Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

117results about How to "Promote spheroidization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength low-temperature-resisting spheroidal graphite cast iron and preparing method thereof

The invention relates to the field of spheroidal graphite cast iron, in particular to high-strength low-temperature-resisting spheroidal graphite cast iron and a preparing method thereof. The spheroidal graphite cast iron comprises, by mass percent, 3.2% to 3.5% of carbon, 2.1% to 2.3% of silicon, 0.4% to 0.5% of manganese, 0.4% to 0.6% of copper, 0.2% to 0.4% of nickel, 0.2% to 0.4% of molybdenum, 0.04% to 0.06% of magnesium, 0.05% to 0.08% of chromium, 0.005% to 0.008% of titanium, 0.002% to 0.003% of vanadium, not larger than 0.04% of phosphorus, not larger than 0.02% of sulphur and the balance iron. The preparing method of the high-strength low-temperature-resisting spheroidal graphite cast iron comprises following steps: firstly, raw materials are smelted; secondly, spheroidizing treatment and inoculation are carried out; and thirdly, heat treatment is carried out. Through reasonable arrangement of all element components, the tensile strength of the spheroidal graphite cast iron is improved, a proper nucleating agent is prepared, internal inoculation matched with inoculation in a ladle is adopted, the inoculation effect is reinforced, meanwhile, during heat treatment, the heating temperature, the heat preservation time, the cooling rate and the manner are reasonably arranged, the strength and low temperature resistance of the iron are effectively improved, the spheroidal graphite cast iron is high in strength and excellent in low temperature resistance, and the preparing method is simple and efficient.

Owner:HANSHAN COUNTY XINGDA DUCTILE IRON FACTORY

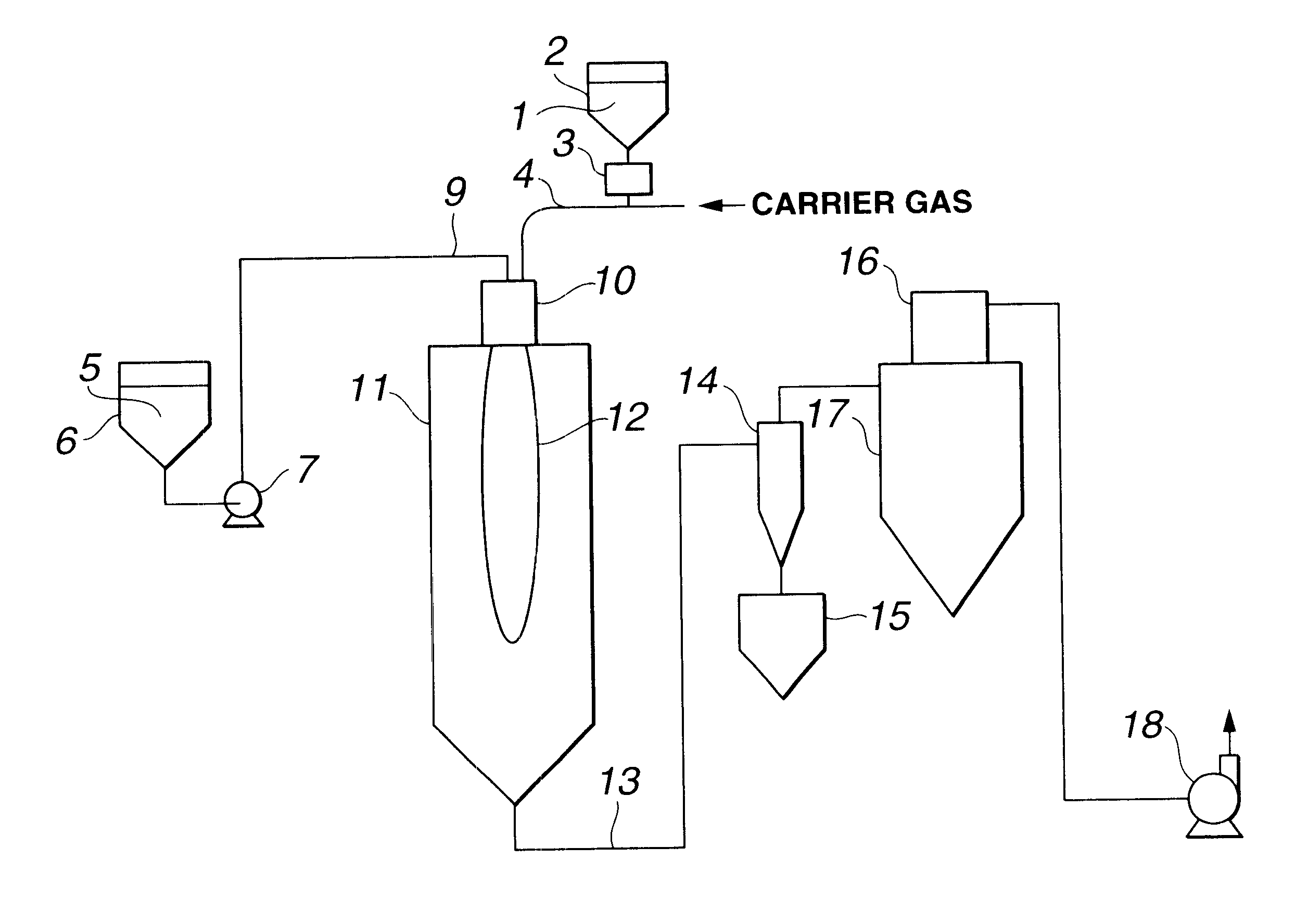

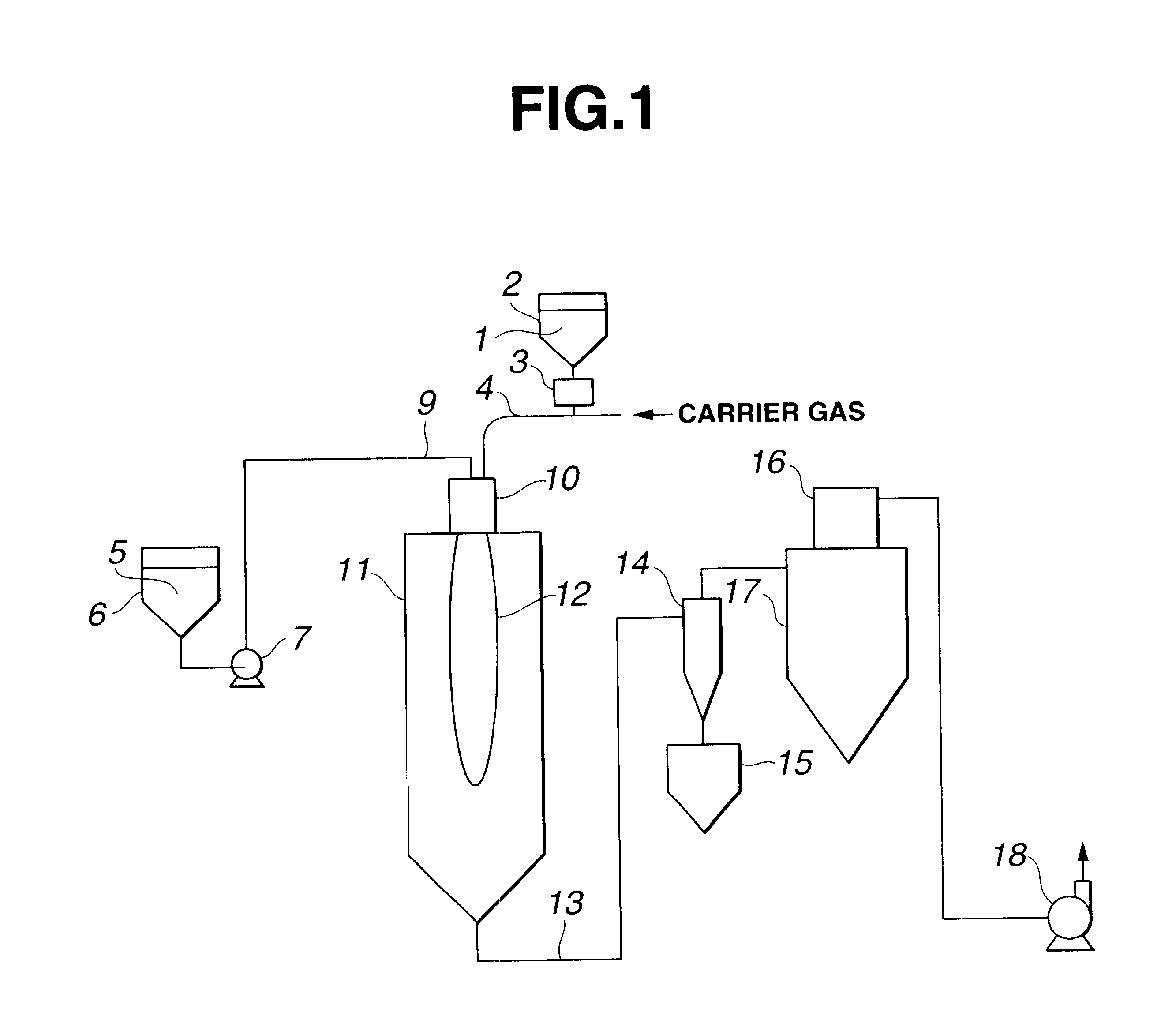

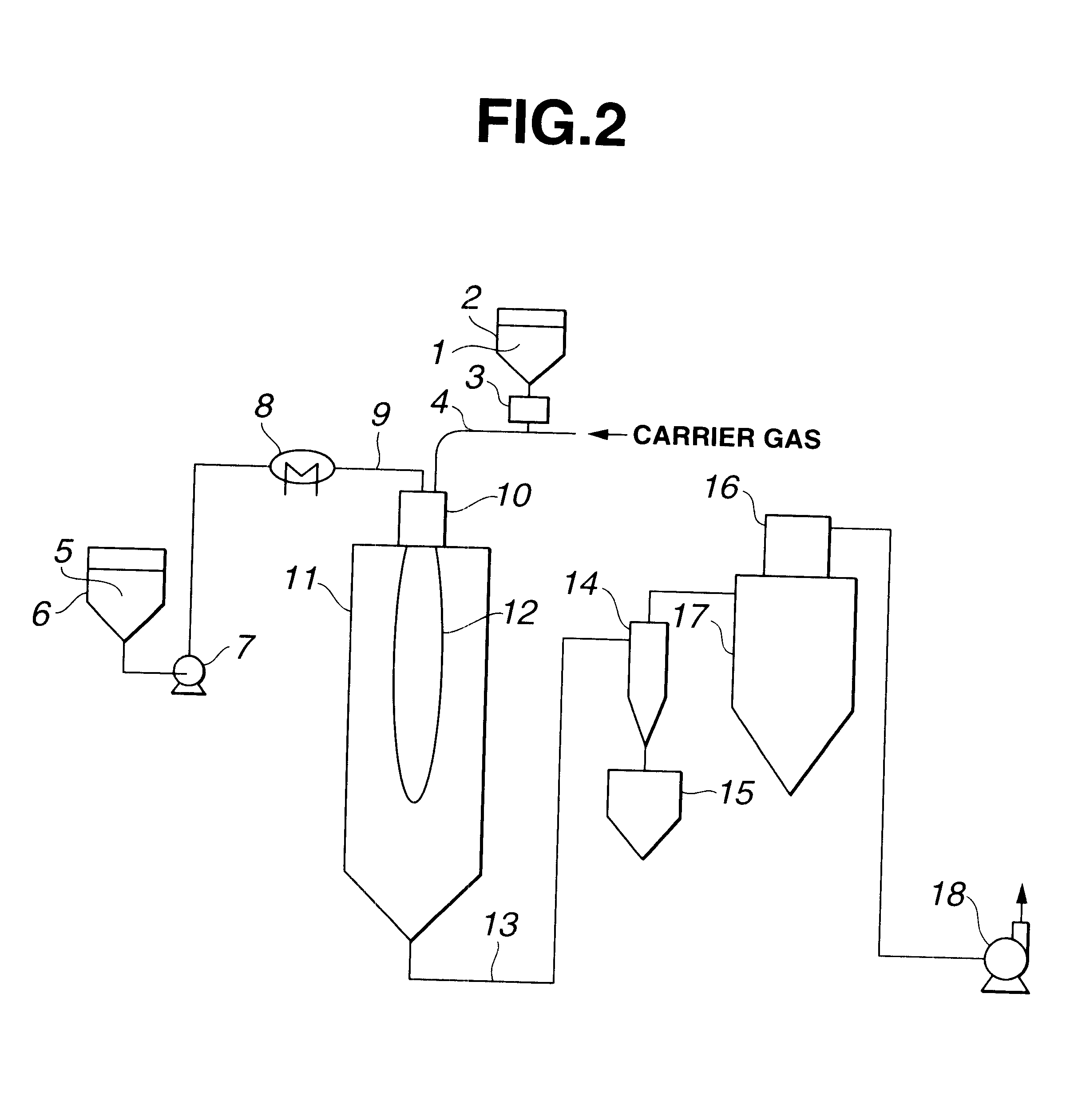

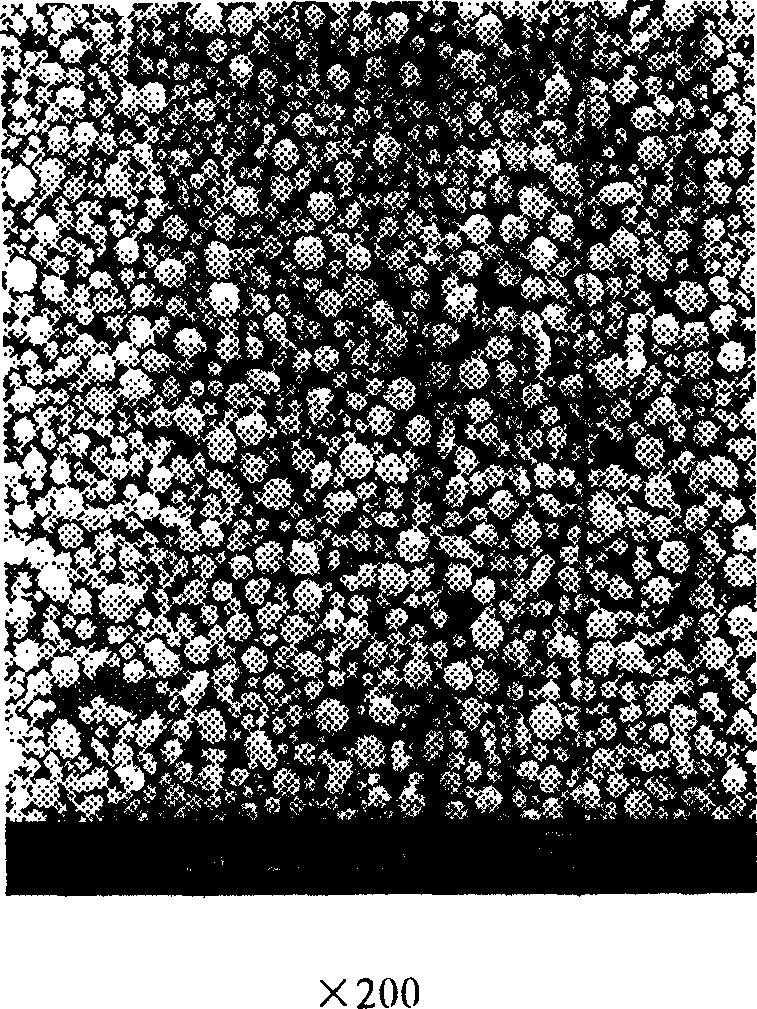

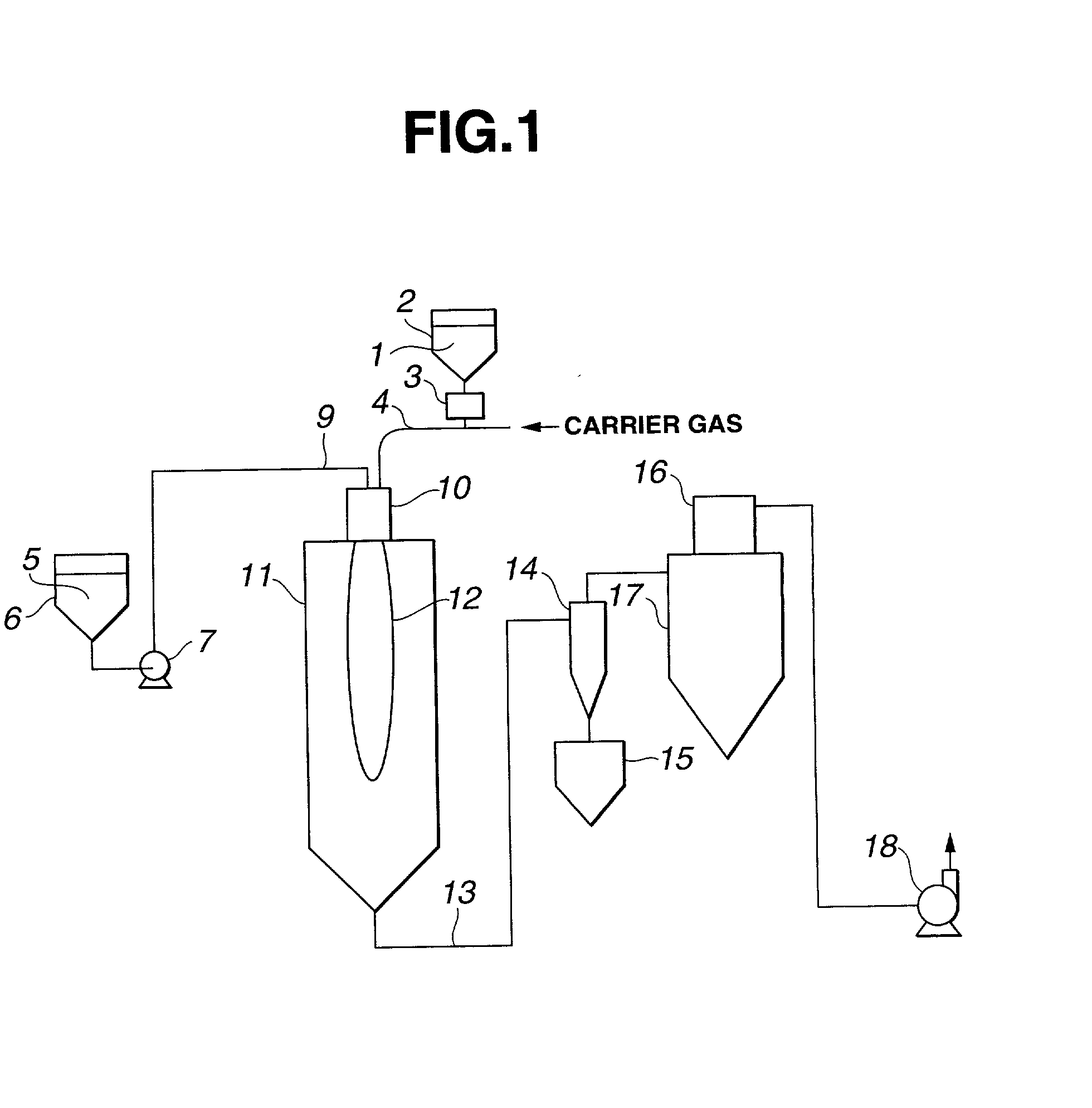

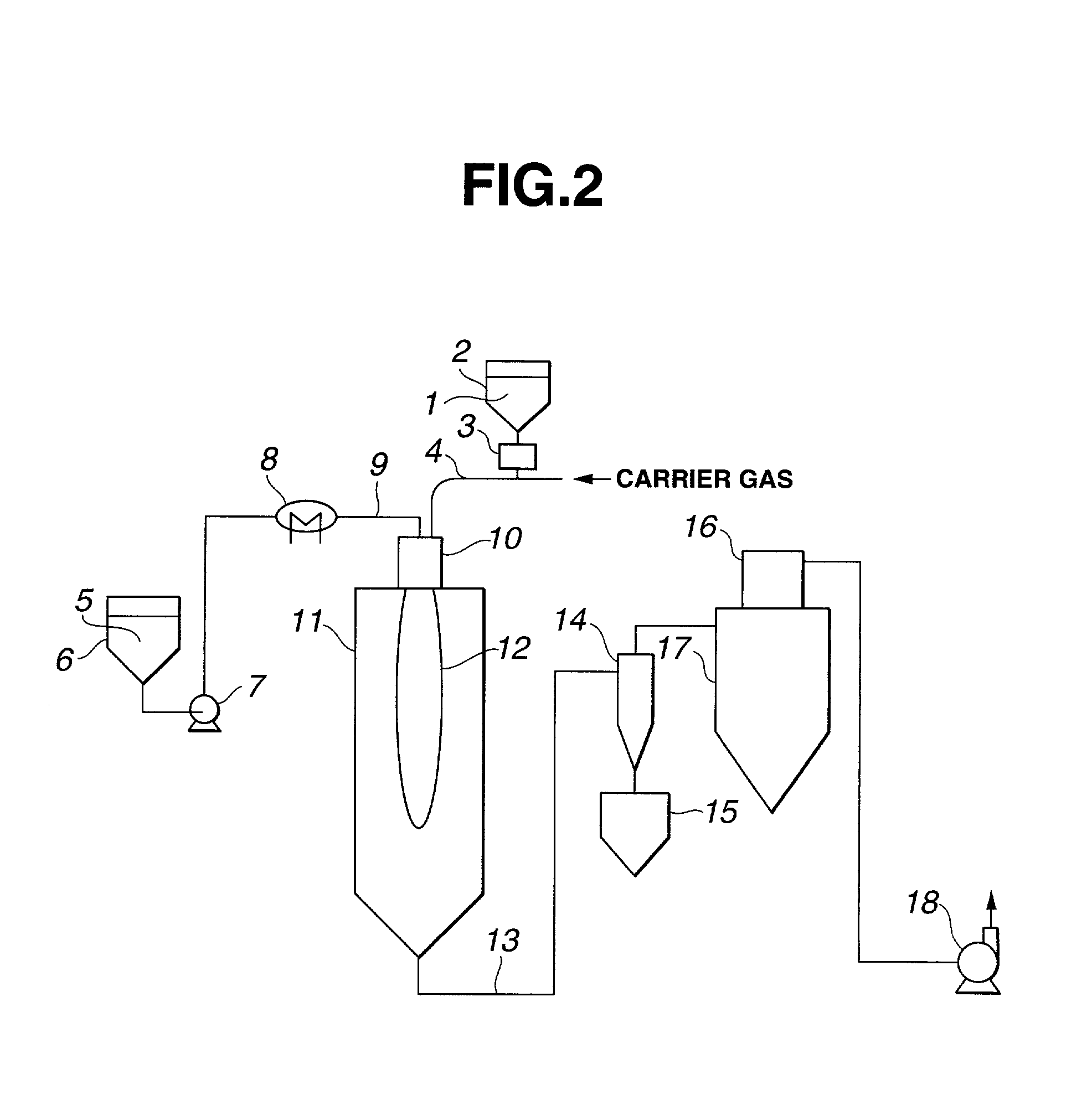

Method of producing spherical silica powder

InactiveUS6387302B1Reduce the amount requiredPromote generationSilicaGlass shaping apparatusSilica particleCombustor

Spherical silica powder is produced by feeding silica powder having an average particle size of 0.3-40 mum to a burner flame formed with a flammable gas so as to continuously melt and spheroidize the particles within the flame. The use of a non-halogenated siloxane and / or alkoxysilane as an auxiliary flame-generating source raises the flame temperature and increases the length of the composite flame formed by combustion of the fuel gas with the siloxane or alkoxysilane. Moreover, the fine particles of silica that form as a result of siloxane or alkoxysilane combustion unite and coalesce with the particles of starting silica. These effects accelerate melting and spheroidization of the starting silica powder, resulting in thermally efficient and cost-effective spherical silica powder production.

Owner:SHIN ETSU CHEM IND CO LTD

Production method of tungsten carbide base ball shaped thermal spray coating powder

A process for preparing the WC-based spherical powder for thermospray coating includes such steps as proportionally mixing WC, Co or mixture of Co and Cr, hexane and paraffin wax, wet grinding, spray drying, granulating, sieving, sintering under protection of H2, and classifying.

Owner:ZIGONG CEMENTED CARBIDE CORP

Method for casting nodular cast iron with large section

The invention discloses a method for casting nodular cast iron with a large section. The carbon content and the number of graphite pebbles per unit area are increased, so that the problem of fragmented graphite can be solved; the ideal carbon content is 4.1 to 4.3 percent; the silicon content is 2.0 to 2.2 percent; instantaneous inoculation is added on the basis of the original inoculation, namely during pouring, pouring cup inoculation is performed by using 1 percent of No.75 silicon powder with the granularity of between 0.3 and 1mm; generally, common rare-earth-magnesium-silicon-iron alloy is used as nodulizer and has a wide application range, but during production of the nodular cast iron with the large section, decaying spheroidisation resistance and distortion-invariant capacity of the graphite are low; and in order to overcome the disadvantages, the improved scheme of D-2 heavy rare earth nodulizer is adopted, and during spheroidization, the common rare-earth-magnesium-silicon-iron alloy accounts for 60 percent and the D-2 heavy rare earth nodulizer accounts for 40 percent based on the total weight of the nodular cast iron. The method has the advantages that: the problems of graphite distortion, a small number of spheroidal graphite and fragmented graphite are solved, so that the spheroidization of the central position of a casting is improved and the requirement of a template of an injection molding machine can be fully met.

Owner:宁波康发铸造有限公司

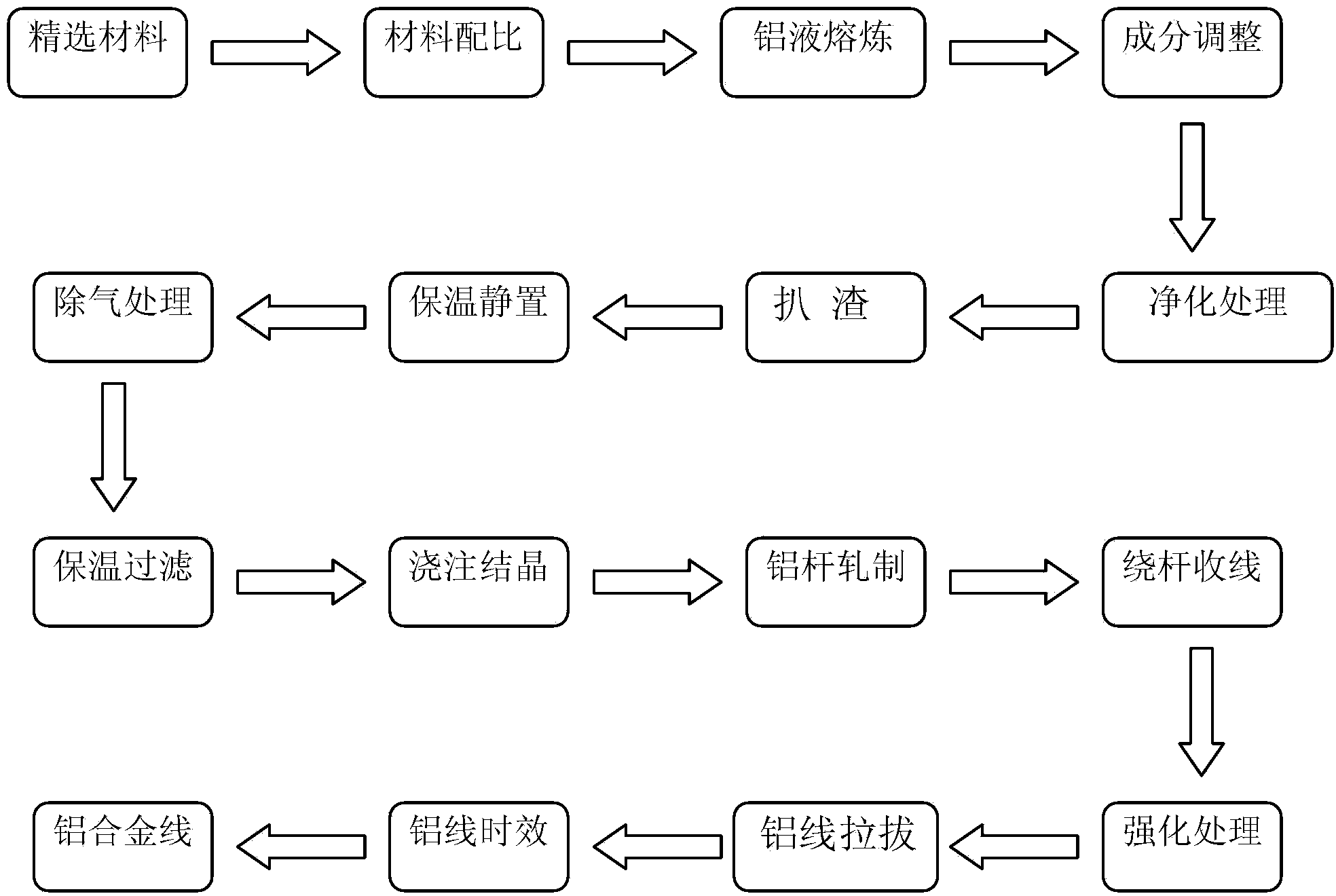

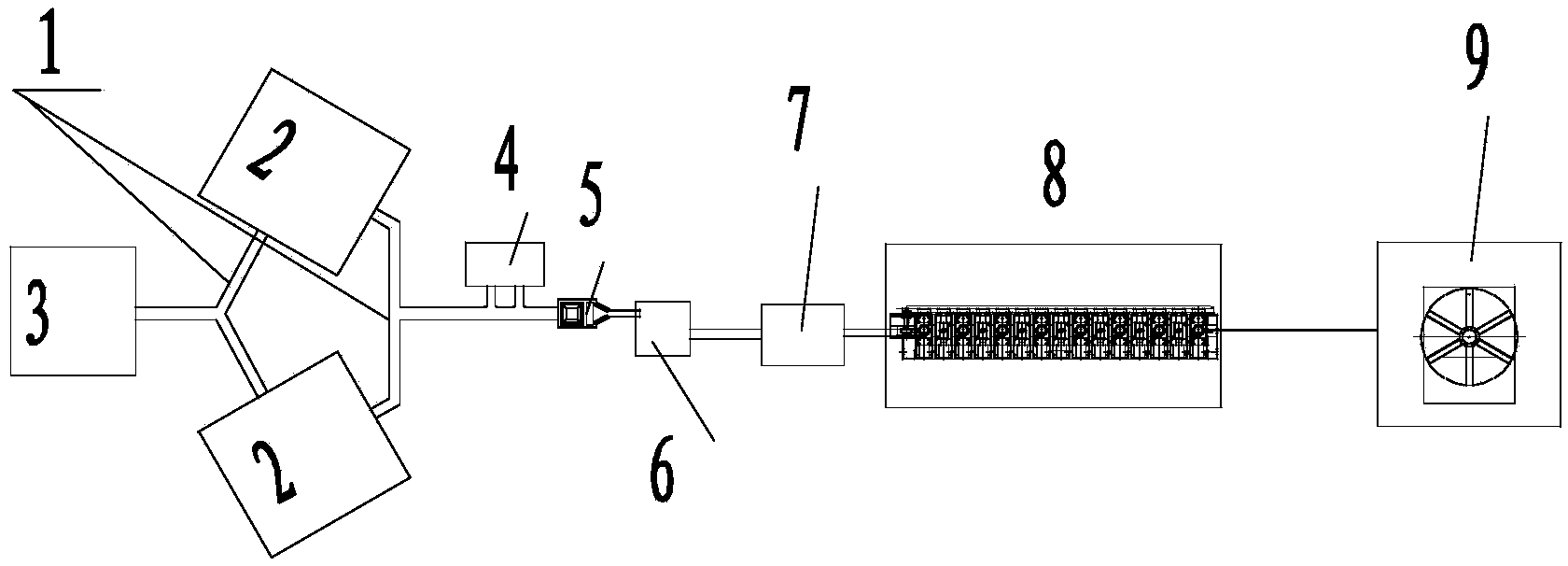

Medium strength aluminium alloy wire with conductivity of 55% IACS, and preparation method thereof

ActiveCN103820686APromote precipitationPromote spheroidizationMetal/alloy conductorsCable/conductor manufactureManufacturing technologyAdditive ingredient

The invention relates to a medium strength aluminium alloy wire with conductivity of 55% IACS, and a preparation method thereof, and belongs to the field of alloy manufacturing technology. The alloy elements comprise, by weight, 0.16%-0.22% of iron, 0.48%-0.54% of silicon, 0.62%-0.67% of magnesium, 0.01%-0.02% of boron and 0.02%-0.05% of ytterbium, with the balance being aluminium. The medium strength aluminium alloy wire with a product conductivity higher than or equal to 55% IACS and tensile strength higher than or equal to 315 MPa is obtained by processes of selecting materials, smelting liquid aluminium, adjusting liquid aluminium ingredients, carrying out purifying treatment, deslagging, standing with heat preservation, degassing, filtering with heat preservation, casting and crystallizing, rolling an aluminum rod, drawing and aging. The wire and cable produced by using the aluminium alloy can be erected continuously by a conventional construction process. In a circuit operation process, circuit loss can be reduced; construction fee can be reduced; and enormous economic benefits and social benefits can be brought about for power transmission and transformation industries.

Owner:WUXI HUANENG ELECTRIC CABLE

Method of producing spherical silica powder

InactiveUS20020024161A1Reduce the amount requiredPromote generationSilicaGlass shaping apparatusSilica particleCombustor

Spherical silica powder is produced by feeding silica powder having an average particle size of 0.3-40 mum to a burner flame formed with a flammable gas so as to continuously melt and spheroidize the particles within the flame. The use of a non-halogenated siloxane and / or alkoxysilane as an auxiliary flame-generating source raises the flame temperature and increases the length of the composite flame formed by combustion of the fuel gas with the siloxane or alkoxysilane. Moreover, the fine particles of silica that form as a result of siloxane or alkoxysilane combustion unite and coalesce with the particles of starting silica. These effects accelerate melting and spheroidization of the starting silica powder, resulting in thermally efficient and cost-effective spherical silica powder production.

Owner:SHIN ETSU CHEM IND CO LTD

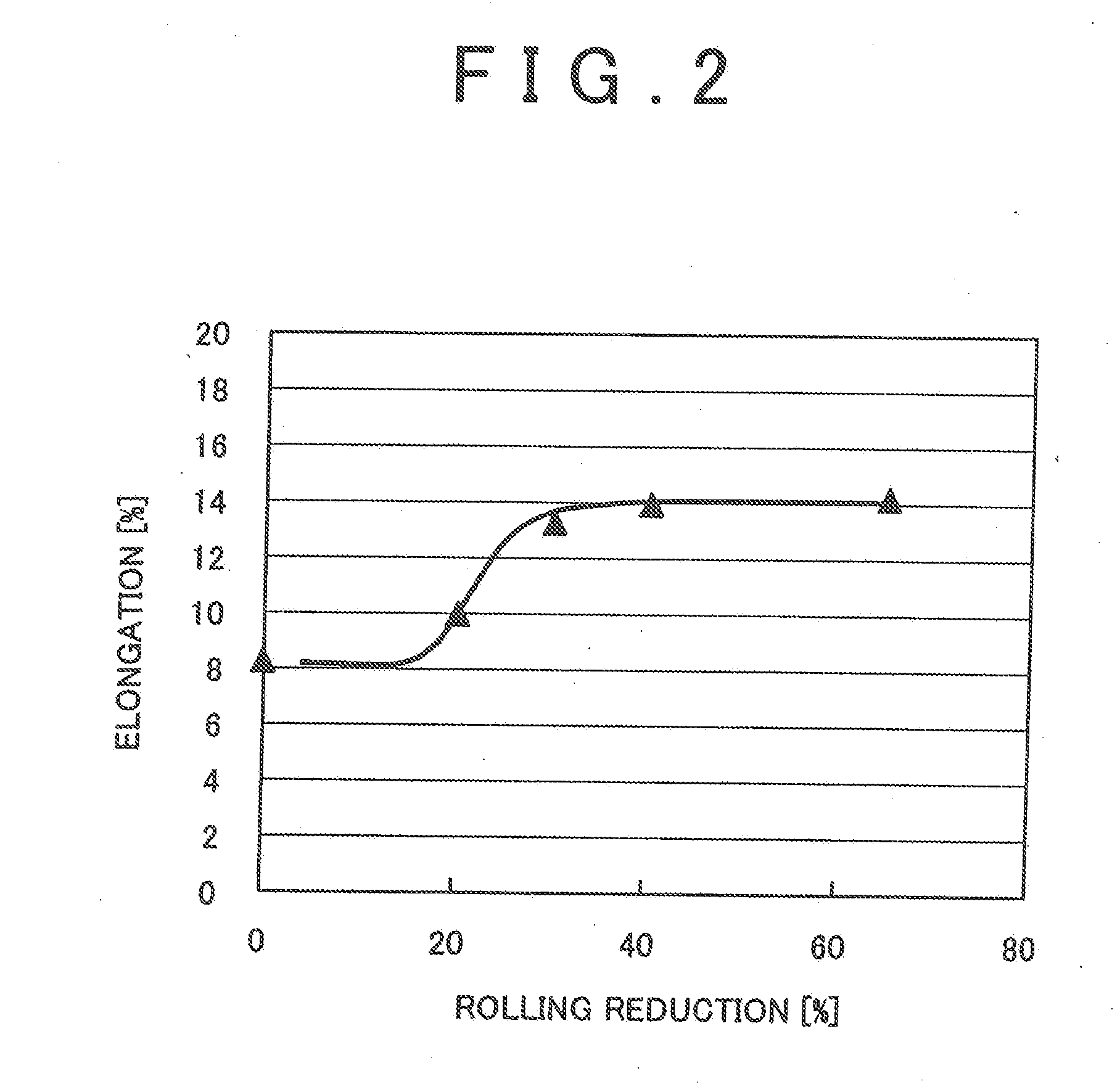

Rolling technology for high-carbon steel in thin slab casting and rolling

ActiveCN104438326AIncrease nucleation sitesUniform nucleationTemperature control deviceTension/compression control deviceThree stageSlow cooling

The invention provides a rolling technology for high-carbon steel in thin slab casting and rolling. The rolling technology includes the processes of continuous casting, heat evening, scale removing, rolling, inter-stand cooling, laminar cooling, reeling and insulation cover slow cooling. The rolling technology is characterized in that the rolling process includes three stages of Austenite perfect recrystallization rolling, non-recrystallization area Austenite rolling and two-phase area rolling. Medium-and-high-carbon steel structures rolled through the rolling technology are even and fine ferrite and particular pearlite, banded structures can be improved, the mechanical property is good, the annealing process does not need to be conducted before forming, cost is reduced, and quite high practicability is achieved.

Owner:武汉钢铁有限公司

Working roll for rolling medium-thickness plate with high grade and high strength and manufacture method thereof

ActiveCN101954378AImproved roll shape retentionImprove wear resistanceRollsMetal rolling arrangementsChemical compositionHardness

The invention discloses a working roll for rolling a medium-thickness plate with high grade and high strength and a manufacture method thereof. The working roll is applied to a medium-thickness plate rolling mill of a rolling steel industry. A working layer comprises the following alloy components in percentage by weight: 3.00-3.50 percent of C, 0.40-1.20 percent of Si, 0.50-1.20 percent of Mn, not more than 0.10 percent of P, not more than 0.05 percent of S, 1.30-2.50 percent of Cr, 3.20-4.50 percent of Ni, 0.20-1.00 percent of Mo, 0.20-2.00 percent of W and 1.00-1.50 percent of V. A roll core comprises the following chemical components in percentage by weight: 2.80-3.50 percent of C, 2.00-2.50 percent of Si, 0.50-1.00 percent of Mn, not more than 0.10 percent of P, not more than 0.05 percent of S, 0.20-0.50 percent of Cr, 0.20-0.60 percent of Ni, not more than 0.20 percent of Mo and not more than 0.30 percent of Re. The working roll manufactured by adopting a centrifugal composite casting process and two-section tempering production at 400-550 DEG C for 25-30 hours is the working roll for rolling the medium-thickness plate with high grade and high strength, which has the advantages of high abrasion resistance and less hardness reduction.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

High-intensity high-damping deforming magnesium alloy with rear earth yttrium

The invention discloses a high-intensity high-damping deforming magnesium alloy with rear earth yttrium, which is characterized by comprising the following components by weight percent: 2.9-3.1 percent of Al, 0.9-1.1 percent of Zn, 0.5-2 percent of Y, 0.29-0.31 percent of Mn and the rest of Mg and unavoidable impurities. The high-intensity high-damping deforming magnesium alloy with rear earth yttrium can greatly increase the mechanical property and the damping performance of the high-intensity AZ series deforming magnesium alloy, successfully solve the conflict of the mechanical property andthe damping performance of the magnesium alloy and satisfy the actual requirements for a high-intensity high-damping light-weight material in the fields of very high-speed trains, automobiles, aerospace, national defense war industry, and the like, moreover, the magnesium alloy material has lower cost, and a technical device is the normal universal device with strong portability and easy operation.

Owner:CHONGQING UNIV

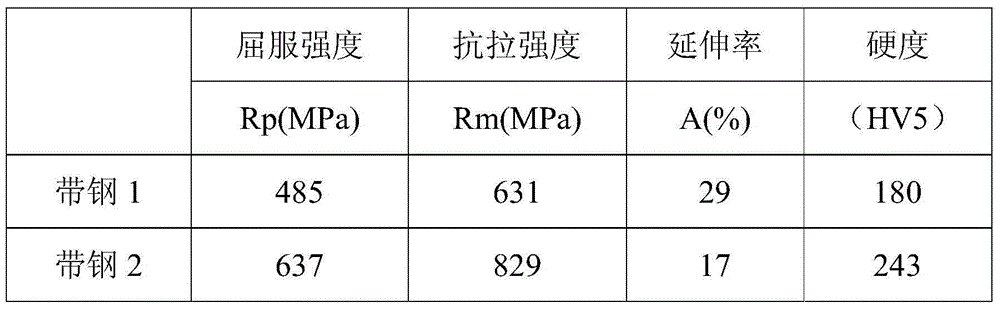

Steel for card clothing

The invention provides steel for card clothing. The steel is prepared from the following components in percentage by mass: 0.75 to 0.85 percent of C, 0.10 to 0.50 percent of Si, 0.30 to 0.90 percent of Mn, 0.20 to 0.50 percent of Cr, smaller than 0.02 percent of P, smaller than 0.01 percent of S, 0.04 to 0.20 percent of V, 0.015 to 0.060 percent of Nb, 0 to 0.50 percent of Ni, 0 to 0.50 percent of Mo, 0 to 0.40 percent of Cu, and the balance being inevitable impurities. According to the steel disclosed by the invention, by adopting a mode of reasonably adding Nb and V, produced card clothing undergoing quenching-tempering heat treatment has crystal particle size of over 12 grades and hardness of over 800HV0.2 can be guaranteed while the steel has good cold processing forming performance, the wear resistance of products is remarkably improved, and the service life is also greatly prolonged.

Owner:金轮针布(江苏)有限公司

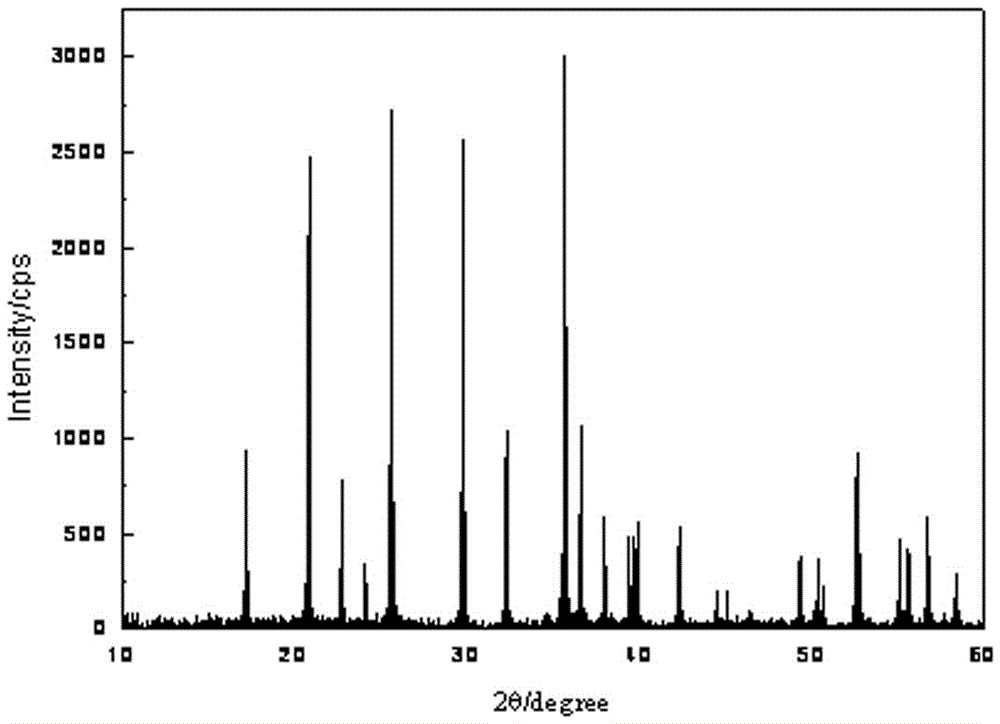

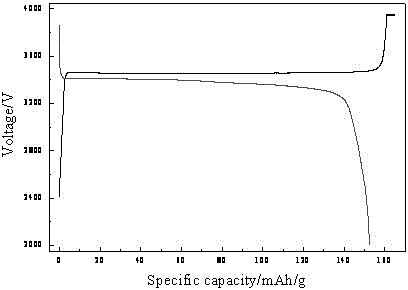

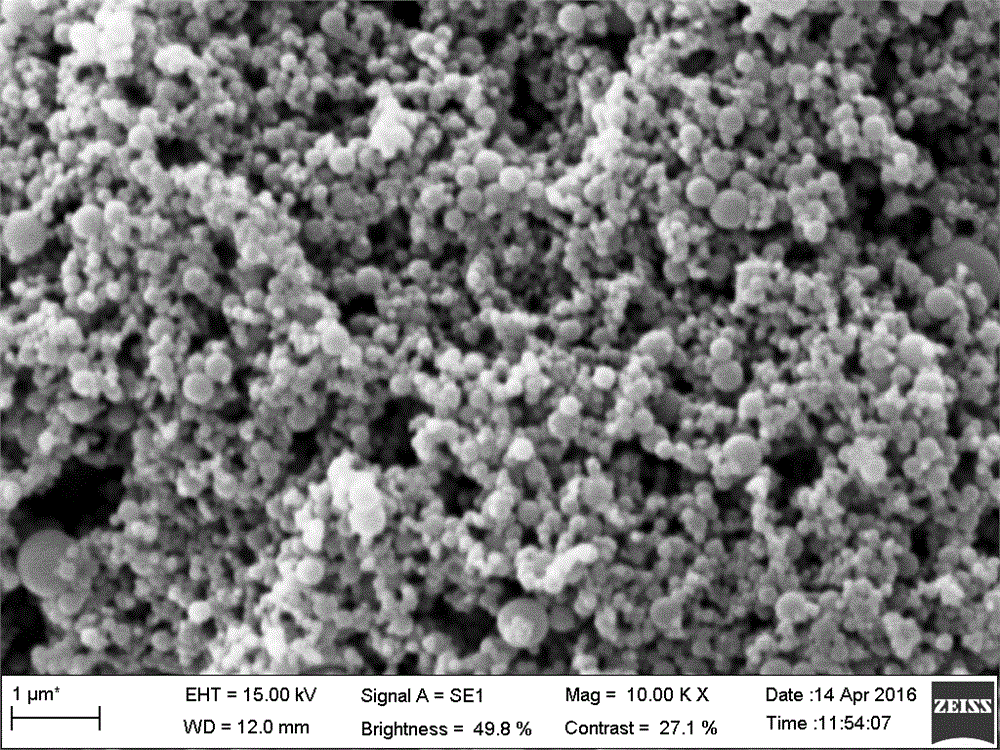

Preparation method for high-activity material

InactiveCN106784702AReduce distanceSmall particle sizeCell electrodesSecondary cellsLithium iron phosphateUltra fine

Disclosed is a preparation method for a high-activity material. The preparation method comprises the following steps of weighing a lithium source, an iron source, a phosphorus source, a carbon source and an additive based on certain proportions, wherein the molar ratio of Li to Fe to P is 0.9-1.2 to 1 to 1, and the molar ratio of the additive to the lithium source is 0.001-0.05 to 1; adding the raw materials into an ultra-fine ball milling-grinder comprising a dispersing agent to be fully grinded to obtain uniformly dispersed slurry; conveying the slurry to a spray dryer to be subjected to drying and pelleting to obtain a lithium iron phosphate precursor; and performing sintering on the lithium iron phosphate precursor in an atmosphere furnace for one time, and cooling instantly, and then performing smashing and mechanical integrating to obtain a lithium iron phosphate product. The preparation method is simple in technological process, low in production cost and suitable for large-scale production.

Owner:德清崎辉机械科技有限公司

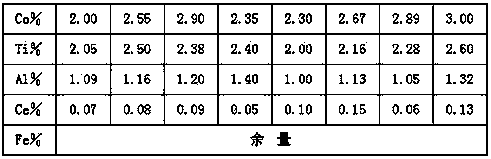

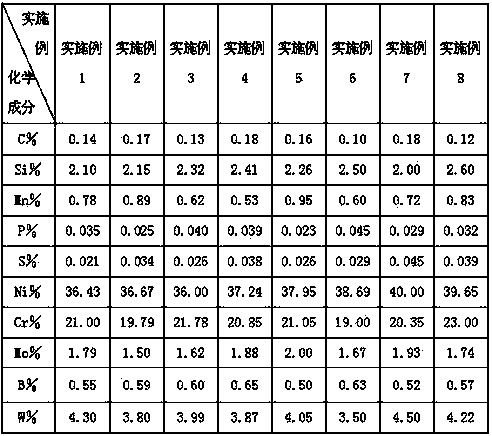

High-temperature-resistant alloy casting and preparation method thereof

ActiveCN104195474AHigh strengthImprove high temperature creep resistanceFoundry mouldsFoundry coresChemical compositionCarbide

The invention relates to a high-temperature-resistant alloy casting and a preparation method thereof. The alloy casting comprises the following chemical components by mass percent: 0.10% to 0.18% of C, 2.0% to 2.6% of Si, less than or equal to 1% of Mn, less than or equal to 0.045% of P, less than or equal to 0.045% of S, 19% to 23% of Cr, 36% to 40% of Ni, 1.5% to 2.0% of Mo, 0.50% to 0.65% of B, 3.5% to 4.5% of W, 1.0% to 1.4% of Al, 2.0% to 2.6% of Ti, 2% to 3% of Co, 0.05% to 0.15% of Ce and the balance of Fe. The preparation method comprises the following steps of the preparation of a wax mould; the preparation of a mould shell; smelting; and pouring. The as-cast hardness of the alloy casting is HB273-285; and an as-cast metallographic structure of the alloy casting is composed of a fine and small dendritic austenite r, a precipitation strengthening phase r', an intermetallic compound, a metal carbide and a metal boride. The obtained inner core cup casting is strong in high-temperature creep resistance, high-temperature resistance and oxidation resistance and is high in strength and stability under a high-temperature condition, so that the long service life of the casting is realized.

Owner:BAODING FENGFAN PRECISION CASTING

Aluminium alloy material for car radiator cooling flat tube

ActiveCN101328552AImprove corrosion resistancePromote spheroidizationZeta potentialRare-earth element

The invention relates to an aluminum alloy material for a radiator cooling flat pipe used in an automobile, belonging to the aluminum alloy material technical field. The material is mainly characterized in that aluminum-manganese alloy with a certain component is added with proper amount of mixed type rare earth(RE) taking Ce as main materials for smelting and casting. Experiments show that the rare earth element has refined action on secondphase such as eutectic phase and exsolution precipitate phase by observing fine texture of the aluminum alloy material containing the mixed type rare earth, and a plurality of small pits of electrochemical corrosion are not found in the texture of the aluminum-manganese alloy added with rare earth, which means that the corrosion resistance of the aluminum-manganese alloy added with rare earth is improved; and the corrosion behavior of the alloy material is tested by the zeta potential scanning polarization curve test technology, which shows that the corrosion resistance of the aluminum-manganese alloy added with rare earth is improved to some extent. The aluminum material provided by the invention can be directly made into the aluminum flat pipe by drawing, and also be used to process plate materials to be manufactured into radiator ribs, and the radiator ribs are not collapsed in the high temperature brazing.

Owner:JIANGSU JIAHE THERMAL SYST RADIATOR +1

Aluminum alloy, method of casting aluminum alloy, and method of producing aluminum alloy product

Owner:TOYOTA JIDOSHA KK

Method for synthesizing aluminium oxide powder by using combustion method

ActiveCN106629799AMany breakthrough processesBreakout cycleAluminium oxide/hydroxide preparationChemical synthesisOxygen delivery

The invention relates to a method for synthesizing aluminium oxide powder by using a combustion method, and belongs to the technical field of chemical synthesis of powder materials. The method comprises the following steps: (1) ignition: continuously or intermittently igniting in a reaction device; (2) oxygen delivery: feeding oxygen into the reaction device; (3) aluminum powder conveying: conveying aluminum powder with the grain size less than or equal to 100 mu m into the reaction device through gas; (4) combustion: igniting the aluminum powder so that the aluminum powder is combusted in oxygen; and (5) cooling: cooling combustion products and collecting the combustion products to obtain the aluminium oxide powder. The problem that preparation of aluminium oxide powder by an existing aqueous solution method has lots of procedures, and is long in production period and large in water consumption is solved. Water is not used in the method, and the aluminium oxide powder which has the size of nanoscale or above and has the various purities of 2N-6N is obtained at one step by using aluminum as a raw material; and the product is high in purity, low in sodium content, uniform in particle size, good in dispersibility and good in spheroidization. A synthetic process is short in technological process, the equipment is simple, the cost is low, energy consumption is low, synthesis efficiency is high, pollution does not exist, and waste gas, waste water and solid wastes do not exist.

Owner:新疆三锐佰德新材料有限公司

High silicon ball iron injection molding machine template casting preparing method

InactiveCN107513658AImprove mechanical propertiesSolve the shrinkage cavityProcess efficiency improvementSlagMolding machine

Disclosed is a high silicon ball iron injection molding machine template casting preparing method. The method comprises the steps that raw materials comprises, by weight, 40-50% of pig iron, 20-30% of scrap steel, 20-30% of foundry returns, 1-1.4% of silicon iron and 0.004-0.005% of Sb, and are configured; melting is conducted, sampling analysis and blending composition are conducted; firstly, a rare earth magnesium nodularizer and Sb are correspondingly placed on the two sides of a bottom transverse blocking of a nodulizing bag, scrap steel sheets covers the surface of the rare earth magnesium nodularizer, and molten iron is poured into the nodulizing bag with Sb on one side, after the nodulizing reaction begins, a ladle-to-ladle inoculant is added into the nodulizing bag for inoculation, meanwhile, the molten iron is stirred, and melting of the ladle-to-ladle inoculant is promoted; and slag removal and pouring are conducted. The high silicon ball iron injection molding machine template casting preparing method has the advantages that the defects such as shrinkage and shrinkage cavity of a casting can be effectively solved, and the brittleness of the casting can be reduced, thus the scrap rate of during high silicon ball iron injection molding machine template casting manufacturing can be greatly reduced.

Owner:RIYUE HEAVY IND

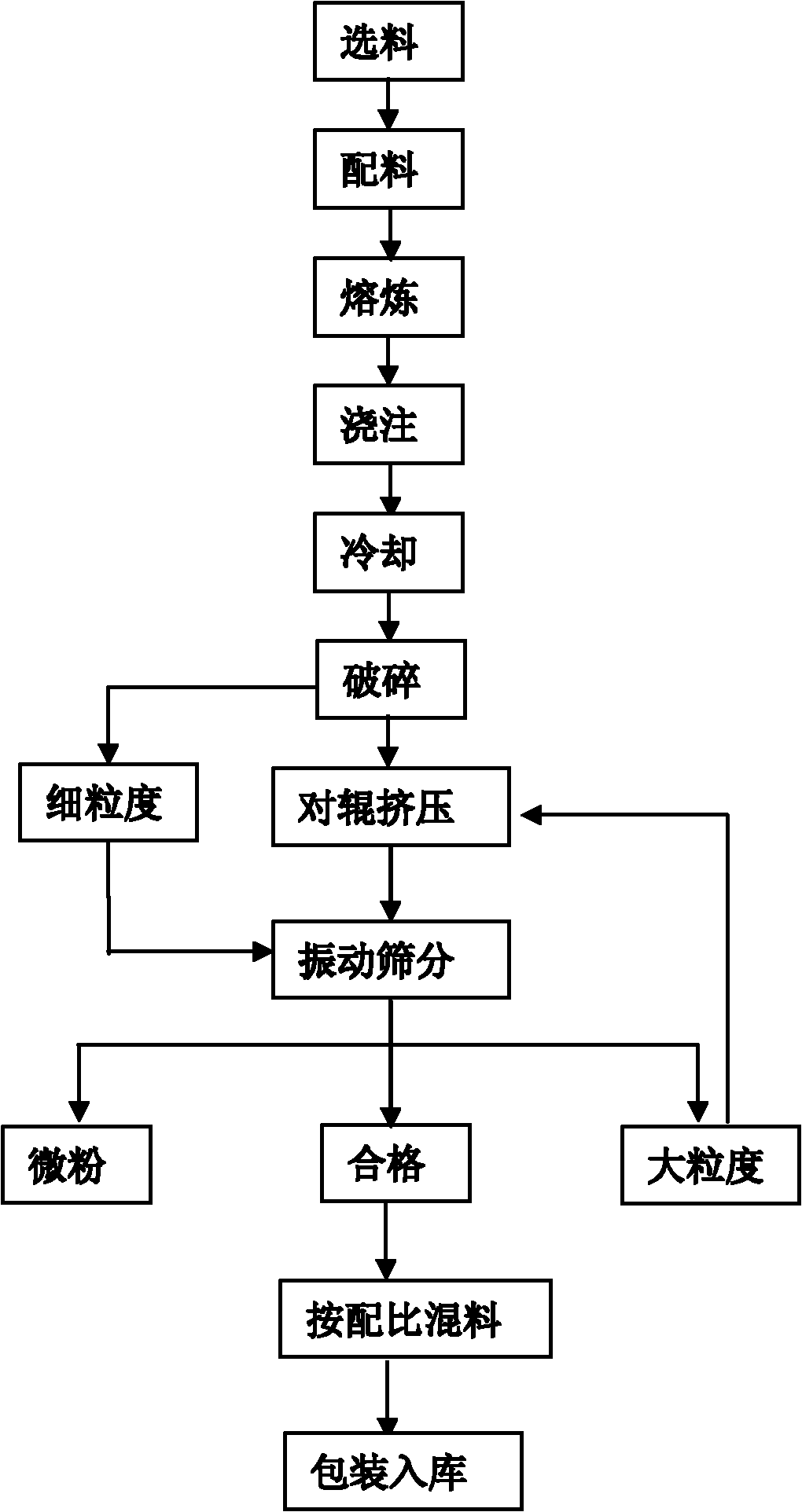

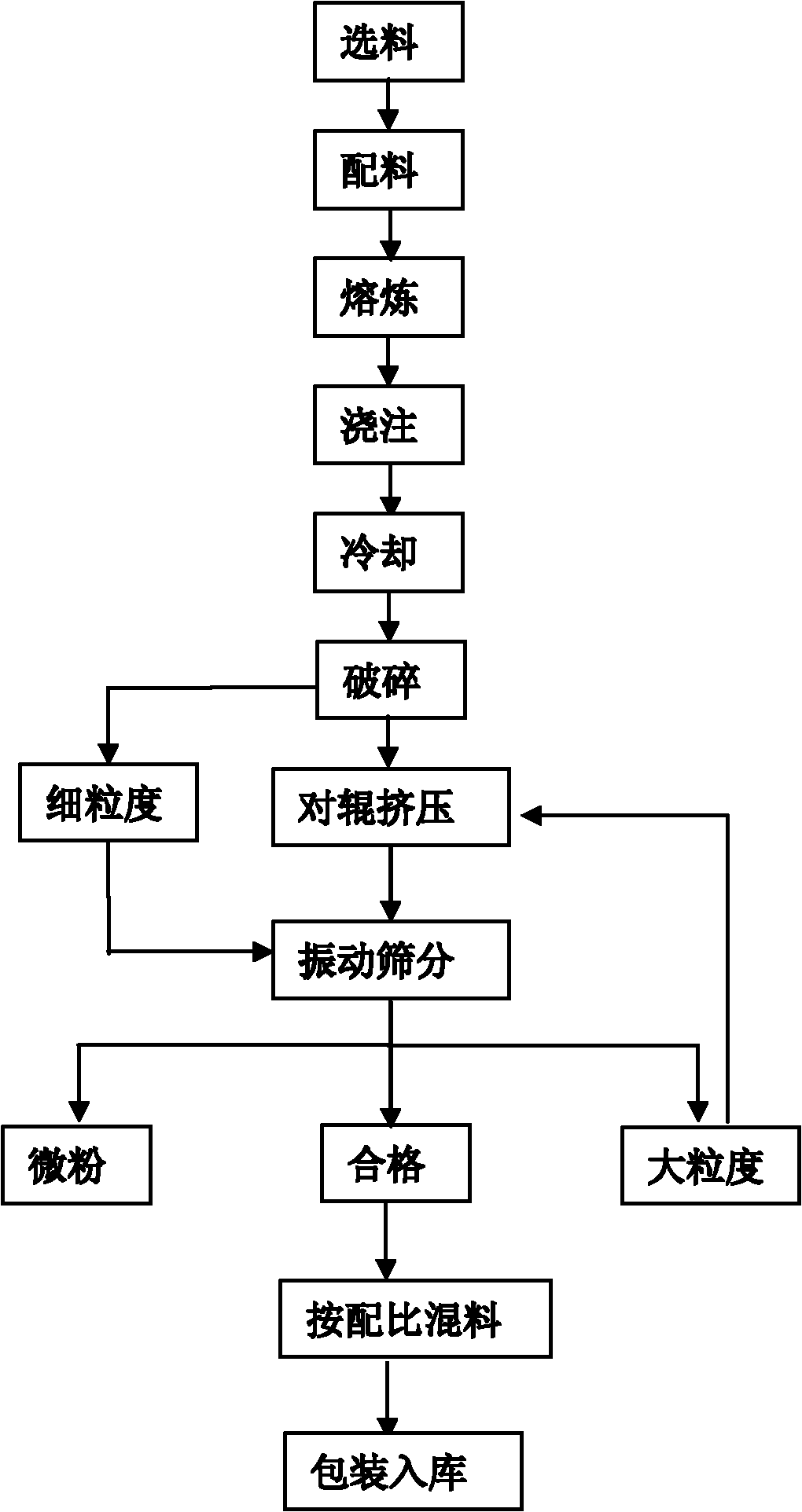

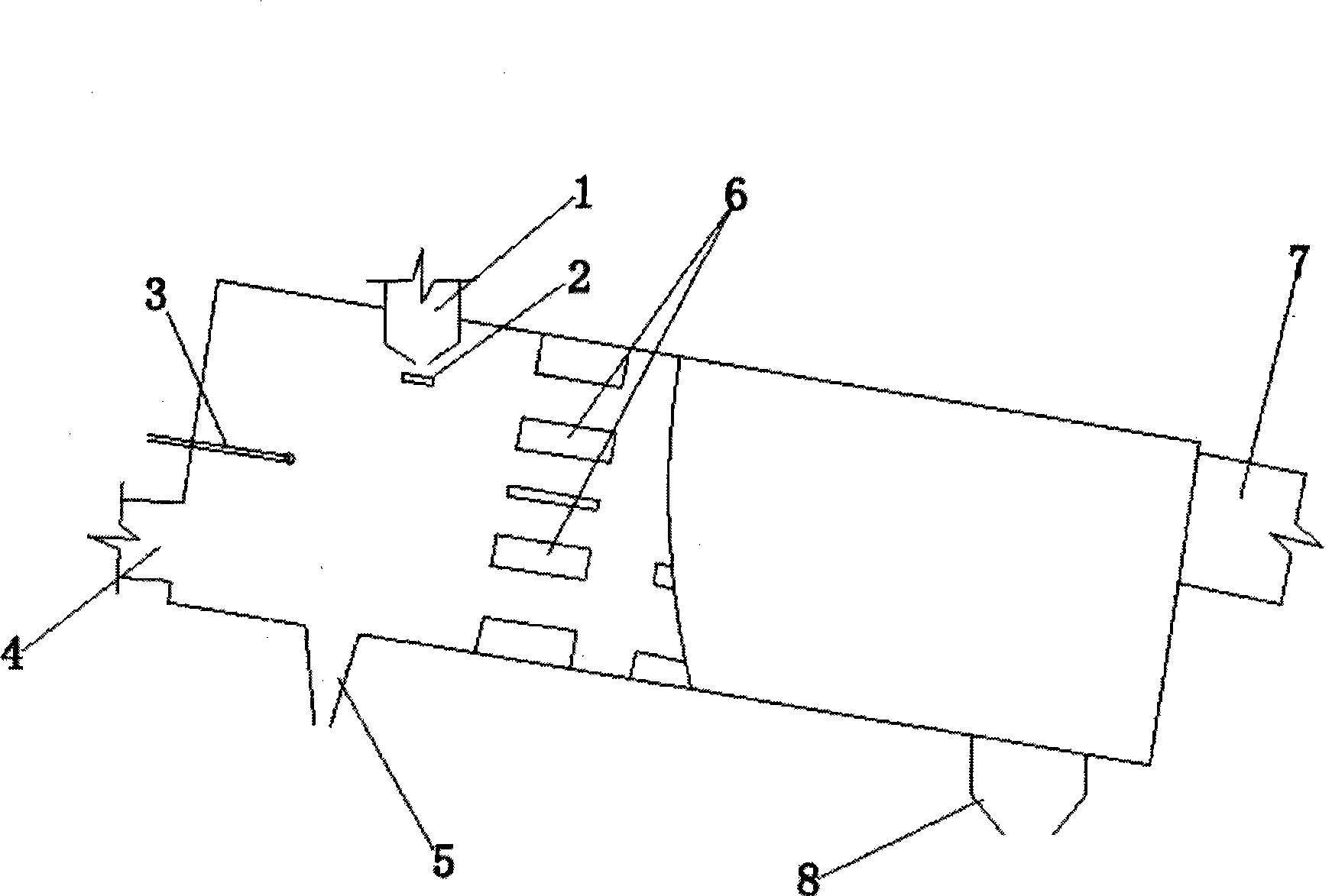

Pipe die powder for centrifugally casting nodular cast iron pipe and preparation process thereof

The invention discloses pipe die powder for centrifugally casting a nodular cast iron pipe and a preparation process thereof. The pipe die powder comprises the following components in percent by mass: 60-65 percent of Si, 1.5-2.0 percent of Ca, 2.0-3.0 percent of Ba, 1.4-1.6 percent of Mn, 1.0-1.5 percent of Mg, 1.0-2.0 percent of Zr, 0.7-1.5 percent of Al and the balance of Fe; and the granularities of pipe die powder comprise less than 1.5 percent of 80 mu, 25-30 percent of 100-120 mu, 40-50 percent of 140-180 mu, 25-30 percent of 200-300 mu and less than 2.5 percent of more than 300 mu. The preparation process comprises the following steps of: preparing, melting, pouring, cooling, crushing, milling, proportioning granularities and packaging in vacuum. The pipe die powder has the advantages of uniform components, consistent melting points and reasonable granulometric class, and is beneficial to the prolonging of the service life of a pipe die of the nodular cast iron pipe, the reduction of a series of casting defects of cockles, poor nodulizing, surface cracks and the like of the nodular cast iron pipe, the improvement of the quality of the nodular cast iron pipe and the yield, and the lowering of the production cost.

Owner:YUZHOU HENGLILAI ALLOY CO LTD

Novel process for preparing spherical calcium chloride with spray of rotary kiln

ActiveCN101367537APromote spheroidizationCalcium/strontium/barium chloridesChlorideUltimate tensile strength

The invention discloses a craftwork for producing the spherical calcium chloride with a rotary kiln in mist spraying way. Calcium chloride concentrated liquid is adopted as the raw material, and the pellet fabrication production is performed through an inoculating crystal in longitudinal mist spraying way in a rotary kiln. The calcium chloride concentrated liquid is atomized by a spraying nozzle at the kiln hood, and is sprayed towards the front inoculating crystal curtain; at the same time, under the effect of a mixing board, the calcium chloride and the particles of the inoculating crystal form multi-layer curtains at different positions inside the kiln, so that the calcium chloride pulp can be adequately conglutinated and forms the fluidization, and the pellet rolls forwards. Under the effect of the guiding plate and the mixing board of the rotary kiln, the atomized liquid drop is conglutinated and rolled with the inoculating crystal to become larger and larger; through the rapid contact between the high-temperature air and the inoculating crystal pellet, anhydrous spherical calcium chloride is formed on the surface of the inoculating crystal, and is discharged from the discharging port at the tail of the kiln, and is classified by a rolling sieve to get the qualified product. The invention realizes the one-step completion of the mist spraying pellet fabrication of the calcium chloride in the rotary kiln and the drying, and realizes the large-scale consecutive production of the spherical calcium chloride. The spherical degree, the surface smoothness and the strength of the prepared calcium chloride pellet are improved.

Owner:青海金锋实业有限公司

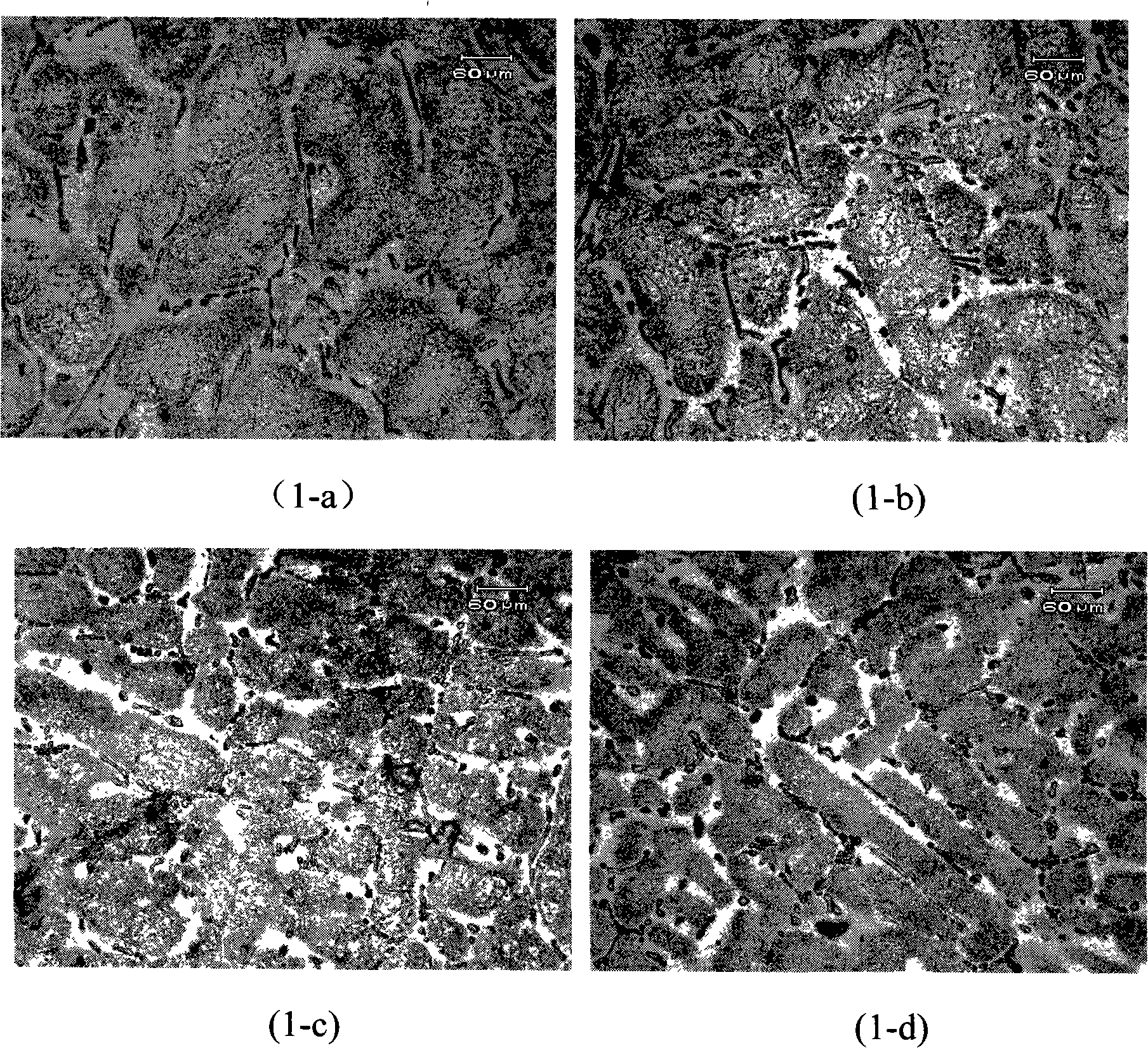

Rare-earth element samarium alloying aluminum-silicon alloy and preparation method thereof

ActiveCN103451489AImprove refinementPromote spheroidizationProcess efficiency improvementRare-earth elementMolten alloy

The invention relates to a rare-earth element samarium alloying aluminum-silicon alloy and a preparation method thereof. The alloy comprises the following components in percentage by weight: 9.0-9.8% of silicon, 0.05-0.4% of samarium and the balance of aluminum. The preparation method comprises the following steps: heating an Al-Si alloy in a graphite crucible to be molten, adding samarium or an aluminum-samarium intermediate alloy according to the weight percents at 770-790 DEG C, and keeping the temperature for 5-8 minutes; performing intermittent ultrasonic treatment on the molten alloy under the conditions that the ultrasonic strength is 10-38 w / cm<2>, the total ultrasonic treatment time is 3-8 minutes, the ultrasonic time of each time is 20-30 seconds and the intermittence time is 20-30 seconds; and cooling the molten alloy to 720-740 DEG C, keeping the temperature for 31-180 minutes, and solidifying at a cooling rate of 40-65 DEG C / min. According to the invention, the refinement and nodularization of an alpha-Al phase can be obviously accelerated; acicular eutectic silicon is changed into punctate or stick-like silicon, and the distribution is more disperse and uniform, thus ensuring that the microscopic structure and mechanical property of the aluminum alloy are obviously improved; the process is simple, safe, reliable and convenient to operate, and has no pollution caused by three wastes.

Owner:优标易站(苏州)电子商务有限公司

Nucleating agent containing rare earth and application of nucleating agent to spheroidal graphite cast iron smelting

InactiveCN105039631AImprove liquidityPromote spheroidizationProcess efficiency improvementRare-earth elementSlag

The invention discloses a nucleating agent containing rare earth. The nucleating agent is composed of the following components of the rare earth, lead, antimony, silicon, calcium, magnesium, aluminum and the balance iron and inevitable microelements. Application of the nucleating agent to spheroidal graphite cast iron smelting comprises three times of nucleation. Compared with the prior art, the nucleating agent has the following beneficial effects that the magnesium is added and combined with rare earth elements, so that alloy crystals have the more stable phase in a reaction and cannot be decomposed when coming across moisture or water, and the stability of the alloy crystals do not become poor along with the time; meanwhile, through multiple times of nucleation, mobility of molten iron can be improved, and the deoxidization effect of the molten iron is improved; and meanwhile, the remarkable effect on spherification and ferritiszation of spheroidal graphite is achieved and casting defects caused by much slag and cavity shrinkage can be effectively overcome.

Owner:HEFEI CITY TENVER PRECISION CASTING

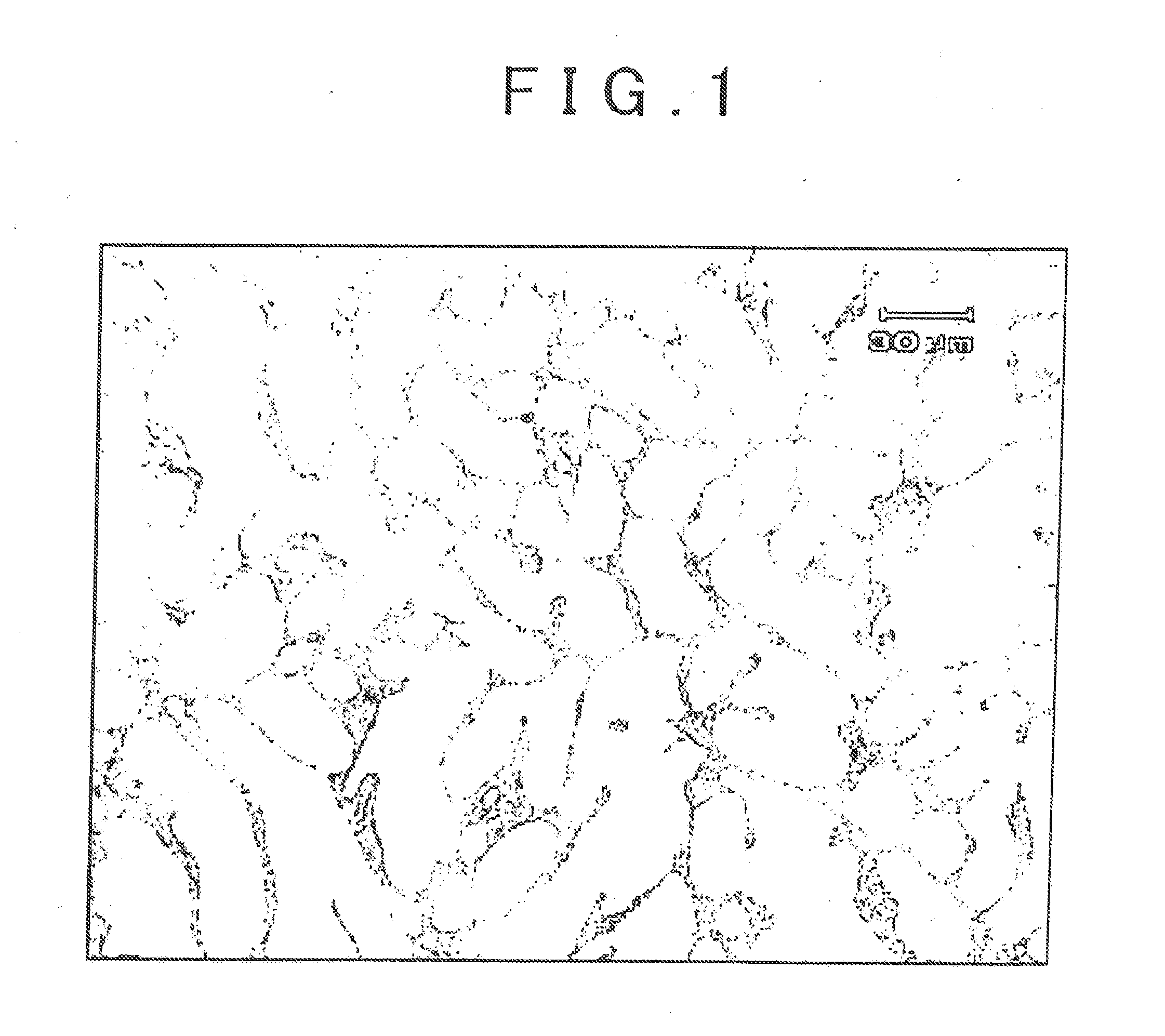

High-uniformity short-process forming method for large metal component

The invention relates to the field of metal forming, in particular to a high-uniformity short-process forming method for a large metal component. Firstly, a cast alloy cast ingot is subjected to superhigh temperature demolding; then soaking is conducted on the liquid core cast ingot, precise control of the liquid fraction of the core part of the cast ingot is achieved, axial upsetting and rollingare conducted on the cast ingot under a forging press, dendrite at the liquid core of the cast ingot is fully crushed and balled, and a uniform and tiny semisolid structure is formed; and finally radial and axial forging is conducted on the cast ingot, and the cast ingot is forged into the needed large metal component structure. Through the high-uniformity short-process forming method, the problems such as shrinkage cavity and porosity and dendritic segregation in the cast ingot are solved, the central mechanical performance of the large metal component can reach the surface performance level,and uniformity of the overall performance of the component is improved. The core part of the cast ingot forms the uniform and tiny semisolid structure, and thus the final forge piece has good comprehensive performance. Forming pressure is small, the requirement for ability of forging equipment is lowered, the technological process is shortened, and production cost can be lowered effectively.

Owner:UNIV OF SCI & TECH BEIJING

As-cast high-strength high-elongation synthetic nodular cast iron and preparation method thereof

The invention relates to the field of as-cast high-strength high-elongation synthetic nodular cast iron. The invention relates to as-cast high-strength high-elongation synthetic nodular cast iron anda preparation method thereof. The nodular cast iron is characterized in that under the as-cast condition, the nodular cast iron meets performance requirements that the tensile strength Rm is larger than or equal to 700 MPa, and the percentage elongation A after fracture is larger than or equal to 10%; the matrix is a pearlite-ferrite mixed matrix; the content of pearlite is 55%-75%, a spheroidizing grade is 1-2, a graphite size grade is 6-7, the nodular cast iron is composed of elements, by mass, 3.5%-3.7% of C, 2.9-3.3% of Si, less than or equal to 0.2% of Mn, less than or equal to 0.035% ofP, less than or equal to 0.02% of S, 0.5%-0.7% of Cu, 0.55%-0.75% of Ni, 0.030%-0.065% of Mg and the balance of Fe and trace elements. The method has the beneficial effects that scrap steel and raw material pure iron are adopted for recarburization, base iron is smelted in a medium-frequency induction furnace, then pretreatment, spheroidizing treatment and inoculation treatment are conducted, final pouring is conducted, and QT700-10 is achieved under the as-cast condition.

Owner:湖北三环铸造股份有限公司

Induction assisted shot blasting and thinning laser additive manufacturing method of light alloy crystal grains

InactiveCN108505033AGrain refinementImprove mechanical propertiesMetallic material coating processesOptoelectronicsAlloy

The invention discloses an induction assisted shot blasting and thinning laser additive manufacturing method of light alloy crystal grains. The induction assisted shot blasting and thinning laser additive manufacturing method comprises the following steps: 1) determining the shape of an induction coil according to a contour shape of a light alloy part to be formed; 2) adjusting the position of aninfrared temperature measurement head to enable a temperature measurement light spot formed by the infrared temperature measurement head to be located on a molded surface of a matrix; 3) starting a laser additive manufacturing system and forming a first cladding layer on the matrix; 4) lifting the induction coil and the infrared temperature measurement head by the height of one cladding layer along a laser additive manufacturing system and then forming a next cladding layer; 5) repeating step 4) and carrying out shot blasting reinforcement on the formed cladding layer every other N cladding layers through a shot blasting device; in a shot blasting reinforcement process, heating the cladding layers through the induction coil until the whole light alloy part is formed. According to the method disclosed by the invention, a formed light alloy forming part has good comprehensive mechanical properties and anisotropic prominent problems are effectively controlled.

Owner:芜湖舍达科技有限公司

Alloy magnetic material and preparation method thereof

The invention provides an alloy magnetic material and a preparation method thereof, and belongs to the field of metal materials. The alloy magnetic material comprises the following components in percentage by weight: 29 to 33 percent of Nd, 0.9 to 1.3 percent of Cu, 0.9 to 1.3 percent of Al, 0.06 to 0.08 percent of Nb, 0.1 to 0.2 percent of Co, 0.9 to 1.2 percent of Ce, 0.9 to 1.2 percent of B, 2 to 6 percent of Dy and the balance of Fe. The preparation method comprises the following steps of: proportioning the components of the alloy magnetic material, preparing iron alloy powder, preparing composite aluminum-copper alloy powder, mixing the iron alloy powder and the composite aluminum-copper alloy powder, forming by using a highly-oriented magnetic field, performing cold isostatic pressing, performing vacuum high temperature sintering, performing double tempering to obtain the alloy magnetic material. The alloy magnetic material is high in magnetic property and low in material cost; and the preparation method for the alloy magnetic material is simple, low in production cost, safely operated and suitable for industrial production.

Owner:江苏禾一电热材料有限公司

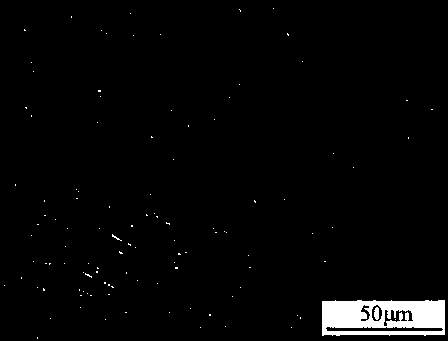

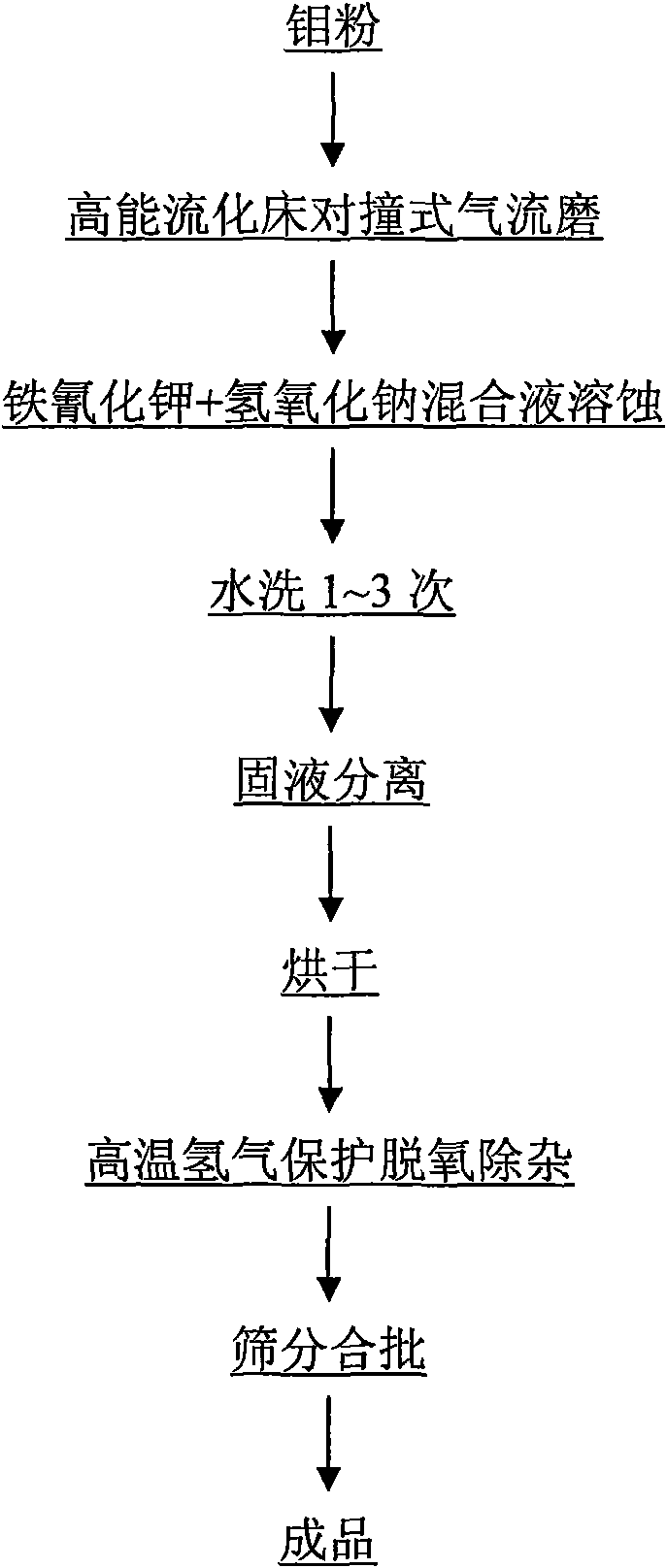

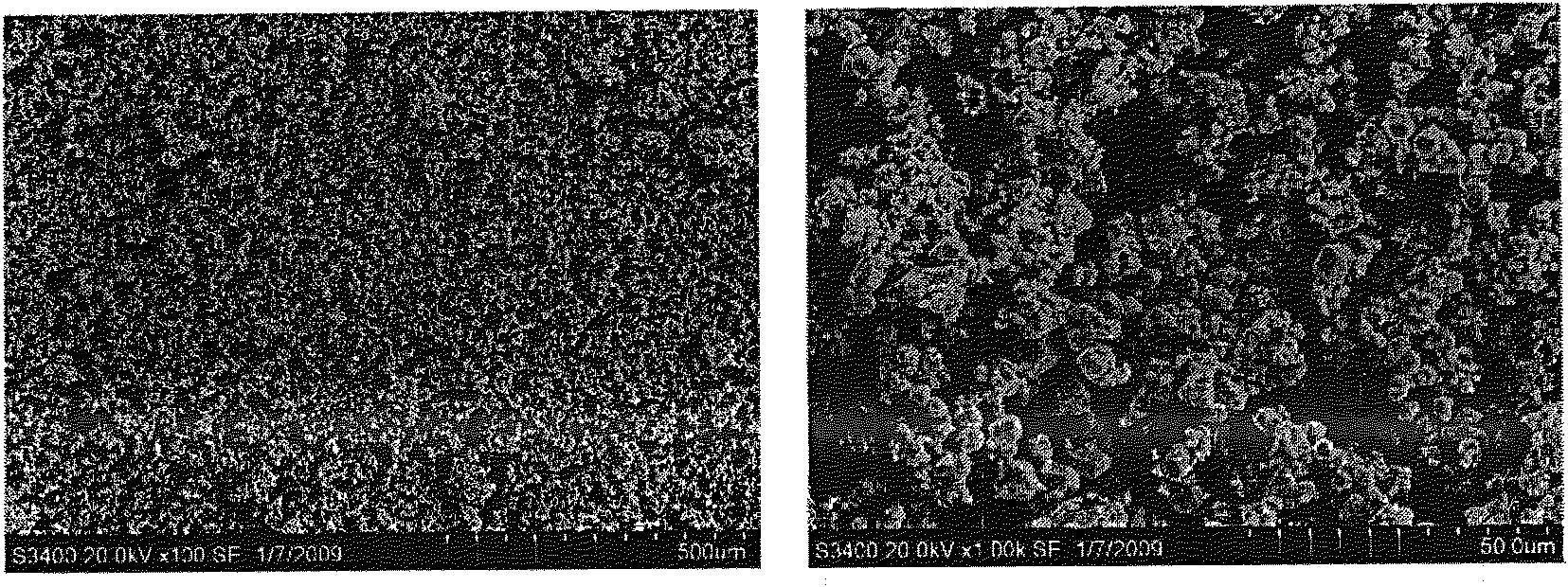

Preparation method of near spherical molybdenum powder

ActiveCN101642814ALow raw material requirementThe production process is easy to controlHigh energyMolybdenum dioxide

The invention relates to a preparation method of near spherical molybdenum powder. The method is characterized by comprising the following steps: taking molybdenum powder prepared by hydrogen reduction on molybdenum dioxide as a raw material; processing the raw material molybdenum powder by a high-energy fluidized-bed collision air-flow mill to obtain single-particle molybdenum powder; spherizingthe molybdenum powder by a chemolysis method; and finally deoxidizing and decontaminating the molybdenum powder at a high temperature under hydrogen protection followed by sieving and combining each batch to obtain the near spherical molybdenum powder. In the method, the common molybdenum powder is processed by the high-energy fluidized-bed collision air-flow mill to disperse agglomerated particles and crush large particles to obtain the molybdenum powder with even single particle; and the single-particle molybdenum powder is spherized by acid-base dissolution action on molybdenum, and the molybdenum powder is deoxidized and decontaminated under hydrogen protection to finally obtain the near spherical molybdenum powder of the invention. The method of the invention has low requirement on the raw material, easy controlled production process, simple operation, applicability to large-scale production, yield rate up to more than 90%, greatly improved apparent density and obviously spherizedshape and no big change on Fisher particle size of the molybdenum powder.

Owner:JINDUICHENG MOLYBDENUM CO LTD

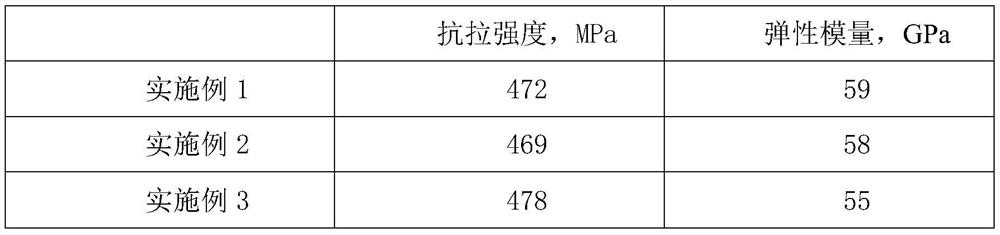

High-strength rare earth wrought magnesium alloy and preparation method thereof

The invention discloses a high-strength rare earth wrought magnesium alloy and a preparation method thereof. The high-strength rare earth wrought magnesium alloy comprises, by mass, 6%-9% of Al, 1.5%-2.5% of Nd, 0.2%-1.5% of Zn, 0.3%-2.0% of Si, 1.2%-2.5% of Zr, 5%-7% of Y, 5%-7% of Gd, 1%-5% of Sm, and the balance Mg and inevitable impurities, wherein (Y+Gd): Sm is equal to 2.8-14; According to the high-strength rare earth wrought magnesium alloy and the preparation method thereof, by adding aluminum, silicon, zinc and various rare earth elements into magnesium alloy raw materials, the tensile strength of the magnesium alloy raw materials is greater than 450 MPa, the elastic modulus of the magnesium alloy raw materials is greater than 55 GPa, the requirements for high strength and high elastic modulus of magnesium alloy in the prior art can be met, and the high-strength rare earth wrought magnesium alloy has the wider application field.

Owner:湖南镁卓新材料科技有限公司

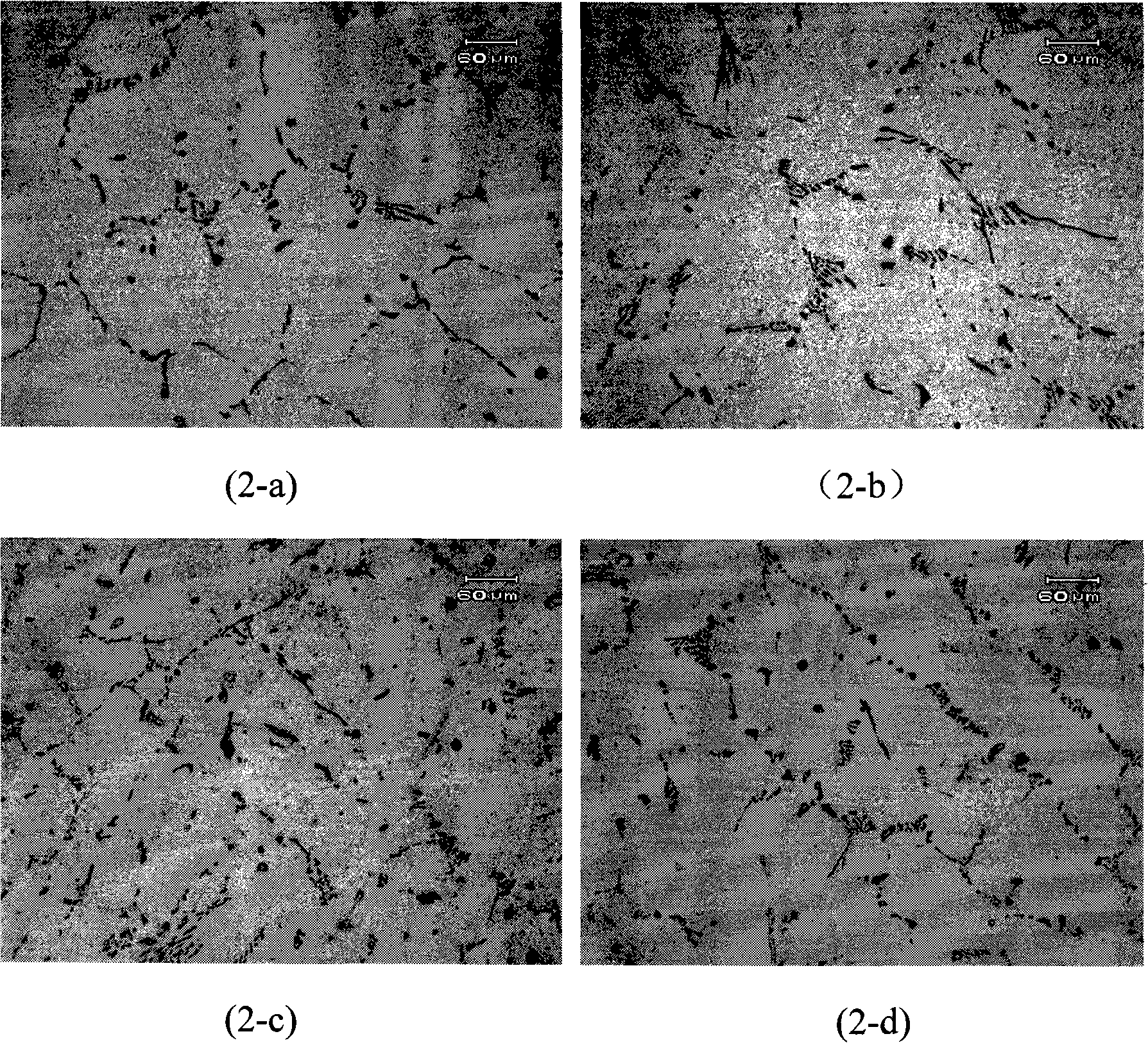

Rare-earth element europium alloying aluminum-silicon alloy and preparation method thereof

The invention relates to a rare-earth element europium alloying aluminum-silicon alloy and a preparation method thereof. The alloy comprises the following components in percentage by weight: 9.0-13.5% of silicon, 0.06-0.09% of europium and the balance of aluminum. The preparation method comprises the following steps: heating an aluminum-silicon alloy in a graphite crucible to be molten, adding europium or an aluminum-europium intermediate alloy according to the weight percents of the components at 710-730 DEG C, and keeping the temperature for 10-15 minutes; performing intermittent ultrasonic treatment on the molten alloy under the conditions that the ultrasonic strength is 10-38 w / cm<2>, the total ultrasonic treatment time is 2-5 minutes, the ultrasonic time of each time is 20-30 seconds and the intermittence time is 20-30 seconds; and cooling the molten alloy to 680-700 DEG C, keeping the temperature for 10-180 minutes, and solidifying at a cooling rate of 40-60 DEG C / min. According to the invention, the refinement and nodularization of an alpha-Al phase can be obviously accelerated; acicular eutectic silicon is changed into punctate or stick-like silicon, and the distribution is more disperse and uniform, thus ensuring that the microscopic structure and mechanical property of the aluminum alloy are obviously improved; and the process is simple, safe, reliable and convenient to operate, and has no pollution caused by three wastes.

Owner:优标易站(苏州)电子商务有限公司

Low-ally CADI wear-resisting material and preparing method thereof

ActiveCN109852875AA large amountHigh hardnessProcess efficiency improvementChemical compositionSulfur

The invention discloses a low-ally CADI wear-resisting material and a preparing method thereof. A chemical component formula, a spheroidizing method and an inoculation process are adopted, good spheroidal graphite and carbide quantity can be obtained in the low-ally CADI material, hardness and impact toughness after casting heat treatment can be improved, the excellent wear-resisting part can be produced, through increasing of the carbon equivalent of the molten iron, the graphite expansion effect in solidification can be improved, the shrinkage tendency of the part can be reduced, and the problem that agricultural implement castings commonly have the poor compactness can be solved; the low sulfur phosphorus content exists, the mechanical property and the impact property of the material and the wear-resisting part can be improved, the stack molding process is adopted, the casting cost of the low-ally CADI material and the wear-resisting part is further reduced, the content of sulfur and phosphorus in the molten iron can be reduced, the spheroidizing process is optimized, the impact toughness of the casting can be improved, the isothermal quenching heat treatment process parametersare adopted, and the whole wear-resisting part with the proper hardness and impact toughness can be obtained.

Owner:FIRST TRACTOR

Composite alterant for nickel aluminum molybdenum-silicon iron alloy loaded nano-aluminum-silicon oxide ball milling cast iron and preparation method thereof

The invention relates to an alterant for ball milling cast iron, in particular to the composite alterant for the nickel aluminum molybdenum-silicon iron alloy loaded nano-aluminum-silicon oxide ball milling cast iron and a preparation method thereof. The alterant is prepared from the following raw materials, by weight, of 2-3 parts of nano-alumina, 1-2 parts of potassium fluoborate, 2-3 parts of nickel powder, 1-2 parts of aluminum powder, 1-2 parts of molybdenum powder, 0.2-0.4 part of oxidized graphene, 1-2 parts of nano silica, 3-5 parts of expanded graphite powder, 1-2 parts of monazite micro powder, 4-5 parts of ferrosilicon powder with the silicon content being 45%, 0.3-0.4 part of magnesium aluminosilicate, 20-25 parts of ethanol aqueous solutions with the concentration being 5%-10% and 0.4-0.5 part of an addition agent. Nano composite powder bodies and a nickel aluminum molybdenum-silicon iron alloy which are loaded by expanded graphite powder are bonded and loaded mutually to prepare the composite alterant with stable performance. The alterant is stable in high temperature, the nucleating effect is good, and graphite spheroidization is stable and durable. According to the alterant, the graphitizing process is facilitated, the structural organization is improved, strength and abrasion resisting are further improved, and compared with a traditional alterant, using is more convenient and faster, and the additional production cost is reduced.

Owner:徐世云

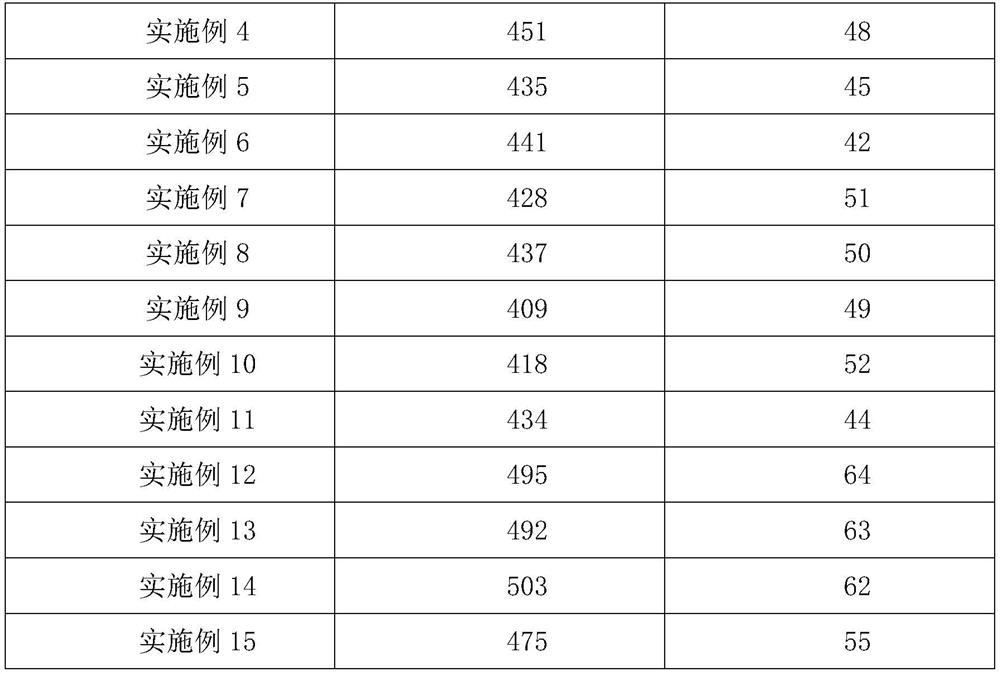

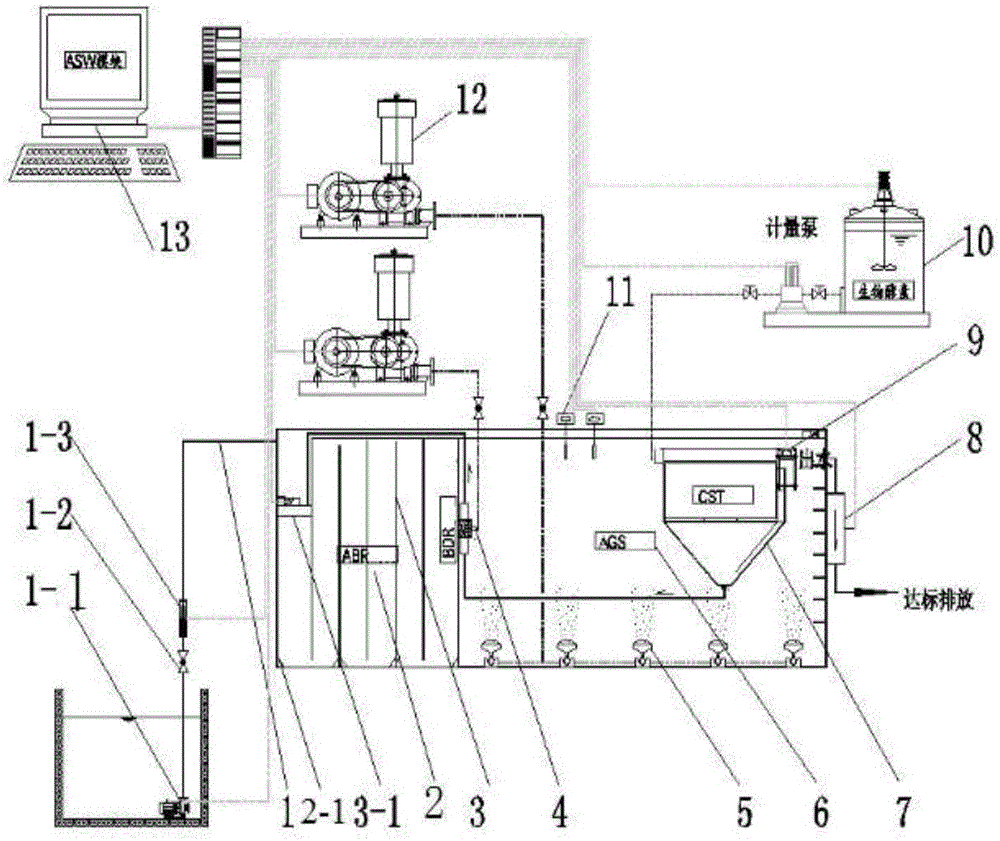

Distributed and structured town sewage pelletization treatment process and pelletization reactor

InactiveCN106007178APurify waterMaintain ultra-high bioconcentrationWater/sewage treatment by irradiationWater/sewage treatment with mechanical oscillationsWater qualityPotassium

The invention discloses a distributed and structured town sewage treatment pelletization reactor which comprises a reactor body, a BDR gas stripping backflow device, a titanium alloy aerator, an ultraviolet disinfection device, an ultrasonic solid-liquid separation device, an ORP oxidoreduction potentiostat, a biological enzyme adding device, an oilless silent air compressor and the like. The reactor body forms an anaerobic granular sludge-aerobic granular sludge-biological enzyme ternary coupling recycling water purification pelletization treatment process. The pelletization reactor is a biological compositing tank, and after anaerobic-aerobic-biological enzyme ternary coupling composting, discharged sludge contains rich enzymes, nitrogen, phosphorus, potassium and other nutrients and can be directly used as high-quality green organic fertilizer. Large-proportion BDR gas stripping backflow is adopted, the very small organic matter concentration gradient in the pelletization reactor is guaranteed, the unevenness of inflow water is eliminated, the problems about town sewage quality and water yield load impacts are solved, and the investment cost per ton of water is greatly reduced. The invention further discloses the distributed and structured town sewage pelletization treatment process.

Owner:阿斯旺(北京)环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com