A feeder for ultra-fine or low bulk density powder in an aluminum electrolytic cell and a feeder method thereof

A technology of aluminum electrolytic cell and bulk density, which is applied in the field of metallurgical industry, can solve the problems such as the deterioration of the production workshop environment and the inability to accurately feed alumina particles into the feeding port, and achieve the effects of simple and reliable structure, reduced flying loss, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

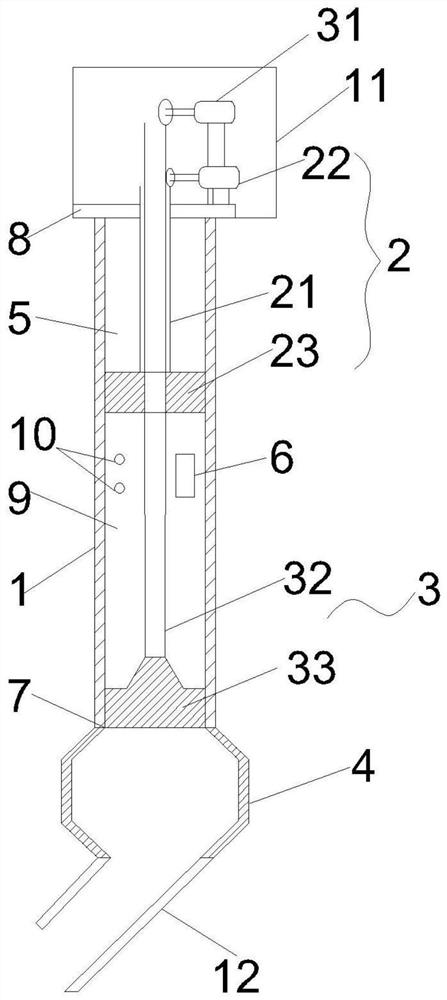

[0066] DETAILED DESCRIPTION OF THE INVENTION 3 . In the actual operating conditions of the electrolytic cell, the alumina flows out of the end of the lower plate, and the distance is 40 cm from the electrolytic cell. If a normal 1.8L is accomplished, the alumina flying loss in the addition process reaches 40-50%. After using the present invention, the alumina flying loss in the addition process is reduced to 5-10% under the same conditions.

[0067] The specific device parameters and operation parameters in this example are:

[0068] The lower molder housing 1 is 10 cm in diameter; the accumulation volume of 1.8L (corresponding to the first piston 23 and the second piston 33 vertical distance is 25 cm); the compression volume is 0.9L (corresponding to the first piston 23, corresponding to the constant direction) The second piston 33 vertically 14 cm); the pressure of the first piston 23 and the second piston 33 is 1.5 MPa; under the action of compressed air, the initial speed disc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com