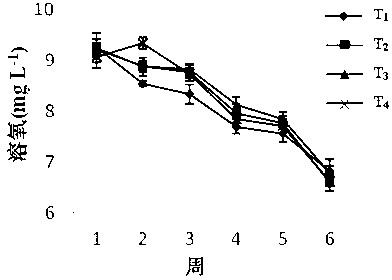

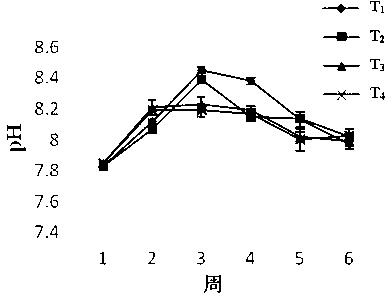

Penaeus vannamei farming method combining bioflocculation technology and multi-trophic-level integrated farming mode

InactiveCN103155891AReduction factorIncrease profitClimate change adaptationAgricultural fishingPolycultureTrophic level

The invention discloses a penaeus vannamei farming method combining bioflocculation technology and a multi-trophic-level integrated farming mode. The penaeus vannamei farming method combining the bioflocculation technology and the multi-trophic-level integrated farming mode includes the steps such as early-stage preparations of farming conditions, putting of penaeus vannamei and small-size fish, swamp cabbage planting, starch addition and feeding feedstuff management. According to the method, the multi-trophic-level integrated farming mode and the bioflocculation technology are innovatively applied to penaeus vannamei farming in a combining mode, namely, a multi-trophic-level integrated farming system composed of polyculture of the penaeus vannamei, the small-size fish and swamp cabbages. Starch is added in the farming system to serve as carbon source cultivation biological floccules. The levels of ammoniacal nitrogen and nitrous nitrogen in a water body are controlled through a bioflocculation action. Simultaneously, residual bait and excrement are utilized to form bacterium floccules which prawns and the small-size fish can ingest and utilize, and therefore the survival rate of the penaeus vannamei and the efficiency of feed utilization are improved. Relative to an ordinary single-farming mode, aspects of ecological benefits, economic benefits and farming effects in the farming system all achieve obvious effects.

Owner:SHANGHAI OCEAN UNIV

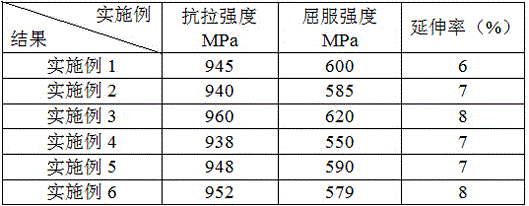

High-strength nodular cast iron QT900-6 and preparation method thereof

ActiveCN106011610AExcellent performanceImprove high temperature mechanical propertiesTrace elementMechanical property

The invention discloses high-strength nodular cast iron QT900-6 which consists of the following elements in percentage by weight: 3.2-3.7% of C, 2.4-2.8% of Si, less than or equal to 0.2% of Mn, less than or equal to 0.03% of P, 0.005-0.02% of S, 0.8-1.4% of Cu and the balance of Fe and unavoidable trace elements. The high-strength nodular cast iron QT900-6 has high compressive strength, high yield strength and excellent mechanical property.

Owner:西峡县内燃机进排气管有限责任公司

Nodular cast iron inoculant and preparation method thereof and application in smelting nodular cast iron

ActiveCN103484749AIncrease the number of ballsIncrease the number ofTrace element compositionAdhesive

The invention relates to a nodular cast iron inoculant and a preparation method thereof and an application in smelting nodular cast iron. The nodular cast iron inoculant consists of 3-6% of Bi, 40-50% of Si, 0.5-3% of Ba, 0.1-3% of La, 10-18% of Ca, 1-3% of O, 0.5-3% of S and the balance of Fe and unavoidable trace elements. The nodular cast iron inoculant is prepared by the steps of mechanically mixing a metal oxide, a metal sulfide and a silicon iron-based alloy; adding an adhesive into a grinding device, and pressing the mixture into a cluster; breaking the cluster, screening and wrapping with an aluminum foil. In use, when the output molten iron accounts for about 1 / 2 of the lip-pour ladle, the inoculant is added to perform inoculation treatment on the nodular cast iron once or multiple times. The inoculant provided by the invention contains the trace elements such as O, S, Bi and the like and is low-silicon and efficient, and multiple heterogeneous nucleation mass points are formed in the iron liquid, thereby increasing the graphite quantity, improving the shock resistance, mechanical property and yield, increasing the utilization rate of foundry returns, and increasing the economic benefits.

Owner:宁波康发铸造有限公司

Vanadium titanium cast iron brake drum and preparation method thereof

The invention relates to a manufacturing technique of an automotive vanadium titanium cast iron brake drum with high strength and high abrasive resistance, and particularly relates to a preparation method of a vanadium titanium cast iron brake drum. The preparation method comprises the following steps: melting base iron, namely b y taking vanadium titanium pig iron, steel scrap, foundry returns, a carburant, ferrosilicon, ferromanganese and ferrochrome as furnace charge, adding the carburant to the furnace bottom; smelting the furnace charges by using a medium-frequency induction furnace to prepare the base iron; heating and purifying molten iron in an overheating manner after the molten iron is molten down, and then carrying out heat preservation at 1520-1530 DEG C; and carrying out drossing, adding a slag conglomeration agent to the surface to carry out heat preservation after drossing, and then adding a little of furnace charge, and adjusting the ingredients and the like of the molten iron. A little of furnace charge is added at the later smelting stage to increase the heterogeneous core technology, so that the chilling tendency of the molten iron is relieved, the graphitization ability of the molten iron is improved, and the inoculation effect is improved. A secondary inoculation treatment process of a launder and a pouring cup is adopted, so that the inoculation effect is improved, the graphite form is improved, carbide and ferrite are removed, and the content of pearlite is improved.

Owner:陈国

Technique for two-stage controlled ecological fresh water aquiculturing Penaeus vannamei Boone

InactiveCN101015284AImprove the breeding effectClimate change adaptationPisciculture and aquariaPrawnBrackish water

The invention relates to an aquaculture technology, which in detail relates to a two- stage controllable ecological and high effective technology for cultivating South America prawn in fresh water. It is characterized in that it comprises: in the first stage culturing young shrimps in temperature controllable shrimp culture pool for 28- 35 days until the prawn grows to 3- 6 cm; moving prawn to brackish water with low salt concentration for 100 days. The invention is suitable for prawn cultivation in north center, realizes cultivation effect in normal field the same to that in high- level pool with membrane in the bottom; the survival rate is high, fertilizer coefficient is only 0.92, and the cultivation quantity and economical benefit for prawn are increased.

Owner:FUJIAN NORMAL UNIV

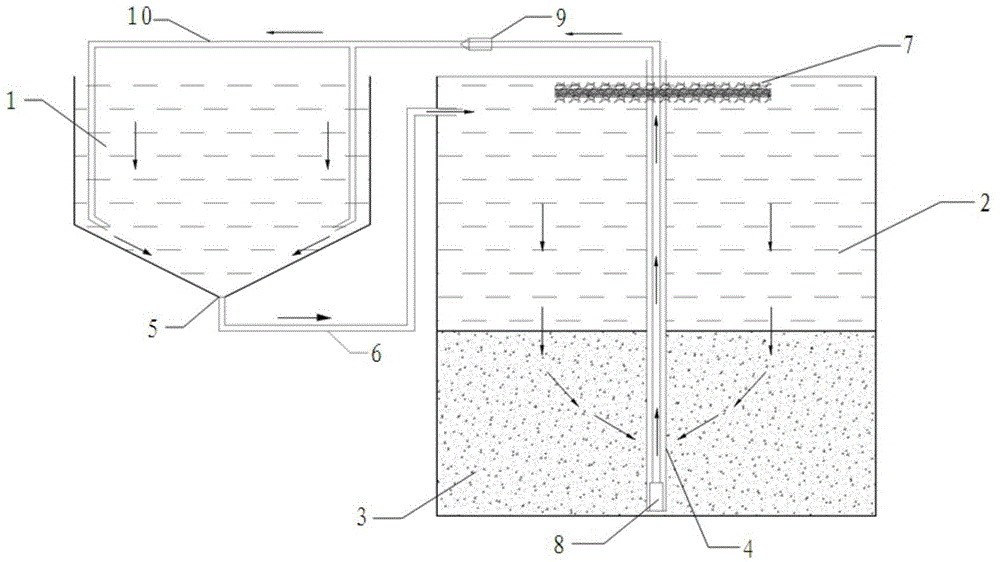

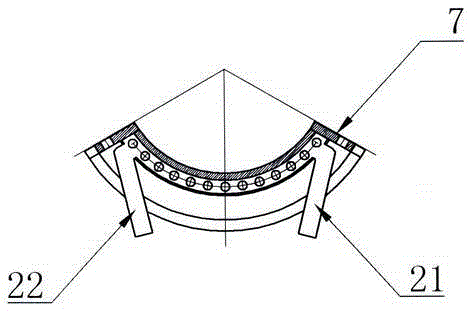

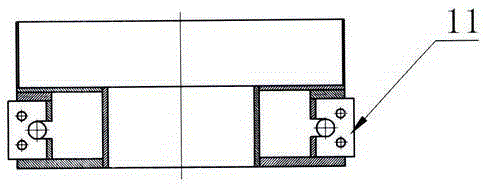

Circulating aquaculture device and method

ActiveCN104585097ALow input and operating costsEasy to operateClimate change adaptationPisciculture and aquariaSoil horizonWater pipe

The invention belongs to the technical field of aquaculture, and relates to a circulating aquaculture device and method. A drain outlet in the bottom part of a self-purification circulating aquaculture pool is communicated with an ecological biology clear water reservoir through a discharge pipe; an artificial floating island for planting aquatic organisms is arranged on a water body held in the ecological biology clear water reservoir; sand is paved on the bottom part of the ecological biology clear water reservoir; an underground soil layer under the sand forms a soil layer microorganism filter bed; an opening vertical shaft is arranged in the center of the ecological biology clear water reservoir; a porous filter pipe and a submerged pump are arranged on the lower end of the opening vertical shaft; the submerged pump is in butt joint with a water intake device; a Venturi oxygenation pipe sleeves the water intake device. According to the method, through interaction of self characteristics of the aquaculture water body and characteristics of microbial flora in the soil layer, the water body can be recycled, purified and reused, the investment and operation cost is low, the operation mode is simple and convenient, the waste discharge amount is almost zero, the culture effect is good, the density is high, and the environment friendliness, the safety and the innocuity are realized.

Owner:青岛中科海水处理有限公司 +1

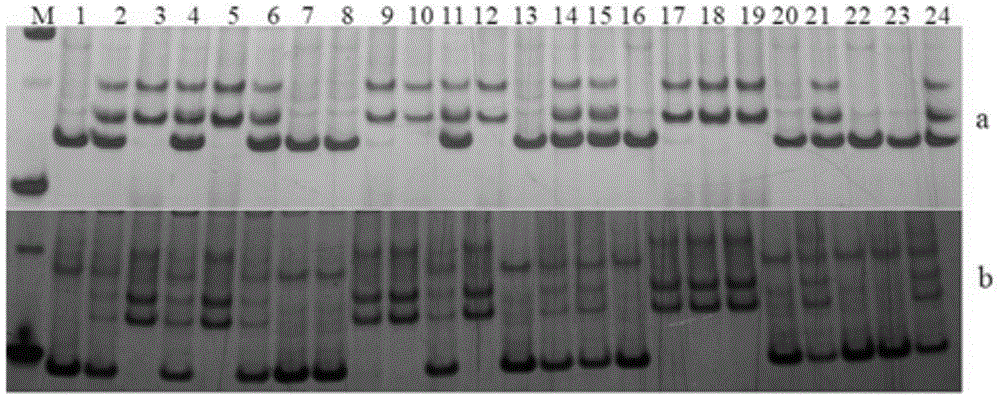

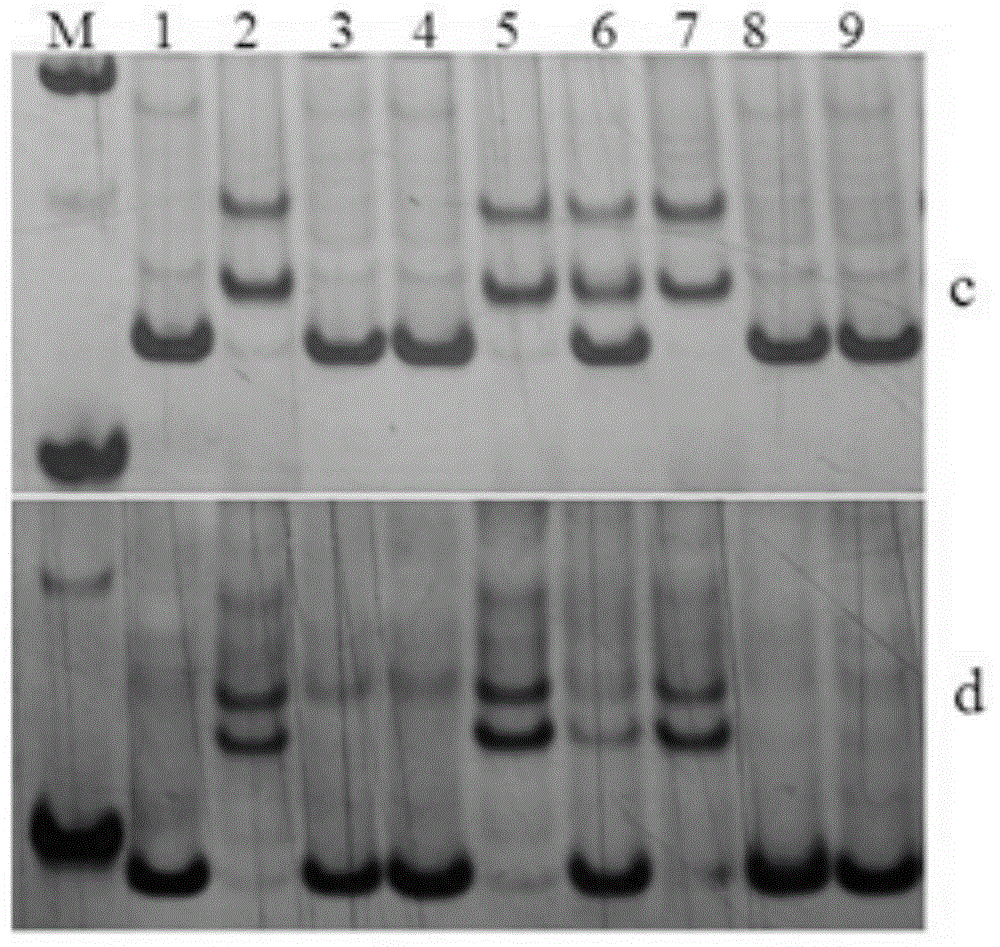

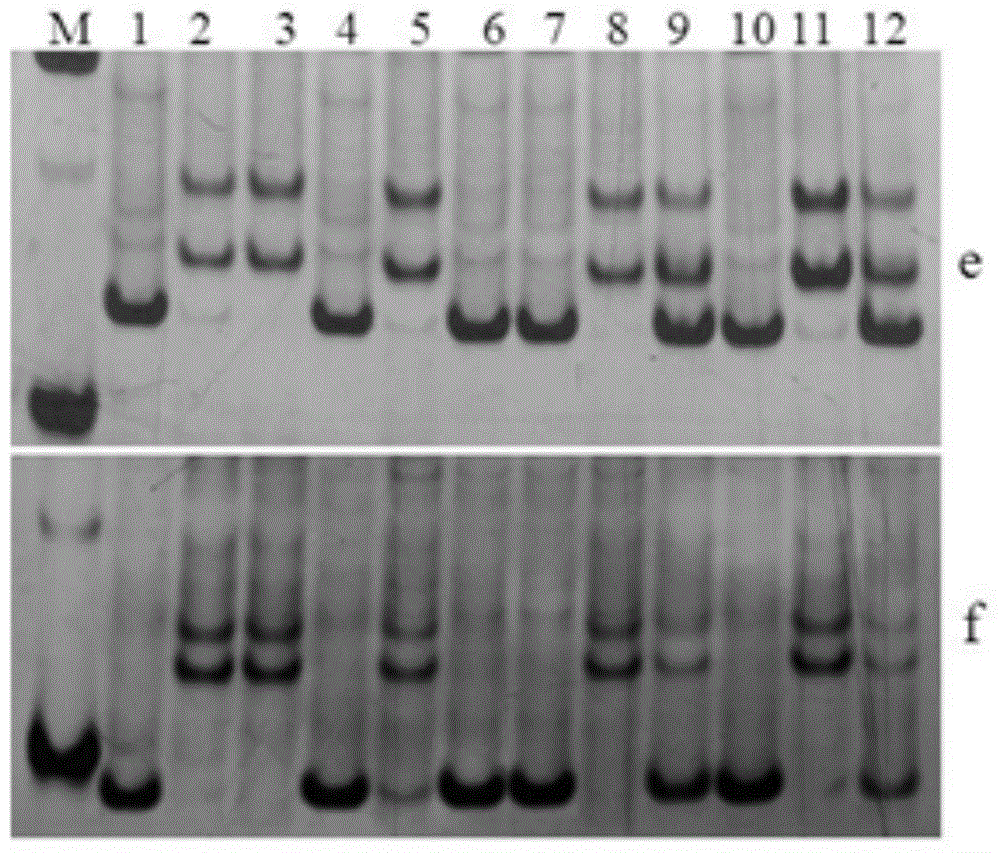

Method for detecting SSR molecular marker of pepper male sterility restoring gene as well as kit of SSR molecular marker

ActiveCN104561297ASpeed up the breeding processImprove breeding effectMicrobiological testing/measurementDNA/RNA fragmentationPolymerase chain reactionAgricultural science

The invention relates to the field of assistant breading in biotechnologies, in particular to an SSR marker linked with a pepper male sterility restoring gene Rf as well as an application of the SSR marker to selection of pepper male sterility breeding materials. The molecular marker closely linked with the pepper male sterility restoring gene is a pep43 marker or a pep20 marker. The development of the SSR molecular marker can accelerate the breeding process of the pepper male sterility, improve the breeding effect and provide a theoretical basis for classification and breeding of three systems of pepper CMS (cytoplasmic male sterility); an independently developed SSR primer and a conventional laboratory PCR (polymerase chain reaction) technology are adopted, and plants with restoring genes are selected through detection of pepper plants. The method is used for detecting genetic materials, is convenient and good in repeatability and can perform detection all the year round. According to a kit, the primer and related reagents for detection are integrally assembled in the kit, operations are convenient to implement, and detection results are stable and reliable.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

Australia crayfish breeding expanded sunken cooperation fodder and production process thereof

InactiveCN105010883AImprove Gut HealthEnhance disease resistanceAnimal feeding stuffAstaxanthinDigestion

The invention relates to Australia crayfish breeding expanded sunken cooperation fodder and a production process thereof and belongs to the technical field of shrimp expanded fodder. The fodder comprises 10-18 parts of fish meal, 5-10 parts of dried-powder of housefly larvae, 10-16 parts of shrimp meal, 4-8 parts of fermented soybean meal, 14-16 parts of soybean meal, 5-15 parts of peanut meal, 12-14 parts of strong flour, 2-4 parts of yeast autolysis powder, 2-5 parts of squid liver, 2-3 parts of shrimp shell meal, 2-5 parts of dried earthworm powder, 1-2 parts of fish oil, 2-3 parts of phosphatide oil, 1.5-2 parts of monocalcium phosphate, 1.66-2.63 parts of bentonite, 0.1-0.2 part of choline chloride, 0.04-0.08 part of calcium bisbutyrate, 0.1-0.2 part of unshell agents, 0.05-0.1 part of astaxanthin, 0.06-0.1 part of synbiotics, 0.2-0.3 part of compound vitamin premix and 0.3-0.5 part of compound trace element premix. By means of the fodder, the intestinal health of Australia crayfish can be substantially improved, the disease resistant capacity of the Australia crayfish is enhanced, the fodder digestion rate is improved, the growth performance is improved, and great social value and economic value are created.

Owner:TONGWEI

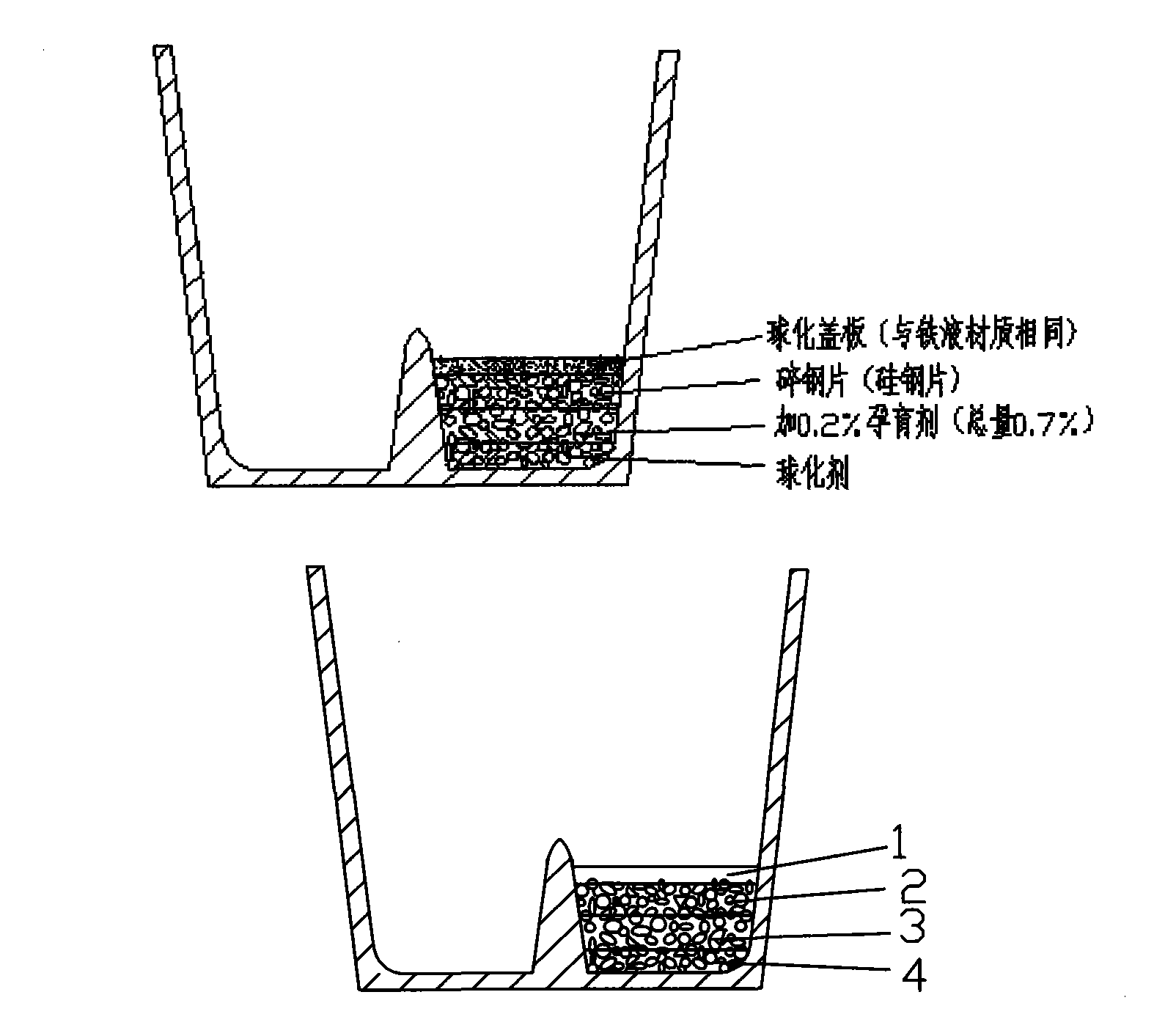

Manufacturing method of spheroidal graphite cast iron casting of wind power yaw variable-pitch device

The invention discloses a manufacturing process of a spheroidal graphite cast iron casting of a wind power yaw variable-pitch device. The process comprises the following processes of mould making, foaming and moulding, paint brushing, boxing and shaping, electric furnace smelting, tundish-covering nodulizing treatment, vacuum-assist pouring and three-time inoculation treatment, wherein the boxing and shaping process is a layered assembling process, so that the production efficiency can be improved and the process yield can be increased; cold iron is vibrated and reasonably arranged, so that the compactness of tissues in the casting can be improved and the defect of shrinkage porosity can be avoided; by virtue of the processes of electric furnace smelting and tundish-covering nodulizing treatment, the nodulizing rate of the casting can be stabilized and increased and the mechanical properties of the casting can meet the technical quality requirements of wind power castings; the spheroidal graphite cast iron casting manufactured by the process is compact and uniform in tissue, hardly has defects, has good surface quality and high size precision; the casting forming of multiple layers of castings can be realized; and the production efficiency and the process product yield are improved.

Owner:CHTC HEAVY IND

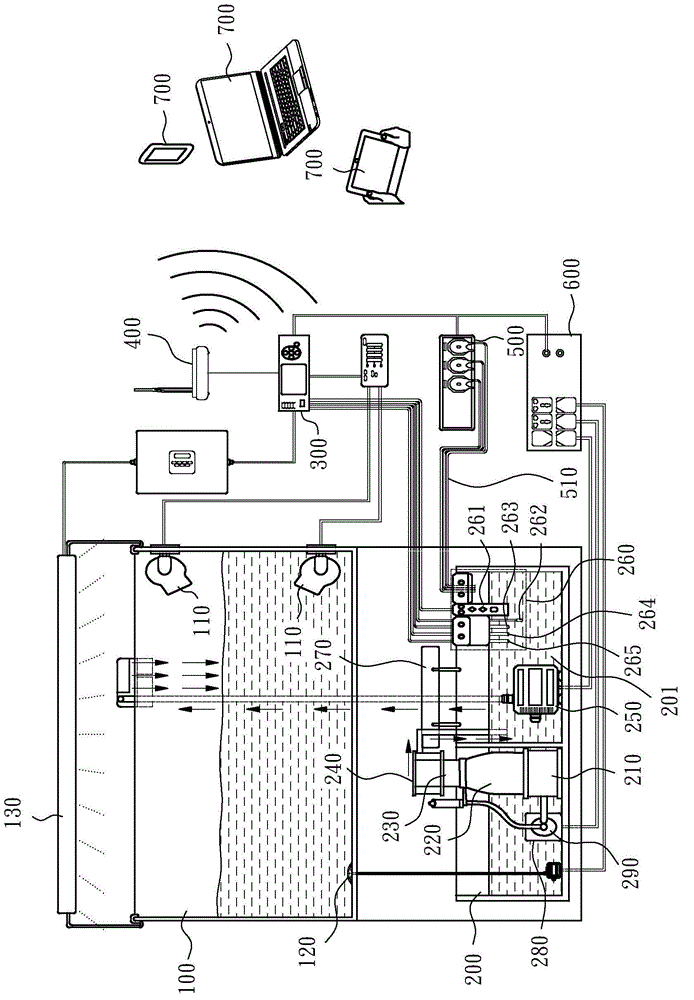

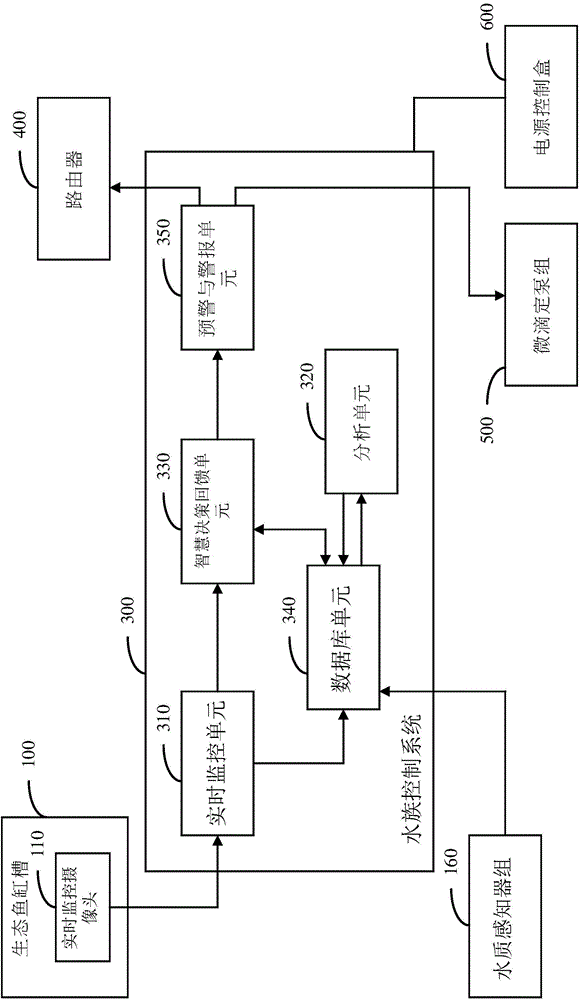

Intelligent aquarium fish tank

The invention discloses an intelligent aquarium fish tank. According to the intelligent aquarium fish tank, the water temperature, illumination, pH, dissolved oxygen and other factors of a water quality environment can be automatically controlled, a simulated artificial raising ecological environment is provided, automatic cleaning and refreshing of the water environment in the fish tank are realized, and actually the goal of avoiding water change for a long term is achieved. The intelligent aquarium fish tank is also provided with an automatic feeding system and a health and bright body color monitoring analysis system so that raised organisms can keep a healthy and colorful state, and the fun of a raiser is enhanced. The intelligent aquarium fish tank is characterized in that in the fish culture facility, a device is composed of a plurality of digital intelligent control systems. The intelligent aquarium fish tank has the advantages of environmental intelligence controllability, ecological and healthy raising (biological safety), automatic regulation, energy conservation and the like and is an important sign of modern technical breeding.

Owner:SAFT BIOTECH COM +1

Method for integrally casting large-sized V-shaped diesel engine body by utilizing nodular cast iron

The invention discloses a method for integrally casting a more-than-25-ton large-sized diesel engine V-shaped body by utilizing nodular cast iron. The method comprises the following steps of A1, smelting the nodular cast iron in a smelting furnace, and adding bariumsili and metallurgical carborundum pretreatment agent after the smelting; A2, placing a spheroidizing agent into a bottommost layer of a dam-type spheroidizing ladle, utilizing a nucleating agent to cover a second layer, and utilizing a low-maganese low-alloy broken steel sheet to completely cover and compact a third layer; A3, adding a calcium-barium nucleating agent, charging the melted iron in one step to carry out the tapping metal-stream inoculation, realizing the nucleating effect while carrying out the spheroidizing treatment on charged melted iron, and carrying out the pouring pretreatment on the melted iron in the ladle; A4, placing the metal-stream inoculation agent into a funnel to carry out the pouring metal-stream inoculation; and A5, finally pouring the melted iron with the temperature being more than or equal to 1400 DEG C into a sand box, forming a cast by mold filling and solidifying the melted iron under the feeding of the feeder head liquid metal, and carrying out the heat treatment by utilizing the waste heat of the cast.

Owner:宜宾普什联动科技有限公司

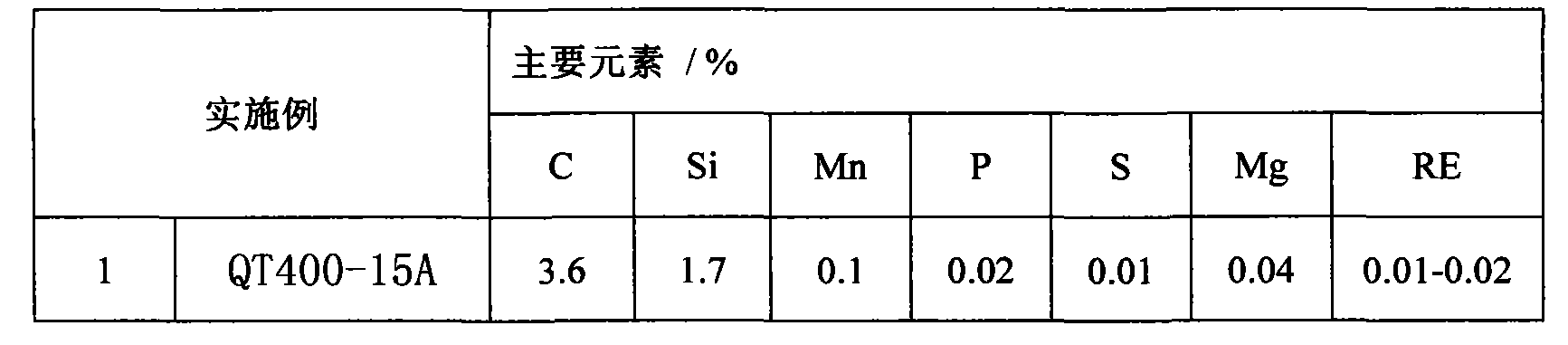

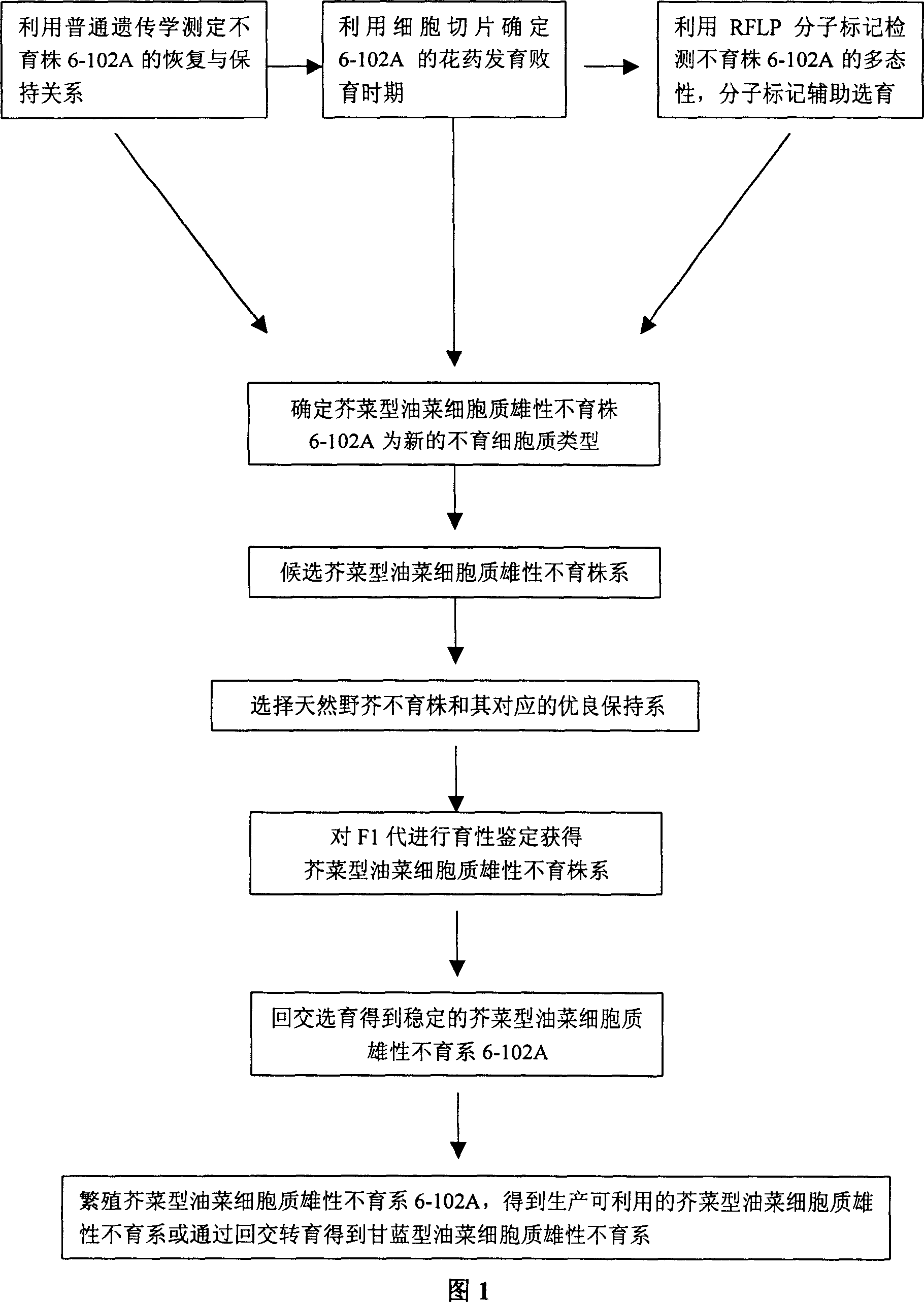

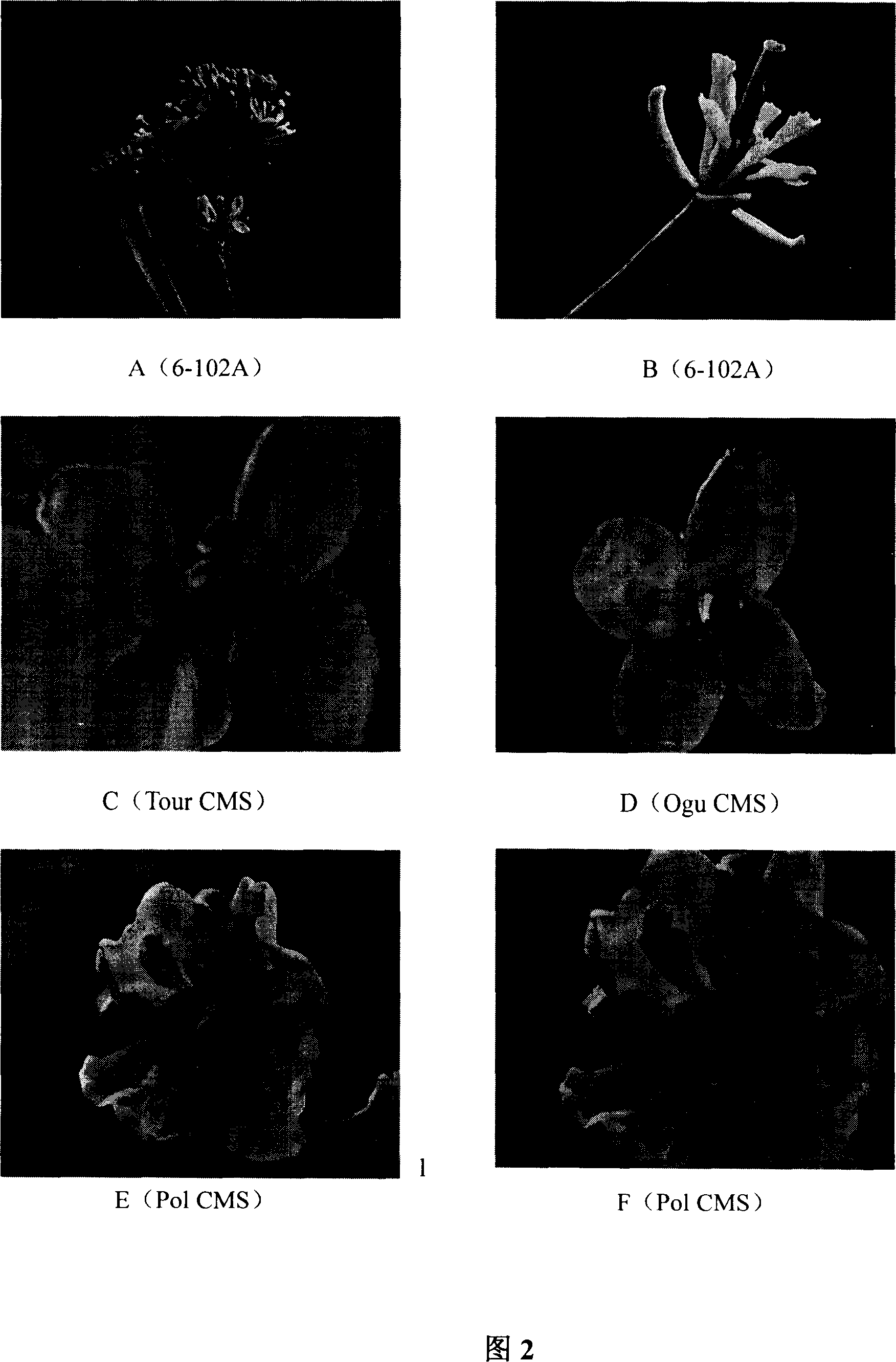

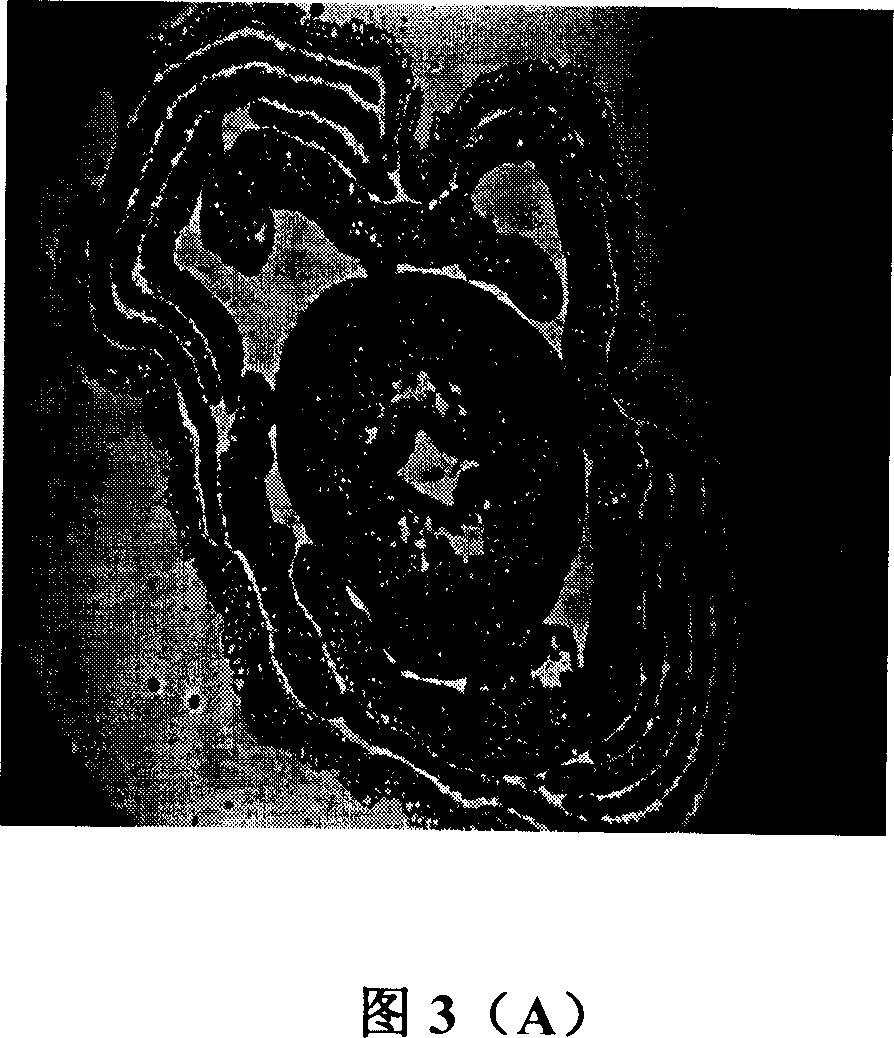

Selective breeding method for rape cytoplasmic male sterile line

InactiveCN1965641ASterility is stable and completeIn line with breeding goalsPlant genotype modificationBiologyCytoplasmic male sterility

The invention relates to a method for selecting male sterility line of rape cytoplasm, wherein the invention comprises that: selecting wide mustard sterility male, using mustard rape as hold line; crossing and molecule mark to assist the selection, to obtain the mustard rape cytoplasm male sterility line and hold line with stable generation; cultivating said sterility line to obtain usable mustard rape cytoplasm male sterility line.

Owner:HUAZHONG AGRI UNIV

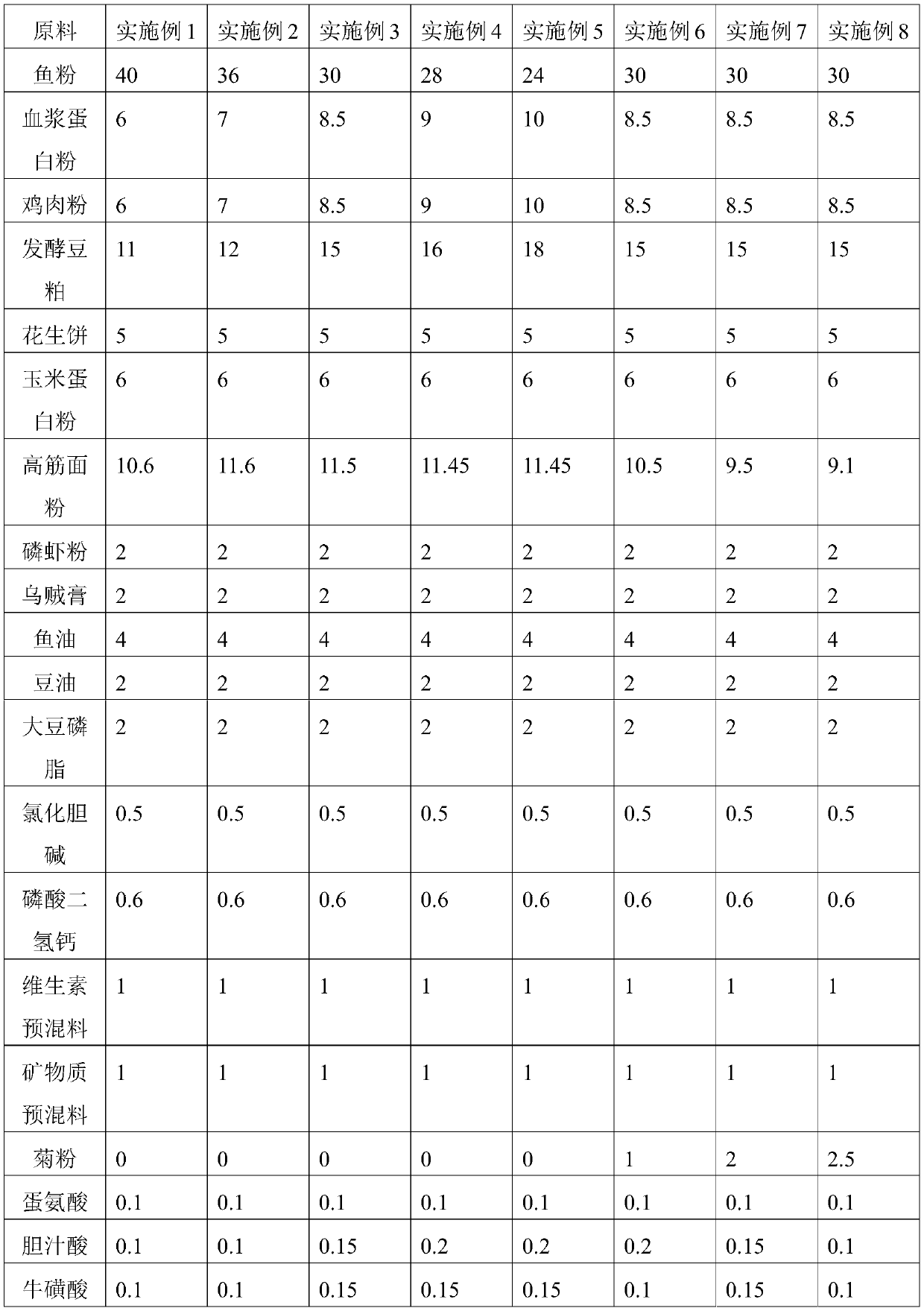

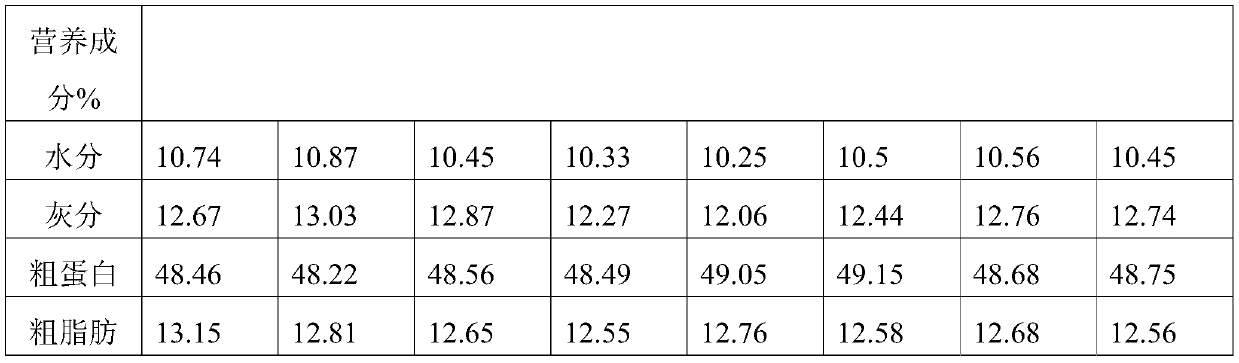

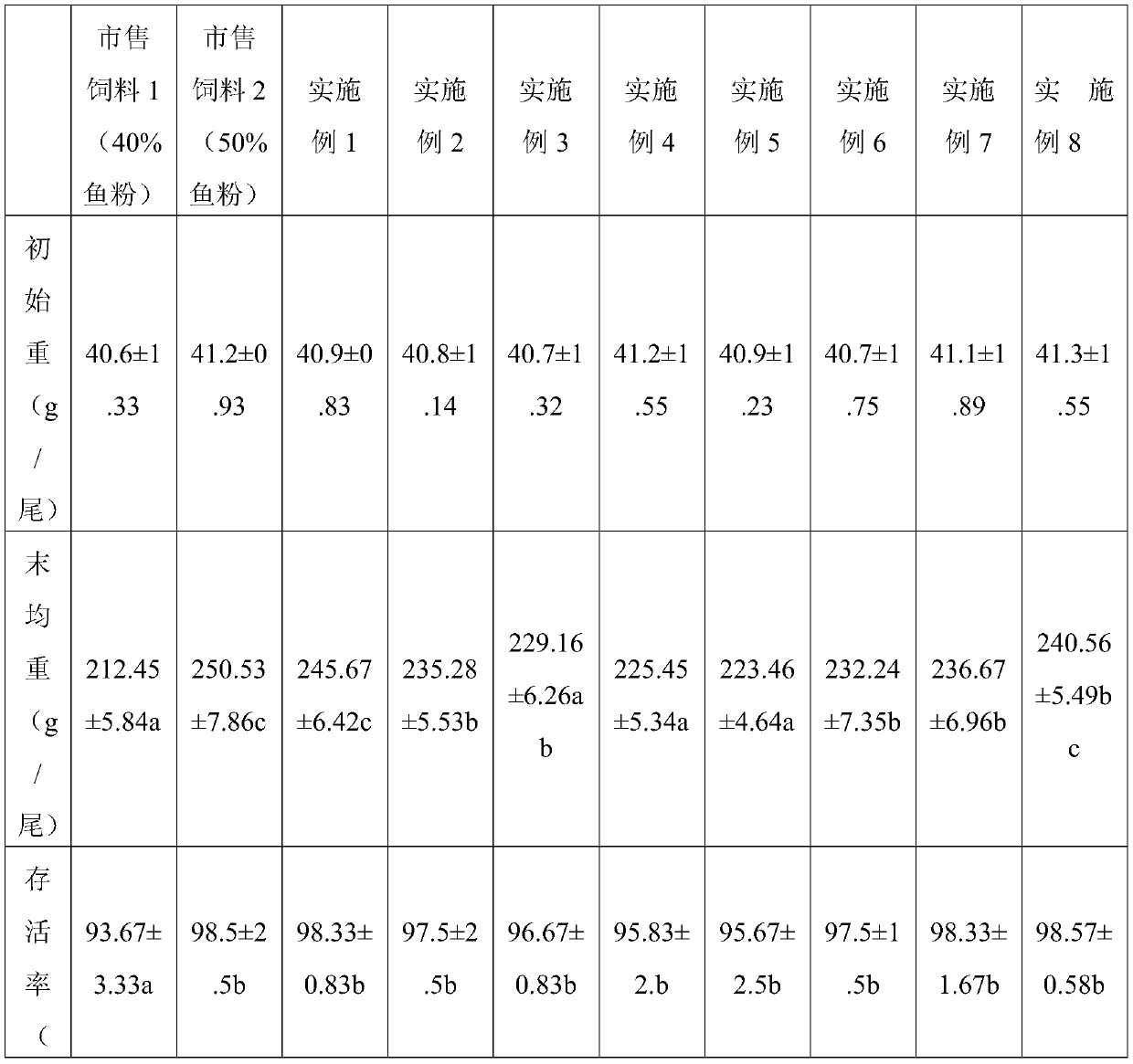

Low-fish-meal compound feed for micropterus salmoides and preparation method of low-fish-meal compound feed

InactiveCN109845918ARetain nutrientsRetain activityClimate change adaptationAnimal feeding stuffAnimal scienceImmunocompetence

The invention discloses a low-fish-meal compound feed for micropterus salmoides. The low-fish-meal compound feed comprises the following components in parts by weight of 25-40 parts of fish meal, 5-15parts of plasma protein powder, 5-15 parts of chicken meat powder, 10-25 parts of fermented soybean meal, 3-10 parts of peanut cakes, 4-10 parts of corn protein powder, 6-15 parts of high gluten flour, 2-6 parts of krill powder, 1-4 parts of cuttlefish cream, 1-6 parts of fish oil, 1-5 parts of soybean oil, 1-5 parts of soybean phospholipid, 0.1-0.5 part of choline chloride, 0.1-0.8 part of calcium dihydrogen phosphate, 0.5-1.5 parts of a vitamin premix, 0.5-1.5 parts of a mineral premix, 1-5 parts of inulin, 0.05-0.3 part of methionine, 0-0.5 part of bile acid and 0-0.4 part of taurine. Thelow-fish-meal compound feed for micropterus salmoides conforms to the nutrient requirement regularity of the micropterus salmoides, and has the advantages of being good in palatability and high in digestibility, increasing the survival rate, reducing the feed coefficient, improving the immunocompetence of the micropterus salmoides, and promoting healthy and quick growth of the micropterus salmoides.

Owner:珠海市德海生物科技有限公司

Manufacturing technology and device for improved forged steel roller neck high nickel chrome molybdenum alloy cast composite roller

ActiveCN105401059AEasy feedingOvercome the defect of prone to tissue segregationFurnace typesProcess efficiency improvementManufacturing technologyFerrosilicon

The invention discloses a manufacturing technology and device for an improved forged steel roller neck high nickel chrome molybdenum alloy cast composite roller. The roller comprises, by mass percent, 3.0%-3.6% of C, 0.60%-1.20% of Si, 0.30%-1.20% of Mn, 3.0%-5.0% of Ni, 1.0%-2.0% of Cr, 0.40%-1.2% of Mo, 0.1%-2% of W, 0.5%-1.0% of Cu, not larger than 0.05% of P, not larger than 0.03% of S, 0.04%-0.06% of Mg, 0.1%-0.3% of Nb, 0.1%-0.30% of Ti, 0.2%-0.6% of V, 0.05%-0.2% of B, 1.5%-2.5% of Ba, 1%-2% of Ca, 1%-3% of Sb, 0.02%-0.18% of N, 1.0%-2.0% of Y / RE and the balance Fe and inevitable micro elements. Yttrium base rare-earth nodulizing and Ba, Ca, and silicon iron composite inoculation are adopted, Nb, Ti, V, B and Sb are added for modification, and the mechanical performance of the roller is improved; by the adoption of the forged steel roller neck, the strength of the roller is improved, an induction heater is adopted to carry out in-mold whole heating casting on a core stick, a water cooled crystallizer is molded, a composite layer interface can be dynamically controlled, the technology is simple, the efficiency is high, power consumption is small, the cost is low, no composition segregation exists, and the service life of the roller is long.

Owner:丹阳恒庆复合材料科技有限公司

Preparation method of large abrasion-proof hollow grinding ball

ActiveCN103639363AImprove organizationImprove hardenabilityFoundry mouldsFoundry coresSmelting processRare earth

The invention discloses a preparation method of a large abrasion-proof hollow grinding ball, and belongs to the technical field of metal abrasion-proof materials. The preparation method comprises the following steps: step 1, preparing a casting shape, wherein an air extraction support mechanism is prearranged in the core part of a foam plastic die sample, and comprises a support part and an extraction branch tube; step 2, performing a smelting process, wherein pouring molten steel comprises the following components in percentage by mass: 0.3-0.5% of C, 0.5-1.5% of Si, 0.5-2% of Mn, 1.0-3.0% of Cr, 1.0-3.0% of Ni, 0.5-2% of Mo, 0.24-0.32% of B, 0.28-0.35% of V, 0.08-0.13% of Ti, 0.8-1.2% of rare earth, less than or equal to 0.02% of P, less than or equal to 0.02% of S, the balance being Fe and inevitable impurities, and C% is equal to 1.2*B%+(0.06 to 0.13); step 3, performing a pouring process; and step 4, performing heat treatment. Through the preparation method of the large abrasion-proof hollow grinding ball, the problems of poor tenacity of the hollow grinding ball, the offset of a conventional sand type casting sand core and uneven ball wall can be solved.

Owner:马鞍山市海天重工科技发展有限公司

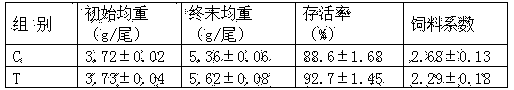

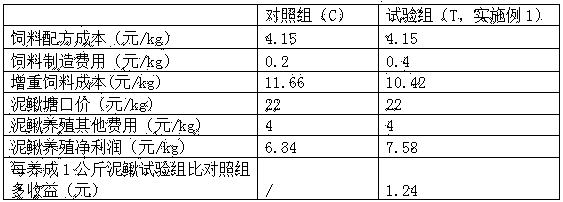

Loach settling-type puffing mixed feed and preparing method thereof

ActiveCN104000050AMaintain Gut HealthImprove Nutrient Utilization EfficiencyFood processingClimate change adaptationSOYBEAN SEED OILNutrition

The invention relates to loach settling-type puffing mixed feed and a preparing method thereof, and belongs to the technical field of puffing feed production used for aquatic products. The feed comprises the following raw materials, that is, fish meal, meat meal, corn gluten meal, spray-dried animal blood cells, fermented soybean meal, soybeans, bean pulp, rapeseed dregs, DDGS, flour, soybean oil, monocalcium phosphate, bentonite, 98.5% lysine hydrochloride, 99% DL methionine, choline chloride, decavitamin premix compound, 35% vitamin C phosphate, composite mineral substance premix compound and sodium butyrate. The loach settling-type puffing mixed feed can well maintain intestinal health of loaches, further improves the nutrition utilization rate, invigorates health and improves anti-stress capacity of the loaches. The prepared loach settling-type puffing mixed feed is used in breeding stage of the loaches, the ingestion characteristics of the loaches are combined, the ingestion and growth states of the loaches are good, the physique of the loaches is strong, the feed coefficient is obviously reduced than that of an existing popular hard particle feed product, the survival rate is obviously improved and culture benefits are substantially improved.

Owner:TONGWEI

Micropterus salmoides adult fish compound feed

ActiveCN104799128APromote bone developmentFast growthFood processingClimate change adaptationKadsura indutaChinese herbs

The invention discloses an additive of a Micropterus salmoides adult fish compound feed. The additive comprises the following air-dried substances in parts by weight: 5-7 parts of poria cocos, 4-6 parts of medlar, 3-5 parts of black sesames, 8-12 parts of fructus psoraleae, 1-2 parts of ferrous sulfate, 4-6 parts of copper sulfate, 2-4 parts of medical stone and 60-70 parts of rice hull powder. By addition of traditional herbal medicines such as the poria cocos, the medlar, the black sesames and the fructus psoraleae which are scientifically combined with mineral salts, skeletal development of Micropterus salmoides adult fishes can be promoted, the growth speed can be remarkably increased, and the cultured Micropterus salmoides adult fishes are elongated.

Owner:珠海海龙生物科技有限公司

Duck feed containing palm kernel meal and preparation method thereof

ActiveCN102038113ASave scarce raw materialsIncrease profitAnimal feeding stuffAccessory food factorsNutritionManihot esculenta

The invention discloses a duck feed containing palm kernel meal and a preparation method thereof. Raw materials comprising corn, cassava slice, corn protein feed, palm kernel meal and the like are adopted, smashed and mixed to be uniform, nutrition preparations comprising lysine hydrochloride, methionine, multiple vitamins and complex enzymes are added, steam blending is carried out, so that raw powder is cured to certain extent, and then granulation is carried out, thus obtaining the finished product, wherein the palm kernel meal is obtained by stewing, peeling, squeezing and separating fresh palm berry fruit strings. In the invention, by products after palm berry fruit is squeezed for oil is used fully, the palm kernel meal is used in meat duck feed, corn and soybean meal raw materials in short supply can be saved, thus reducing production cost; other raw materials are combined, thus product is full of nutrients, has balance of protein and amino acid, is rich in vitamins microelements, has good palatability and high digestibility and can be applicable to different meat ducks, especially cherry valley meat ducks.

Owner:JIEYANG TONGWEI FEED

Method for cultivating scatophagus argus in indoor cement pool

ActiveCN103636546AIncrease breeding densityEasy to observeClimate change adaptationPisciculture and aquariaFish weightRiver mouth

The invention provides a method for cultivating scatophagus argus in an indoor cement pool, and relates to scatophagus argus cultivation. The method comprises the steps of yearling cultivation, overwintering cultivation and adult fish cultivation, and is characterized in that juvenile fish is firstly placed in a cement pool net cage in a vinyl house for temporary rearing after transported to the destination, the adapted juvenile fish is placed in a cement pool for domestication cultivation, cultivation water adopts natural seawater in river mouth district, the salinity is 8-15, the cultivation water is filtered by 200-mesh bolting silk after secondary precipitation, the cultivation is performed until November to December, the water temperature is lower than 12 DEG C, scatophagus argus is transferred to the indoor cement pool for overwintering cultivation, seawater buoyancy No. 2 grains are fed by two times every day according to 1%-3% of fish weight during the overwintering cultivation, and the water temperature during the overwintering cultivation is kept higher than 12 DEG C; and the water temperature in the spring of next year is increased to be higher than 15 DEG C, yearlings are transferred to the cement pool in the vinyl house from the indoor cement pool for adult fish cultivation, the body length of adult fish is up to 8-10 cm, pool separation is performed, and fresh enteromorpha or filamentous algae are fed during daily management period.

Owner:上海市水产研究所(上海市水产技术推广站)

Method for alternately breeding South America white shrimps and giant freshwater prawns for three batches in pond greenhouse

ActiveCN103828748AIncrease profitAdaptableClimate change adaptationPisciculture and aquariaFresh water organismGreenhouse

The invention discloses a method for alternately breeding South America white shrimps and giant freshwater prawns for three batches in a pond greenhouse. The method comprises the steps of building the pond greenhouse, cleaning and sterilizing the pond greenhouse, breeding the South America white shrimps and the giant freshwater prawns in a small shed, arranging offspring throwing time of the three batches, throwing fodder, managing water quality, supplementing oxygen in a combination mode, preventing and controlling diseases, and fishing the South America white shrimps and giant freshwater prawns of the three batches. The method is characterized in that the small shed is built in the greenhouse, and the offsprings are thrown to a pond after being bred in the small shed in a storing mode; the offsprings of the South America white shrimps of the first batch are thrown from March 18th to March 22nd, the offsprings of the South America white shrimps of the second batch are thrown from July 1st to July 6th, and the offsprings of the giant freshwater prawns of the third batch are thrown from October 20th to October 22nd; the first fishing time of the South America white shrimps of the first batch starts from May 20th to May 25th, and the last fishing time of the South America white shrimps of the first batch and pond clearing start from June 10th to June 20th; the first fishing time of the South America white shrimps of the second batch starts from October 5th to October 10th, and the last fishing time of the South America white shrimps of the second batch and pond clearing start from October 18th to October 20th; the first fishing time of the giant freshwater prawns of the third batch starts from November 18th to November 20th, and the last fishing time of the giant freshwater prawns of the third batch and pond clearing start from December 18th to December 25th.

Owner:上海市水产研究所(上海市水产技术推广站) +1

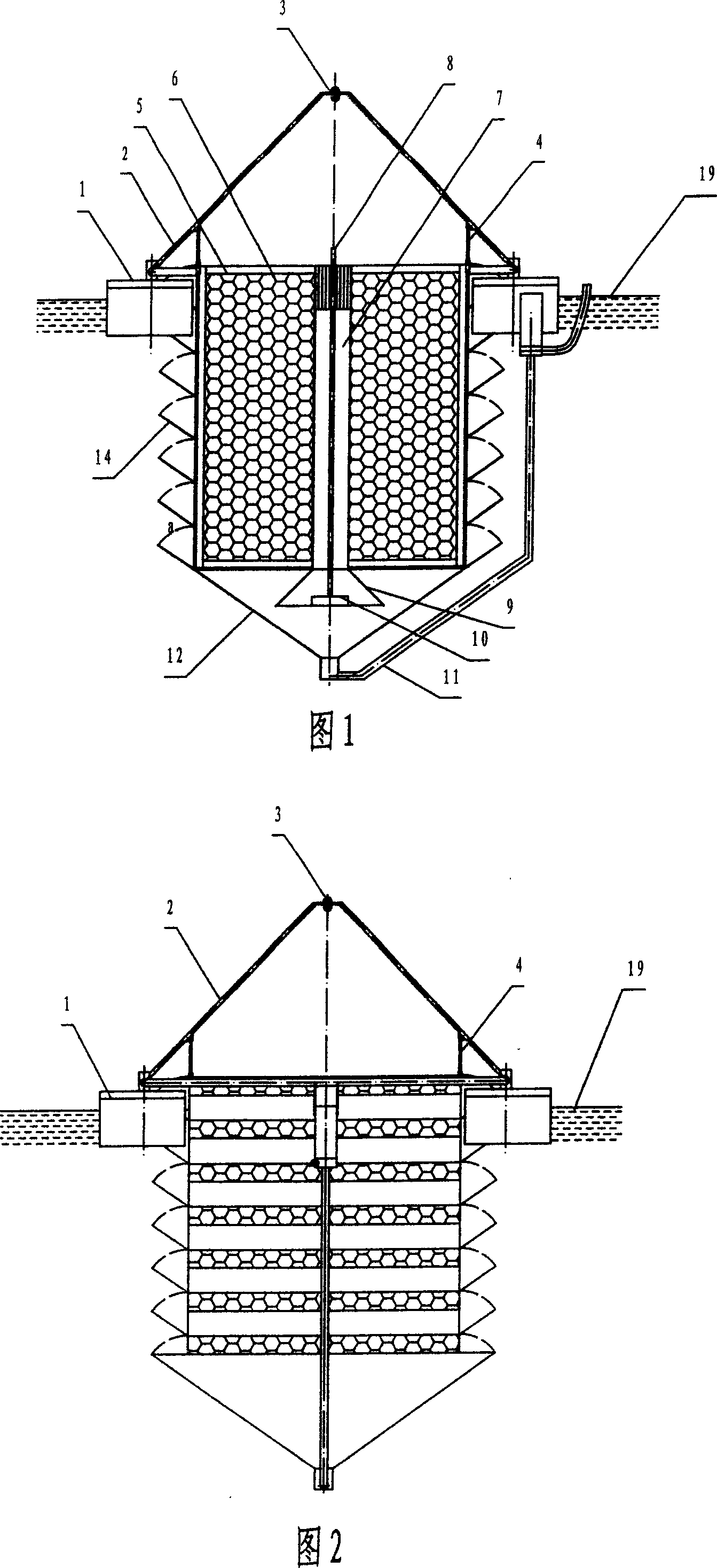

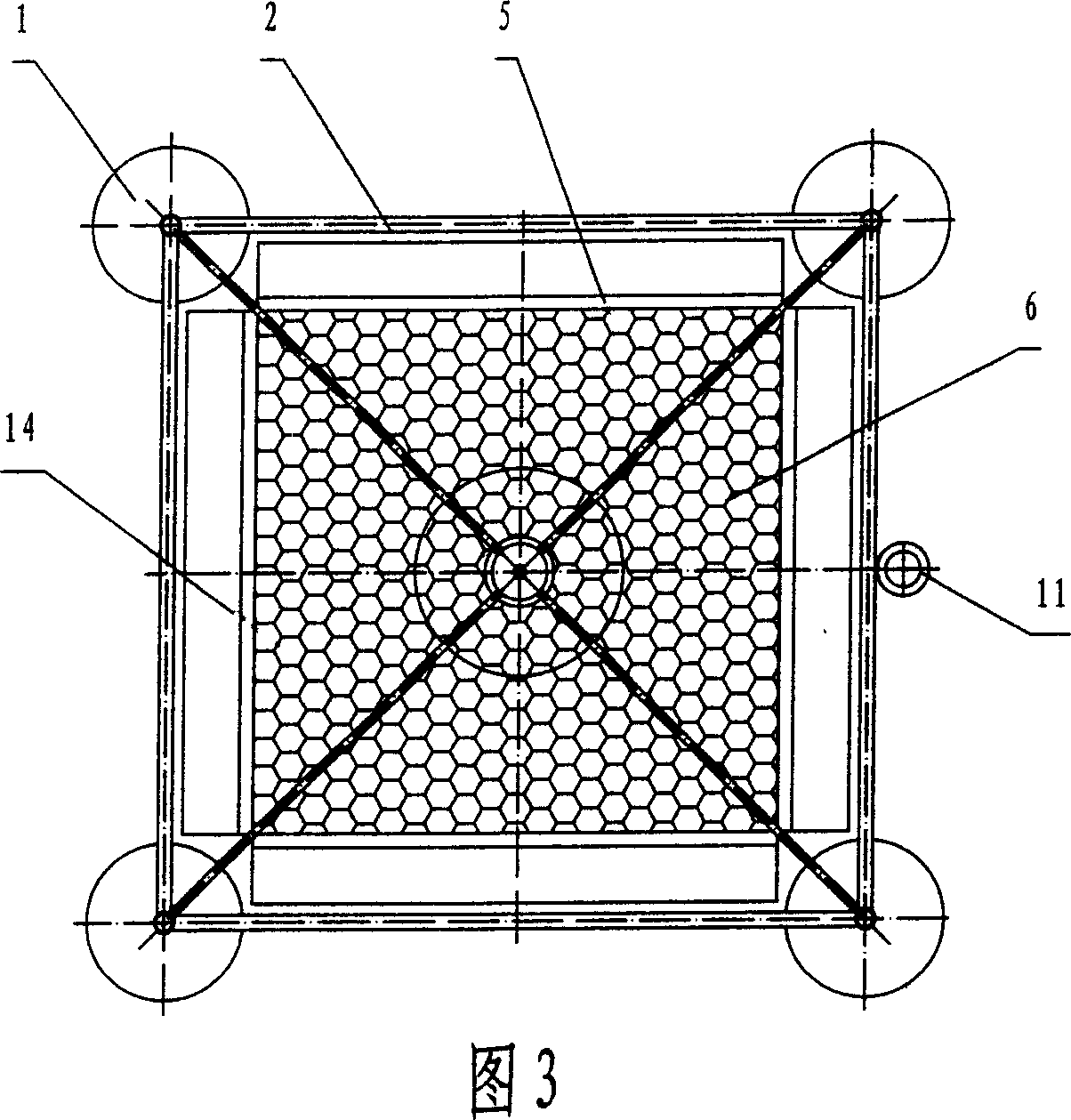

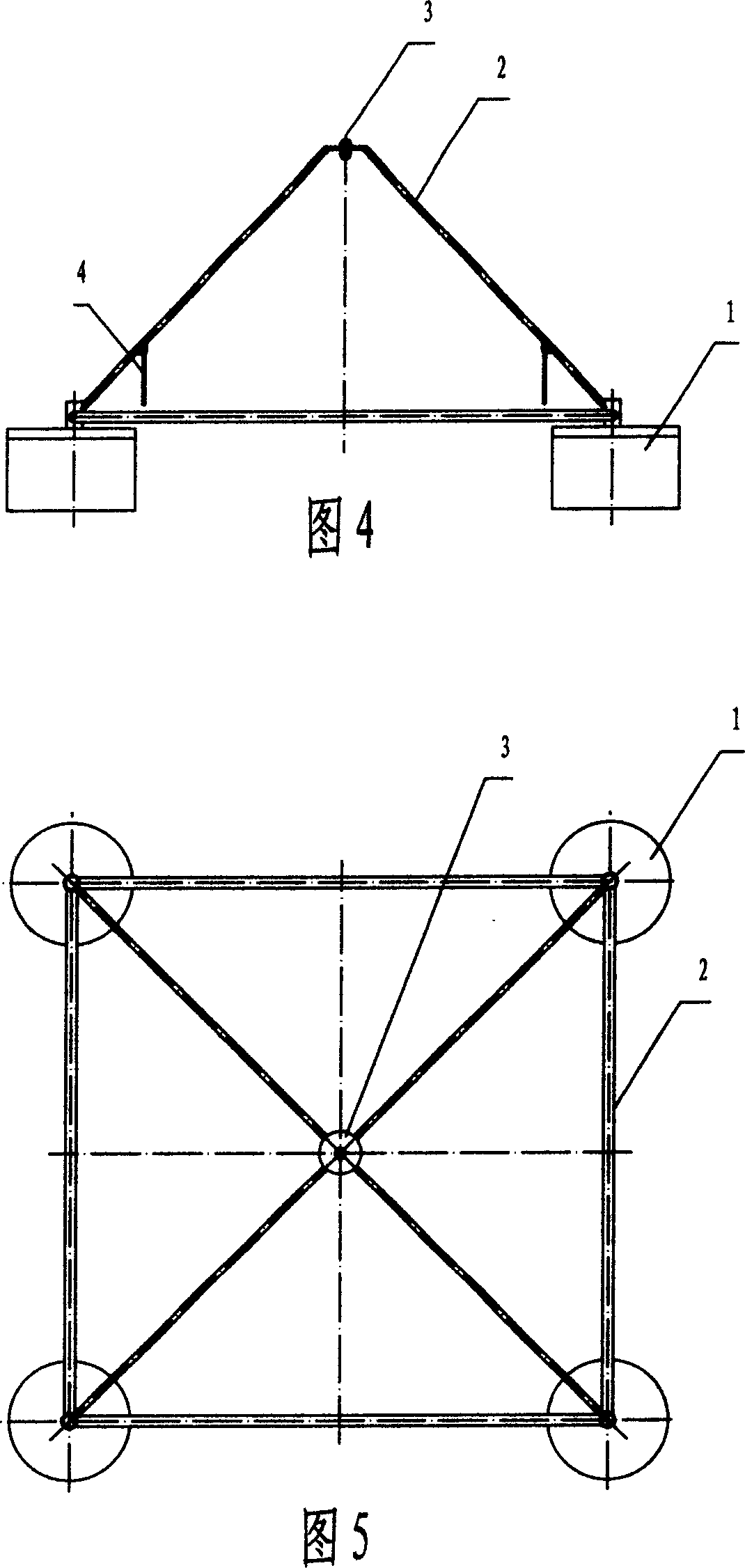

Controllable environment-friendly type fish culture box

InactiveCN101011043AIncrease breeding capacityImprove efficiencyClimate change adaptationPisciculture and aquariaEngineeringDrainage tubes

The invention relates to a controllable environment-friend fish box, which is formed by a floating support, a box, and a box bottom. The floating support comprises a floater, a support, a suspending ring, and a hook of fish box. The box comprises a frame, a mesh plate, a leaf side baffle plate, a suspending plate, a positioning plate, a lifting ear, a floating cylinder, a support of floating cylinder, a gas tube, a gas frame, and an aeration disc. The box bottom comprises a drainage groove, a hook of drainage groove, and a drainage tube. The frame of the fish box is arranged with outside leaf side baffle plate. The fish box mesh plate is arranged around the box and at the bottom. The floating cylinder, the gas frame, and the aeration disc are concentrically connected, via the support of floating cylinder to be fixed at the center of frame of fish box. The box bottom is arranged with the reverse-taper drainage groove, which is connected to the fixing hole of positioning plate via the hook of drainage groove. The floating support is partly arranged with a floater arranged on the support. The hook of fish box is connected with the lifting ear of positioning plate. The invention has simple structure.

Owner:天津市水产研究所

Low-temperature-resistance high-toughness as-cast ductile iron, and production method and application thereof

The invention discloses low-temperature-resistance high-toughness as-cast ductile iron, which comprises the following chemical ingredients in percentage by weight: 3.4 to 3.6 percent of C, 2.0 to 2.3 percent of Si, at most 0.2 percent of Mn, at most 0.02 percent of P, at most 0.01 percent of S, 0.035 to 0.05 percent of Mg residue, 0.015 to 0.025 percent of sigma Re residue, 0.05 to 0.1 percent of Sr, 0.15 to 0.25 percent of Ni, 0.10 to 0.15 percent of Ti and the balance Fe. The invention also discloses a production method and application of the low-temperature-resistance high-toughness as-cast ductile iron to the preparation of wind-power generator accessories, automobile accessories, boat accessories and petrochemical engineering. The low-temperature-resistance high-toughness as-cast ductile iron produced by the method provided by the invention can reach each technical index of QT400-18L of GB / T1348-2009 in the cast state, the graphitizing annealing heat treatment is avoided, the energy consumption is reduced, and meanwhile, the low-temperature-resistance high-toughness as-cast ductile iron has the outstanding advantages of stable quality and the like, and the operation is simple and convenient.

Owner:四川海工科技有限公司

Casting process of nodular cast iron planet carrier

The invention relates to a casting process of a nodular cast iron planet carrier, which comprises the following procedures of modeling, iron melt melting, spheroidizing, modifying, casting and stress relieving and annealing. The design of a casting system adopts a step casting method which takes consideration of both bottom casting and top casting to improve the finished product rate of castings, and also adopts technical schemes of placing chill iron at the position of thick walls, adding Sn element in the iron melt, optimizing, spheroidizing, modifying, casting and the like, so that the produced planet carrier not only meets the high demands on property, but also achieves great improvement in production cost and efficiency.

Owner:JIANGSU HONGDE SPECIAL PARTS CO LTD

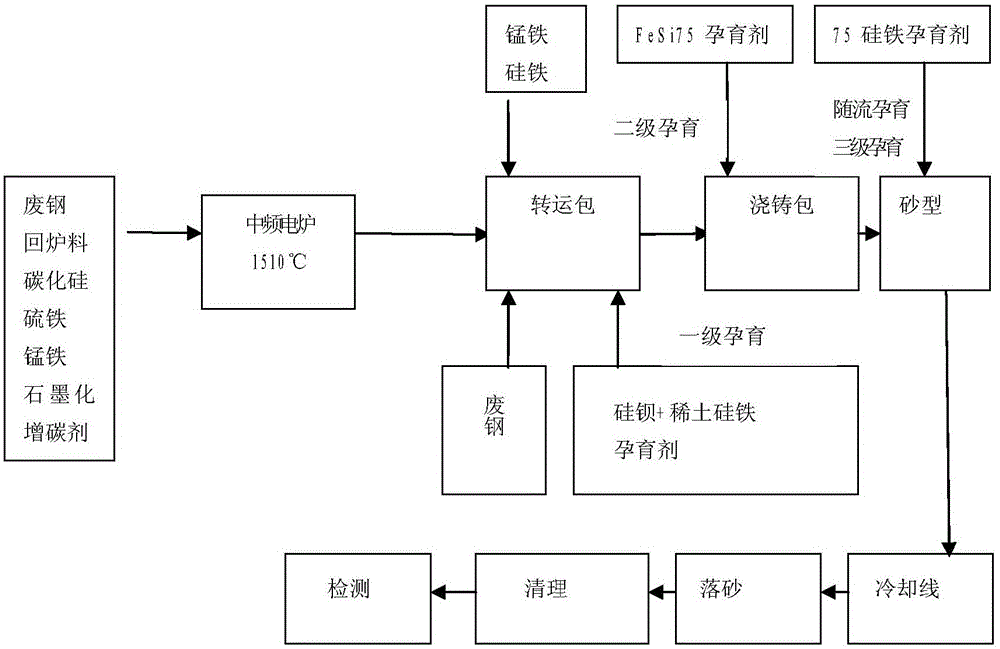

Manufacturing method for hydraulic castings produced through non-alloyed high-strength gray cast iron

InactiveCN105088056AIncrease the number ofImprove fertilityProcess efficiency improvementThree levelInduction furnace

The invention relates to a manufacturing method for hydraulic castings produced through non-alloyed high-strength gray cast iron. The method comprises the following steps that firstly, the mutual relation of elements and chemical components needed by the castings are determined; secondly, a medium-frequency induction furnace is adopted for smelting; thirdly, a stokehole molten iron transfer ladle is used for furnace charge to be mixed with alloy and steel scrap; fourthly, three-level inoculation is performed on molten iron; and fifthly, the cooling time is controlled to obtain the castings HT250 and HT300. On the non-alloyed premise, the high carbon equivalent is adopted, full steel scrap smelting silicon carbide increasing treatment is performed, a graphitizing carburant is used for adjusting the carbon quantity for synthesizing cast iron, the number of crystal nucleuses and the amount of cast iron are increased, the graphite form is improved, the overall molten iron quality is improved, and therefore the high-strength gray cast iron hydraulic castings HT250 and HT300 are stably obtained.

Owner:ANHUI DATIAN CASTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com