Method for spheroidizing heat treatment of eutectic silicon in eutectic aluminium-silicon alloy

A heat treatment method, eutectic aluminum-silicon technology, which is applied in the field of metal heat treatment, can solve the problems of improving the strength and toughness of eutectic aluminum-silicon alloy, the eutectic silicon shape is not in the best state, and the deterioration effect is poor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

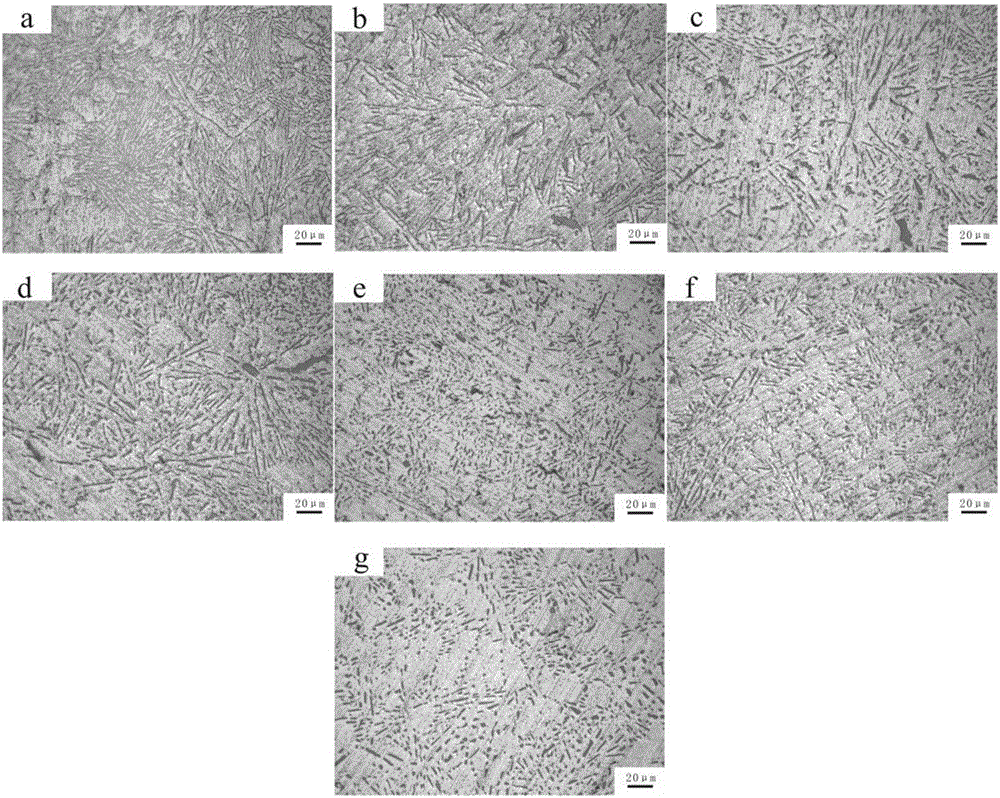

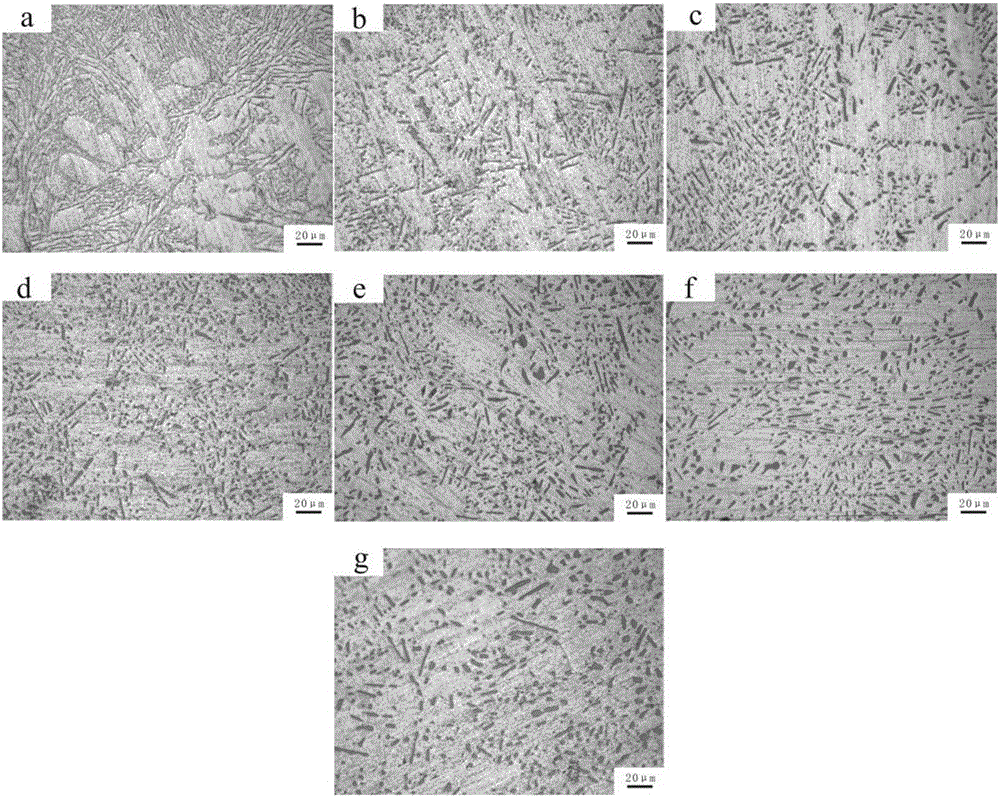

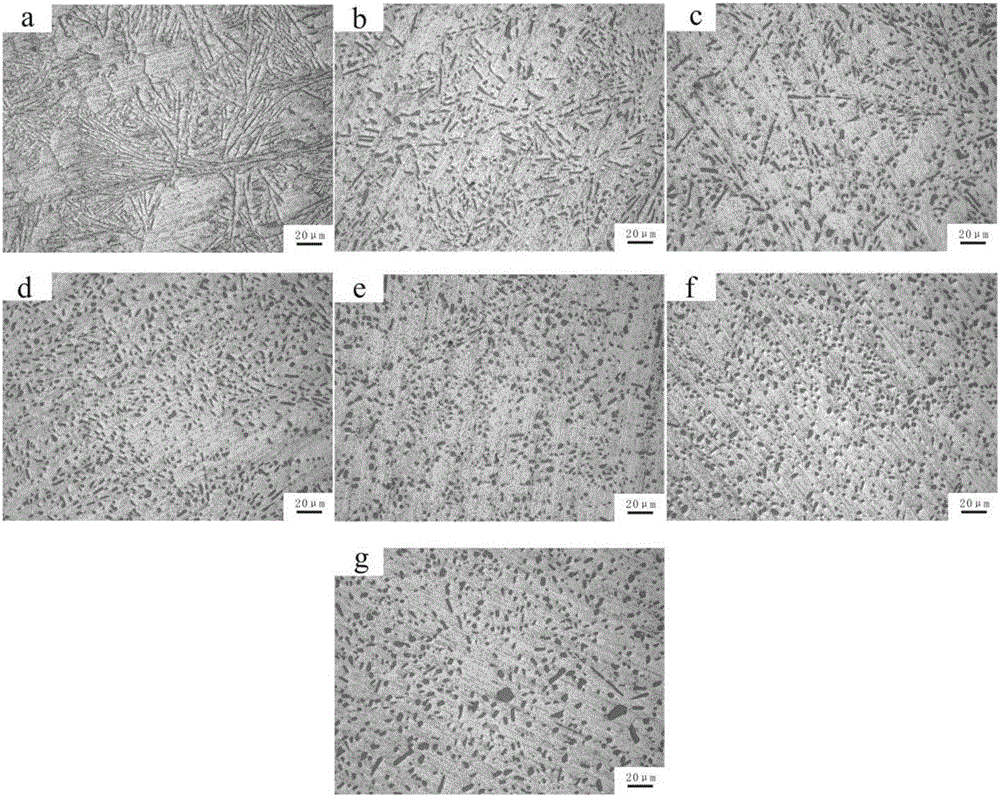

[0021] Example 1: Eutectic Al-Si alloy annealed at 577°C for 1 hour

[0022] An Al-11.7wt.% Si eutectic aluminum-silicon alloy was smelted in a graphite crucible using a well-type electric furnace, and the alloy liquid was poured into a metal mold to obtain a eutectic aluminum-silicon alloy sample with a diameter of 10 mm. The samples were placed in a tubular annealing furnace at 577°C for 1 hour of spheroidizing annealing treatment. After annealing, the samples were taken out for air cooling. The microstructure of the eutectic Al-Si alloy after spheroidizing annealing for 1 hour is as follows: image 3 As shown in (b), it can be seen that after annealing at 577°C for 1 hour, about 30% of the eutectic silicon has been spheroidized.

Embodiment 2

[0023] Example 2: Eutectic Al-Si alloy annealed at 577°C for 2 hours

[0024] An Al-11.7wt.% Si eutectic aluminum-silicon alloy was smelted in a graphite crucible using a well-type electric furnace, and the alloy liquid was poured into a metal mold to obtain a eutectic aluminum-silicon alloy sample with a diameter of 10 mm. The samples were respectively placed in a tubular annealing furnace at 577°C for 2 hours of spheroidizing annealing treatment. After annealing, the samples were taken out for air cooling. The microstructure of the eutectic Al-Si alloy after spheroidizing annealing for 1 hour is as follows: image 3 As shown in (c), it can be seen that after annealing at 577°C for 2 hours, about 50% of the eutectic silicon has been spheroidized.

Embodiment 3

[0025] Example 3: Eutectic Al-Si alloy annealed at 577°C for 3 hours

[0026] An Al-11.7wt.% Si eutectic aluminum-silicon alloy was smelted in a graphite crucible using a well-type electric furnace, and the alloy liquid was poured into a metal mold to obtain a eutectic aluminum-silicon alloy sample with a diameter of 10 mm. The samples were respectively placed in a tubular annealing furnace at 577°C for 3 hours of spheroidizing annealing treatment. After annealing, the samples were taken out for air cooling. The microstructure of the eutectic Al-Si alloy after spheroidizing annealing for 1 hour is as follows: image 3 As shown in (d), it can be seen that after annealing at 577°C for 3 hours, about 95% of the eutectic silicon has been spheroidized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com