High Strength Gas Cylinder Head and Its Production Technology

A production process and gas cylinder technology, which is applied in the field of high-strength gas cylinder head and its production process, can solve the problems of cylinder block and cylinder head waste, uneven hardness of blank castings, and poor inoculation effect, so as to reduce impurities and improve inoculation Quality, the effect of improving the nodularization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

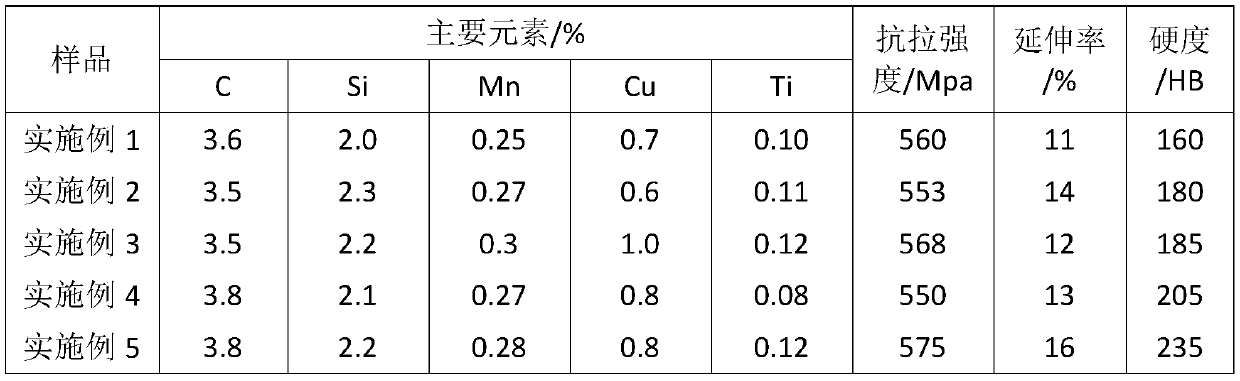

Examples

Embodiment 1

[0026] The production process of the high-strength gas cylinder head provided in this embodiment comprises the following steps:

[0027] Step (1): Prepare the charge, select low-S ductile iron pig iron and pure carbon steel scrap, and melt the pig iron and carbon steel scrap at a weight ratio of 7:3; use an intermediate frequency induction furnace to melt the prepared metal charge, Control the smelting temperature at 1500°C, detect the content of each element in the molten iron after melting, and adjust the content of each element to meet the formula requirements, control the range of Mn content in the molten iron to 0.25-0.30wt%, blow argon into the molten iron, blow The gas depth is 20% from the bottom of the furnace, and the gas blowing time is 5 minutes, and then the molten iron is tapped;

[0028] Step (2): Spheroidization and the first inoculation treatment, using the flushing method, adding a nodulizer into the pit of the nodulizer, the composition of the nodulizer is: ...

Embodiment 2

[0032] The production process of the high-strength gas cylinder head provided in this embodiment comprises the following steps:

[0033] Step (1): Prepare the charge, select low-S ductile iron pig iron and pure carbon steel scrap, and a graphite recarburizer with a carbon content of 98%, and smelt the pig iron and carbon steel scrap in a weight ratio of 7:3; Use medium frequency induction furnace to smelt the prepared metal charge, control the smelting temperature at 1550°C, detect the content of each element in the molten iron after melting, and adjust the content of each element to meet the formula requirements, and control the Mn content in the molten iron. The range is 0.25- 0.30wt%, blowing argon into the molten iron, the blowing depth is 40% from the bottom of the furnace, the blowing time is 8 minutes, and then the molten iron is tapped;

[0034] Step (2): Spheroidization and the first inoculation treatment, using the flushing method, adding a nodulizer into the pit of ...

Embodiment 3

[0038] The production process of the high-strength gas cylinder head provided in this embodiment comprises the following steps:

[0039] Step (1): Prepare the charge, select low-S ductile iron pig iron and pure carbon steel scrap, and a graphite recarburizer with a carbon content of 98%, and smelt the pig iron and carbon steel scrap in a weight ratio of 7:3; The prepared metal charge is smelted in an intermediate frequency induction furnace, and the smelting temperature is controlled at 1520°C. After melting, the content of each element in the molten iron is detected, and the content of each element is adjusted to meet the formula requirements. The Mn content in the molten iron is controlled within a range of 0.25- 0.30wt%, blowing argon into the molten iron, the blowing depth is 30% from the bottom of the furnace, the blowing time is 6 minutes, and then the molten iron is tapped;

[0040] Step (2): Spheroidization and the first inoculation treatment, using the flushing method...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com