Processing method of pure mulberry freeze dried powder

A processing method and technology of freeze-dried powder, applied in the processing field of simple mulberry freeze-dried powder, can solve the problem that mulberry pulp cannot be made into freeze-dried powder, and achieve the effect of improving wet stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Determination of sugar content

[0037] Determination of reducing sugars (including glucose, fructose, maltose)

[0038] GB / T 5009.7-2003

[0039] 1. Measuring principle:

[0040] After removing the protein from the sample, directly titrate the calibrated Fehling's solution under heating conditions. After the Fehling's solution is reduced to precipitate cuprous oxide, the excess reducing sugar will immediately reduce the methylene blue and make the blue color fade. . Calculate the amount of reducing sugar based on the consumed volume of the sample.

[0041] 2. Reagents

[0042] Unless otherwise specified, the experimental water was distilled water, and the reagents were of analytical grade.

[0043] (1) Ferrin A solution: Weigh 15g of copper sulfate (CuSO4·5H2O), and 0.05g of methylene blue, dissolve in water and dilute to 1L.

[0044] (2) Feilin B solution: Weigh 50g potassium sodium tartrate and 75g sodium hydroxide, dissolve in water, then add 4g potas...

Embodiment 2

[0087] Processing of mulberry freeze-dried powder

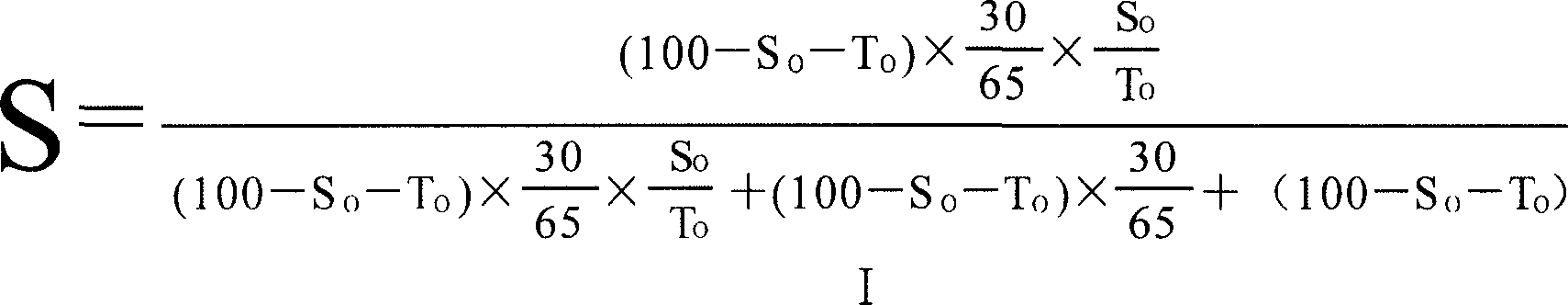

[0088] The mulberries used in this embodiment, whose ripening period coincides with continuous rainy days, are washed with clear water after bubbling, then sprayed, air-dried at room temperature, and then entered into a beater to make a pulp, and continue to stir for 5 minutes. Detect the obtained fruit pulp, its water content is 90%, and the sugar content is 7%. Put the pulp into a quick-freezing tray, control the thickness of the pulp to 4 cm, and freeze it to -20°C to make it completely solidified. Take out the quick-frozen plate, thaw at room temperature (30°C), filter off the leached water, and check that the moisture content of the remaining pulp is 80%, which is in line with S0 / (6S 0 +19T 0 ) formula requirements, dehydration and desugaring are completed. It is air-dried at a low temperature of -20°C until the water content is 5%, and crushed by ultrasonic waves, so that the particle size is less than 10 microns, a...

Embodiment 3

[0090] Processing of control group mulberry freeze-dried powder

[0091] After the mulberry fruit is picked, it is rinsed by bubbling with clean water, then sprayed, air-dried at room temperature, and then put into a beater to make a pulp, and continue to stir for 5 minutes. Without testing, it is air-dried at -20°C to a moisture content of 5%, and crushed by ultrasonic waves until the particle size is less than 10 microns, then the processing is complete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com