Casting method for large wind power casting and casting produced through casting method

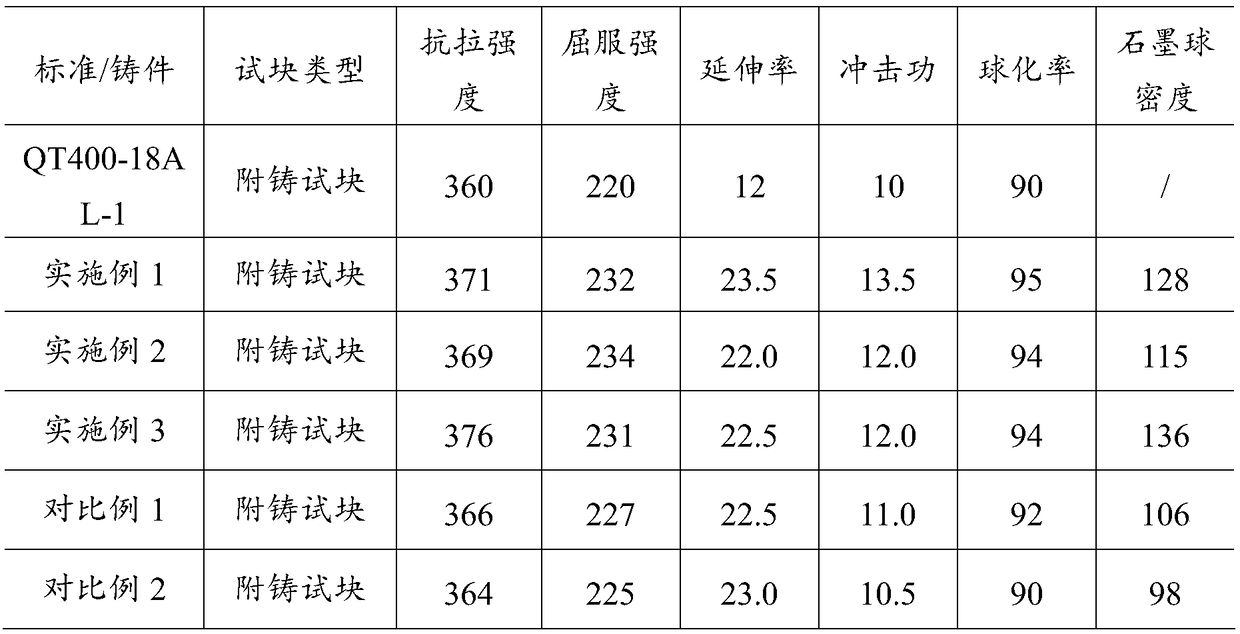

A casting and wind power technology, which is applied in the field of casting technology, can solve the problems of low density and roundness of graphite balls, unstable performance of castings, and low spheroidization rate of castings, and achieve good spheroidization effect, more graphite balls, and longer Effect of spheroidization reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

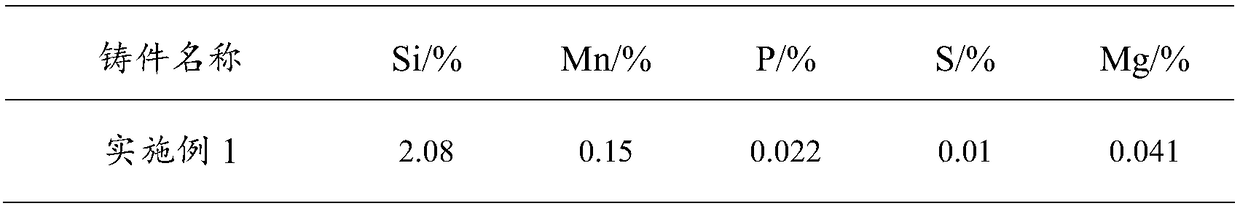

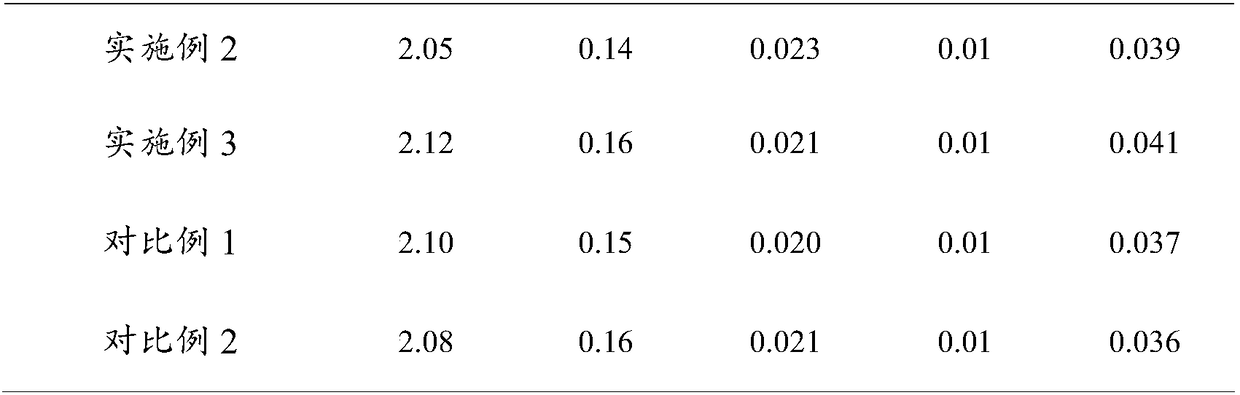

Embodiment 1

[0035] Example 1 Casting of Goldwind 2.5MW stator main shaft

[0036] Casting steps:

[0037] (a) Smelting of charge

[0038] Furnace charge: 45-70wt% of nodular pig iron, 20-45wt% of returned charge, 5-30wt% of steel scrap.

[0039]Ductile iron is Q10 pig iron, wherein C: 4.0-4.5wt%, Si: 0.7-1.0wt%, Mn: ≤0.15wt%, P: ≤0.040wt%, S: ≤0.030wt%, Cr≤0.030wt%, Ti≤0.040wt% and the sum of despheroidizing harmful alloying elements≤0.1wt%. Scrap steel is flake carbon scrap steel, wherein C:≤0.15wt%, Mn:≤0.40wt%, P:≤0.03wt%, S:≤0.03wt%, Cr≤0.08wt%.

[0040] Melting molten iron temperature: 1500°C.

[0041] During the smelting process, the composition of the charge is adjusted by spectral analysis, and the elements in the molten iron are controlled: C: 3.65-3.90wt%, Si: 0.8-1.2wt%, Mn: 0.05-0.20wt%, P: ≤0.035wt%, S: 0.006 ~0.015 wt%.

[0042] (b) Spheroidization, inoculation and filling

[0043] The molten iron obtained from smelting is subjected to spheroidization treatment and in...

Embodiment 2

[0047] The difference with embodiment 1 is:

[0048] The amount of covering agent is 0.4wt% of molten iron.

[0049] All the other are with embodiment 1.

Embodiment 3

[0051] The difference with embodiment 1 is:

[0052] The amount of covering agent is 0.7wt% of molten iron.

[0053] All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com