Preparation method of large-tonnage nodular cast iron casting

A technology of nodular cast iron and large tonnage, which is applied in the casting field of iron castings. It can solve the problems of insufficient pearlite content in thick wall parts, excessive carburization volume in thin wall parts, and unbalanced graphite quantity, so as to achieve the effect of promoting spheroidization, The effect of not deforming the mechanical properties and improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

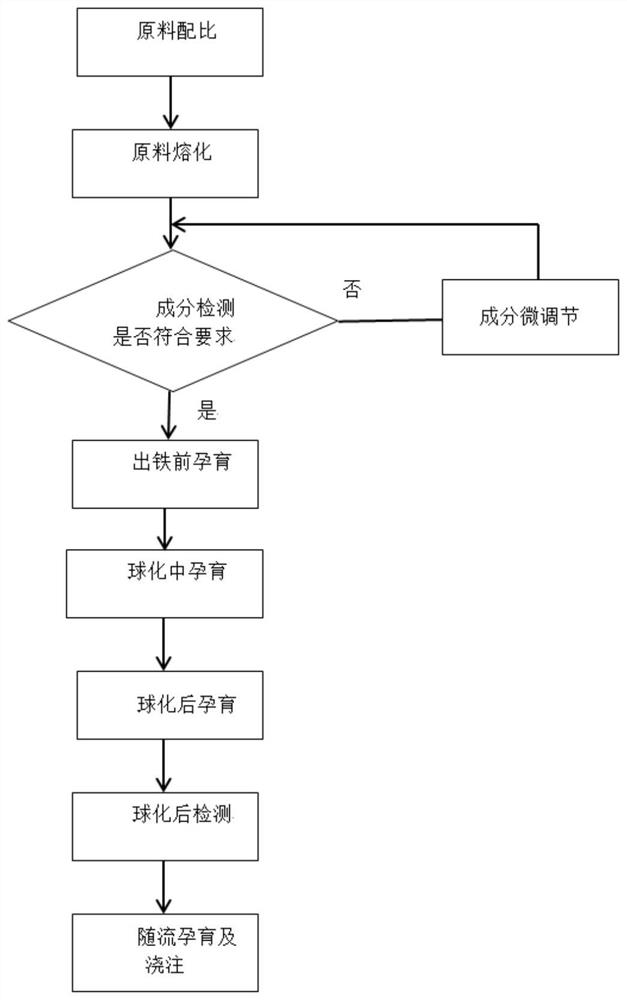

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of the large-tonnage ductile iron casting in this embodiment includes the following steps: the first step, the ratio of raw materials: the raw materials are selected from 45% to 60% of Q10 pig iron, 55% to 40% of high-quality scrap steel, and 0.6% to 1.0% of silicon carbide. As well as an appropriate amount of recarburizer and an appropriate amount of ferrosilicon. Among them, high-quality scrap steel can be selected from high-quality carbon scrap.

[0034]The second step, melting of raw materials: before the raw materials are melted, the furnace chamber is kept clean and free of slag, and the raw materials are added to the smelting furnace. After the molten iron is melted, the temperature is raised to 1380 ° C ~ 1420 ° C for slag removal and sampling. After the slag removal and sampling, silicon carbide is added, and then the Add recarburizer in batches; adjust the composition in the molten iron to meet the requirements, and then heat up to 1500 ...

Embodiment 2

[0058] In order to prolong the dissolution time of the inoculant in the molten iron, increase the reaction time, so that the inoculant effect can be fully exerted in the molten iron. At the same time, it can also allow the molten iron to fully exist in the temperature and concentration fluctuation areas, which can promote the spheroidization effect of the molten iron, reduce the impact of the inoculant on the molten iron, and ensure the inoculation effect. The inoculant block is obtained by directly purchasing the compacted inoculant in the market, or by compacting or vibrating the purchased small particle or powder inoculant by the foundry, and the compacted or tapped inoculant becomes a block. , and finally encapsulated and obtained the inoculant block that is put into actual production. The tap density of the inoculant block after compaction is higher than that of the small particle inoculant in the conventional loose state. By compressing and compacting the inoculant bloc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com