Grass tree structural board and production technology thereof

A production process and a technology for structural panels, applied in the field of Hemu structural panels and their production processes, can solve the problems of large fluctuations in product quality, difficult quality assurance, low production efficiency, etc., and achieve great economic benefits and social value, and fiber quality. Guaranteed, improved efficiency and quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

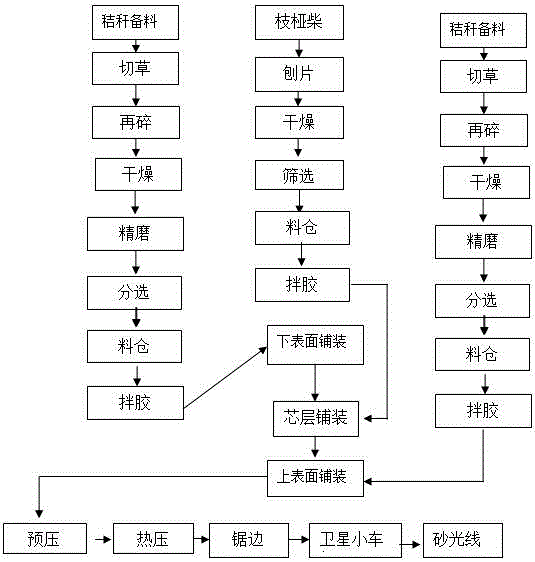

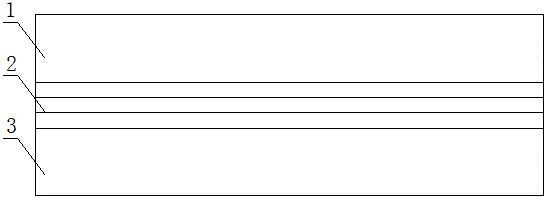

[0031] Such as Figure 1-3 Shown: a kind of Hemu structural board, comprises successively the lower layer fiber skin layer 3, the multi-layer wood oriented strand core board layer 2 in the middle and the upper layer fiber skin layer 1, described lower layer fiber skin layer 3, the middle multi-layer The first layer of wood oriented strand board layer 2 and the upper layer of fiber surface board layer 1 are integrally pressed and formed. Its production process comprises the following steps:

[0032] 1. Any one or more kinds of straw raw materials in wheat straw, rice straw, corn stalk, sorghum stalk, reed stalk, cotton stalk, hemp stalk, sunflower stalk, and bean stalk are cut into 8cm length by cutting machine, and then enter into re-shredding Operation, when adopting multiple crop stalks, its mixing ratio can be any ratio.

[0033] 2. The 8cm straw raw material section is crushed into 1cm strips by the re-crusher and then enters the drying process. By fully cutting and crus...

Embodiment 2

[0047] The difference between the present embodiment and embodiment one is: in the step 1 in its production process, the stalk raw material is truncated to be 12cm long;

[0048] In step 2, the crushed length is 1.5cm;

[0049] The fiber sizing ratio in the step 6 is 80kg / m3;

[0050] In step 7, the water content after drying is 4%, the wood chip sizing ratio is 55kg adhesive / 1m3 wood chips, and the water content after sizing is controlled at 10%;

[0051] In step 8, the thickness of the upper and lower surface layers is 30mm, and the thickness of the core layer is 200mm;

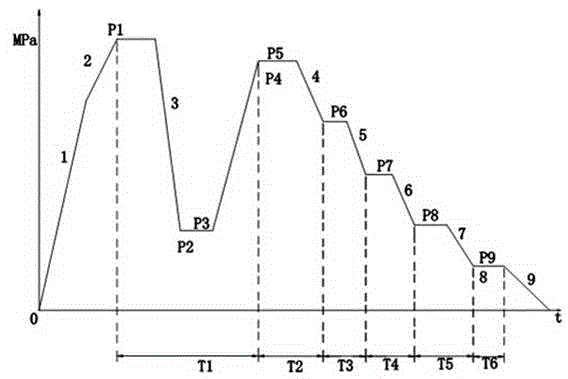

[0052] Step 9 adopts the pressure of 10Mpa to preload;

[0053] In step 10, the temperature of the platen of the press is controlled at 190°C.

[0054] Adopt the production process of the present embodiment to produce the same type of grass structural board and take samples for inspection, and the inspection results are as follows:

[0055] Fiber layer density (g / cm 3 ) Core layer density...

Embodiment 3

[0057] The difference between this embodiment and embodiment one or two is: in the step 1 in its production process, the stalk raw material is truncated to be 20cm long;

[0058] In step 2, the crushed length is 2cm;

[0059] The fiber sizing ratio in the step 6 is 90kg / m3;

[0060] In step 7, the water content after drying is 5%, the wood chip sizing ratio is 60kg adhesive / 1m3 wood chips, and the water content after sizing is controlled at 12%;

[0061] In step 8, the thickness of the upper and lower surface layers is 50mm, and the thickness of the core layer is 300mm;

[0062] Step 9 adopts the pressure of 12Mpa to preload;

[0063] In step 10, the temperature of the platen of the press is controlled at 200°C.

[0064] Adopt the production process of the present embodiment to produce the same type of grass structural board and take samples for inspection, and the inspection results are as follows:

[0065] Fiber layer density (g / cm 3 ) Core layer density (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com