Medium strength aluminium alloy wire with conductivity of 55% IACS, and preparation method thereof

A technology of aluminum alloy wire and conductivity, which is applied in the direction of metal/alloy conductor, cable/conductor manufacturing, circuit, etc., to achieve the effect of improving strength, saving construction cost and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

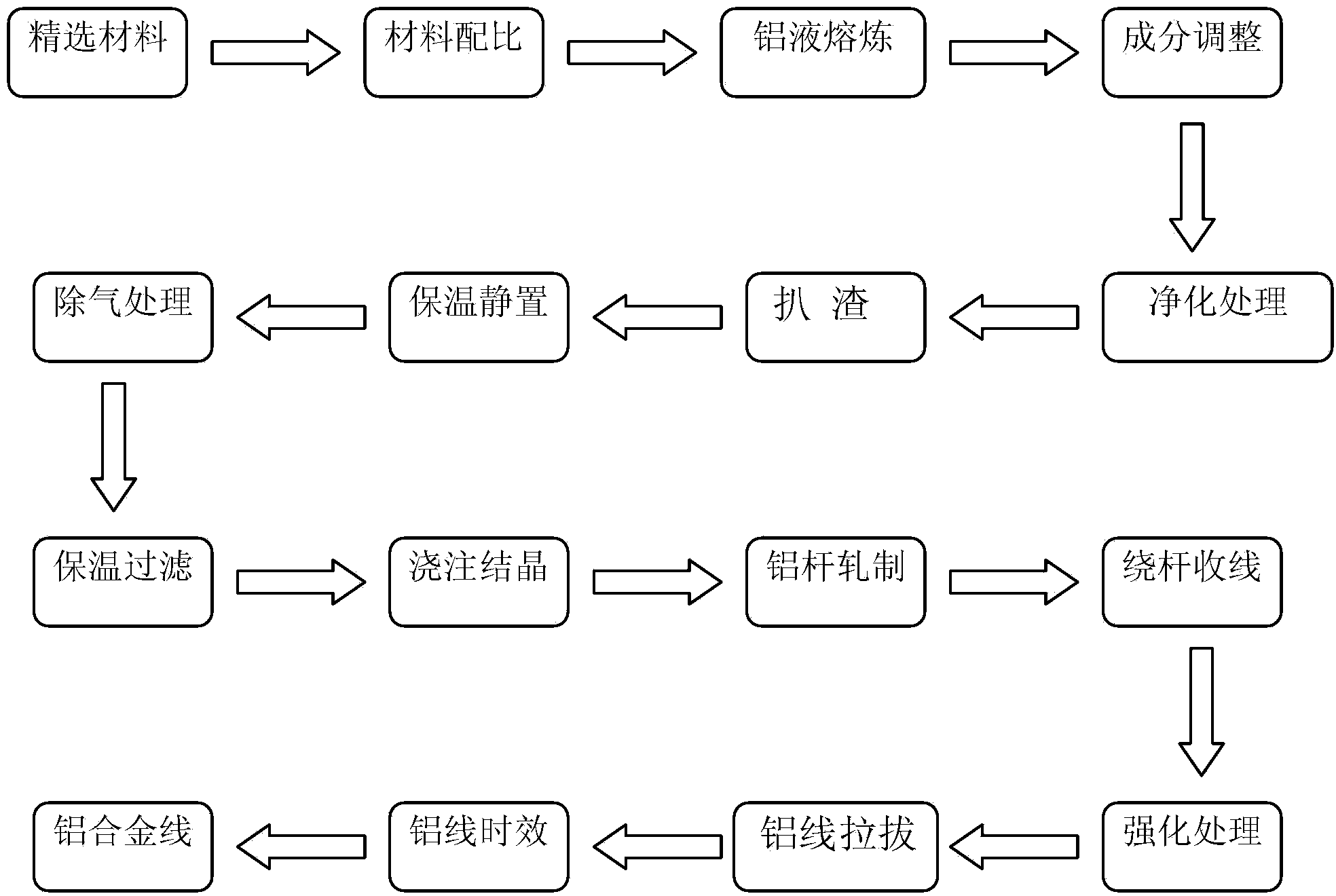

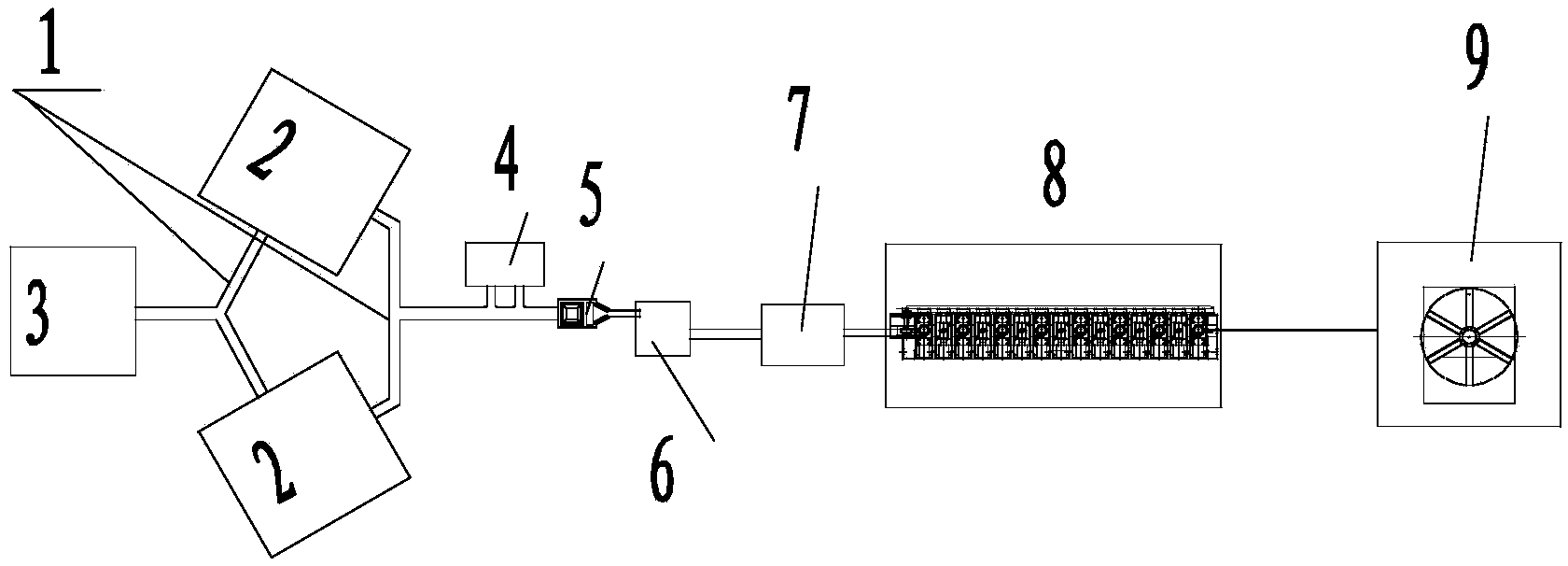

Method used

Image

Examples

Embodiment 1

[0049] A high-strength aluminum alloy wire with an electrical conductivity of 55% IACS, the proportion of which is as follows by weight percentage: iron 0.16%-0.22%, silicon 0.48%-0.54%, magnesium 0.62%-0.67%, boron 0.01%-0.02% , Ytterbium 0.02%-0.05%, the rest is aluminum.

[0050] The preparation method of the high-strength aluminum alloy wire with the conductivity of 55%IACS, the steps are as follows:

[0051] (1) Material selection: by weight percentage:

[0052] a. Selection of aluminum ingot: choose 8 tons of aluminum ingot with grade Al99.70, Si 0.08%; Fe 0.15%; Cu 0.002%; Ti+Mn+Cr+V 0.015%; other impurities ≤0.03%; aluminum;

[0053] b. Aluminum-iron master alloy: aluminum-iron master alloy 52kg, Fe 5%; Si 0.16%; Cu 0.008%; Ti+Mn+Cr+V≤0.03%; other impurities ≤0.03%; the rest are aluminum;

[0054] c. Aluminum-silicon master alloy: 335kg of aluminum-silicon master alloy, Si 10%; Fe 0.18%; Cu 0.004%; Ti+Mn+Cr+V≤0.052%; other impurities ≤0.03%; the rest are aluminum; ...

Embodiment 2

[0079] A high-strength aluminum alloy wire with a conductivity of 55% IACS, the proportion of which is as follows by weight percentage: iron 0.16%-0.22%, silicon 0.48%-0.54%, magnesium 0.62%-0.67%, boron 0.01%-0.02% , Ytterbium 0.02%-0.05%, the rest is aluminum.

[0080] The preparation method of the high-strength aluminum alloy wire with the conductivity of 55%IACS, the steps are as follows:

[0081] (1) Material selection: by weight percentage:

[0082] a. Selection of aluminum ingots: Select 7.5 tons of aluminum ingots with the grade Al99.60 to ensure that in the molten aluminum melted from aluminum ingots: Si 0.12%; Fe 0.19%; Cu 0.009%; Ti+Mn+Cr+V 0.02 %; other impurity content ≤ 0.03%; the rest are aluminum;

[0083] b. Aluminum-iron master alloy: 10kg of aluminum-iron master alloy, Fe 5%; Si 0.18%; Cu 0.008%; Ti+Mn+Cr+V≤0.03%; other impurities ≤0.03%; the rest are aluminum;

[0084] c. Aluminum-silicon master alloy: 305kg of aluminum-silicon master alloy, Si 10%; Fe 0...

Embodiment 3

[0109] A high-strength aluminum alloy wire with an electrical conductivity of 55% IACS, the formula ratio is as follows by weight percentage: 0.2% iron, 0.51% silicon, 0.66% magnesium, 0.015% boron, 0.04% ytterbium, and the rest is aluminum.

[0110] The preparation method of the high-strength aluminum alloy wire with the conductivity of 55%IACS, the steps are as follows:

[0111] (1) Material selection: by weight percentage:

[0112] a. Selection of aluminum ingots: ensure that Si≤0.16%; Fe≤0.20%; Cu≤0.01%; Ti+Mn+Cr+V≤0.02%; other impurity content≤0.03% in molten aluminum melted from aluminum ingots ; The rest are aluminum;

[0113] b. Aluminum-iron master alloy: Fe 5%; Si≤0.2%; Cu≤0.1%; Ti+Mn+Cr+V≤0.1%; other impurities ≤0.03%; the rest are aluminum;

[0114] c. Aluminum-silicon master alloy: Si 10%; Fe≤0.2%; Cu≤0.1%; Ti+Mn+Cr+V≤0.1%; other impurities ≤0.03%; the rest are aluminum;

[0115] d. Aluminum boron master alloy: B 3%; Si ≤ 0.2%; Fe ≤ 0.4%; Cu ≤ 0.01%; other impu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com