Preparation method for nodular cast iron

A ductile iron and spherical technology, applied in the field of ductile iron preparation, can solve the problems of large one-time investment in production equipment, difficult casting, and high energy consumption, and achieve the effects of reducing flash and smoke, reducing production costs, and having a reasonable ratio of elements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

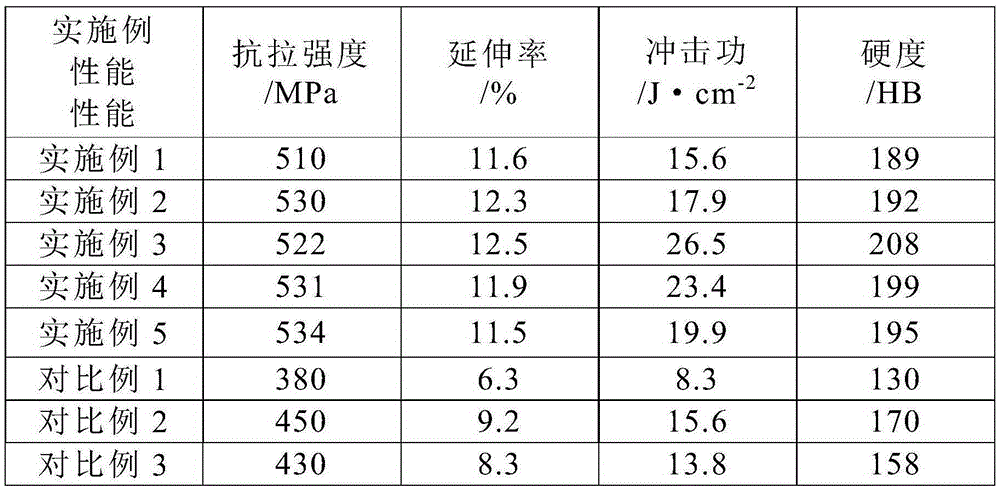

Examples

Embodiment 1

[0032] Add coke, limestone, pig iron, returned steel and scrap steel with a mass ratio of 100:30:58:26:10 into the smelting furnace and smelt it into molten iron;

[0033] Use pulverizer and ball mill to pulverize and refine the spheroidizing agent into ultra-fine powder with a particle size of 1-25 μm, and wrap it with cold-rolled low-carbon steel plate to make the first spheroidizing agent and the second spheroidizing agent with a diameter of 5-15 mm. Spheroidizing agent, and then put the first layer of inoculant accounting for 0.1% of the molten iron mass on the bottom side of the spheroidizing bag with a capacity of 1t of molten iron, and place a layer of 0.9% of the molten iron mass on the first layer of inoculant The first spheroidizing agent, on the first spheroidizing agent, cover a layer of pig iron sheet I with a thickness of 9mm, and cover the second layer of inoculant accounting for 0.3% of the molten iron mass on the pig iron sheet I, and then in the second inocula...

Embodiment 2

[0038] Add coke, limestone, pig iron, returned steel and scrap steel with a mass ratio of 100:30:59:27:11 into the smelting furnace and smelt it into molten iron;

[0039] Use pulverizer and ball mill to pulverize and refine the spheroidizing agent into ultra-fine powder with a particle size of 3-20 μm, and wrap it with cold-rolled low-carbon steel plate to make the first spheroidizing agent and the second spheroidizing agent with a diameter of 5-13mm. Spheroidizing agent, and then put the first layer of inoculant accounting for 0.15% of the mass of molten iron on the bottom side of the nodularizing bag with a capacity of 1t of molten iron, and place a layer of 1.0% of the mass of molten iron on the first layer of inoculant The first spheroidizing agent, on the first spheroidizing agent, cover a layer of pig iron sheet I with a thickness of 10mm, and cover the second layer of inoculant accounting for 0.35% of the molten iron mass on the pig iron sheet I, and then in the second ...

Embodiment 3

[0044] Add coke, limestone, pig iron, returned steel and scrap steel with a mass ratio of 100:30:60:28:12 into the smelting furnace and smelt it into molten iron;

[0045] Use a pulverizer and a ball mill to crush and refine the spheroidizing agent into an ultrafine powder with a particle size of 5-15 μm, and wrap it with a cold-rolled low-carbon steel plate to make the first spheroidizing agent and the second spheroidizing agent with a diameter of 6-11 mm. Spheroidizing agent, and then put a first layer of inoculant accounting for 0.2% of the molten iron mass on the bottom side of the nodularizing bag with a capacity of 1t of molten iron, and place a layer of 1.1% of the molten iron mass on the first layer of inoculant The first spheroidizing agent, on the first spheroidizing agent, cover a layer of pig iron sheet I with a thickness of 11mm, and cover the second layer of inoculant accounting for 0.4% of the molten iron mass on the pig iron sheet I, and then in the second inocu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com