Novel process for preparing spherical calcium chloride with spray of rotary kiln

A calcium chloride, rotary kiln technology, applied in the direction of calcium/strontium/barium chloride, calcium/strontium/barium halide, etc., can solve the problems of waste of resources, pollution, flash evaporation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0025] Example 1 produces 74% dihydrate spherical calcium chloride

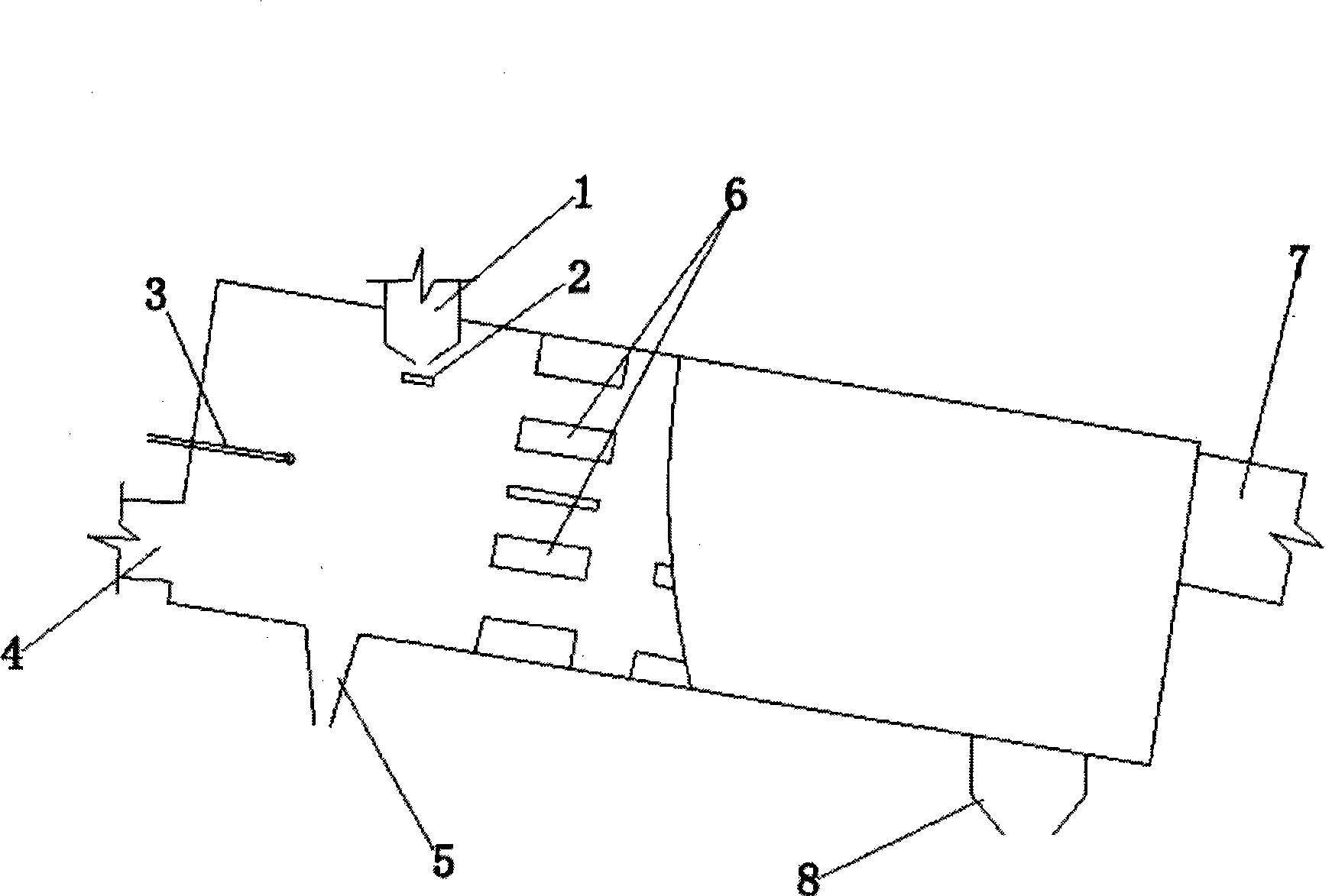

[0026] Rotary kiln spray pelletizing key equipment such as figure 1 As shown, the feeding bin 1 at the head of the rotary kiln stores the returned material crystal seeds, and distributes the crystal seeds evenly into the kiln through the distribution plate 2 in front of the nozzle, and at the same time, the atomizing nozzle 3 sprays the concentrated calcium chloride solution to the crystal seed material curtain , the too fine seed crystals are brought into the cyclone separator from the outlet 4 by the induced wind, and the seed crystal dust that is not taken away by the induced wind is discharged from the discharge port 5 of the kiln head. Under the action of the material guide plate and the copy plate 6, Make the crystal seeds continuously adhere to the calcium chloride slurry and roll forward, and the spherical calcium chloride product obtained by drying the high-temperature air entering through the tuyere...

example 2

[0029] Example 2 Production of 95% Anhydrous Spherical Calcium Chloride

[0030] The pelletizing equipment and process flow are the same as in Example 1, and the control process parameters are: nozzle hydraulic pressure 0.4Mpa, air pressure 0.3Mpa, calcium chloride concentrated liquid temperature 150-160°C, return seed crystal 3.5-4.0t / h, particle size less than 1mm, Nozzle flow 8m 3 / h, adjust the high-temperature air intake and induced air volume, so that the intake temperature is between 400-420°C, the temperature of the rotary kiln head is 210-225°C, the rotary kiln speed is 8 rpm, and the pellets are sieved and cooled. Packaged as anhydrous calcium chloride product.

[0031] After testing, the calcium chloride content of the product is 95.2%, and the proportion of the ball diameter φ2.0-4.0mm is greater than 91%.

example 3

[0032] Example 3 is used for comparison. When the temperature of the calcium chloride concentrate is 130-135°C, the hydraulic pressure of the nozzle is 0.6Mpa, the air pressure is 0.45Mpa, the return material seed crystal is 5.5-6.0t / h, the seed crystal particle size is 0.5-2.0mm, and the nozzle flow rate is 11m 3 / h, adjust the high-temperature air intake and induced air volume, so that the intake temperature is 440-450°C, the hot air temperature at the kiln head is 220-240°C, and when the rotary kiln speed is 4 rpm, the content of spherical products can reach about 95%, but the spheroidization is not ideal, and the ratio of diameter φ2.0~5.0mm is about 75%.

[0033] When the temperature of the calcium chloride concentrate is 150-160°C, the hydraulic pressure of the nozzle is 0.4Mpa, the air pressure is 0.3Mpa, the return seed crystal is 3.5-4.0t / h, the particle size is less than 1mm, and the flow rate of the nozzle is 8m 3 / h, adjust the high-temperature air intake and indu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com