Spheroidizing agent for spheroidal graphite cast iron, and preparation method thereof

A technology of nodular cast iron and nodularizing agent, which is applied in the field of nodularizing agent for nodular cast iron and its preparation, and achieves the effects of high ferrite content, high toughness and high nodularization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

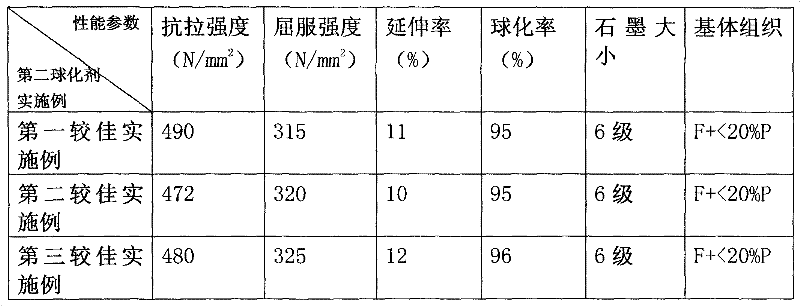

Examples

Embodiment Construction

[0015] There are many kinds of spheroidizing elements found so far, such as Ce, Mg, Ca, Y, Na, Bi, Tn, etc., but many of these elements can only show spheroidizing ability in pure molten iron, and have real industrial value The only ones are Mg, Ca, Y and so on.

[0016] Among them, Mg is the strongest spheroidizing agent, which can spheroidize graphite in molten iron with hypoeutectic, eutectic and hypereutectic components and has good desulfurization and oxygen absorption capacity. But only when pure magnesium is used as the nodulizer, it has the following disadvantages: (1) the boiling point of Mg is lower than the molten iron temperature, and Mg directly added to molten iron has violent boiling, unsafe operation and low absorption rate of molten iron to Mg, The spheroidization is unstable; (2) The molten iron treated with pure Mg shrinks greatly when it solidifies, and the shrinkage cavity formed inside the casting is difficult to completely remove; (3) It is difficult to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com