Composite particle reinforced roller of hot-rolling seamless steel pipe sizing mill or reducing mill and preparation method thereof

A technology of composite particles and seamless steel pipes is applied in the field of roll manufacturing to achieve the effects of improving spheroidizing effect, improving service life, and reducing manufacturing and production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

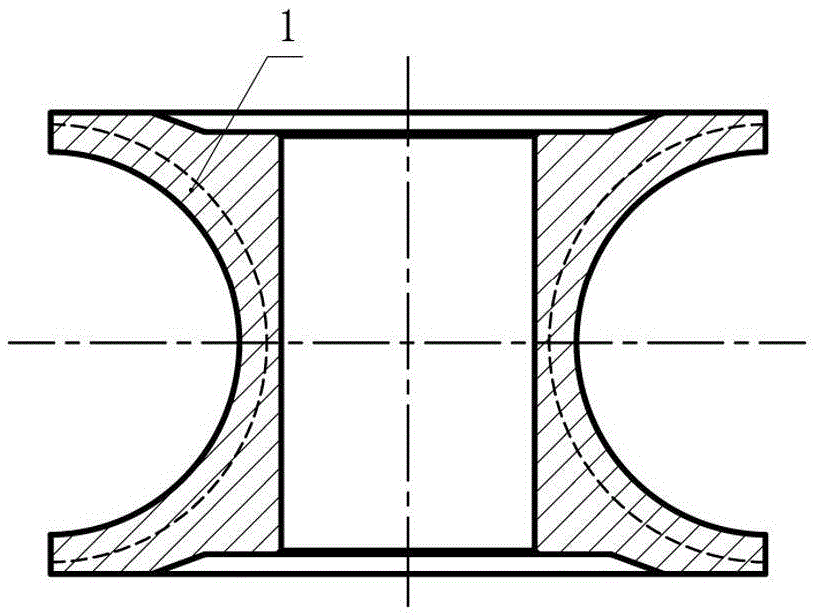

[0029] Refer to attached figure 1 , This embodiment is to manufacture Φ460 hot-rolled seamless steel pipe unit two-roller sizing mill or reducing mill compound particle reinforced roll. Weight 898kg.

[0030] The proportions of the composite strengthening particle elements of the roll in this embodiment are as follows: 22.5kg TiC, 22.5kg WC, 5kg Ni powder, 5kg Nb powder, 35kg iron powder, 0.03kg bismuth powder, and 0.015kg antimony powder. The above elements are stirred in a ball mill for 2 hours, mixed evenly, and then pressed into 5-10 mm composite strengthening particle blocks for use.

[0031] The composition of the ductile iron matrix is: C: 3.4%, Si: 1.8%, Mn: 0.30%, P: 0.017%, S: 0.014%, Cu: 0.40%, Mg: 0.06%.

[0032] Conventional smelting of ductile iron matrix metal melt, after the smelting is completed, put the composite strengthening particle block preheated to 350-400 ℃ in the ladle, and then pour the matrix metal melt into the ladle, so that the matrix metal mel...

Embodiment 2

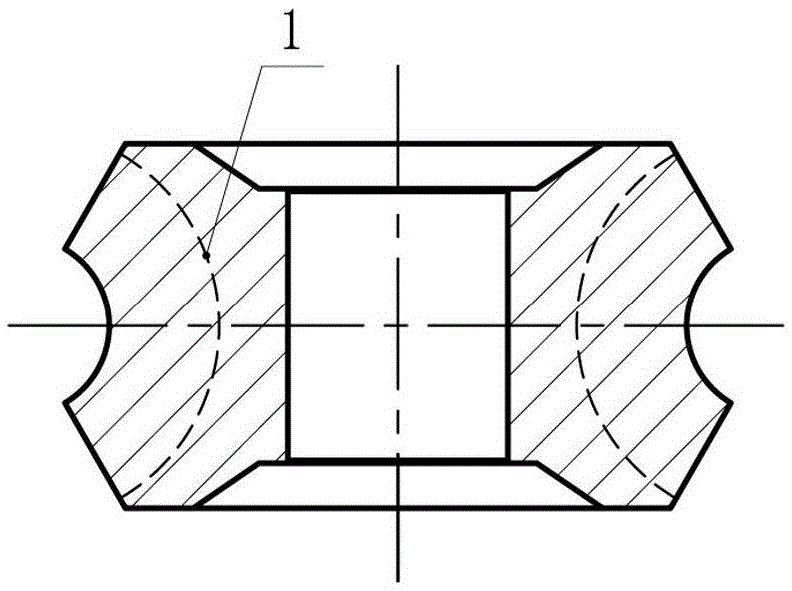

[0035] Refer to attached figure 2 , This embodiment is to manufacture Φ250 hot-rolled seamless steel pipe unit three-roll sizing mill or reducing mill roll compound particle reinforced roll, weighing 242kg.

[0036] The ratio of the composite strengthening particle elements of the roll adopts: TiC8kg, WC8kg, B4C8kg, Ni powder 2kg, Nb powder 2kg, industrial reduced iron powder 20kg, bismuth powder 0.03kg, antimony powder 0.018kg. Stir the above elements in a ball mill for 2 hours to make them evenly mixed, press them into 5-10mm composite reinforced particle blocks, and preheat them to 350-400°C for use; the chemical composition of the ductile iron matrix is: C: 3.6%, Si : 2.1%, Mn: 0.32%, P: 0.017%, S: 0.014%, Cu: 0.25%, Mg: 0.05%.

[0037] After that, the smelting of the conventional nodular cast iron matrix metal melt is carried out. After the smelting is completed, put the composite strengthened particle block preheated to 350-400°C in the ladle, then pour the matrix met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com