A method and device for improving the particle size of high-chromium and low-iron vanadium fine slag

A technology for iron vanadium slag and high chromium is applied in the field of vanadium extraction from vanadium slag, which can solve the problems of inability to meet the requirements for roasting production of vanadium fine slag, high production and operation cost of vanadium pentoxide, low roasting conversion rate and output, etc. Soda ash utilization rate, good roasting effect, and the effect of reducing soda ash consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

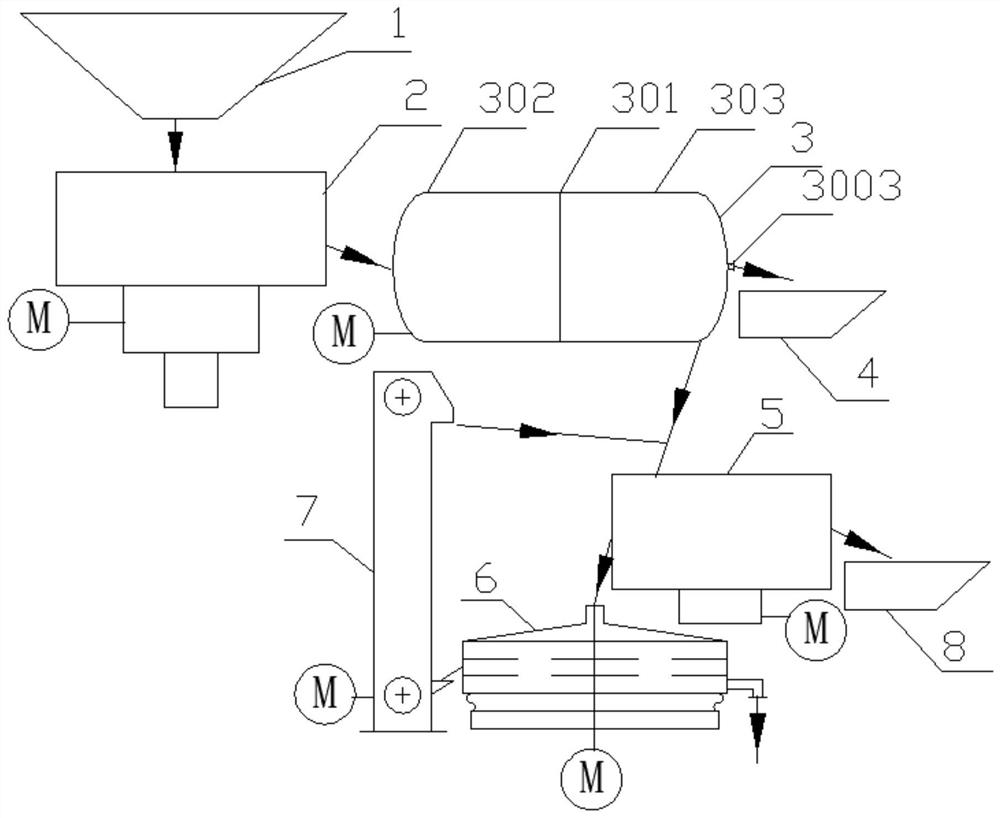

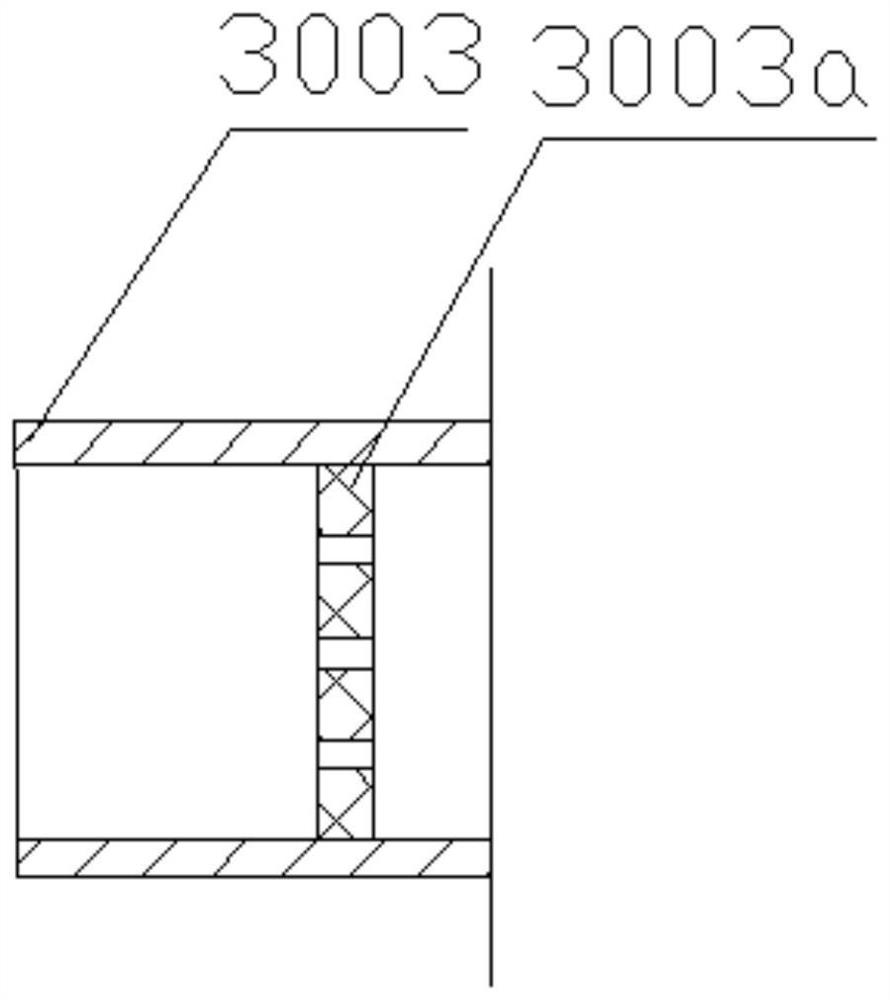

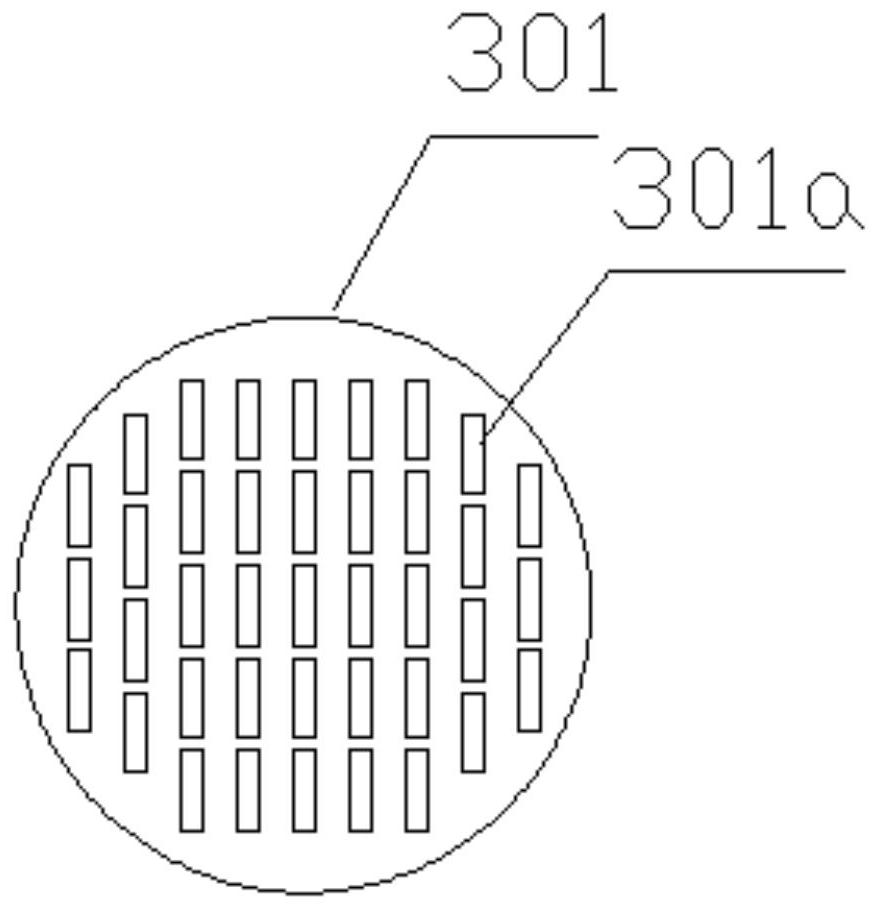

[0037] As shown in the figure, the device for improving the particle size of high-chromium and low-iron vanadium fine slag includes a silo 1, and a disc feeder 2 is provided below the discharging chute at the bottom of the silo 1. The disc feeder 2 The unloading chute is connected with the ball mill 3 through pipes, and the silo of the ball mill 3 is provided with a partition board 301 to separate the silo into a coarse silo 302 and a fine silo 303, and the partition board 301 is evenly distributed with 30mm×18mm strips. The discharge hole 301a has a lifting end 3003 on the side of the fine bin 303 of the ball mill 3, and a grate 3003a with a diameter of 5mm×10mm is arranged on the lifting end 3003 of the ball mill 3. The bottom of 303 is provided with a discharge chute, the lifting end 3003 of the ball mill 3 is connected with a hopper I4 through a pipeline, and the discharge chute of the ball mill 3 is connected with a magnetic separator 5 through the magnetic separator 5 fee...

Embodiment 2

[0045] The device for improving the particle size of the high-chromium, low-iron vanadium fine slag is the same as in Example 1.

[0046] The operation process of increasing the proportion of 140 mesh undersize fine slag with high chromium and low iron vanadium is as follows:

[0047] (1) The low chromium high iron vanadium slag, the chromium content (in terms of Cr 2 O 3 total) 1.5%wt, metallic iron content 15%wt, add to silo 1, pass through disc feeder 2, add ball mill 3 coarse silo 302 at one time, filling factor 30%, add chromium-containing silo 302 to ball mill 3 coarse silo 302 20% wt steel ball, steel ball with a diameter of 120mm accounting for 20% of the mass, and 80mm accounting for 80% of the mass. After 48 hours of continuous grinding, the iron-containing vanadium slag is discharged, and the irregular-shaped steel block is prefabricated as the grinding body;

[0048] (2) adding 20% wt steel balls containing chromium to the coarse warehouse 302 of the ball mill ...

Embodiment 3

[0053] The device for improving the particle size of the high-chromium, low-iron vanadium fine slag is the same as in Example 1.

[0054] The operation process of increasing the proportion of 140 mesh undersize fine slag with high chromium and low iron vanadium is as follows:

[0055] (1) The low chromium high iron vanadium slag, the chromium content (in terms of Cr 2 O 3 total) 3.1%wt, metallic iron content of 20%wt, added to silo 1, passed through disc feeder 2, added to ball mill 3 coarse silo 302 at one time, filling factor 22%, added chromium-containing silo 302 to ball mill 3 coarse silo 302 20% wt steel ball, steel ball diameter 120mm, 30% by mass, 80mm, 70% by mass, after 48 hours of continuous grinding, the iron-containing vanadium slag is discharged, and the irregular-shaped steel block is prefabricated as the grinding body;

[0056] (2) adding 20% wt steel balls containing chromium to the coarse warehouse 302 of the ball mill 3, the diameter of the steel balls i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com