Silicon solid melt reinforced ferrite nodular cast iron and preparation technique thereof

A ductile iron and ferrite technology is applied in the field of silicon solid solution strengthened ferritic ductile iron and its preparation. The effect of simple preparation method and easy steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

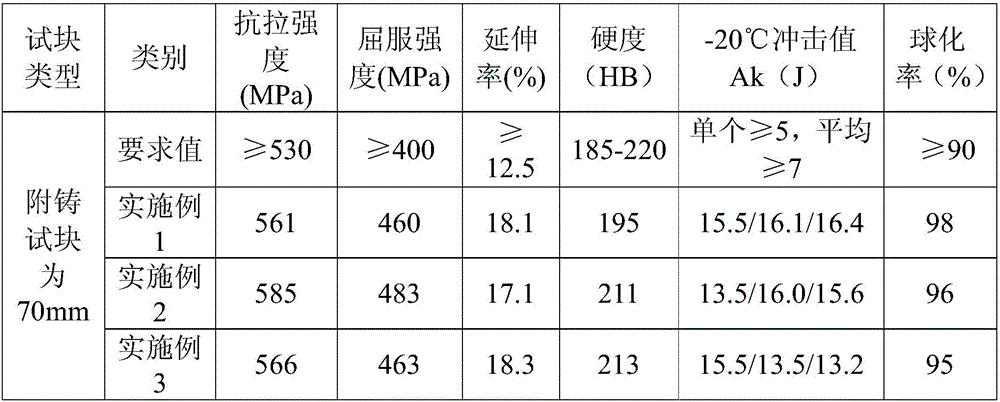

Examples

Embodiment 1

[0021] The preparation process of QT580-13 ferritic ductile iron includes the following steps:

[0022] (1) Selection of raw materials: by weight, select 20 parts of pig iron with a phosphorus content of less than or equal to 0.035%, a sulfur content of less than or equal to 0.020%, 15 parts of manganese content of less than or equal to 0.1%, a phosphorus content of less than or equal to 0.030%, and a sulfur content of less than or equal to 0.030%. 0.030% scrap steel, then packaged and formed, 65 parts of the company's wind power casting ductile iron return material, and melted in an electric furnace, adjusted the chemical composition, heated to 1430 ~ 1480 ℃, until all melted into molten iron;

[0023] (2) configuration of raw materials in the spheroidizing bag: in terms of the mass of molten iron obtained in step (1), put nodularizing agents A and B in the spheroidizing bag, and the additions of spheroidizing agents A and B are 0.55 of the molten iron weight. %, compact; eve...

Embodiment 2

[0034] The preparation process of QT580-13 ferritic ductile iron includes the following steps:

[0035] (1) Selection of raw materials: In parts by weight, select 60 parts of pig iron with a phosphorus content of less than or equal to 0.035%, sulfur content of less than or equal to 0.020%, 35 parts of manganese content of less than or equal to 0.1%, phosphorus content of less than or equal to 0.030%, and sulfur content of less than or equal to 0.030%. 0.030% scrap steel, then packaged and formed, 15 parts of the company's wind power casting ductile iron return material, and melted in an electric furnace, adjusted the chemical composition, heated to 1430 ~ 1480 ℃, until all melted into molten iron;

[0036] (2) configuration of raw materials in the spheroidizing bag: in terms of the quality of the molten iron obtained in step (1), put nodularizing agents A and B in the spheroidizing bag, and the additions of the spheroidizing agents A and B are 0.60 of the molten iron weight. %...

Embodiment 3

[0047] The preparation process of QT580-13 ferritic ductile iron includes the following steps:

[0048] (1) Selection of raw materials: In parts by weight, select 65 parts of pig iron with a phosphorus content of less than or equal to 0.035%, a sulfur content of less than or equal to 0.020%, 25 parts of manganese content of less than or equal to 0.1%, a phosphorus content of less than or equal to 0.030%, and a sulfur content of less than or equal to 0.030%. 0.030% scrap steel, then packaged and formed, 10 parts of the company's wind power casting ductile iron return material, and melted in an electric furnace, adjusted the chemical composition, heated to 1430 ~ 1480 ℃, until all melted into molten iron;

[0049] (2) configuration of raw materials in the spheroidizing bag: in terms of the mass of molten iron obtained in step (1), put nodularizing agents A and B in the spheroidizing bag, and the additions of spheroidizing agents A and B are 0.50 of the molten iron weight. %, com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com