Low-fish-meal compound feed for micropterus salmoides and preparation method of low-fish-meal compound feed

A compound feed and low-fishmeal technology, applied in animal feed, animal feed, additional food elements, etc., can solve the problems of strong dependence on fishmeal, high cost of breeding California sea bass, and reduce starch content, so as to overcome amino acid imbalance and improve growth Performance and immune function of the body, the effect of reducing starch content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

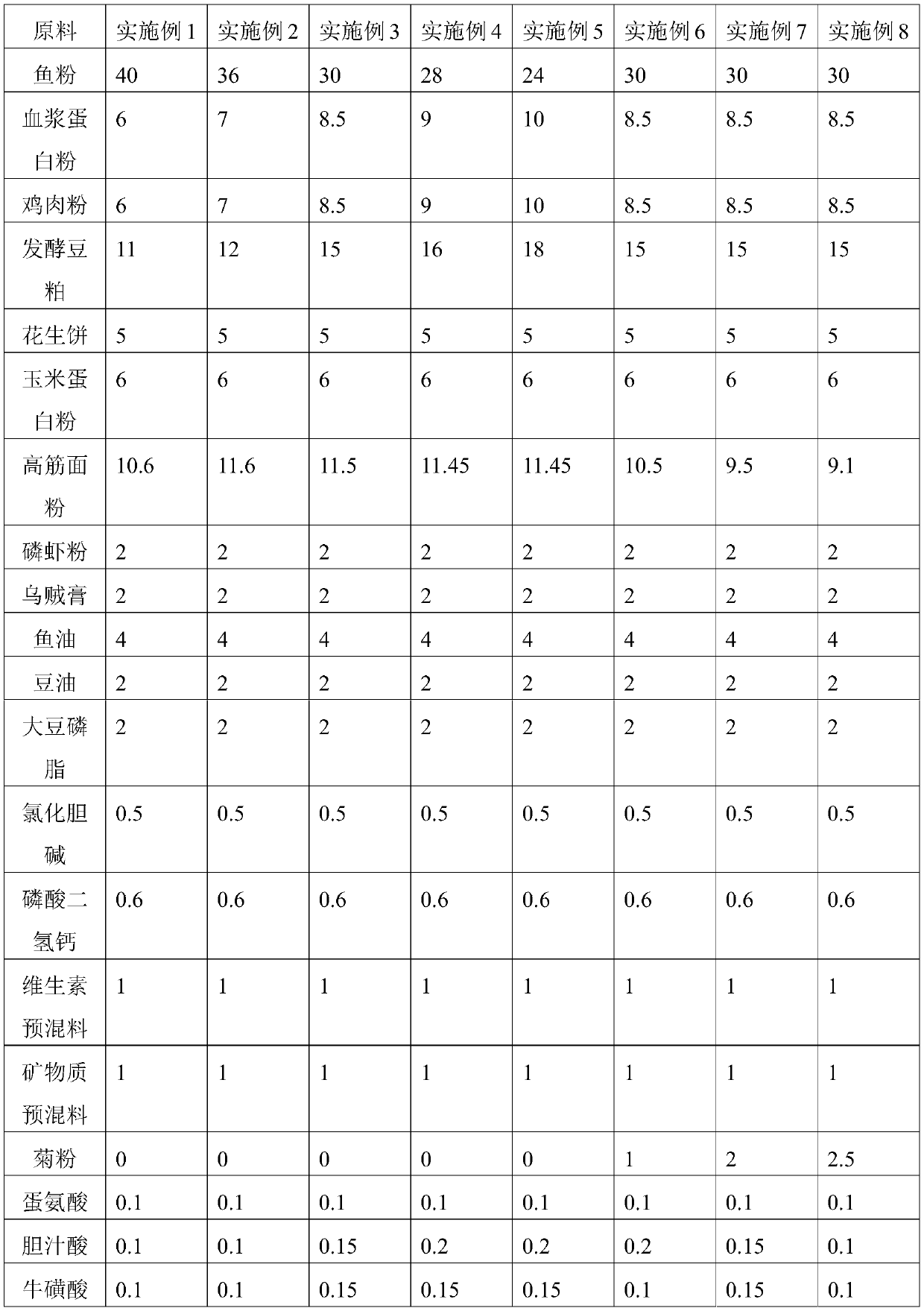

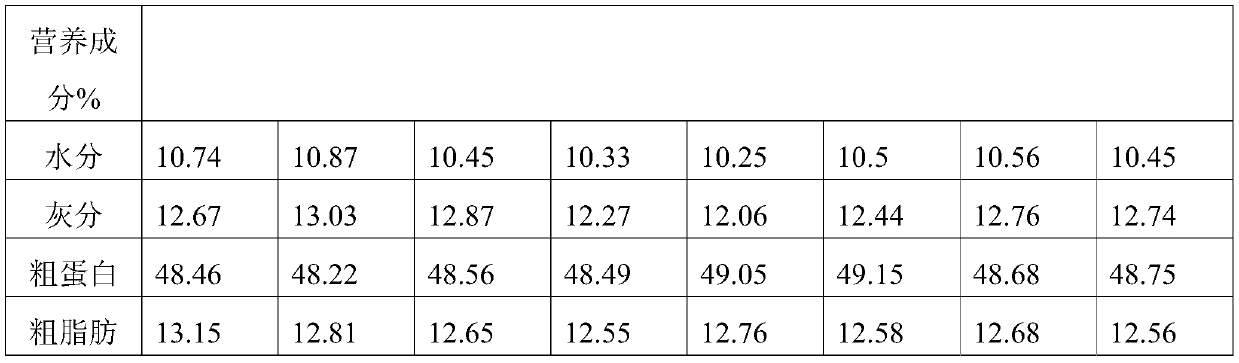

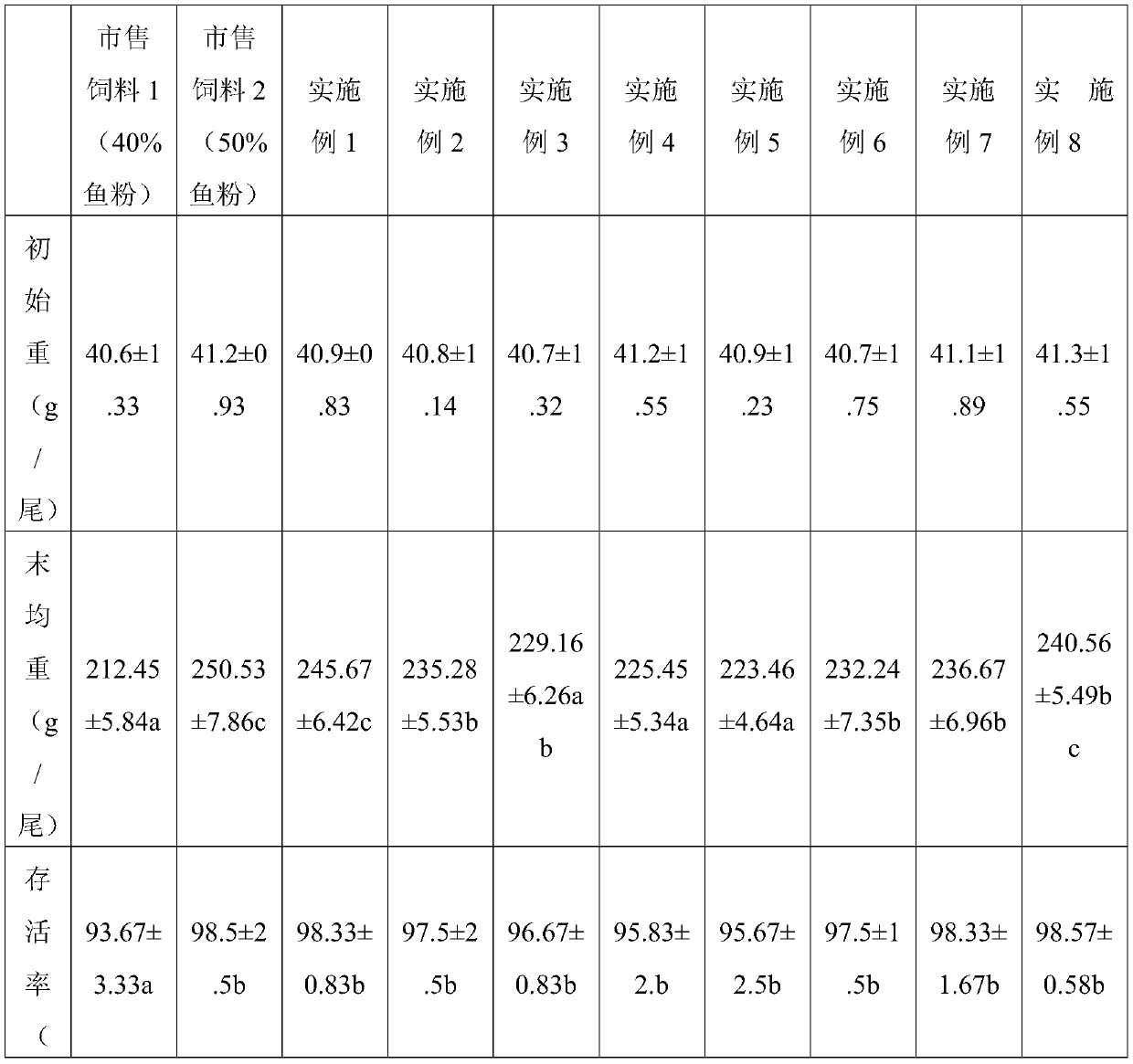

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further elaborated below in conjunction with specific examples, which are only used to explain the present invention, and are not intended to limit the scope of the present invention. The test methods used in the following examples are conventional methods unless otherwise specified; the materials and reagents used are commercially available reagents and materials unless otherwise specified.

[0033] Weight gain rate described in each embodiment, specific growth rate, survival rate and feed factor are calculated by the following formula:

[0034] Weight gain rate WG(%)=(final weight-initial weight)×100 / initial weight

[0035] Specific growth rate SGR(%d-1)=100×(ln final weight-ln initial weight) / feeding days

[0036] Survival rate SR (%) = (the number of remaining fish tails at the end of the experiment / the number of fish tails at the beginning of the experiment) × 100

[0037] Feed coefficient (FCR) = Feed feeding amount / (final weight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com