Vanadium titanium cast iron brake drum and preparation method thereof

A brake drum and gray cast iron technology, applied in the field of casting metal materials, can solve the problems of failure to produce in large quantities, differences in composition range, and no mass production, etc., and achieve the effects of improving the inoculation effect, increasing the strength, and improving the inoculation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

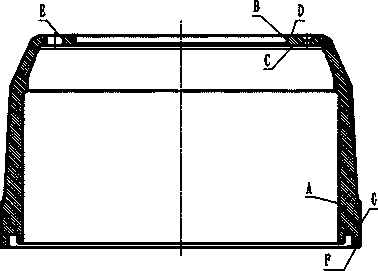

Image

Examples

preparation example Construction

[0039] The preparation method of vanadium-titanium gray cast iron brake drum among the present invention, comprises the following steps:

[0040] 1) Melting the original molten iron: taking vanadium-titanium pig iron, scrap steel, returned charge, recarburizer, ferrosilicon, ferromanganese, and ferrochrome as charge, the weight percentage of each chemical component in the charge is: C: 3.2-3.6%, Si : 1.3~1.6%, Mn: 0.6~0.9%, P≤0.10%, S: 0.07~0.12%, V: 0.15~0.20%, Ti: 0.0:7~0.12%, Cr: 0.25~0.35%, balance It is Fe and other unavoidable impurities; smelt with medium frequency induction furnace, heat up and purify molten iron after melting, keep it at 1520-1530°C for 10 minutes; The brake drum is returned to the furnace charge, and the composition of the molten iron is adjusted to meet the requirements; the slag accumulator is expanded perlite, and the composition and percentage content of the expanded perlite are: SiO 2 : 68~74%, Ai 2 o 3 : 10~16%, the balance is Na 2 O, K 2 ...

Embodiment

[0046] According to the preparation method of the vanadium-titanium gray cast iron brake drum in the specific embodiment of the present invention, prepare 4 furnaces the vanadium-titanium gray cast iron brake drum of different compositions combination within the scope of the composition specified in the present invention, check its chemical composition, metallographic structure and mechanical Performance, the results are shown in Table 3 and Table 4.

[0047] Table 3 prepares vanadium-titanium gray cast iron brake drum chemical composition (wt%):

[0048] serial number C Si mn P S V Ti Cr Example 1 3.43 1.71 0.88 0.085 0.081 0.171 0.075 0.26 Example 2 3.36 1.82 0.83 0.092 0.083 0.182 0.091 0.29 Example 3 3.35 1.76 0.85 0.083 0.092 0.195 0.100 0.32 Example 4 3.40 1.77 0.81 0.089 0.088 0.187 0.093 0.30

[0049] Table 4 Metallographic structure and mechanical properties of vanadium-titanium gray cast iro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com