Production method of tungsten carbide base ball shaped thermal spray coating powder

A technology of thermal spraying powder and production method, which is applied in the production field of tungsten carbide-based cemented carbide spherical thermal spraying powder, which can solve problems such as easy cake formation, burning loss, and large equipment investment, and achieve regular powder shape and wear resistance The effect of improved performance and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

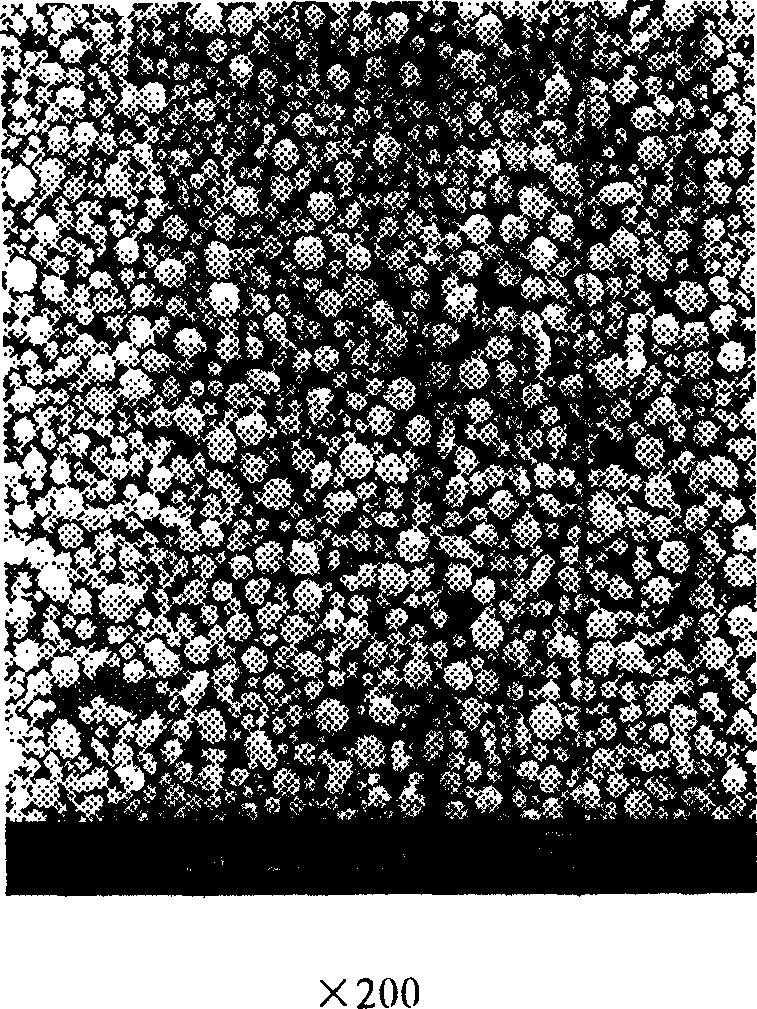

Image

Examples

Embodiment 1

[0015] The present embodiment is a production method of spherical thermal spray powder with WC as a base material and Co as a binding phase, and its method is:

[0016] A. Wet grinding to prepare slurry: 252kg of WC powder and 48kg of Co powder that meet the requirements of the national standard for industrial production are placed in the ball mill, and 67kg of hexane with a purity of 99% (industrial purity) is added simultaneously, and wet for 30 hours to powder The Fisher particle size is 1.0 ~ 3.0μm, then add 4kg of paraffin and then wet grinding for 4 hours to make a slurry;

[0017] B, spray-drying granulation: the prepared slurry is sent into the slurry stirring tank of the closed-loop pressure spray drying device with model HC-3000, and then 33kg of hexane is added to adjust the solid-to-liquid ratio of the slurry to 3 : 1, under stirring conditions, the slurry is sprayed into the drying chamber for drying and granulation; wherein: the diameter of the spray sheet is φ0....

Embodiment 2

[0023] The present embodiment is a production method of spherical thermal spray powder with WC as the base material and Co and Cr as the binding phase, and the method is:

[0024] A. Wet grinding to prepare slurry: put 258.45kg of WC powder, 30.15kg of Co powder, and 11.4kg of Cr powder that meet the requirements of the national standard for industrial production into the ball mill, add 67kg of industrially pure hexane at the same time, and wet-mill for 31 hours until the powder is Feiji grains reach 1.0-3.0μm, then add 6kg of paraffin and then wet-grind for 4.5 hours to prepare a slurry;

[0025] B, spray drying granulation: the prepared slurry is sent into the slurry stirring tank of the closed-loop pressure spray drying device, then 33 kg of hexane is added to adjust its solid-liquid ratio to 3:1, and under stirring conditions, the The slurry is sprayed into the drying chamber for drying and granulation; the diameter of the spray sheet is φ0.8mm, the spray pressure is 1.3Mp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fisherman's particle size | aaaaa | aaaaa |

| Fisherman's particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com