Preparation method of near spherical molybdenum powder

A near-spherical, molybdenum powder technology is applied in the field of preparation of near-spherical molybdenum powder. , the effect of low raw material requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

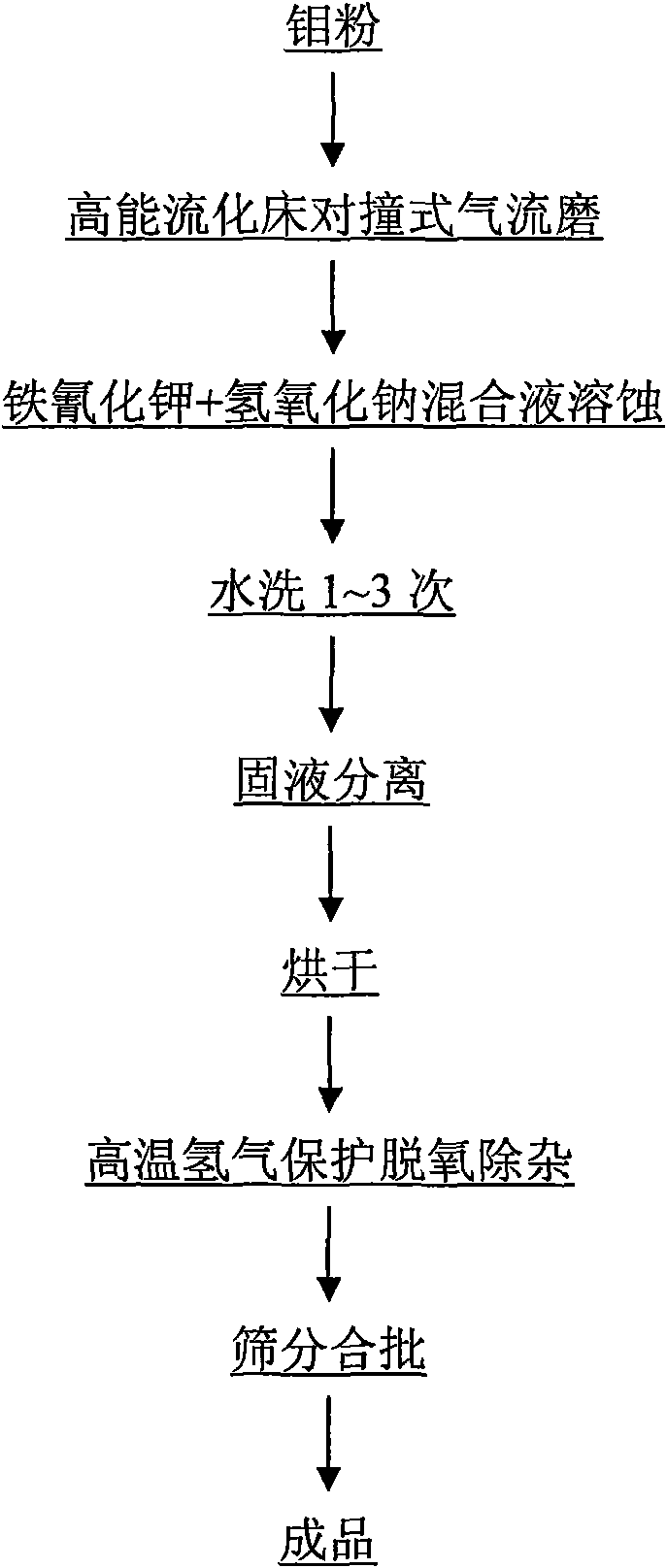

[0013] A kind of preparation method of nearly spherical molybdenum powder, the operation step of its preparation comprises:

[0014] (1) adopt molybdenum powder as raw material, and molybdenum powder is commercially available common molybdenum powder;

[0015] (2) The raw material molybdenum powder is processed with a high-energy fluidized bed colliding jet mill, and a QLM-100K miniature high-energy fluidized bed colliding jet mill is selected, with a rotating speed of 15000 rpm and a treatment time of 2 hours to obtain single particle molybdenum powder;

[0016] (3) Dissolve single-particle molybdenum powder in 10% potassium ferricyanide aqueous solution and 10% sodium hydroxide aqueous solution, or in a mixed solution composed of 40% hydrofluoric acid, 60% nitric acid and distilled water in a ratio of 1:2:4 spheroidizing the single-particle molybdenum powder with a solid-to-liquid ratio of 1:2 to 5; after filtering, the above-mentioned single-particle spheroidized molybdenum...

Embodiment 1

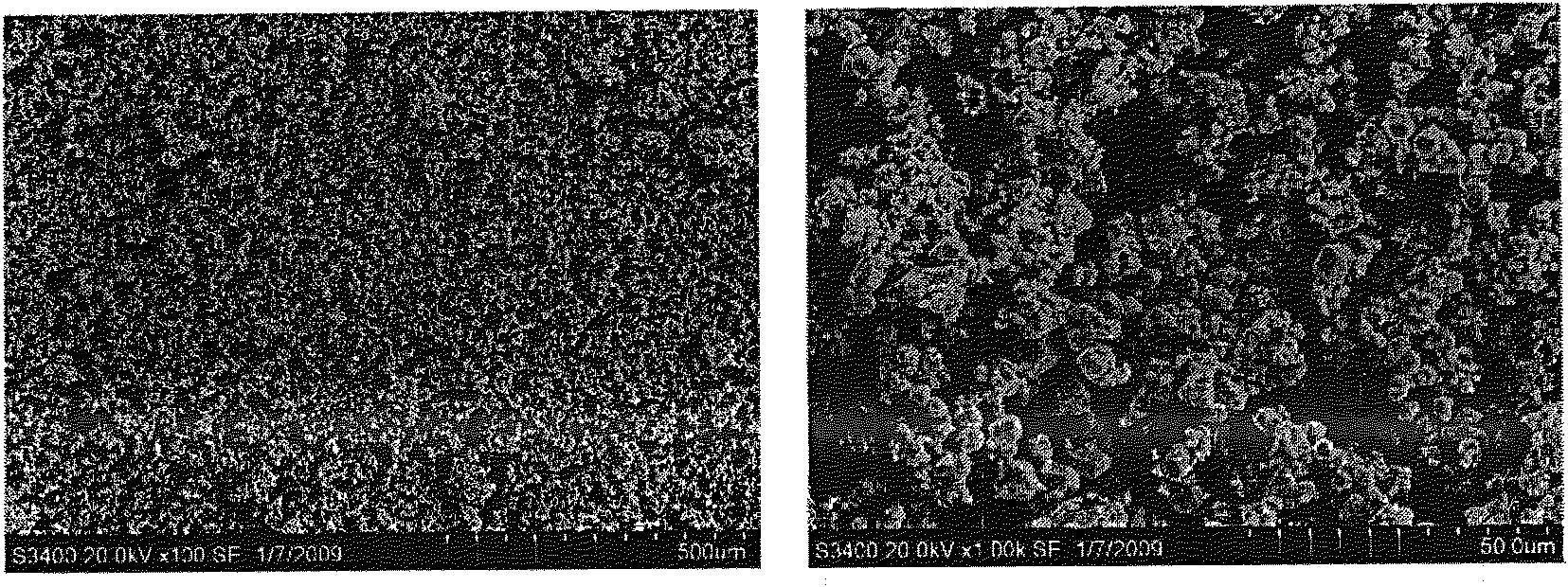

[0021] Take 50kg of ordinary molybdenum powder, the particle size is 4.30μm, and the bulk density is 1.05g / cm 3 . Using QLM-100K miniature high-energy fluidized bed colliding jet mill with a rotating speed of 15,000 rpm and a processing time of 2 hours, 48.16 kg of molybdenum powder was collected in the crushing area. The particle size is 4.22μm, and the bulk density is 2.74g / cm 3 .

[0022] 48.16 kg of the above-mentioned molybdenum powder was etched in a mixed solution of 10% potassium ferricyanide aqueous solution and 10% sodium hydroxide aqueous solution, the solid-liquid ratio was 1:3, time was 1 hour, room temperature. After the solid-liquid separation, wash with water twice, the solid-liquid ratio is 1:3, the time is 2 hours, and the temperature is 80°C. Dry after solid-liquid separation, time 6h, temperature 150°C. Receive molybdenum powder 46.32kg.

[0023] 46.32kg of the above-mentioned molybdenum powder was deoxidized and impurity removed in a single-tube one-t...

Embodiment 2

[0026] Take 10kg of ordinary molybdenum powder, the particle size is 3.70μm, and the bulk density is 1.01g / cm 3 . Using QLM-100K miniature high-energy fluidized bed colliding jet mill with a rotating speed of 10,000 rpm and a processing time of 3 hours, 9.91 kg of molybdenum powder was collected in the crushing area. The particle size is 3.56μm, and the bulk density is 2.26g / cm 3 .

[0027] Dissolve 9.91kg of the above molybdenum powder in a mixture of 40% hydrofluoric acid, 60% nitric acid and distilled water at a ratio of 1:2:4, solid-liquid ratio 1:4, time 1h, room temperature. After the solid-liquid separation, wash with water three times, the solid-liquid ratio is 1:3, the time is 2 hours, and the temperature is 80°C. Dry after solid-liquid separation, time 6h, temperature 150°C. Receive molybdenum powder 9.07kg.

[0028] 9.07kg of the above molybdenum powder was deoxidized and impurity removed in a single-tube one-temperature zone muffle furnace at a temperature of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com