Method for drying fluorspar

A drying method, fluorite technology, applied in drying solid materials, heating to dry solid materials, drying, etc., can solve problems such as adverse effects on employees' health, small contact area between materials and airflow, and complicated rotary kiln control technology. To achieve the effect of favorable design and layout, less dust flying points, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

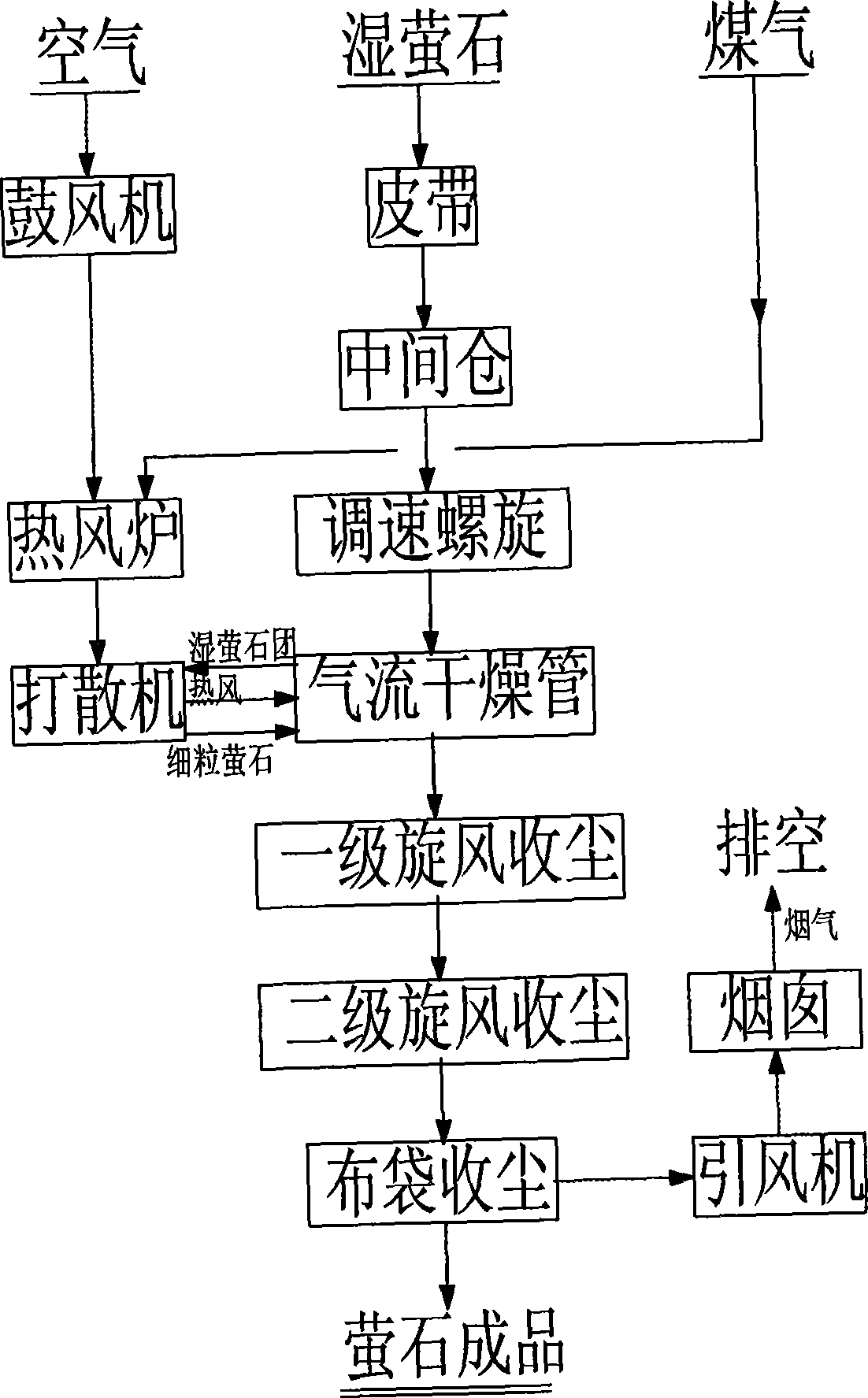

[0009] Such as figure 1 As shown, the fluorite drying method of the present invention includes the following steps: the wet fluorite that goes down to the fluorite silo is sent to the intermediate silo through a belt conveyor, and then is added to the airflow drying pipe through a speed-regulating screw, and the small particle material is taken from The high-temperature airflow in the combustion chamber is directly dried and then sent to the finished product silo through the cyclone dust removal. The wet agglomerated materials that are not completely dried by the hot airflow are supplemented with hot air and dry while freely falling, and then they are sent to the mixer installed at the lower part of the airflow pipe for beating. Crushed into small particles and blown up again for drying, the dried particles are collected into the finished product silo after the first-level and second-level cyclone dedusting. In the warehouse.

[0010] Finally, it should be noted that: the abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com