Production method for effectively reducing emission of dust and sulfur dioxide in flue gas of alkali recovery furnace

A sulfur dioxide and production method technology, which is applied in the field of alkali recovery, can solve the problems of dust and sulfur dioxide emissions not up to standard, achieve good social and ecological benefits, and reduce the effect of dust concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

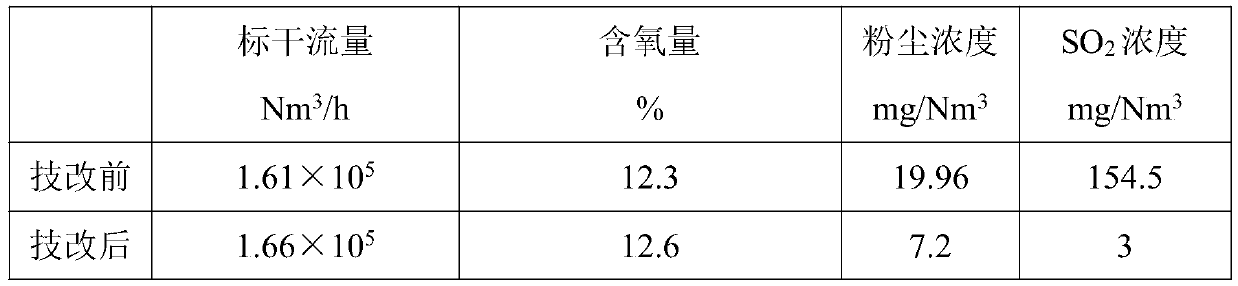

Examples

Embodiment Construction

[0026] In order to facilitate a better understanding of the present invention, the following examples are used to illustrate, and these examples belong to the protection scope of the present invention, but do not limit the protection scope of the present invention.

[0027] The production method for effectively reducing dust and sulfur dioxide emissions in the flue gas of the alkali recovery furnace comprises the following steps:

[0028] (1) Black liquor ultra-concentrated technology: increase the concentration and crystallization effect, increase the black liquor concentration to more than 72%; adopt super-concentrated combustion technology, change the air supply system of the alkali furnace, and the air supply system adopts the secondary air front and rear walls The air is crossed, and the secondary air is hot air with a temperature of 150°C for stable and efficient combustion. The ultra-concentrated technology effectively increases the temperature of the furnace cushion, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com