Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

117results about How to "Good spherical effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength high-tenacity cast-state QT700-10 and production method thereof

ActiveCN106811676AIncrease the number ofReduce oxidation burnProcess efficiency improvementHigh intensityDuctile iron

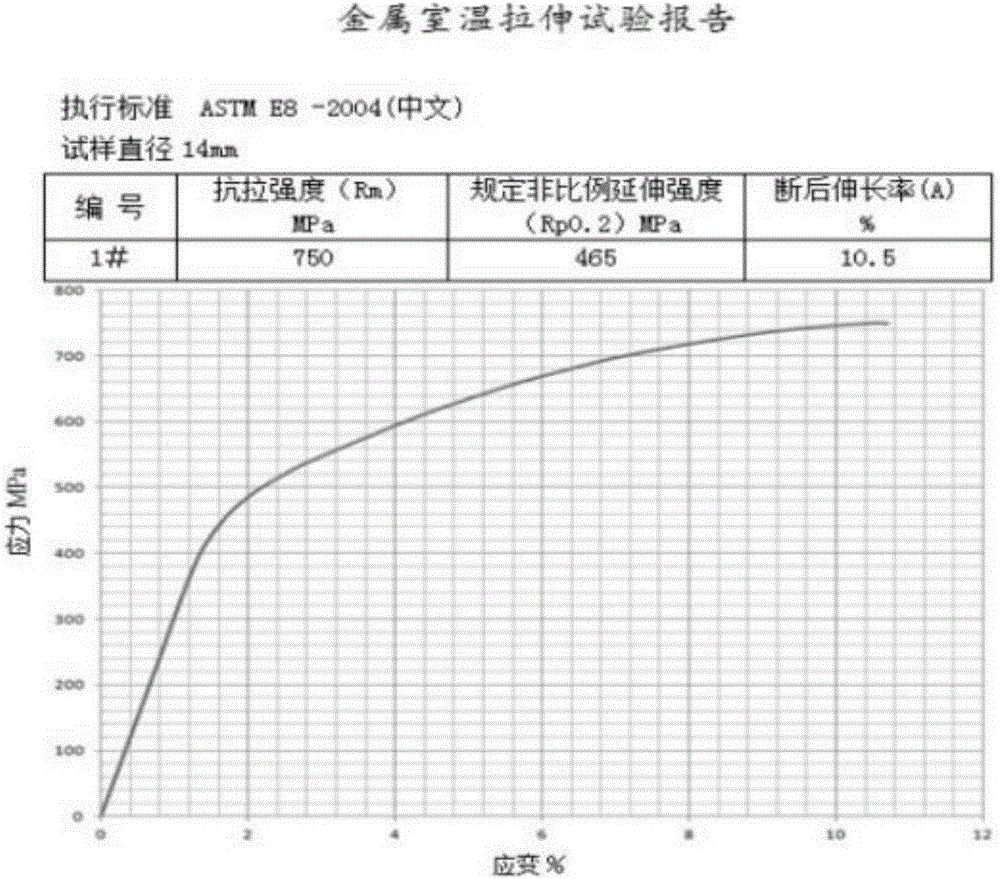

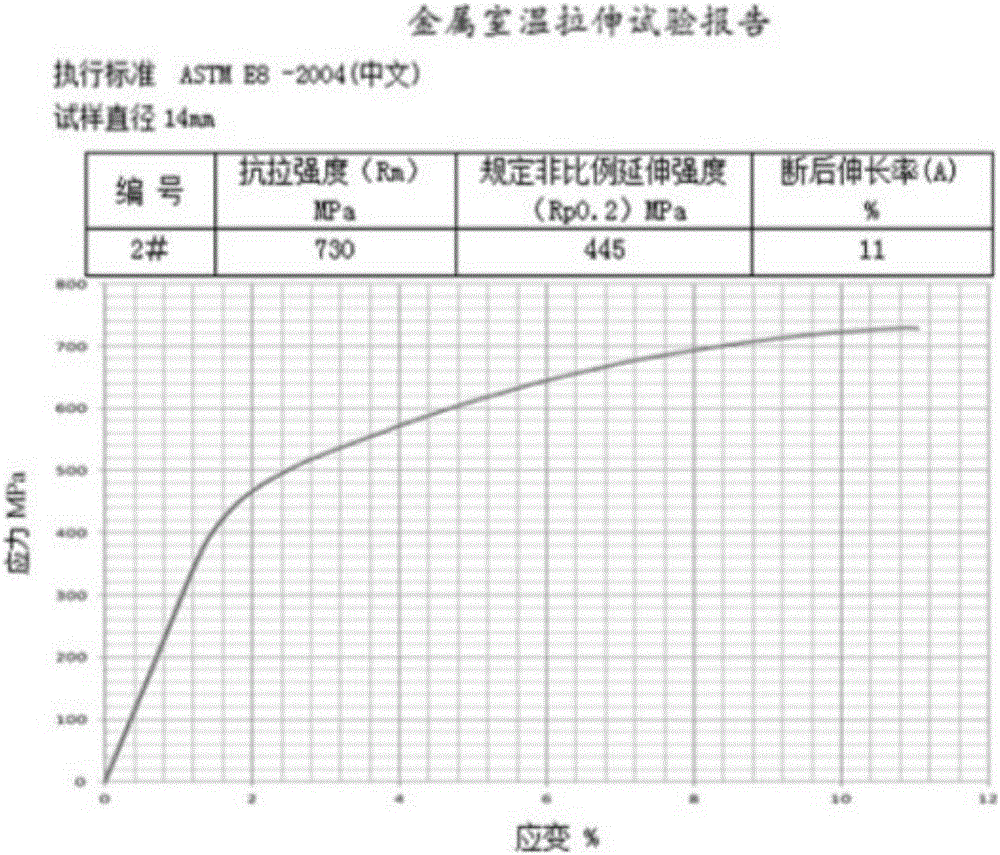

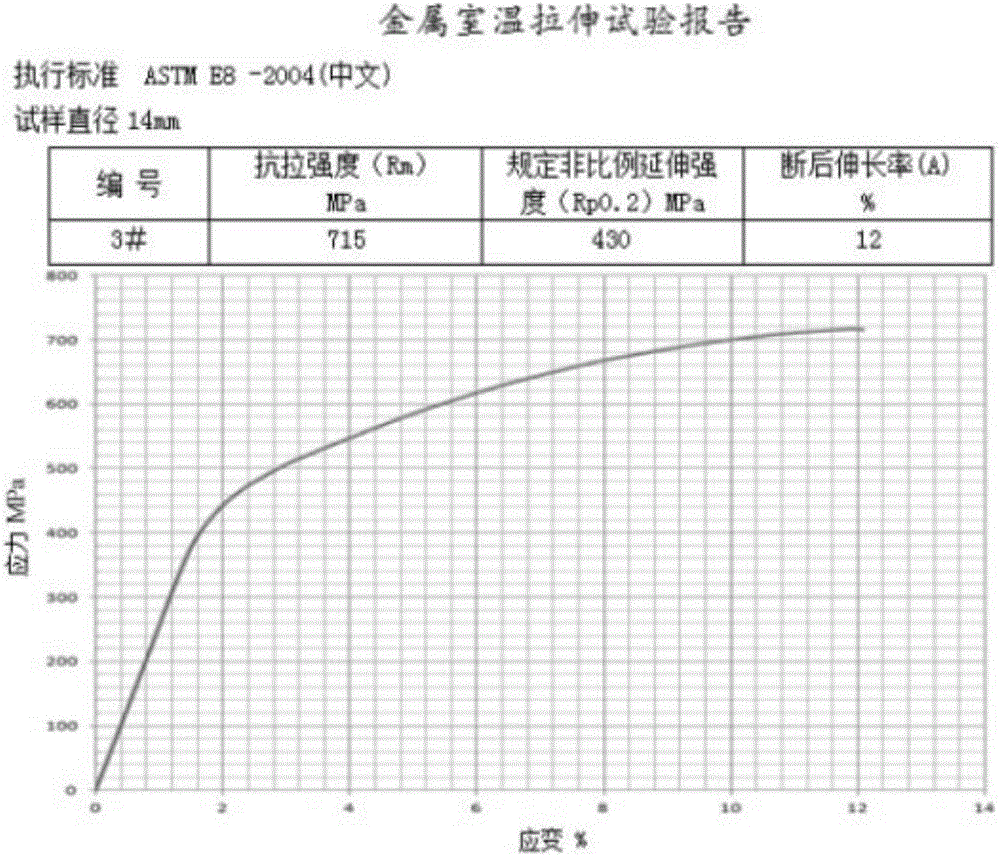

The invention belongs to the field of casting technologies and new materials and particularly relates to a high-strength high-tenacity cast-state QT700-10 and a production method thereof. Compared with ductile iron produced in the prior art, the high-strength high-tenacity cast-state QT700-10 has high strength and a high elongation rate, heat treatment is not needed, heavy metal, such as, Ni and Mo are not added in production, the tensile strength Rm in the cast state is larger than or equal to 700 MPa, the elongation rate A is larger than or equal to 10%, compared with the standard brand QT 450-10, the lowest tensile strength is improved by 55% under the same elongation rate; and compared with the standard brand QT 700-2, the lowest elongation rate is improved by four times under the same tensile strength. The high-strength high-tenacity cast-state QT700-10 can meet requirements of automobile ductile iron castings with high requirements for safety and comprehensive mechanical properties.

Owner:山东汇金股份有限公司

Spheroidizing annealing process of superplasticity fastener wire rod

InactiveCN102994710AImprove ductilityReduce hardnessFurnace typesHeat treatment furnacesWire rodMetallic materials

The invention relates to an annealing process of metal materials, in particular to a spheroidizing annealing process of a superplasticity fastener wire rod. The process includes the following steps that the fastener wire rod is placed in a thermal treatment furnace, protective gases are fed into the thermal treatment furnace, the interior temperature of the furnace is increased to 740 DEG C to 760 DEG C, and the temperature is maintained for 5 to 7 hours; according to first-stage cooling, the interior temperature of the furnace is decreased to 660 DEG C to 680 DEG C at the speed of 30 DEG C per hour, and the temperature is maintained for 4 to 6 hours; according to second-stage cooling, the interior temperature of the furnace is continued to be decreased to 390 DEG C to 410 DEG C at the speed of 50 DEG C per hour; and according to third-stage cooling, the fastener wire rod is naturally cooled to a room temperature. The fastener wire rod processed by the process has the advantages that the malleability is high, the hardness is low, the process is suitable for subsequent plastic working forming, and the product forming cracking rate is low.

Owner:DONGGUAN KELEE STEEL WIRE

Graphite spheroidization method and production system thereby

The invention discloses a graphite spheroidization method and a production system thereby. The method comprises the following three steps of: (1) ultra-fine pulverizing, namely pulverizing graphite to a proper granularity by utilizing an ultra-fine high-energy pulverizer; (2) reshaping treatment, namely performing reshaping treatment on the pulverized graphite by utilizing a batch-type or continuous reshaping system consisting of one or more special reshaping devices and a micro-nano particle reshaping cladding system; and (3) ultra-fine multilevel classification, namely performing high-precision multilevel series classification on the graphite subjected to reshaping treatment by utilizing an ultra-fin multilevel classification system, so as to obtain narrow granular spherical graphite with the D50 of 3-35mu m. The method and the system haves the following advantages: the product spheroidization effect is good, the tap density is large, the yield of finished products is high, a favorable reshaping effect can be achieved for artificial graphite which is difficult to reshape, the preparation period is short, the processing equipment is compact, and the method is safe and environmentally-friendly.

Owner:WUHU ZHEXIN NEW ENERGY

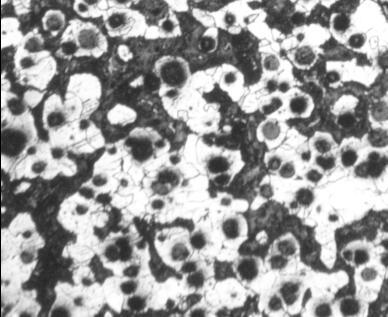

Silicon solid melt reinforced ferrite nodular cast iron and preparation technique thereof

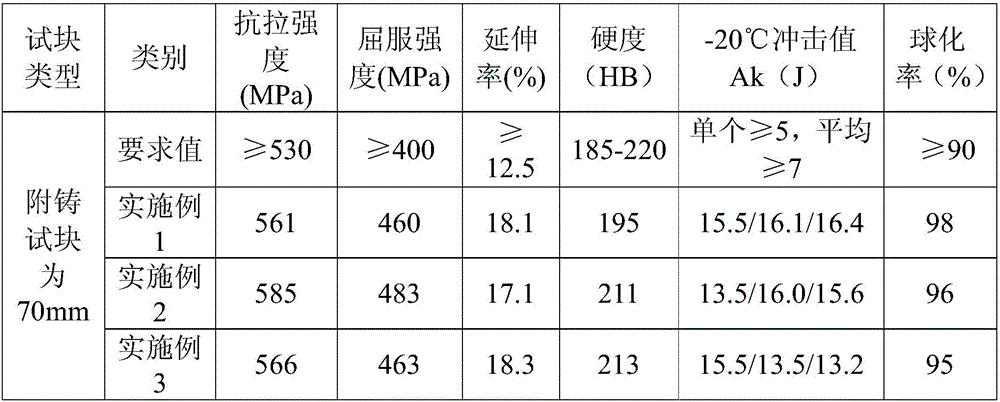

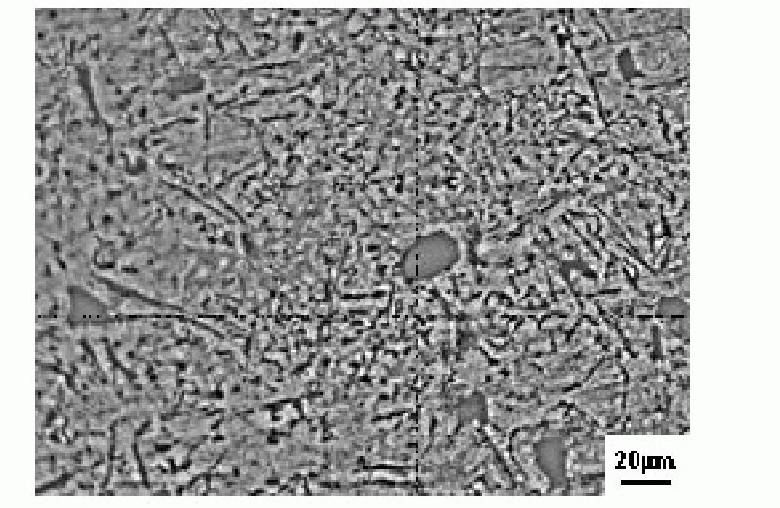

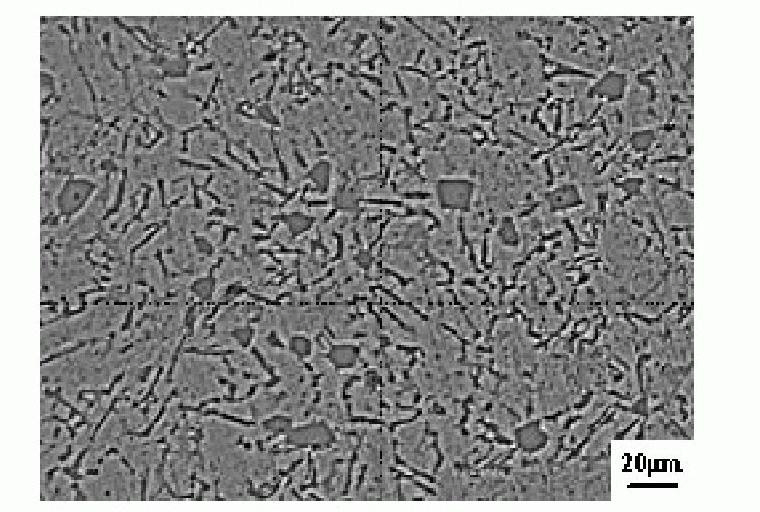

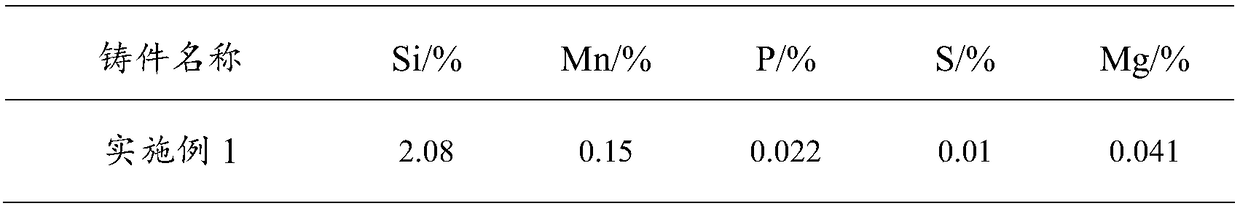

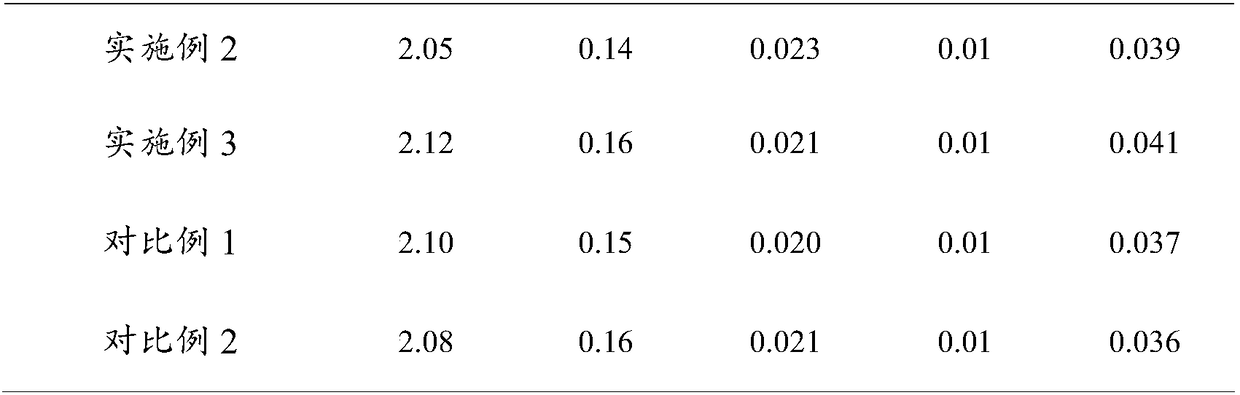

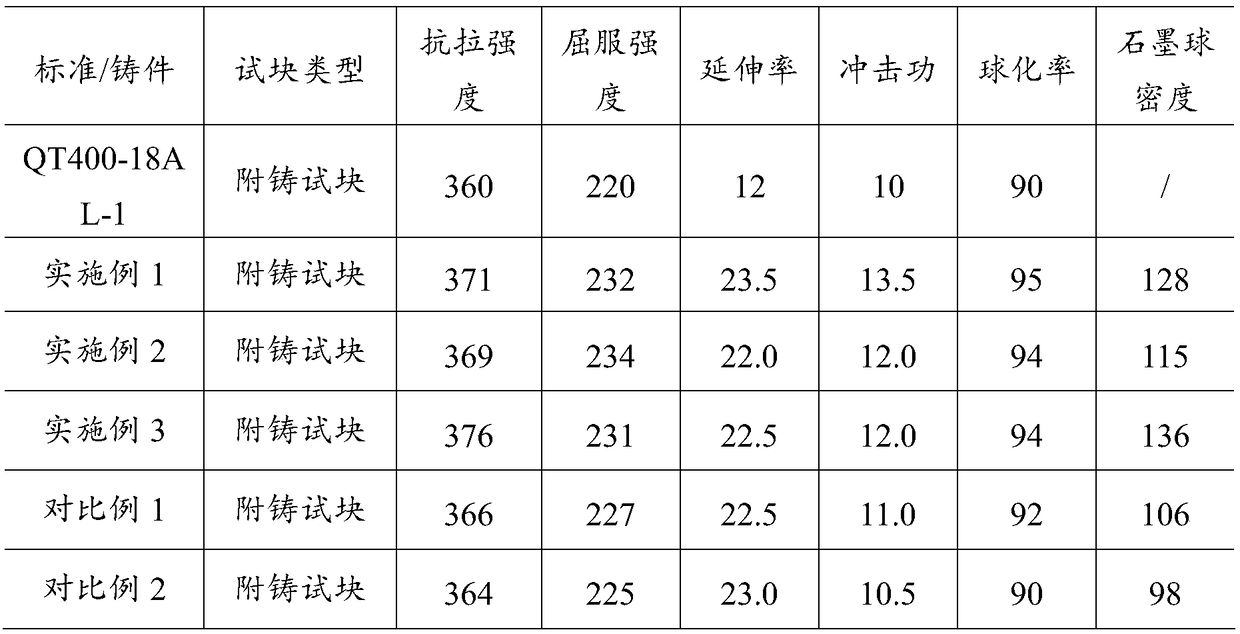

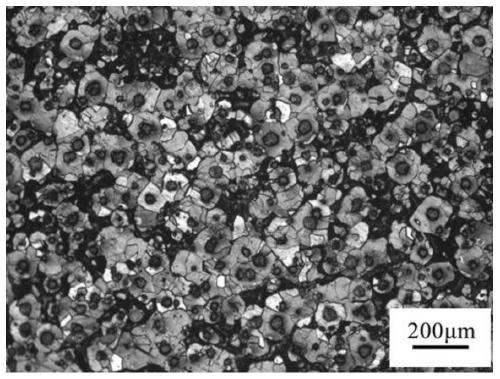

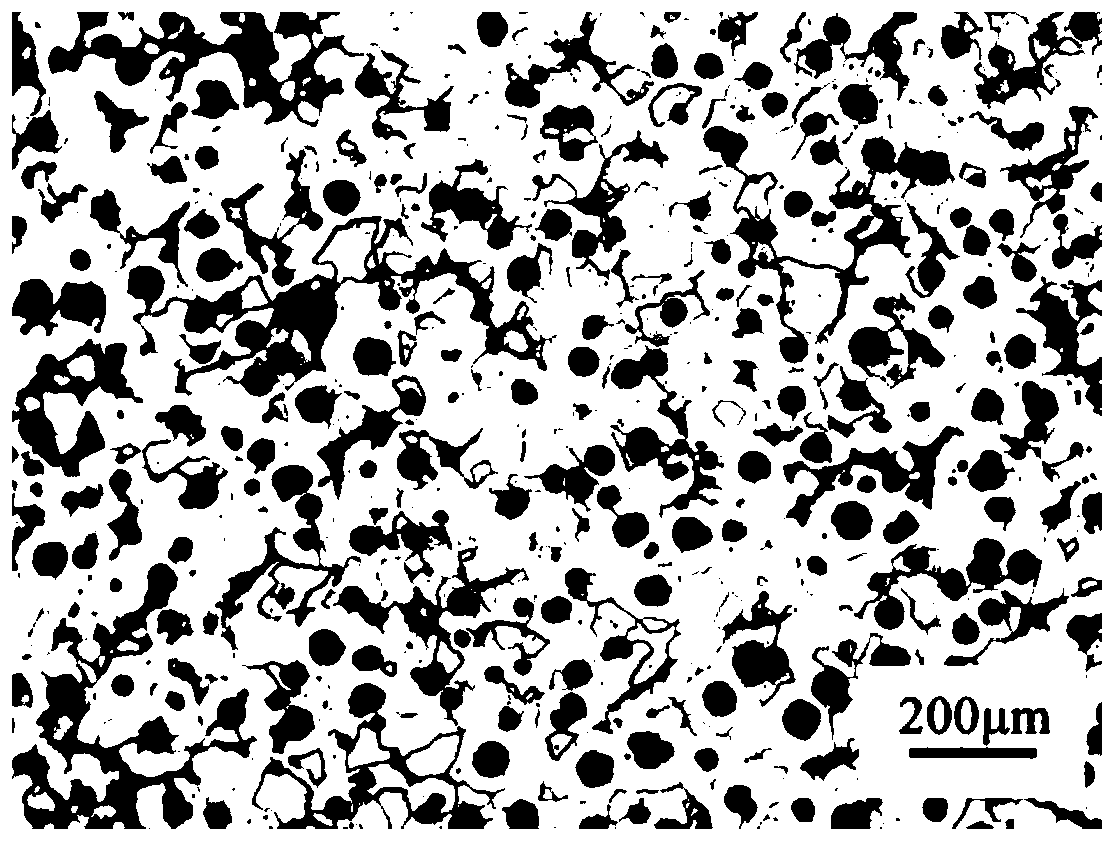

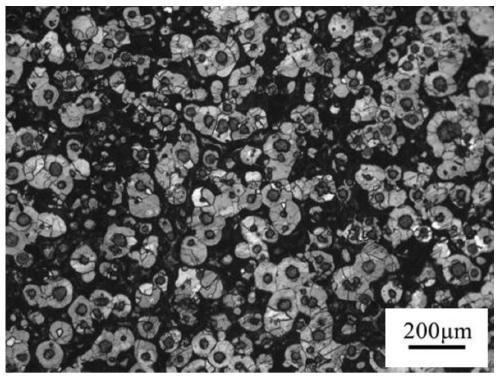

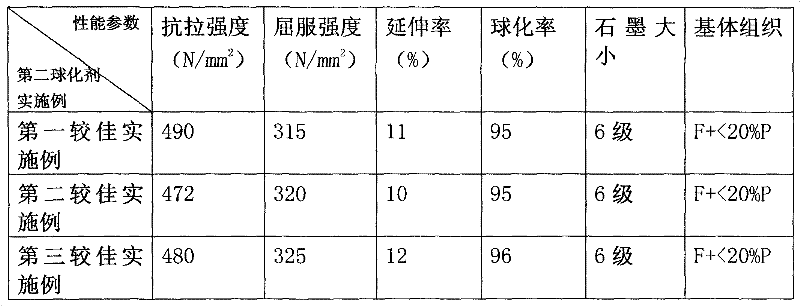

The invention relates to silicon solid melt reinforced ferrite nodular cast iron and a preparation technique thereof. The silicon solid melt reinforced ferrite nodular cast iron is composed of, by weight, 3.05-3.30% of C, 3.80-4.00% of Si, 0.15-0.25% of Mn, 0.035-0.050% of Mg, 0-0.035% of P, 0-0.015% of S, 0.0030-0.0040% of Ce, 0.0045-0.0055% of Sb and the balance iron. In the preparation process, high-quality pig iron and scrap steel are selected, molten iron is melted through an electric furnace, the content of carbon, the content of silicon and the content of manganese are controlled, a certain quantity of pretreating agents, nodulizing agents A, nodulizing agents B and inoculants are added into spheroidizing tundishes for molten iron treatment, a certain amount of antimony is added at the same time so as to adjust the content of cerium, and the spheroidizing effect is good; and inoculant blocks are embedded in a sprue basin, stream inoculation devices are arranged near the sprue basin for stream inoculation, and slagging-off and casting are conducted. The preparation method is simple, the tensile strength, the yield strength and the ductility of the silicon solid melt reinforced ferrite nodular cast iron obtained through preparation reach and exceed the required values, and the impact value at the temperature of -20 DEG C under the condition that no V-shaped notch exists also meets the requirements, so that the metallographical effect is good.

Owner:JIANGSU FAW FOUNDRY

Spheroidizing annealing process of screw wire rod

ActiveCN102876859AImprove ductilityReduce hardnessFurnace typesHeat treatment furnacesWire rodMetallic materials

The invention relates to an annealing process of a metal material, in particular to a spheroidizing annealing process of a screw wire rod. The spheroidizing annealing process comprises the following steps: placing the screw wire rod into a heat treatment furnace, filing insert gas into the heat treatment furnace, heating the temperature in the furnace to 710-730 DEG C, and thermally insulating for 5-8 hours; cooling at the first stage, that is to say, cooling the temperature in the furnace to 540-560 DEG C at the speed of 20 DEG C per hour; cooling at the first stage, that is to say, cooling the temperature in the furnace to 390-410 DEG C at the speed of 80 DEG C per hour; and cooling in the third stage, that is to say, discharging the screw wire rod and naturally cooling to normal temperature. The screw wire rod treated by the process method provided in the invention has the advantages of high ductility and low hardness, and is suitable for sequential plastic processing molding, and a product has low molding cracking rate.

Owner:DONGGUAN KELEE STEEL WIRE

High-silicon-molybdenum ductile iron material and preparation method thereof

The invention discloses a high-silicon-molybdenum ductile iron material and a preparation method thereof. The high-silicon-molybdenum ductile iron material comprises the following components in percentage by weight: 2.90 to 3.35 percent of C, 4.40 to 4.80 percent of Si, 0.50 to 0.75 percent of Mo, 0.30 to 0.50 percentage of Cr, 0.20 to 0.45 percent of V, 0.10 to 0.30 percent of Mn, 0.04 to 0.07 percent of Mg, less than or equal to 0.07 percent of P, less than or equal to 0.02 percent of S, and the balance of Fe. For the high-silicon-molybdenum ductile iron material, the tensile strength is more than or equal to 710 MPa, the yield strength is more than or equal to 500 MPa, the extensibility is more than or equal to 10 percent, and the hardness is 230 to 265 HBW5 / 750. The high-silicon-molybdenum ductile iron material also contains a trace amount of Sn and Sb. The high-silicon-molybdenum ductile iron material eliminates fragmental graphite and graphite deterioration layers, ensures the spheroidization grades of the parts with different wall thicknesses, and the defects of microscopic shrinkage and the like are overcome.

Owner:CRRC CHANGZHOU AUTO PARTS CO LTD +1

Spherical graphite production process

The invention discloses a spherical graphite production process.The spherical graphite production process comprises the steps of 1 raw material pretreatment, 2 smashing and balling, 3 grading, 4 primary purification, 5 second purification, 6 drying, 7 magnetic separation and 8 screening and package, wherein three smashing machines are arranged for the step 2.The spherical graphite production process is simple, spherical graphite is high in purity, smaller in surface area and higher in ramming density, and the rate of finished products is high.

Owner:青岛昕昊阳新能源材料有限公司

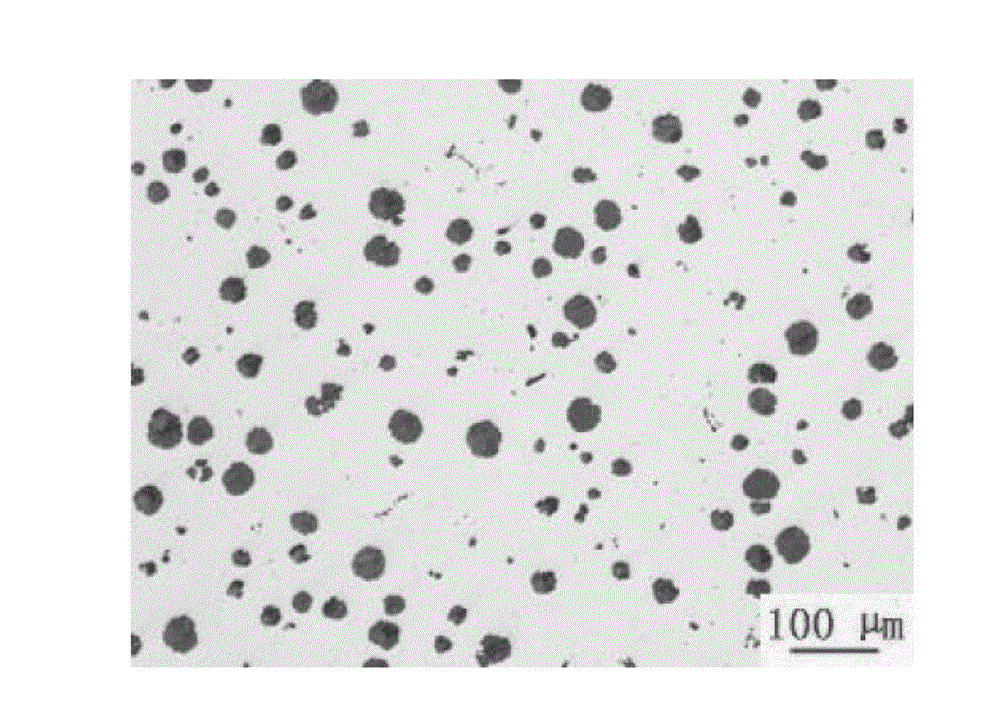

4032 alloy alterant and use method thereof

The invention relates to a 4032 alloy alterant and a use method thereof; the alterant comprises an Al-P and Al-5Ti-B intermediate alloy, and the following components in percentage by weight: P: 0.028 to 0.056 percent, Ti: 0.01 to 0.07 percent, B: 0.002 to 0.014 percent, and the balance aluminum. The essentials of the use method thereof are as follows: after the 4032 alloy is initially refined, Al-3.5 percent P alterant which is 0.6 to 1.6 percent of the ingredient weight of the 4032 alloy is added in at 750 to 850DEG C, to be uniformly stirred, and the heat is insulated for 15 to 100min; the materials are refined again; and Al-5Ti-B which is 0.3 to 1.6 percent of the weight of the 4032 alloy is added in at 750 to 770DEG C, and the heat is insulated for 5 to 12min. The alterant and the use method thereof can refine the primary crystal silicon to 18mu m before the thermal processing and the heat treatment of the 4032 alloy, and the nodularity is higher than 50 percent, and the mechanical property is greatly improved. The invention realizes the effective metamorphism of the 4032 alloy, and simultaneously develops a novel idea for the metamorphic technology of Al-Si eutectic alloys.

Owner:CENT SOUTH UNIV

Casting method for large wind power casting and casting produced through casting method

The invention discloses a casting method for a large wind power casting. The casting method comprises the following steps of (a) smelting furnace burden into molten iron, and (b) carrying out spheroidizing treatment and inoculation treatment on the molten iron and then carrying out casting, mold filling and solidifying so as to obtain the casting, wherein in the step a, the content of C in the molten iron is controlled to be 3.65-3.90wt%, the content of Si is controlled to be 0.8-1.2wt%, the content of Mn is controlled to be 0.05-0.20wt%, the content of P is controlled to be less than or equalto 0.035wt%, the content of S is controlled to be 0.006-0.015wt%, in the step b, the spheroidizing treatment specifically comprises the following steps of firstly, adding spheroidizing agents accounting for 1.00-1.20wt% of the molten iron into a spheroidizing chamber, then covering the spheroidizing agents with covering agents accounting for 0.4-0.7wt% of the molten iron and finally, pouring themolten iron into the spheroidizing chamber for spheroidizing and inoculation treatment, and in the step b, the inoculation treatment is carried out specifically in three steps. According to the casting method, the density and the roundness of graphite balls can be improved by using a large number of covering agents and a repeated inoculation mode. The invention further discloses the wind power casting. The wind power casting cast by the method has the advantages of being relatively high in strength and impact absorbing energy and excellent in mechanical performance.

Owner:JIANGSU JIXIN WIND ENERGY TECH

Alloy ductile iron crankshaft and heat treatment process thereof

The invention relates to an alloy ductile iron crankshaft and a heat treatment process thereof. The heat treatment process comprises the following steps: the carbon structural steel or the tool steel is taken as the raw material, carburant and ferrosilicon are added during the smelting process of an electric furnace in sequence, and the alloy ductile iron crankshaft comprises the following components (weight percentage): C accounts for 3.50-4.00, Si accounts for 1.6-2.5, Mn accounts for 0.3-0.9, P is less than 0.040, S is less than 0.03, Cr accounts for 0.03-0.07, Cu accounts for 0.2-0.5, Mg is less than 0.08, Ti is less than 0.02 and the balance is Fe. The austenization processing temperature is 840-920 DEG C, the heat preservation is carried out for 0.5-2.5 h, the three-phase region processing is performed at the temperature of 770-850 DEG C along with furnace cooling, and the time for the three-phase region processing is 1-3 h. The invention improves the nodularizing effect and the inoculation quality of the crankshaft, has low Ti content and effectively inhibits the influence of the heredity of the molten iron to the quality of the casting part; the heat treatment is added in the three-phase region processing; and the tensile strength of the alloy ductile iron crankshaft is equal to or more than 900 MPa, the yield strength is equal to or more than 500 MPa, the elongation rate is larger than or equal to 5 percent, and the alloy ductile iron crankshaft has excellent comprehensive properties and can be manufactured into high-trademark QT900-5 crankshaft.

Owner:TIANRUN IND TECH CO LTD

Preparation method of as-cast mixed matrix QT600-10 ductile iron

PendingCN111074034AAffect the overall performanceGuaranteed plasticityProcess efficiency improvementFoundryMetal particle

The invention provides a preparation method of as-cast mixed matrix QT600-10 ductile iron. The preparation method comprises the following steps of S1, adding of raw materials: adding 40 to 60 percentby mass of pig iron, 25 to 40 percent by mass of scrap steel, 10 to 20 percent by mass of foundry returns and 0.1 to 0.3 percent by mass of electrolytic copper anode; S2, molten iron smelting: addingthe electrolytic copper anode after the scrap steel, pig iron and foundry returns are all smelted; S3, in-ladle melt treatment: placing a rare earth-containing nodulizing agent into one side of a bottommost part of a nodulizing ladle, placing a silicon-barium-calcium inoculant into an upper part of metal particles of the rare earth-containing nodulizing agent, and discharging molten iron into thenodulizing ladle for nodulizing and in-ladle inoculation, wherein the nodulizing treatment temperature is 1,500 to 1,550 DEG C; and S4, pouring: transferring the molten iron in the nodulizing ladle into a pouring site for pouring at a temperature of 1,380 to 1,420 DEG C, and adding a strontium-silicon following inoculant along with the molten iron during pouring. According to the preparation method, the content ranges of pearlite and ferrite in a matrix structure are regulated and controlled through the selection and control of raw materials as well as the alloy component design, so as to obtain a ductile iron material suitable for elevator parts.

Owner:SHANGHAI TOBACCO MACHINERY +1

Medium silicon molybdenum niobium spheroidal graphite cast iron material and preparation method thereof

The invention discloses a medium silicon molybdenum niobium spheroidal graphite cast iron material and a preparation method thereof. The medium silicon molybdenum niobium spheroidal graphite cast iron material is prepared from the following chemical components in percentage by mass: 2.8-3.2% of C, 4.2-4.5% of Si, less than or equal to 0.4% of Mn, less than or equal to 0.04% of P, less than or equal to 0.015% of S, 0.8-0.9% of Mo, 0.6-0.9% of Ni, 0.4-0.7% of Nb, 0.03-0.06% of Mg, 0.15-0.25% of V and the balance of Fe and inevitable other elements. Since C04 high-purity pig iron and waste steel are taken as raw materials, a medium-frequency induction furnace is adopted for smelting, and a carburant, silicon carbide, ferrocolumbium, nickel plates, ferrosilicon and ferrovanadium are added in different time phases of smelting, raw iron chemical components and smelting temperature expected by design can be achieved, and the product disclosed by the invention can be prepared through nodulization and two times of inoculation. By adopting the edium silicon molybdenum niobium spheroidal graphite cast iron material disclosed by the invention, an exhaust manifold of an engine can work under a working condition of about 800 DEG C, the high-temperature use property of the exhaust manifold can be improved, and the service life of the exhaust manifold can be prolonged.

Owner:西峡县内燃机进排气管有限责任公司

Casting technology of low-temperature and high-tenacity spheroidal graphite cast iron butterfly valve containing carbides

InactiveCN106435342AIdeal chemical compositionExcellent metallographic detection indexSmeltingHeat treated

The invention provides a casting technology of a low-temperature and high-tenacity spheroidal graphite cast iron butterfly valve containing carbides and belongs to the technical field of casting technologies. The spheroidal graphite cast iron butterfly valve with high impact tenacity, high wear resistance and long impact fatigue life is obtained through smelting, spheroidization, pouring, box pulling and heat treatment.

Owner:CHANGZHOU HONGSHENG TECH CO LTD

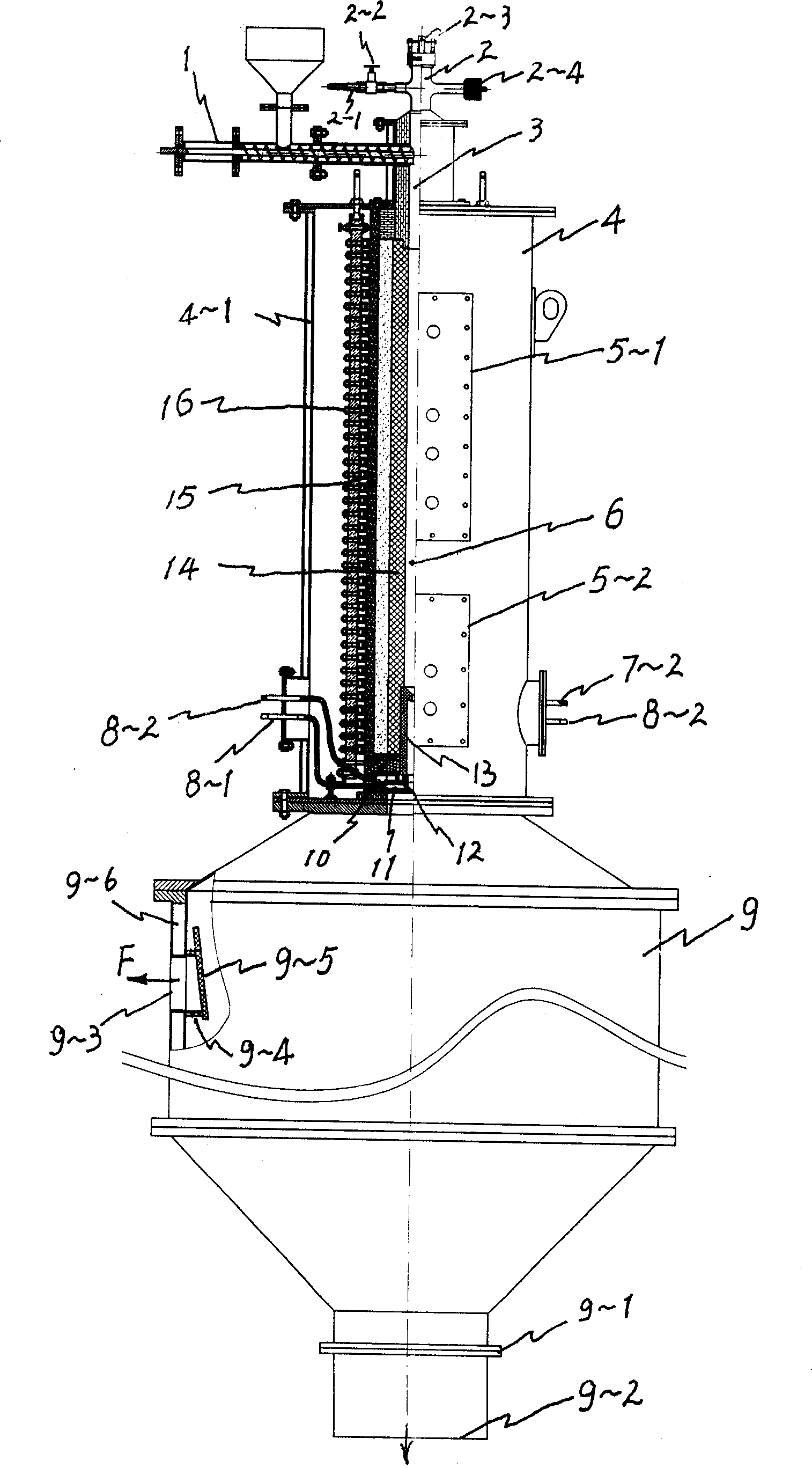

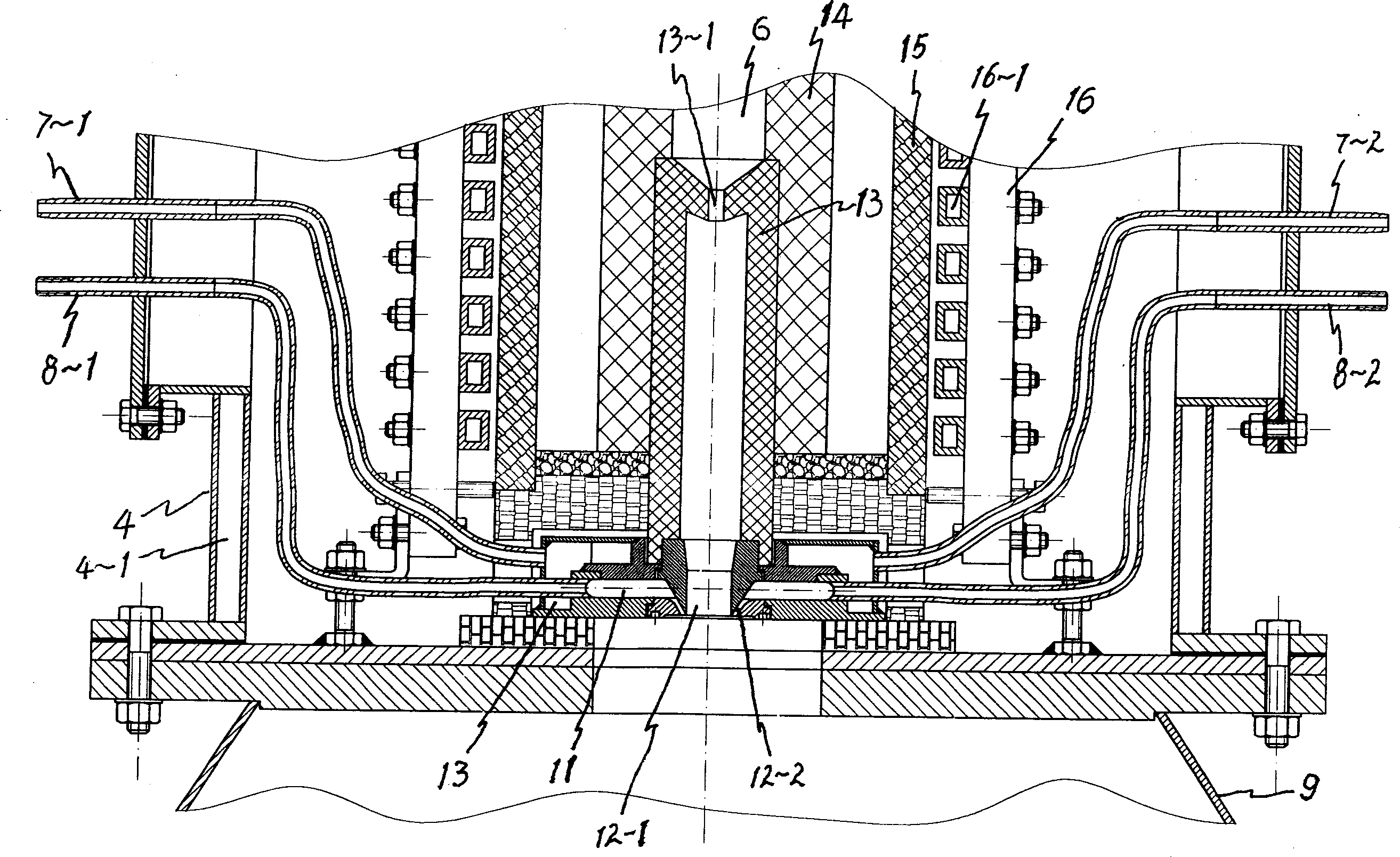

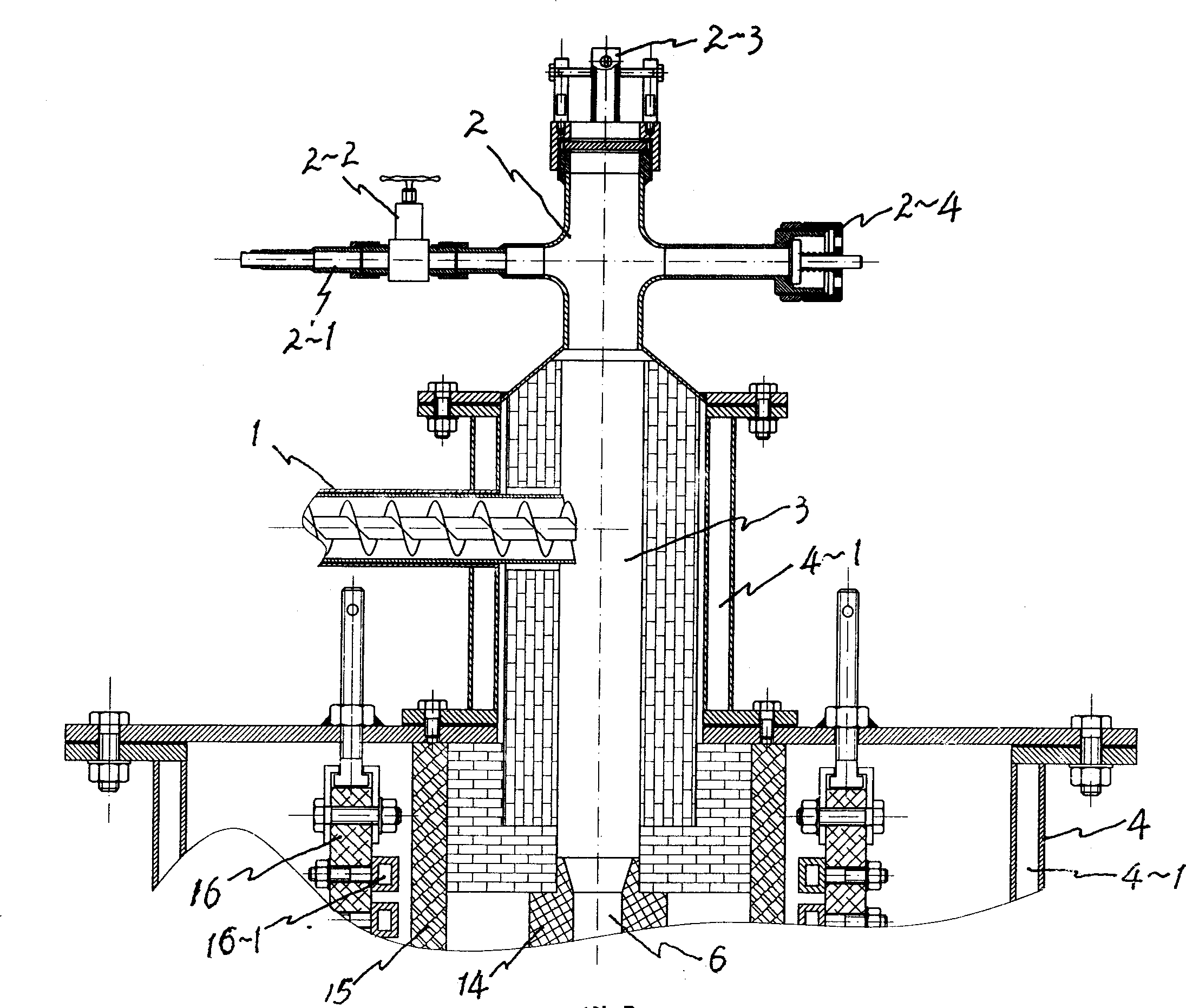

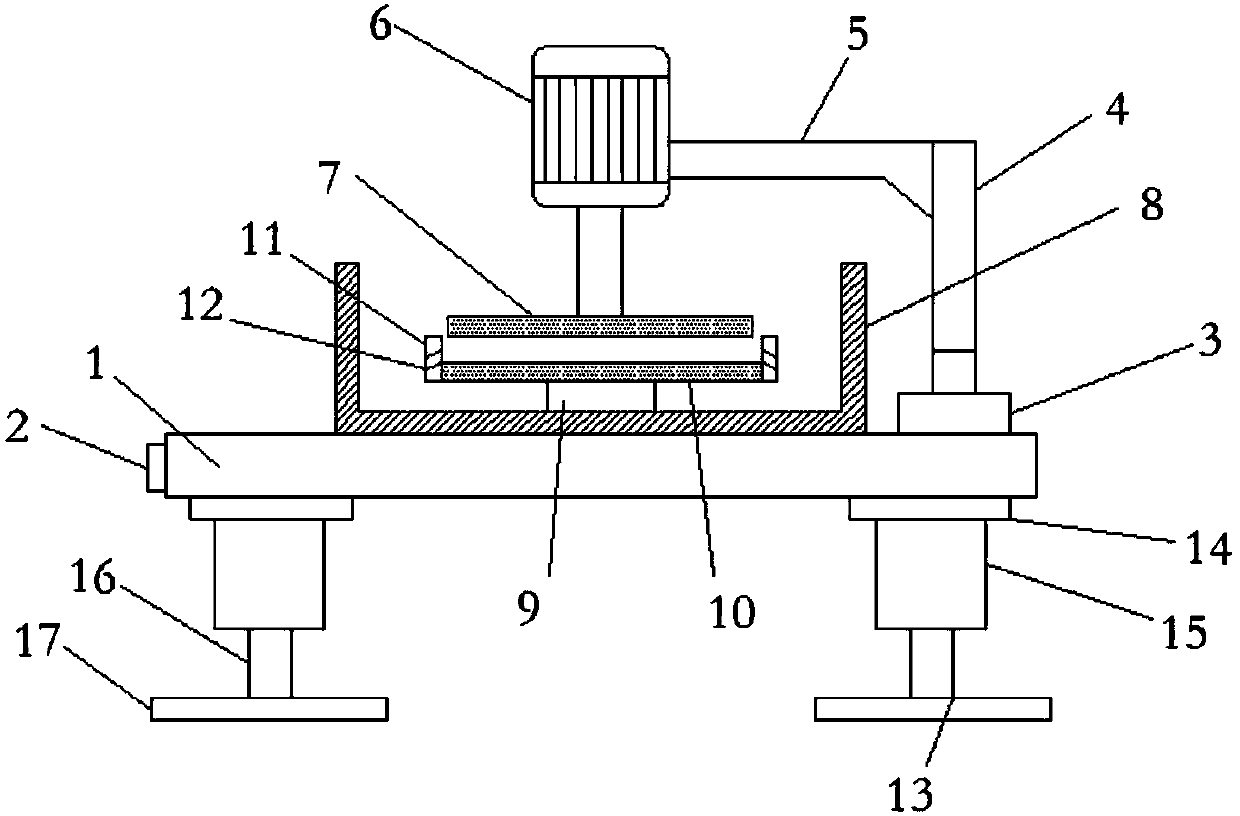

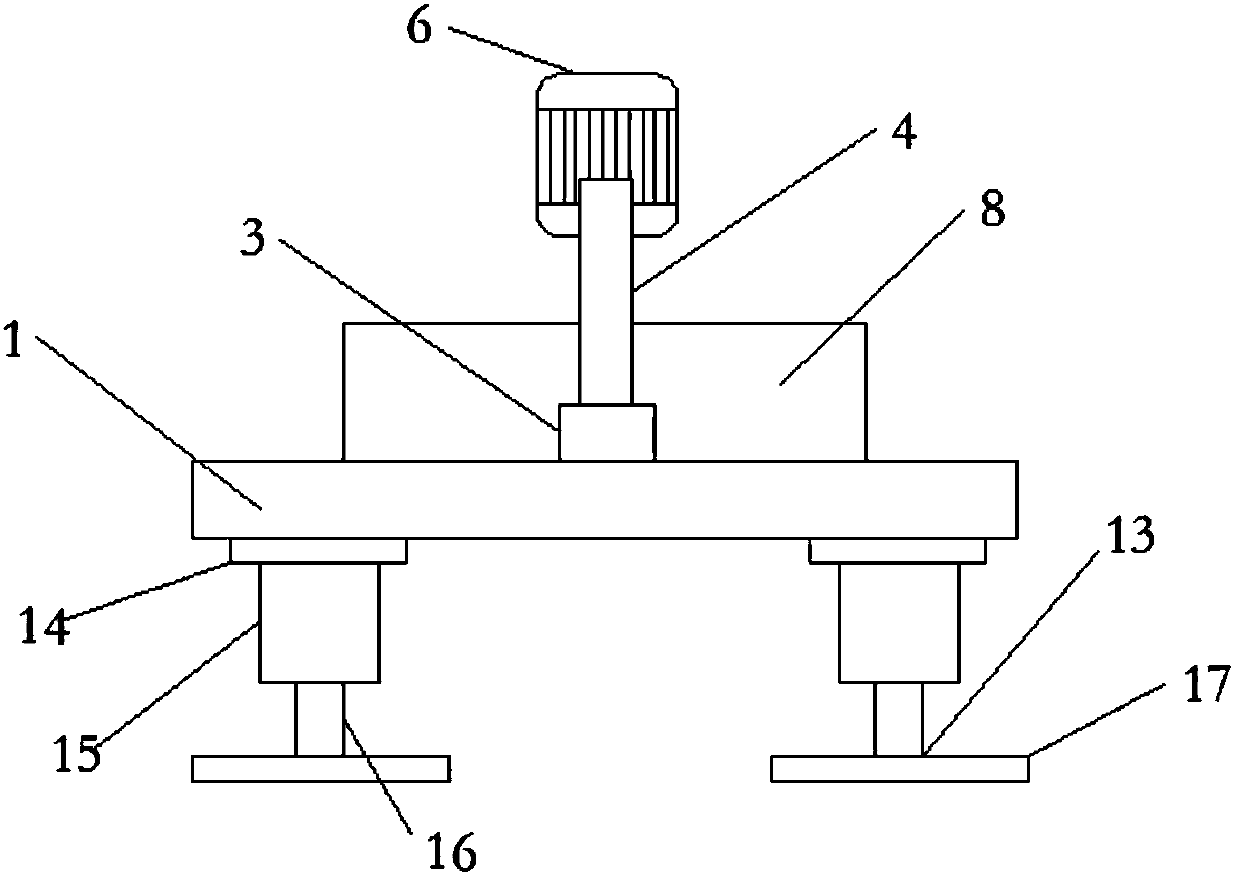

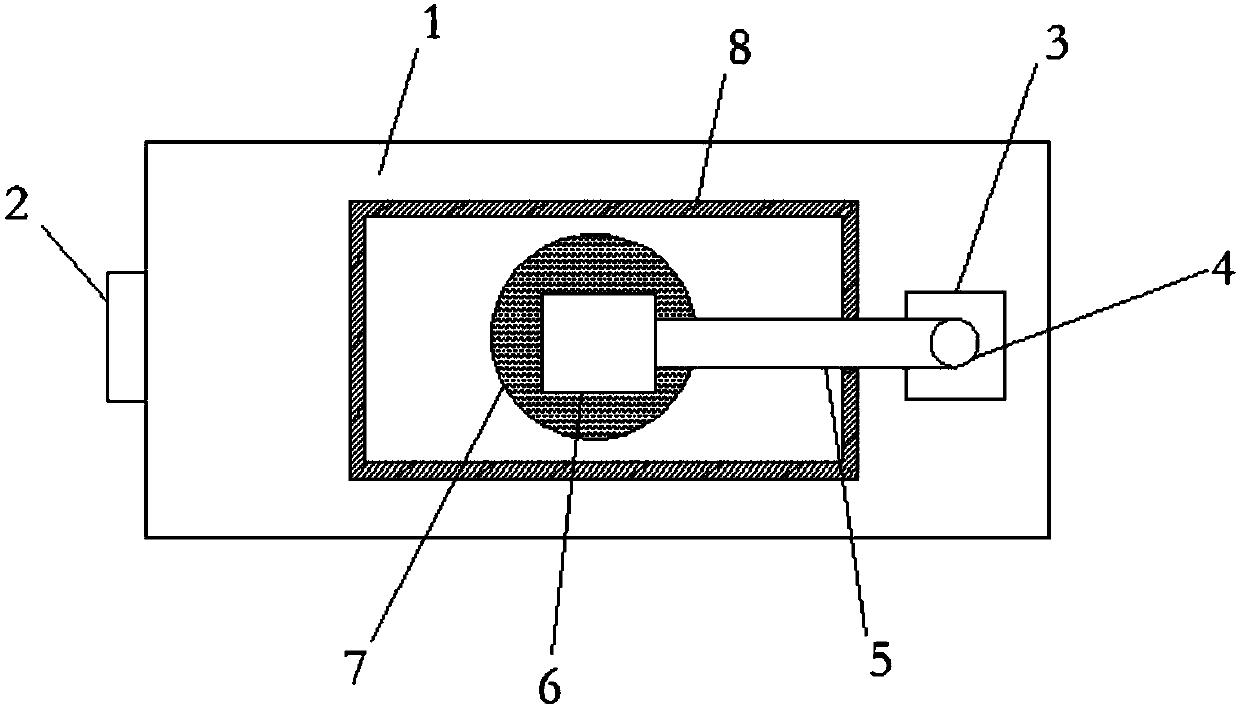

Atomizing formation apparatus for producing spherical casting WC powder

The atomizing formation apparatus for producing spherical casting WC powder includes low pressure inert gas intake assembly; furnace shaft containing the feeding mechanism, heater and graphite furnace tube; jetting and atomizing formation assembly containing beam current tube, inner and outer nozzles, high pressure inert gas supplying mechanism and atomizing formation barrel; and water cooling circulation mechanism. Owing to that the melt of the material in the protection of inert gas is acted by the high pressure inert gas flow to be jetted, atomized and formed into spherical powder, the produced spherical casting WC powder has compact structure and low cost. The technological process of the present invention is short, high in production efficiency, stable in product quality, low in power consumption and production cost and good in product using effect.

Owner:HUNAN DINGLI NEW MATERIAL ENG CENT +1

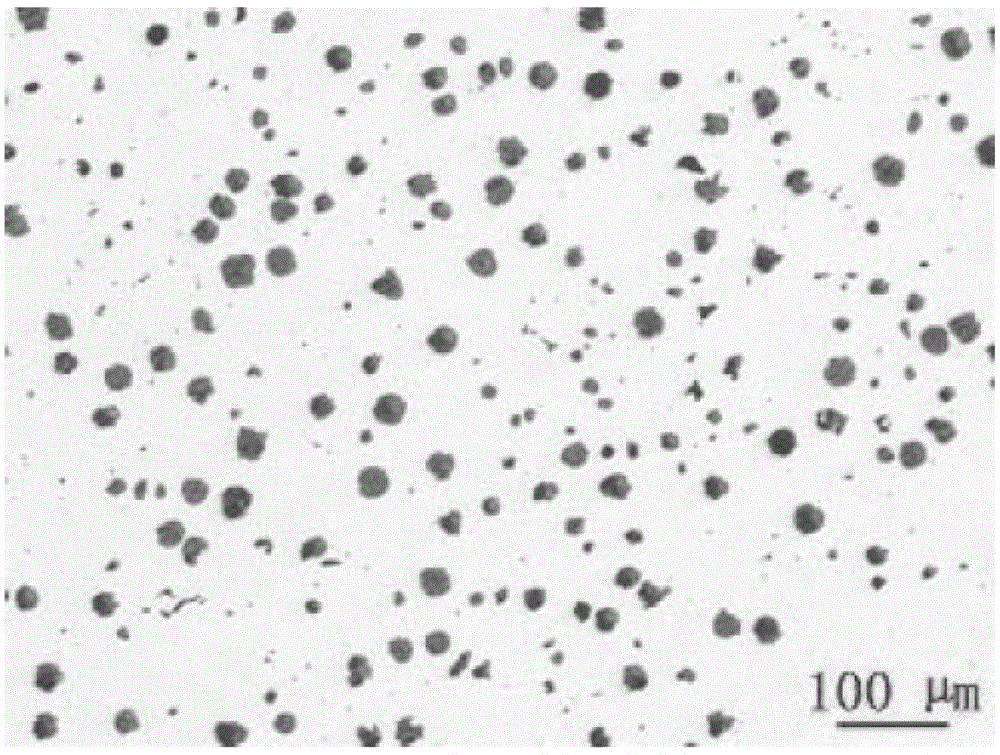

Method for preparing B4C/Y112 aluminum base composite material semi-solid slurry

The invention provides a method for preparing B4C / Y112 aluminum base composite material semi-solid slurry. The method comprises the following steps of: first, putting a matrix material Y112 aluminum alloy ingot into a melting furnace and heating the aluminum alloy ingot to reach the temperature of 630-640 DEG C; refining the aluminum alloy ingot at the temperature; after standing for 20-30 min, cooling the aluminum alloy ingot to reach 595-605 DEG C; pouring liquid aluminum alloy into mechanical stirring equipment by using a pouring pipe; stirring the liquid aluminum alloy for 5-8 min at a speed of 400-600 r / min to reach a set stirring temperature of 565-585 DEG C; adding B4C reinforcing particles; and stirring for 5-8 min at a constant temperature of 565-585 DEG C so as to obtain the B4C / Y112 aluminum base composite material semi-solid slurry. The method for preparing the B4C / Y112 aluminum base composite material semi-solid slurry, provided by the invention, has the advantages of fine and uniform B4C / Y112 semi-solid structures, good nodulizing effect, simple process, safety, reliability, convenience for operation and no pollution of three wastes; and the semi-solid forming requirement is completely satisfied.

Owner:NANCHANG UNIV

Spheroidizing agent for spheroidal graphite cast iron, and preparation method thereof

The invention discloses a spheroidizing agent for spheroidal graphite cast iron, belonging to the field of cast iron metallurgical technology, and aiming at overcoming the defects that the spheroidizing effect of the spheroidizing agent in the prior art is poor, and the mechanical properties of the obtained spheroidal graphite cast iron can not meet the requirements. The spheroidizing agent for the spheroidal graphite cast iron comprises the components by mass percent: 2-7% of Y, 7-9% of Mg, 37-44% of Si, 2-3% of Ca, 0.3-0.4% of Sb, 0.1-0.4% of Mn, 0.2-0.5% of Al, 0.2-0.5% of Ti, and the balance of Fe and unavoidable trace elements. The invention also discloses a preparation method of the spheroidizing agent for the spheroidal graphite cast iron. The spheroidizing agent is good in spheroidizing effect, and the spheroidal graphite cast iron obtained by spheroidizing has high toughness, ferrite quantity and spheroidization rate so as to be especially suitable for castings of various machine moulds with high strength and impact power.

Owner:宁波康发铸造有限公司

Preparation method for nodular cast iron

The invention relates to a preparation method for nodular cast iron and belongs to the technical field of cast iron smelting. The preparation method comprises the steps that coke, limestone, pig iron, melt down steel and scrap steel with the mass ratio of 100: 30: (58-62): (26-30): (10-14) are smelted into iron liquid; nodulizing agents are made into ultrafine powder with the grain size of 1-25 micrometers, the ultrafine powder is wrapped into a first spherical nodulizing agent and a second spherical nodulizing agent with the diameters of 5-15 mm through steel boards, a first layer of nucleating agent is put into a nodulizing package, the first spherical nodulizing agent covers the first layer of nucleating agent, a pig iron scrap I covers the first spherical nodulizing agent, a second layer of nucleating agent covers the pig iron scrap I, the second spherical nodulizing agent, a pig iron scrap II and a third layer of nucleating agent cover the second layer of nucleating agent in sequence, and the iron liquid is poured for nodulizing and nucleating treatment; and the iron liquid is poured and subjected to heat treatment, and the finished nodular cast iron is obtained. The preparation method is convenient to implement and little in pollution, absorptivity of the nodulizing agents is high, the nodulizing effect is good, and the prepared nodular cast iron is high in intensity and good in toughness and size stability.

Owner:宁波康发铸造有限公司

Method for producing globular casting tungsten carbide powder by atomising

InactiveCN1488463ASimple production processContinuous Industrialization OperationTungsten/molybdenum carbideProduction rateHigh pressure

The invention discloses a kind of spheric casting tungsten-carbide powder with atomization forming method, it includes batch, smelting, atomization forming, sifting. Because that it melts the materials under the protection of inert gas in sealed condition and atomization forms into spheric powder by high pressure, strong inert gas, the craft flow is short. The operation is convenient, the product has a very good quality and high rigidity, the cost is decreased.

Owner:ZIGONG CEMENTED CARBIDE CORP +1

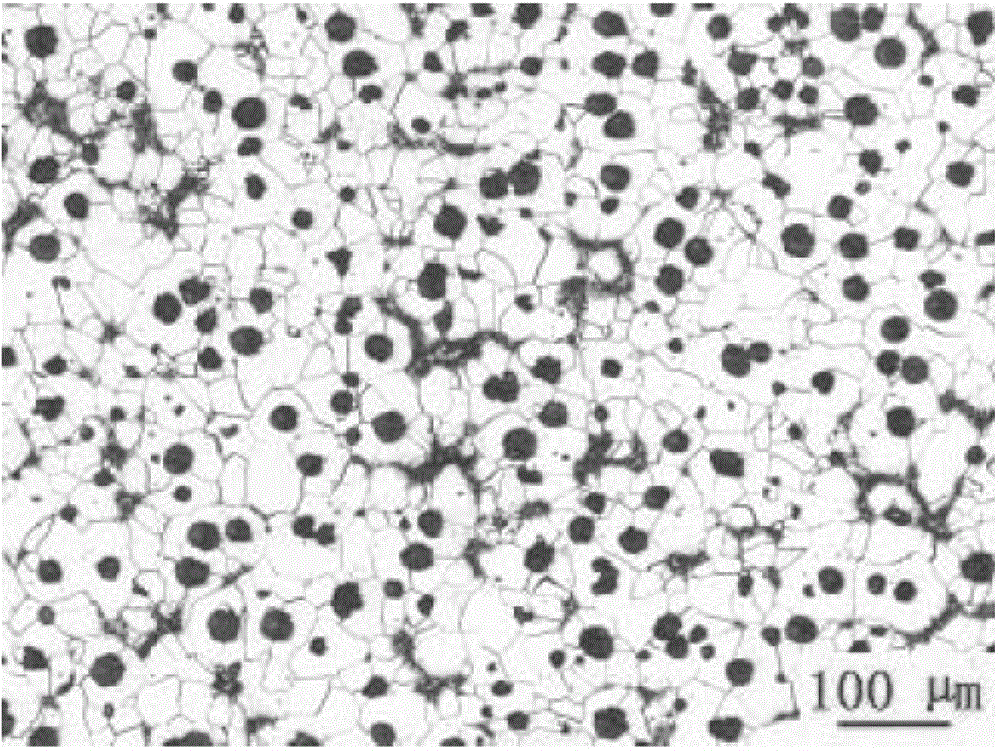

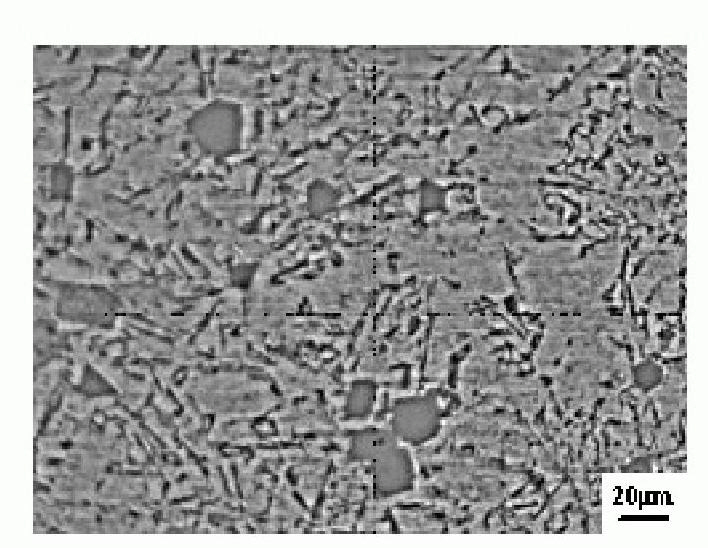

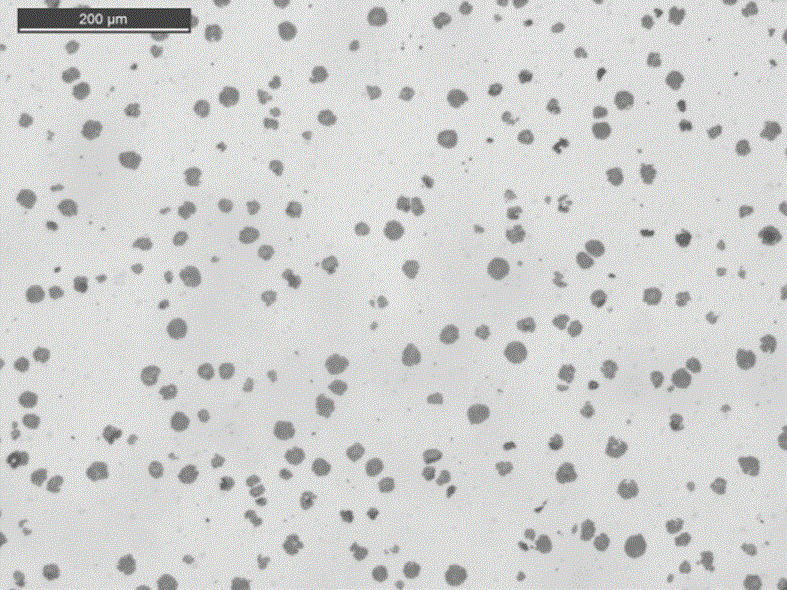

Method for spheroidizing heat treatment of eutectic silicon in eutectic aluminium-silicon alloy

ActiveCN106367700AGood spherical effectIncreased nodularization speedSilicon alloyMechanical property

The invention relates to a method for spheroidizing heat treatment of eutectic silicon in eutectic aluminium-silicon alloy. The method refers to carrying out spheroidizing annealing at the eutectic temperature (577 DEG C) of aluminium-silicon alloy. According to the method, annealing is carried out on the alloy at the eutectic temperature (577 DEG C) of aluminium-silicon alloy to enable needlelike eutectic silicon to have rapid balling; and the method is a simple and effective method for spheroidizing heat treatment of eutectic silicon to improve the mechanical property of eutectic aluminium-silicon alloy.

Owner:CHANGZHOU UNIV

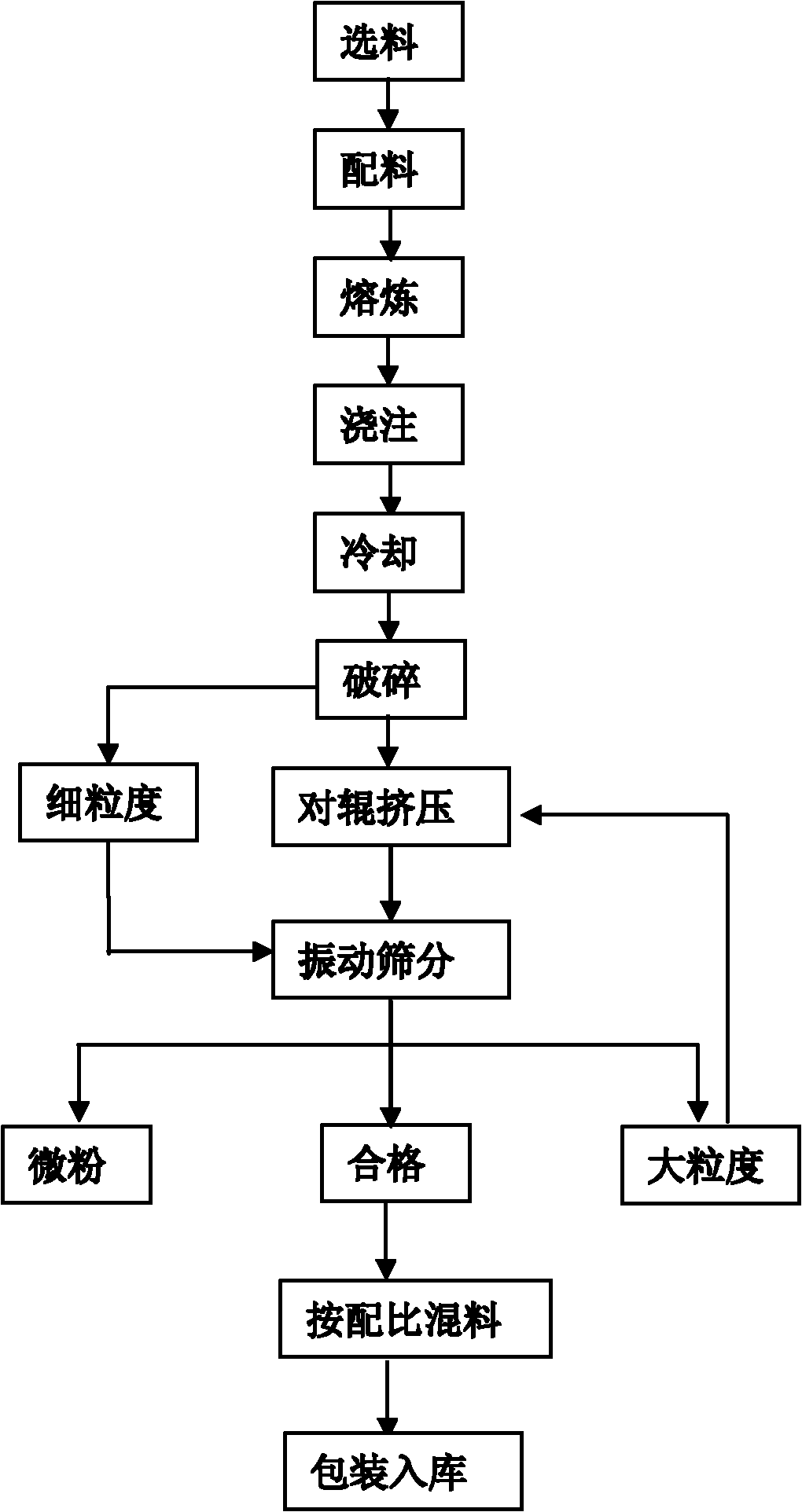

Pipe die powder for centrifugally casting nodular cast iron pipe and preparation process thereof

The invention discloses pipe die powder for centrifugally casting a nodular cast iron pipe and a preparation process thereof. The pipe die powder comprises the following components in percent by mass: 60-65 percent of Si, 1.5-2.0 percent of Ca, 2.0-3.0 percent of Ba, 1.4-1.6 percent of Mn, 1.0-1.5 percent of Mg, 1.0-2.0 percent of Zr, 0.7-1.5 percent of Al and the balance of Fe; and the granularities of pipe die powder comprise less than 1.5 percent of 80 mu, 25-30 percent of 100-120 mu, 40-50 percent of 140-180 mu, 25-30 percent of 200-300 mu and less than 2.5 percent of more than 300 mu. The preparation process comprises the following steps of: preparing, melting, pouring, cooling, crushing, milling, proportioning granularities and packaging in vacuum. The pipe die powder has the advantages of uniform components, consistent melting points and reasonable granulometric class, and is beneficial to the prolonging of the service life of a pipe die of the nodular cast iron pipe, the reduction of a series of casting defects of cockles, poor nodulizing, surface cracks and the like of the nodular cast iron pipe, the improvement of the quality of the nodular cast iron pipe and the yield, and the lowering of the production cost.

Owner:YUZHOU HENGLILAI ALLOY CO LTD

Spheroidizing annealing technology of high-tenacity fastener wire rod

InactiveCN104232858AUniform metallographic structureImprove toughnessFurnace typesHeat treatment furnacesFastenerHeat conservation

The invention discloses a spheroidizing annealing technology of a high-tenacity fastener wire rod. The spheroidizing annealing technology comprises the following steps: placing a fastener wire rod into a thermal treatment furnace, introducing a protective gas into the thermal treatment furnace, raising the temperature in the furnace to 720-740DEG C, and performing heat preservation for 1-3h; carrying out first-stage cooling: cooling the temperature in the furnace to 680-700DEG C at the speed of 10DEG C / h, and performing heat preservation for 2-4h; carrying out second-stage cooling: further reducing the temperature in the furnace to 630-650DEG C at the speed of 20DEG C / h; and carrying out third-stage cooling: naturally cooling the fastener wire rod to normal temperature. The fastener wire rod treated by adopting the technological method is uniform in metallographic structure, high in tenacity, high in ductility, low in hardness and suitable for subsequent high-difficulty repeated plastic machining forming, and the forming cracking rate of the product is low.

Owner:DONGGUAN KELEE STEEL WIRE

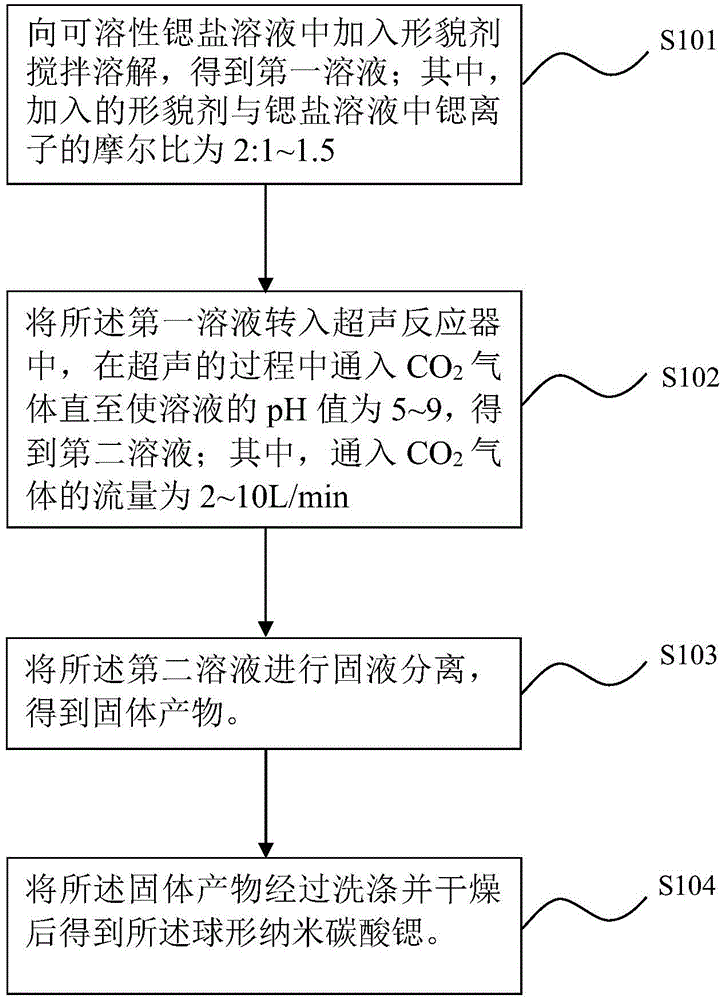

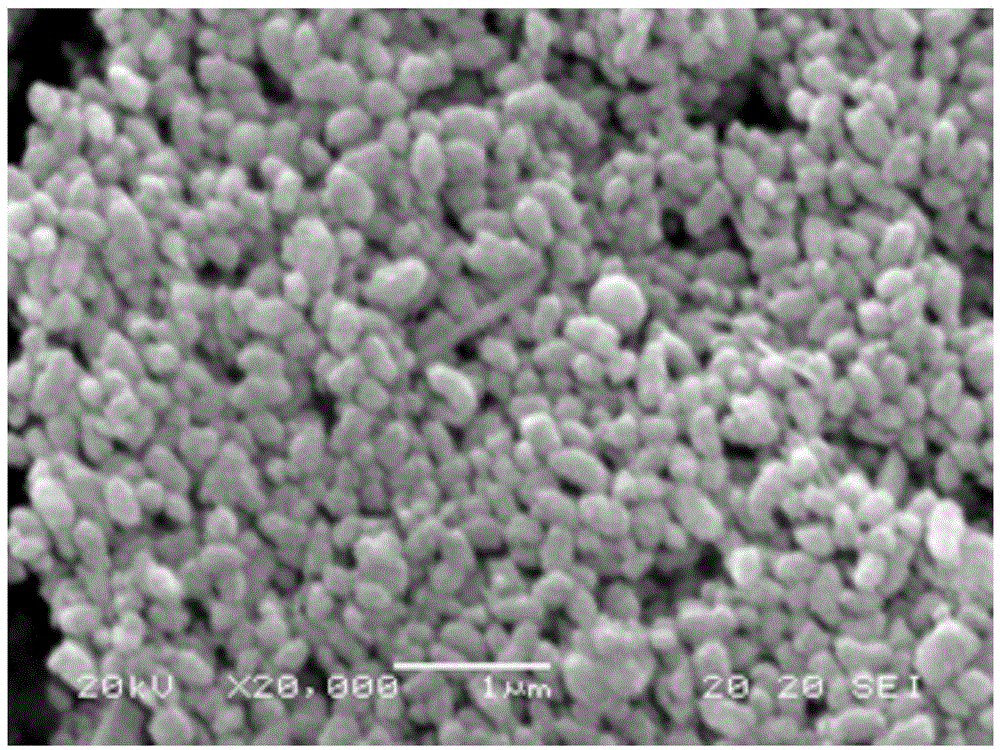

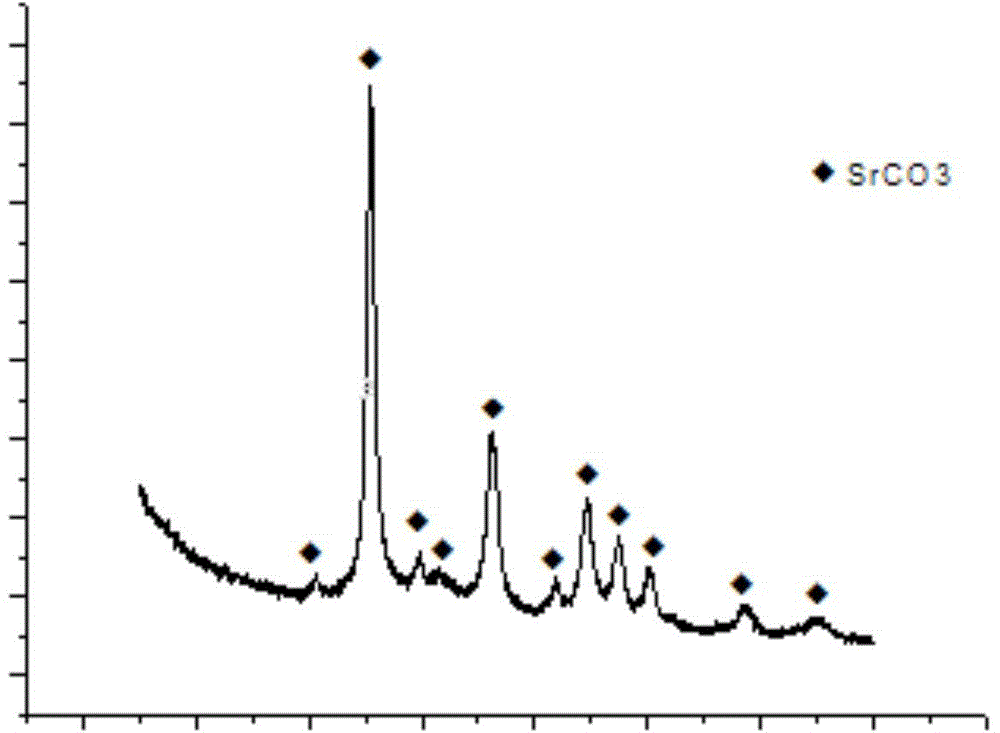

Spherical nano strontium carbonate and preparation method thereof

InactiveCN104016394AReduce pollutionSimple preparation processCalcium/strontium/barium carbonatesMaterial nanotechnologyStrontium carbonateSalt solution

The invention discloses a preparation method of spherical nano strontium carbonate, which comprises the following steps: S101. adding a shape agent into a soluble strontium salt solution, and dissolving by stirring to obtain a first solution, wherein the mole ratio of the shape agent to the strontium ions in the strontium salt solution is 2:(1-1.5); S102. transferring the first solution into the ultrasonic reactor, and introducing CO2 gas in the ultrasonic process until the pH value of the solution is neutral, thereby obtaining a second solution, wherein the flow rate of the introduced CO2 gas is 2-10 L / minute; S103. carrying out solid-liquid separation on the second solution to obtain a solid product; and S104. washing the solid product, and drying to obtain the spherical nano strontium carbonate. The invention also discloses the spherical nano strontium carbonate prepared by the preparation method.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

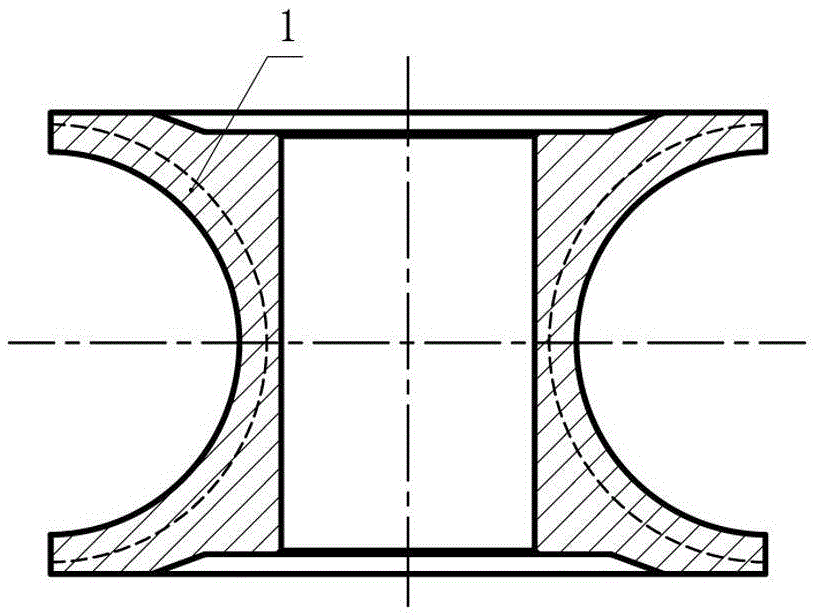

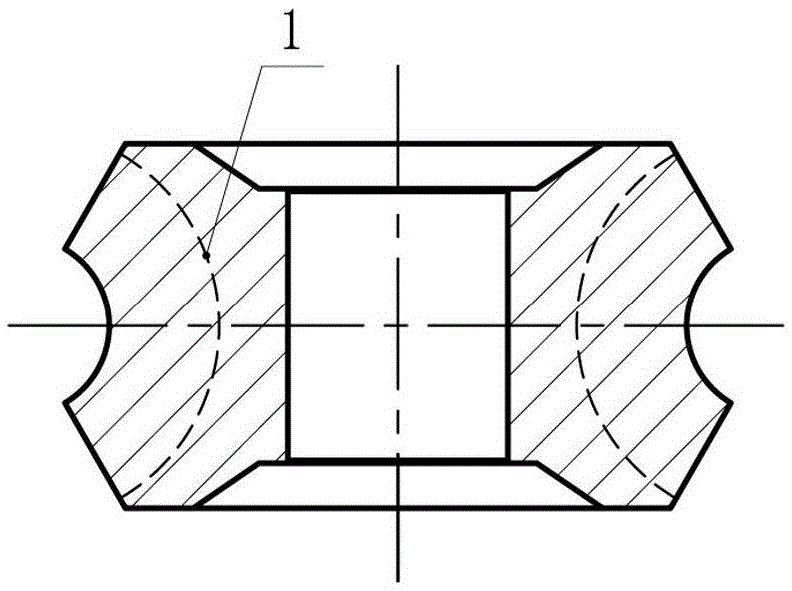

Composite particle reinforced roller of hot-rolling seamless steel pipe sizing mill or reducing mill and preparation method thereof

ActiveCN105618485AImprove ball effectImprove comprehensive mechanical propertiesFurnace typesRollsQuenchingSizing

The invention discloses a composite particle reinforced roller of a hot-rolling seamless steel pipe sizing mill or reducing mill and a preparation method thereof. Composite particles are composed of hardening particles, active wetting agents and matrix reinforcing agents. The composite particle reinforced roller of the sizing mill or reducing mill is cast after nodular cast iron matrix molten metal is reinforced; and the high-strength and high-toughness composite particle reinforced roller is obtained by conducting isothermal quenching and machining on the roller. The composite particle reinforced roller is resistant to abrasion and impact; the service life of the roller is prolonged by over two times; the production cost is lowered; the production efficiency of a steel pipe production enterprise is improved, and economic benefits of the steel pipe production enterprise are increased.

Owner:SHANDONG SIFANG STEEL PIPE EQUIP MFG

Manufacturing process of high-temperature nodular cast iron

The invention discloses a manufacturing process of high-temperature nodular cast iron. The manufacturing process comprises the steps of (A) mixing materials including scrap steel, pig iron, foundry returns, ferromanganese, silicon carbide, a carburant, ferrosilicon and ferromolybdenum; (B) conducing smelting, specifically, charging the mixed materials into a furnace to be melted into molten iron;(C) conducting heating and standing, heating the molten iron to 1520-1550 DEG C, stopping heating and conducting standing to reach 1460-1480 DEG C; (D) conducting filling, specifically, preheating a casting ladle, filling a nodulizing agent into the pit side of the bottom of the casting ladle, tamping the nodulizing agent with a hammer, covering the nodulizing agent with a layer of nodulizing insulation covering agent, conducting tamping with the hammer, and covering the nodulizing insulation covering agent with a nucleating agent; (E) conducting nodulizing and inoculation, specifically, filling the molten iron into the casting ladle, preventing the molten iron from making contact with the nodulizing agent, adding the nucleating agent again when the molten iron yield is one half of the total treatment amount, stirring the molten iron and then conducting standing for 1.5-3.0 min; (F) conducting casting; and (G) conducting cooling and unpacking. Through the manufacturing process, the microstructure of a casting can be improved to obtain the good graphite from and reduce the pearlite content, the high-temperature strength can be substantially improved, the use requirements are met, and the service life of products is prolonged.

Owner:SICHUAN HAIKE MACHINERY MFG

As-cast high-strength high-elongation synthetic nodular cast iron and preparation method thereof

The invention relates to the field of as-cast high-strength high-elongation synthetic nodular cast iron. The invention relates to as-cast high-strength high-elongation synthetic nodular cast iron anda preparation method thereof. The nodular cast iron is characterized in that under the as-cast condition, the nodular cast iron meets performance requirements that the tensile strength Rm is larger than or equal to 700 MPa, and the percentage elongation A after fracture is larger than or equal to 10%; the matrix is a pearlite-ferrite mixed matrix; the content of pearlite is 55%-75%, a spheroidizing grade is 1-2, a graphite size grade is 6-7, the nodular cast iron is composed of elements, by mass, 3.5%-3.7% of C, 2.9-3.3% of Si, less than or equal to 0.2% of Mn, less than or equal to 0.035% ofP, less than or equal to 0.02% of S, 0.5%-0.7% of Cu, 0.55%-0.75% of Ni, 0.030%-0.065% of Mg and the balance of Fe and trace elements. The method has the beneficial effects that scrap steel and raw material pure iron are adopted for recarburization, base iron is smelted in a medium-frequency induction furnace, then pretreatment, spheroidizing treatment and inoculation treatment are conducted, final pouring is conducted, and QT700-10 is achieved under the as-cast condition.

Owner:湖北三环铸造股份有限公司

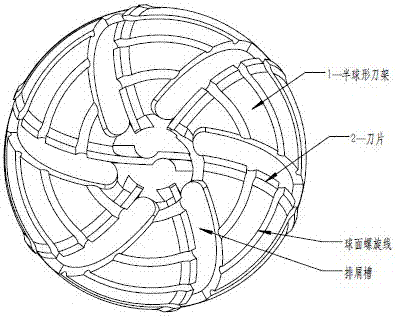

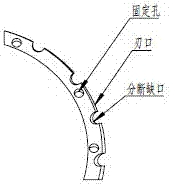

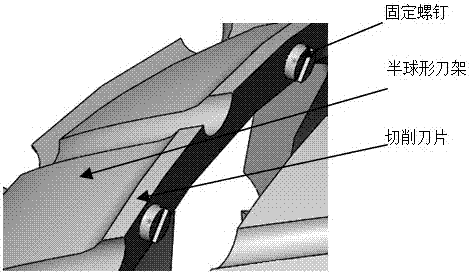

Combined acetabulum file

The invention relates to the technical field of surgery department medical instruments, and discloses a combined acetabulum file. The combined acetabulum file comprises a hemisphere tool rest and detachable blades, the axis of a hemisphere is adopted as the rotating axis of the acetabulum file, 2-5 pairs of cutting blades are mounted on the hemisphere face of the hemisphere, each pair of cutting blades are symmetrically arranged relative to the rotating axis, each cutting edge is divided into 3-6 sections by small gaps on the cutting edge, and the adjacent blades are spirally distributed along the hemisphere face. The cutting edges of the acetabulum file are not likely to be abraded and can be repeatedly used, after the blades are abraded, the blades can be replaced, and the cutting effect is good.

Owner:WUHAN YIJIABAO BIOMATERIAL CO LTD

Method for preparing base of vertical annealing furnace

ActiveCN102489669AGood spherical effectReduce white mouth tendencyFoundry mouldsFoundry coresCompressive strengthLost-foam casting

The invention discloses a method for preparing a base of a vertical annealing furnace. The method provided by the invention is characterized in that a lost foam casting technology is adopted; molten iron is injected into a mold from the bottom to form a casting; a pour-over spheroidizing technology is adopted; and a spheroidizing inoculation technology is adopted. The base obtained by the method has advantages of good mechanical properties, good flexibility, high tensile strength, high compression strength, low rejection rate, high heat resistance, high fatigue resistance, and large elongation.

Owner:SICHUAN CHUANJIAN PIPES

Spheroidizing annealing process of superplastic medium carbon steel wire

InactiveCN105018712AImprove ductilityReduce hardnessFurnace typesHeat treatment furnacesShielding gasHeat conservation

The invention discloses a spheroidizing annealing process of a superplastic medium carbon steel wire. The spheroidizing annealing process comprises the following steps of placing a steel wire into a thermal treatment furnace, charging protective gas into the thermal treatment furnace, raising the temperature inside the furnace to 720-740 DEG C, and preserving the heat for 3-5 hours; cooling at the first stage, namely reducing the temperature inside the furnace to 660-680 DEG C at the speed of 10 DEG C / h, and preserving the heat for 3-5 hours; cooling at the second stage, namely further reducing the temperature inside the furnace to 610-630 DEG C at the speed of 20 DEG C / h; and cooling at the third stage, namely naturally cooling the steel wire to the normal temperature. The steel wire treated by using the process disclosed by the invention is uniform in metallographic structure, high in plasticity and ductility, suitable for subsequent repeated high-difficulty plastic processing and molding and low in molding cracking rate.

Owner:DONGGUAN KELEE STEEL WIRE

Spheroidizing annealing process for high-toughness medium carbon steel wires

InactiveCN103993141AImprove ductilityReduce hardnessFurnace typesHeat treatment furnacesCarbon steelDuctility

The invention discloses a spheroidizing annealing process for high-toughness medium carbon steel wires. The spheroidizing annealing process comprises the steps as follows: putting the steel wires into a heat treatment furnace, charging protective gases into the heat treatment furnace, raising the temperature in the furnace to 710-730 DEG C, and keeping the temperature for 3-5 hours; performing first-stage cooling: cooling the temperature in the furnace to 680-700 DEG C at a speed of 10 DEG C / hour, and keeping the temperature for 2-4 hours; performing second-stage cooling: continuously cooling the temperature in the furnace to 630-650 DEG C at the speed of 10 DEG C / hour; and performing third-stage cooling: naturally cooling the medium carbon steel wires to a normal temperature. The medium carbon steel wires, which are processed by the process provided by the invention, are uniform in metallographic structure, high in toughness, high in malleability, and low in hardness; and the medium carbon steel wires are suitable for subsequent difficult multi-step stamping and forming, and are low in flattening, bending, and cracking rate.

Owner:DONGGUAN KELEE STEEL WIRE

Processing and preparation process for floating oil seal

InactiveCN107790640AImprove performanceReduce manufacturing costFoundry mouldsLapping machinesTinCrystallite

The invention provides a processing and preparation process for a floating oil seal. The processing and preparation process for the floating oil seal comprises the following steps of precoated sand modeling through a rubber mold, casting, shot blasting, blank check, grinding, quenching heat treatment, oil grinding, cleaning, oil injection, installation of a rubber ring, check, packaging, storage and the like. The processing and preparation process for the floating oil seal has the beneficial effects that the formula and the process are simple, and industrialization is achieved easily; the performance of castings obtained from the as-cast mode is greatly improved; by adding low-phosphorus steel scraps in the castings, the performance of the castings is effectively improved and the production cost of the castings is reduced; by adding ferromanganese in the castings, sufficient toughness is achieved, the pearlite content can be increased, and high strength and hardness are obtained; by adding silicon carbide in the castings, the abrasion resistance of the castings can be improved and the service life is doubled or tripled; by adding a proper quantity of copper scraps and tin scraps inthe castings, generation of pearlite can be effectively promoted, and texture crystal grains are refined; and a grinding machine grinds both the upper surface and the lower surface so that the flatness and smoothness of the outer surface of the floating oil seal can be ensured.

Owner:ZHEJIANG GUANGLI ENG MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com