Method for treating clinker dust by sintering process

A treatment method, sintering technology, applied in solid waste removal, aluminum oxide/aluminum hydroxide, etc., can solve problems affecting the control of technical indicators, affecting on-site sanitation, and excessive dust accumulation, and achieves significant economic and social benefits , physical health protection, and the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

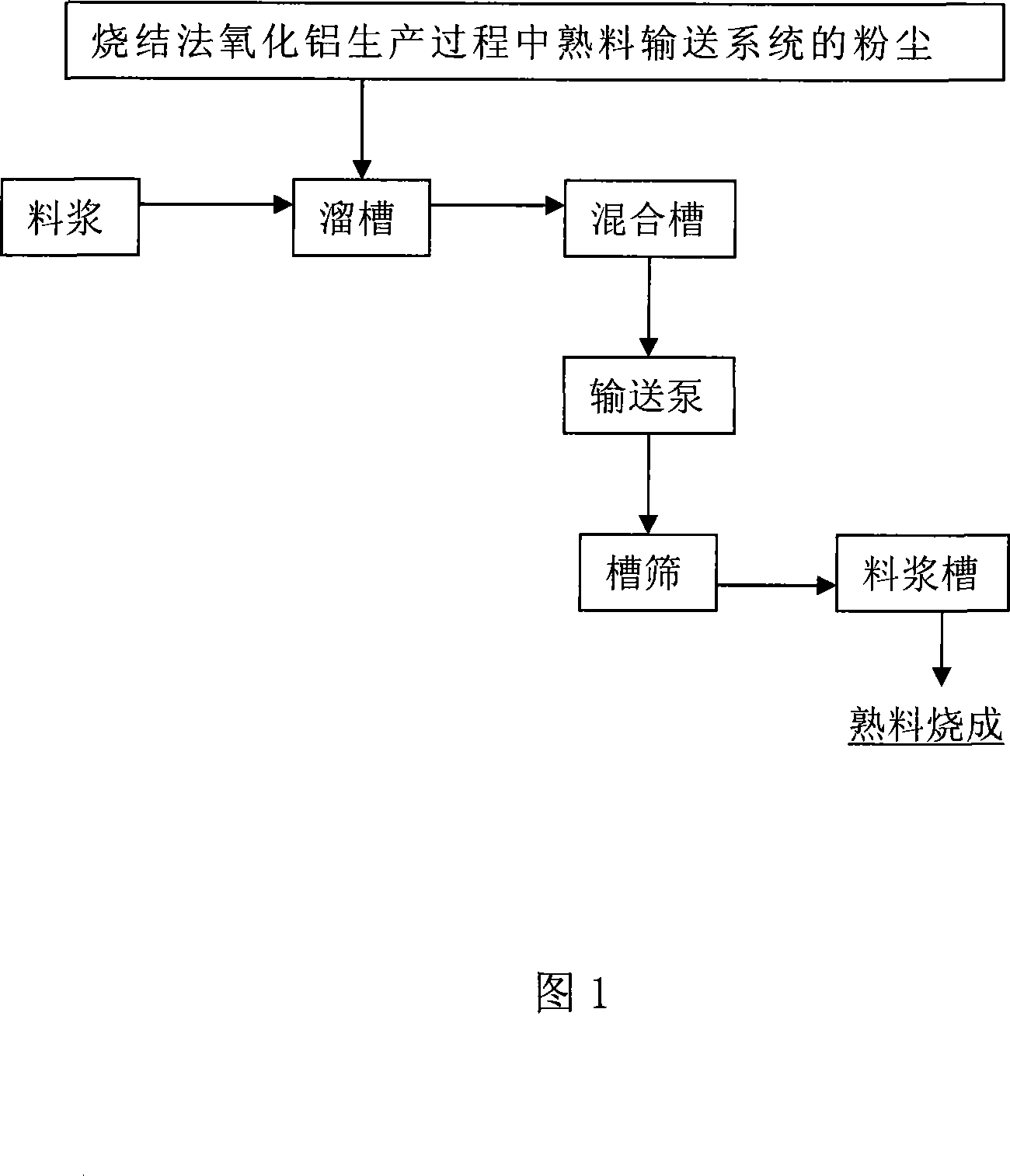

[0015] In the sintered alumina production process, a mixing tank is built under the electric dust collector of the clinker conveying system, and then the raw slurry sent by the batching process is directly introduced into the mixing tank through a pipeline, and the raw slurry and the mixing tank are mixed. The dust is fully stirred and mixed, and then pumped into the slurry tank of the firing process, and sent into the kiln together with the existing raw slurry for sintering into qualified clinker, so as to fully recover the alumina and sodium oxide in it, reaching The purpose of saving energy and reducing consumption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com